Preparation method of quadripolymer pour point depressant for diesel oil

A technology of diesel pour point depressant and quaternary copolymer, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problem that the diesel pour point depressant has a single component, cannot adapt to petroleum products with different structures, and has poor pour point depressant effect Ideal and other issues, to achieve the effect of good pour point depressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

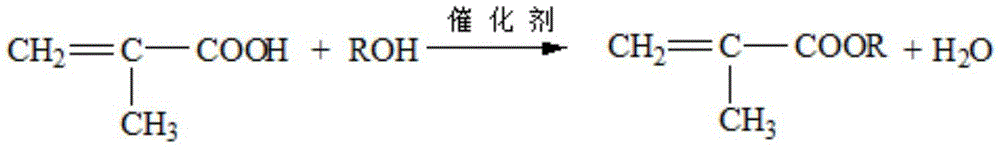

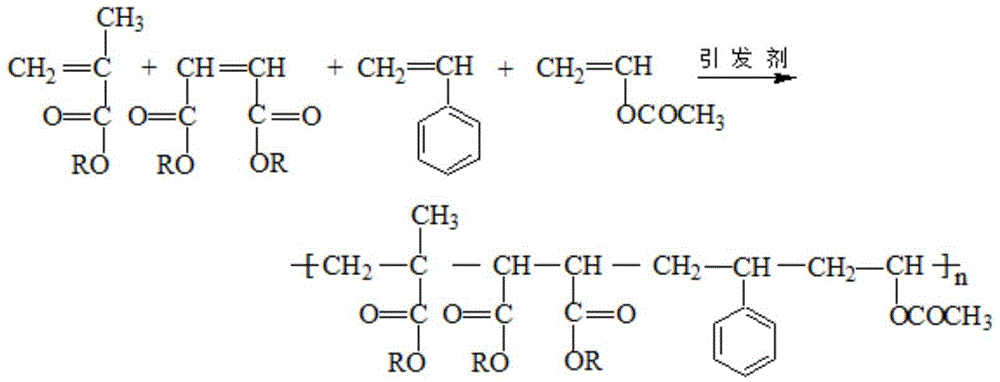

[0025] a. Add cetyl alcohol, methacrylic acid and solvent toluene into a three-necked flask equipped with a thermometer, agitator, reflux condenser and water separator, heat the reaction system to 65°C to dissolve them all, and then add the catalyst p-Toluenesulfonic acid. Heat up the reaction system to 110°C and reflux occurs, maintain the reaction temperature at 120°C, and reflux for about 3 hours to obtain cetyl methacrylate; during this process, the chemical reactions occur as follows:

[0026]

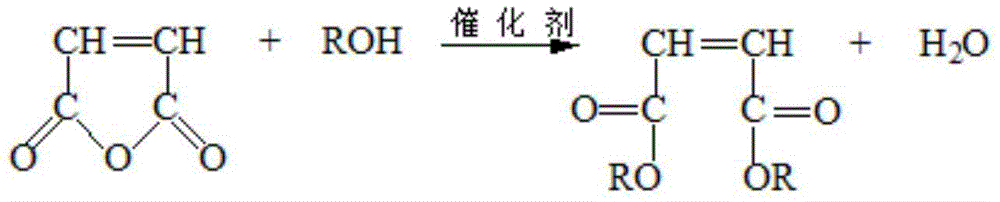

[0027] Among them, R represents the alkyl group of sixteen carbon atoms

[0028] b. Add maleic anhydride and cetyl alcohol in turn to a three-necked flask equipped with a thermometer, agitator, reflux condenser, and water separator, add solvent toluene, heat to 60°C to dissolve them all, and then add catalyst p-toluene sulfonic acid. Heat to 110°C and reflux occurs, maintain the reaction temperature at 120°C, and reflux for about 3 hours to obtain cetyl alcohol ester of malei...

Embodiment 2

[0036] a. In a three-necked flask equipped with a thermometer, agitator, reflux condenser, and water separator, add stearyl alcohol, methacrylic acid, and solvent toluene, heat the reaction system to 60°C to dissolve them all, and then add the catalyst p-Toluenesulfonic acid. Heating and heating the reaction system to 110°C to reflux, maintaining the reaction temperature at 130°C, and refluxing for about 2 hours to obtain stearyl methacrylate;

[0037] b. Add maleic anhydride and stearyl alcohol in sequence to a three-necked flask equipped with a thermometer, agitator, reflux condenser, and water separator, add solvent toluene, heat to 60°C to dissolve them all, and then add catalyst p-toluene sulfonic acid. Heat to 110°C and reflux occurs, maintain the reaction temperature at 130°C, and reflux for about 2 hours to obtain stearyl maleic anhydride;

[0038] c. Distill the stearyl methacrylate obtained in step a under reduced pressure to remove unreacted methacrylic acid and s...

Embodiment 3

[0041]a. In a three-necked flask equipped with a thermometer, agitator, reflux condenser and water separator, add stearyl alcohol, methacrylic acid and solvent toluene, heat the reaction system to 70°C to dissolve them all, and then add the catalyst p-Toluenesulfonic acid. Heating and heating the reaction system to 110°C to reflux, maintaining the reaction temperature at 110°C, and refluxing for about 4 hours to obtain stearyl methacrylate;

[0042] b. Add maleic anhydride and stearyl alcohol in sequence to a three-necked flask equipped with a thermometer, agitator, reflux condenser, and water separator, add solvent toluene, heat to 80°C to dissolve them all, and then add catalyst p-toluene sulfonic acid. Heat to 110°C and reflux occurs, maintain the reaction temperature at 110°C, and reflux for about 4 hours to obtain stearyl maleic anhydride;

[0043] c. Distill the stearyl methacrylate obtained in step a under reduced pressure to remove unreacted methacrylic acid and solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com