Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reduced melt strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant fiber-reinforced polylactic acid foam material and preparation method thereof

The invention discloses a plant fiber-reinforced polylactic acid foam material, which is prepared from the following components: 20 to 95 percent of polylactic acid, 1 to 60 percent of plant fiber powder, 1 to 5 percent of foaming agent, 1 to 5 percent of nucleating agent, 1 to 5 percent of antioxidant and 1 to 5 percent of bulking agent. The invention also discloses a preparation method for the material. The foam material has the advantages of low apparent density, biodegradability, no environmental pollution, capacity of replacing polyolefin foam materials, wide application in the fields of heat insulation, buffer and packaging, simple preparation process and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

High-rate crosslinking foaming polypropylene sheet and preparation method thereof

The invention relates to a novel high-rate crosslinking foaming polypropylene sheet and a preparation method thereof. The high-rate crosslinking foaming polypropylene sheet comprises the following four components in percentage by weight: 60-80 percent of polypropylene resin, 5-10 percent of cross-linking agent, 0.1-1 percent of anti-aging agent and 10-30 percent foaming agent. The invention sufficiently combines the characteristics of material properties and production processes, overcomes the defect that the strength of a polypropylene melt quickly descends after the temperature is higher than the melting point by utilizing an irradiation method and prepares a product with good properties, and the properties of tensile strength, elongation at break, and the like of the material are obviously improved.

Owner:钟果平

Polycarbonate/ABS polymer and its prepn process

The present invention relates to organic chemical technology, and is one kind of polycarbonate / ABS polymer material and its preparation process. The polycarbonate / ABS polymer material is prepared with polycarbonate 40-70 wt%, ABS polymer 15-40 wt%, acrylonitrile-styrene copolymer 5-15 wt%, roughening compatibilizing agent 3-15 wt%, PTFE 1-3 wt%, lubricant 0.2-1 wt% and antioxidant 0.4-1 wt%, and through drying, mixing, extruding and cutting into grain. The polycarbonate / ABS polymer material has high rigidity and very high impact resistance.

Owner:威海联桥新材料科技股份有限公司

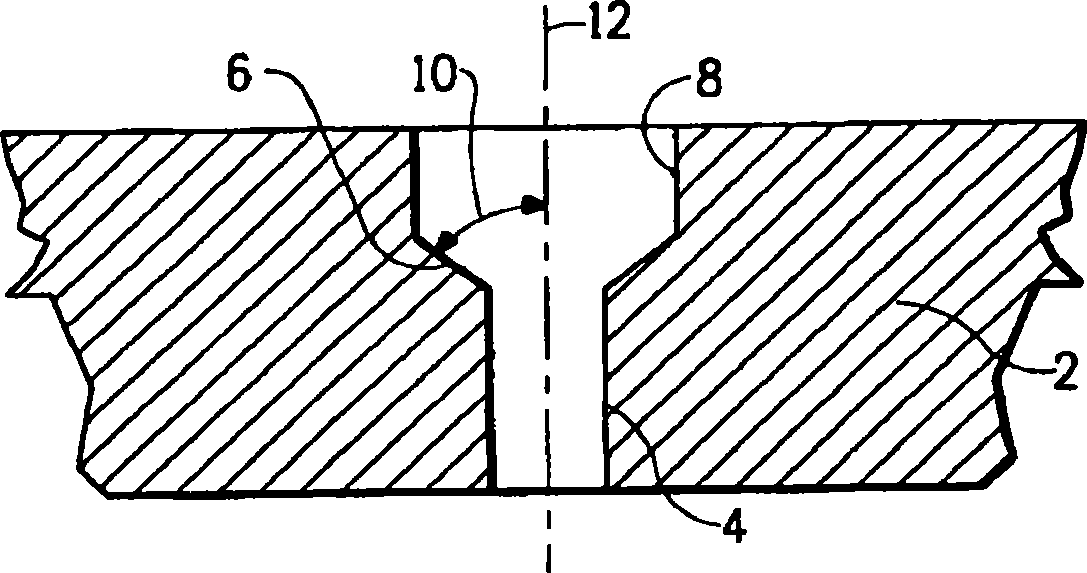

Method of making graded index polymeric optical fibers

InactiveUS6106745AImprove scalabilityReduced melt strengthOptical fibre with graded refractive index core/claddingOptical articlesFiberPolymer science

Disclosed is a method of making a graded index polymer optical fiber comprising a multicomponent spinning process employing spinning masses comprising a core spinning mass and a sheath spinning mass, the spinning masses comprising a polymer, a polymerizable monomer, and an initiator. The monomer in the core spinning mass has a higher refractive index than the monomer in the sheath spinning mass, and the spinning masses are extruded and cured. The spinning conditions are chosen such that the monomers are substantially contained within the fiber during extrusion and curing and the total of the spinning masses is intrinsically thread forming. The spinning masses may be extruded in, e.g., water. The core and the sheath polymer may be, e.g., poly(methyl methacrylate); the core monomer may be methyl methacrylate, and the sheath monomer may be 2,2,3,3-tetrafluoropropyl methacrylate; or the core and the sheath polymer may be, e.g., poly(styrene-co-acrylonitrile); the core monomer may be benzyl methacrylate, and the sheath monomer may be methyl methacrylate. The spinning masses are solutions of the polymer in the monomer having a polymer concentration of from 20 to 70% by weight.

Owner:AKZO NOBEL NV

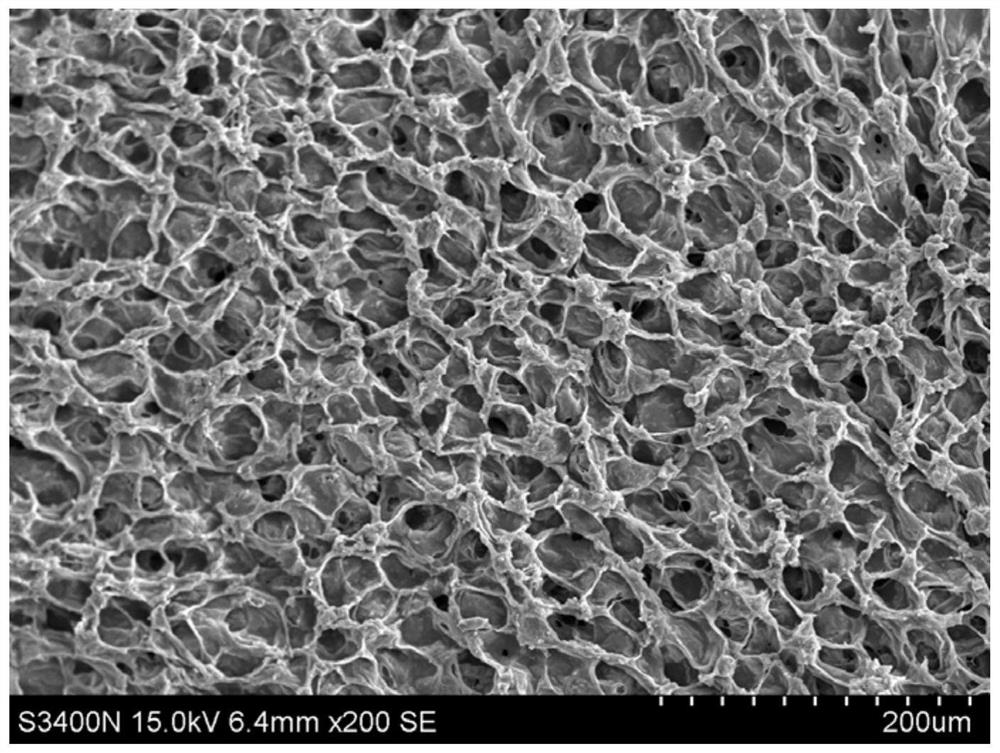

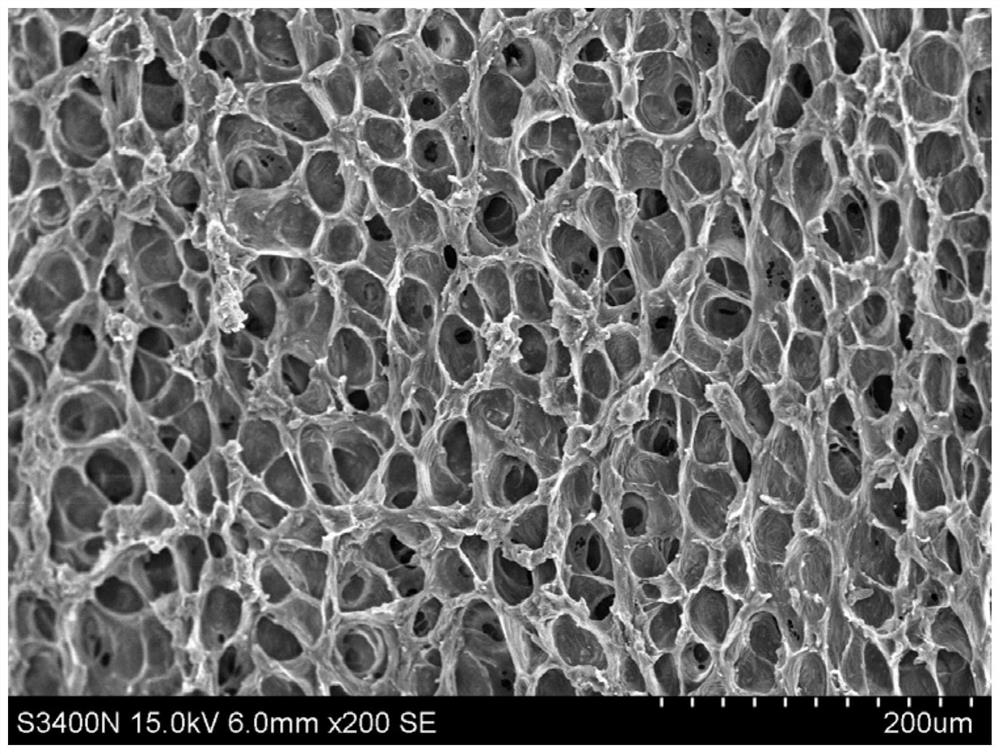

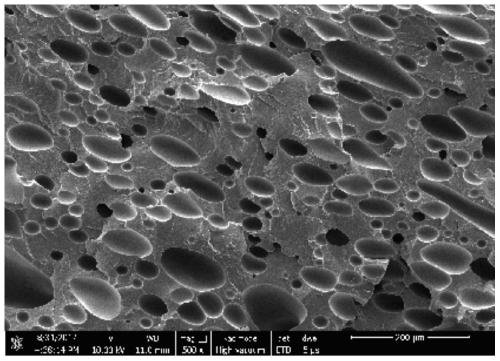

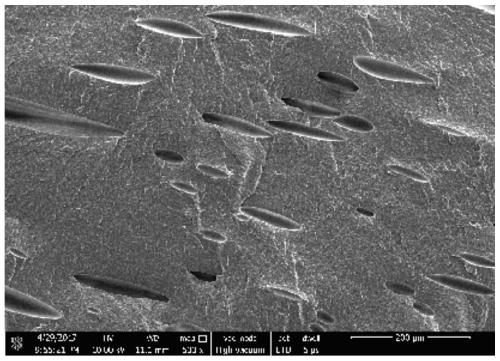

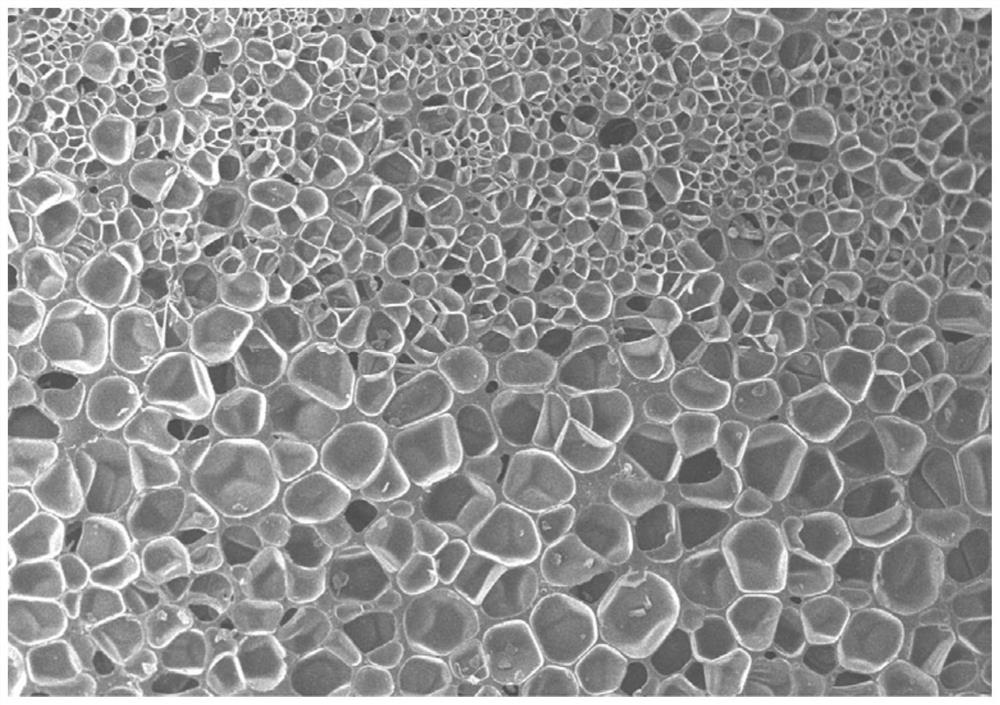

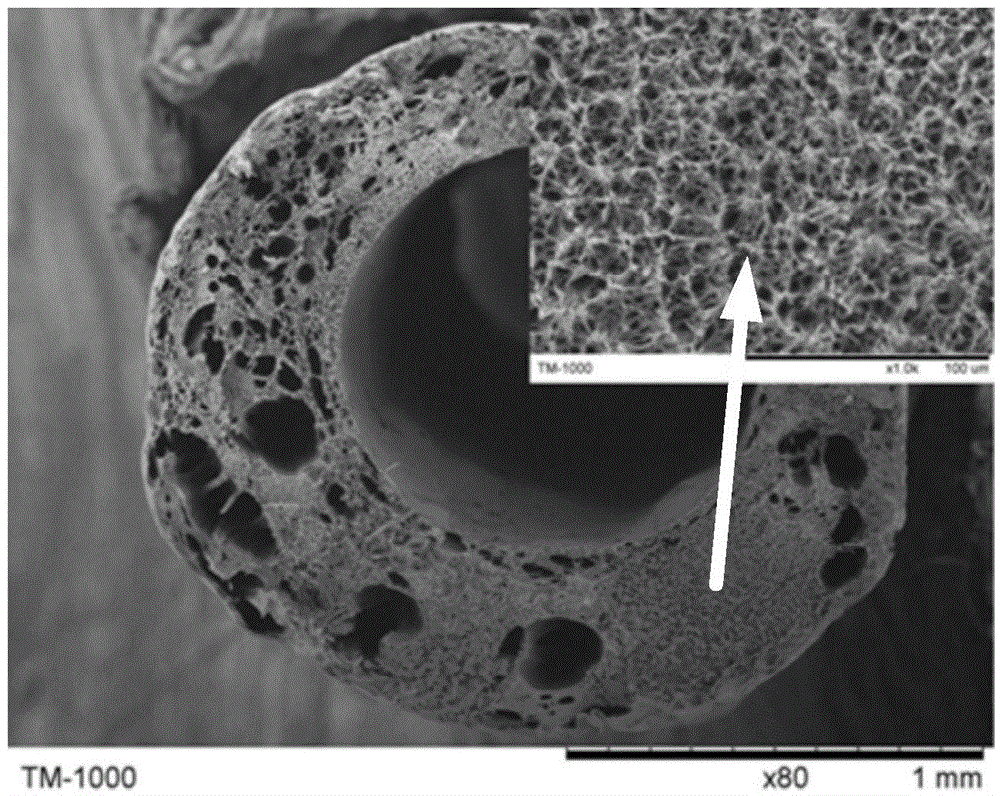

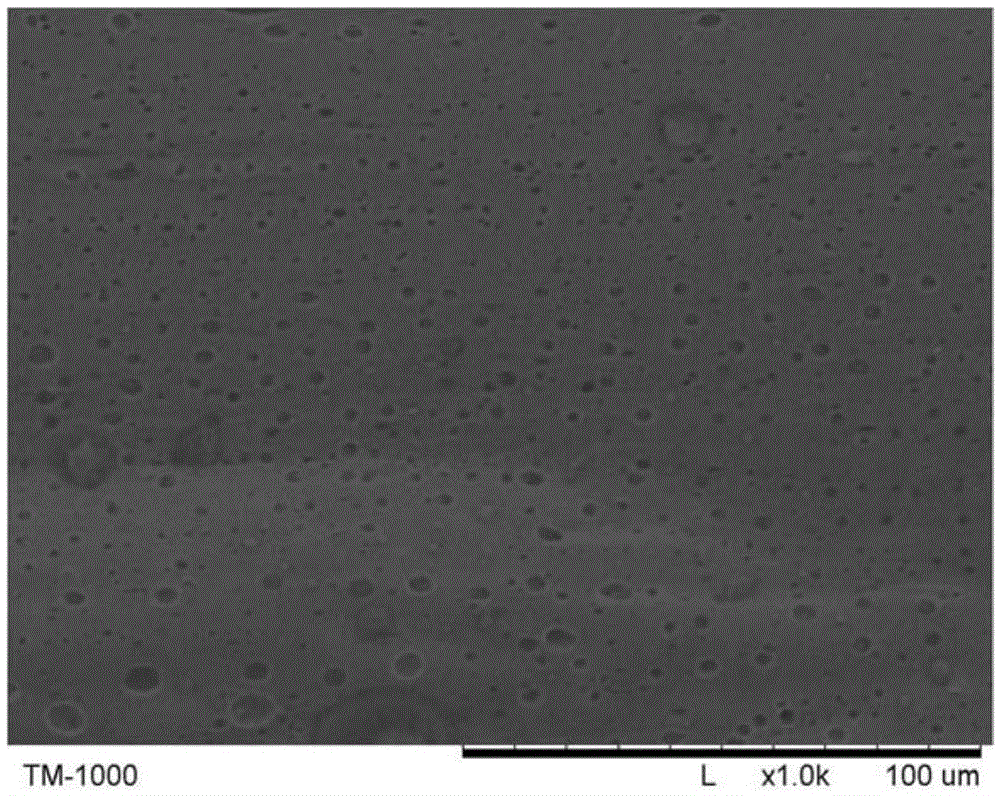

Open-celled polypropylene microcellular foaming sheet and production method thereof

The invention relates to an open-celled polypropylene microcellular foaming sheet. The open-celled polypropylene microcellular foaming sheet comprises the following components: 100 parts by weight of polypropylene resin and 50-100 parts by weight of polyethylene resin. A production method of the open-celled polypropylene microcellular foaming sheet comprises the following steps: plastifying, mixing, sizing, cutting and forming a bicontinuous phase polypropylene / polyethylene blend foaming base material by virtue of a double-screw extruder, and then carrying out supercritical carbon dioxide solid foaming. The open-celled polypropylene microcellular foaming sheet has the advantages that the bicontinuous phase polypropylene / polyethylene blend base material is formed, and then the base material is foamed at a polypropylene foaming temperature by adopting a solid foaming technology, cells formed in a polyethylene phase in a complete molten state are completely cut-through and penetrate through cell walls of the cells formed in a polypropylene phase, and the open-celled polypropylene microcellular foaming sheet is formed; meanwhile, the obtained open-celled polypropylene microcellular foaming sheet is small in cell size, high foaming ratio and high porosity and can be widely applied to the fields of filtering, sound absorption, ventilation and the like.

Owner:ZHEJIANG XINHENGTAI ADVANCED MATERIAL

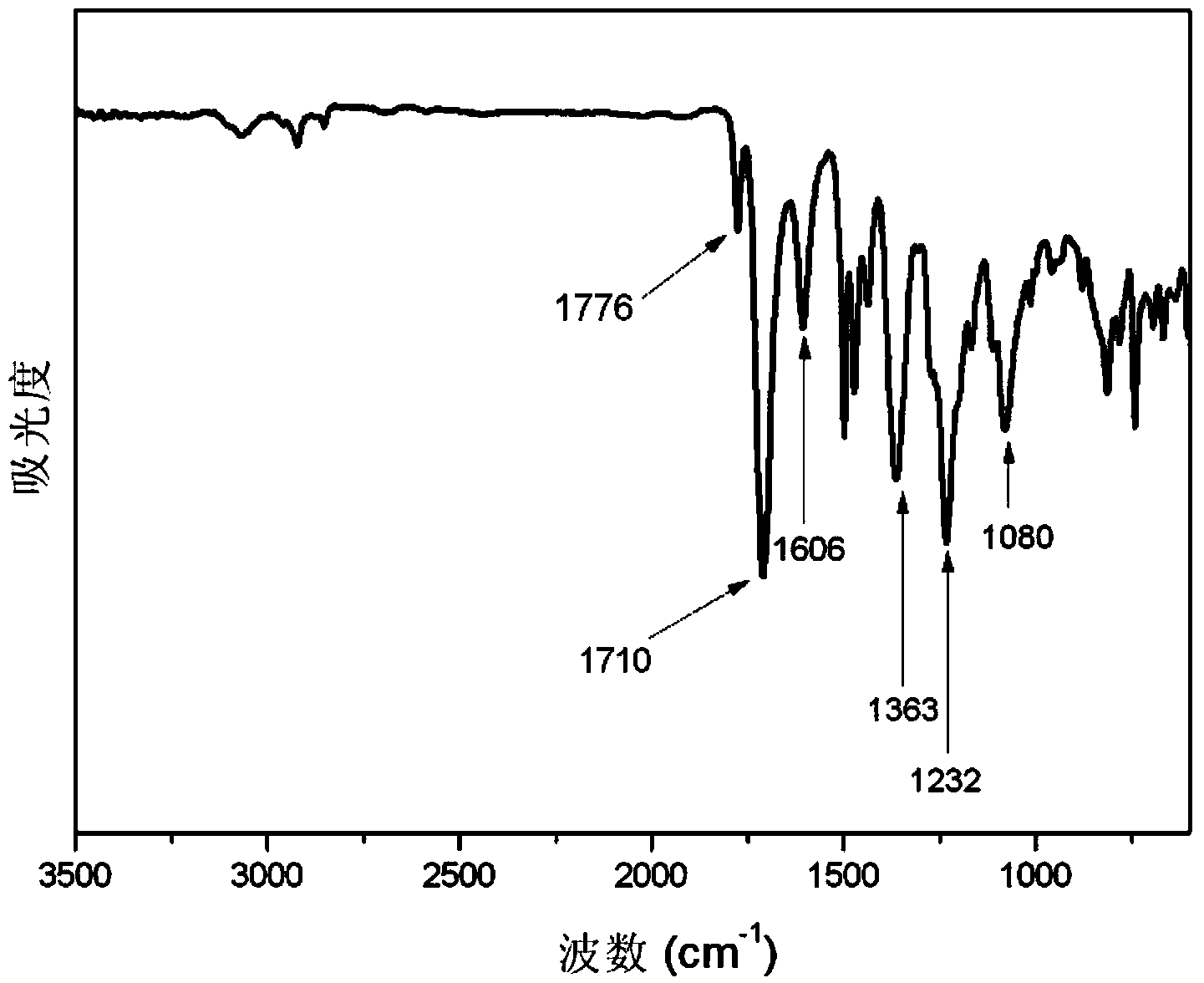

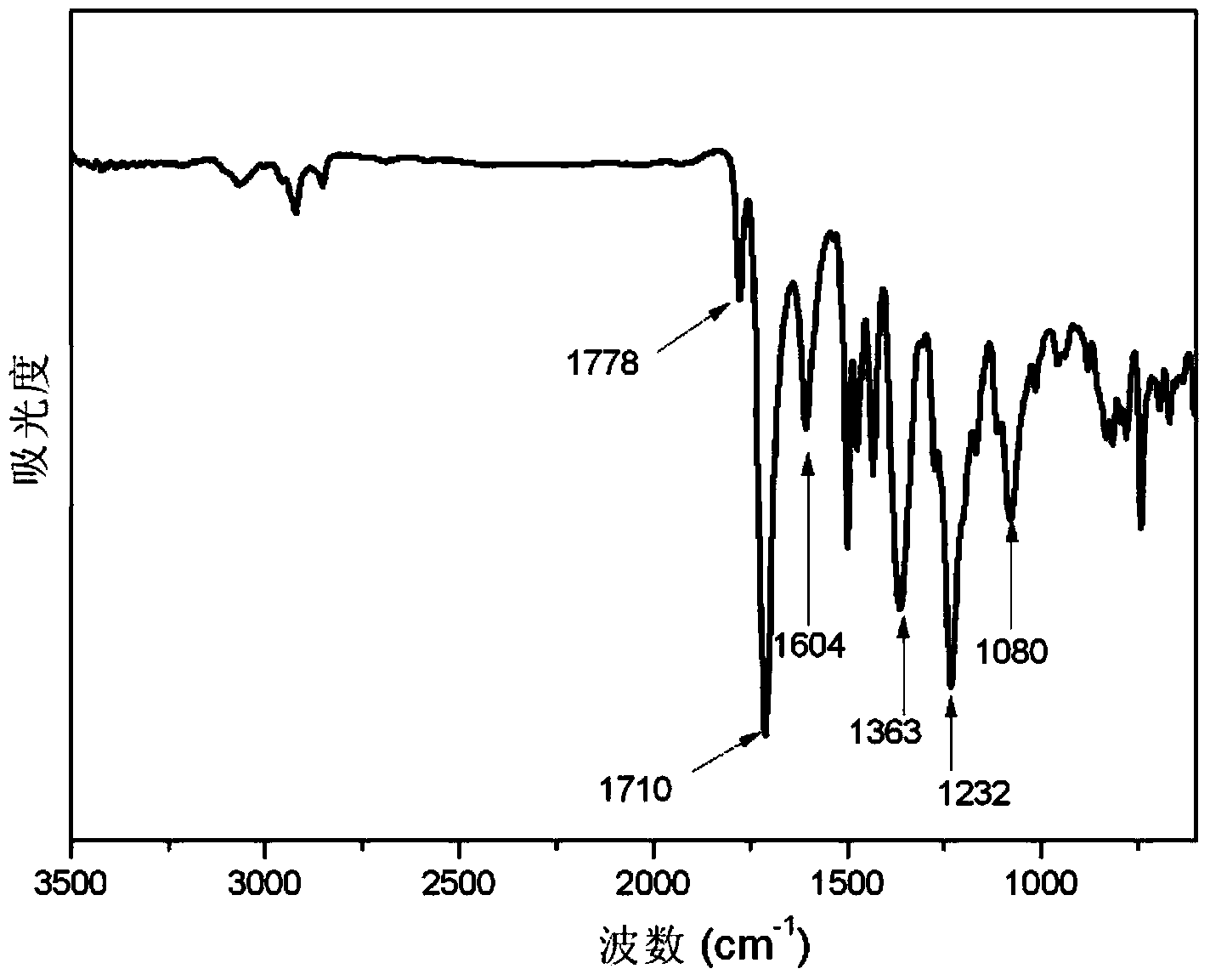

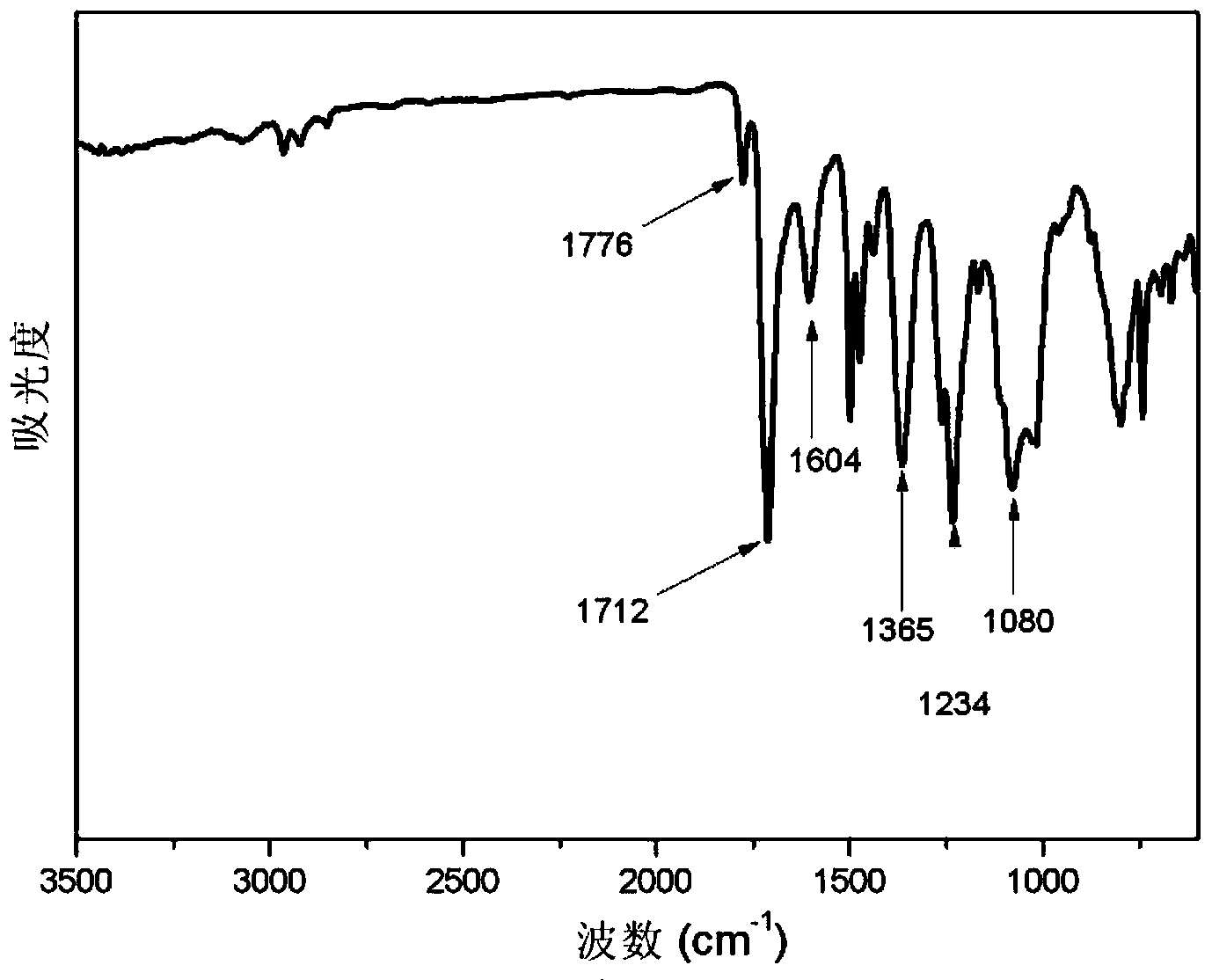

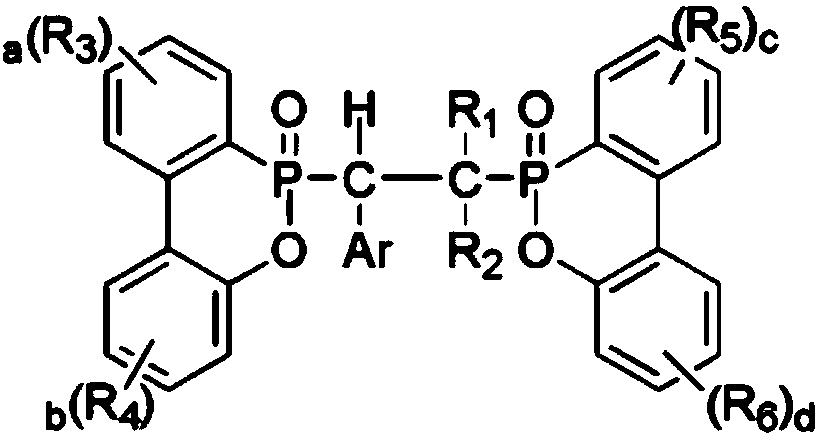

Polyimide adhesive and preparation method thereof

The invention provides a polyimide adhesive which is of a structure as shown in the formula I. In the formula I as shown in the specification, R2 is a nitrogen aromatic ring structure; R4 is a siloxane chain link; and the nitrogen aromatic ring structure is a phenylpyridine structure or a phenyl pyrimidine structure. Due to adoption of the nitrogen aromatic ring structure, the peeling strength of polyimide from metal is improved; due to adoption of the siloxane chain link, the melt strength of the polyimide adhesive is reduced, the molding of the adhesive is improved, and the peeling resistance is improved. The experiment result shows that the peeling strength of the polyimide adhesive provided by the invention from metal foil is 10.2-16.2N / cm, the vitrification conversion temperature of the polyimide adhesive is 170-250 DEG C, the hygroscopicity of the polyimide adhesive is 1.09-1.9%, and the solderability of the polyimide adhesive is qualified.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Polylactic acid foaming composite material as well as preparation method and application thereof

The invention belongs to the technical field of biodegradable foaming materials, and discloses a polylactic acid foaming composite material as well as a preparation method and application thereof. The polylactic acid foaming composite material comprises the following components in parts by weight: 100 parts of polylactic acid resin, 5-15 parts of other biodegradable materials, 0.5-3 parts of a bio-based nucleating agent, 0.5-4 parts of a chain extender and 0.1-1 part of a lubricant. The preparation method comprises the steps of mixing, extruding, drawing and pelletizing the components to prepare a polylactic acid foaming master batch; and putting the polylactic acid foaming master batch into a high-pressure reaction kettle, introducing a fluid serving as a foaming agent into the high-pressure reaction kettle, controlling the temperature of the high-pressure reaction kettle to be 40-200 DEG C and the pressure of the high-pressure reaction kettle to be 8-20 MPa, keeping the temperature and the pressure for 30-120 minutes, releasing gas in the reaction kettle, reducing the pressure to normal pressure, and taking out polylactic acid foaming particles from the reaction kettle, so as to obtain the particles, namely, the polylactic acid foaming composite material.

Owner:GUANGDONG UNIV OF TECH

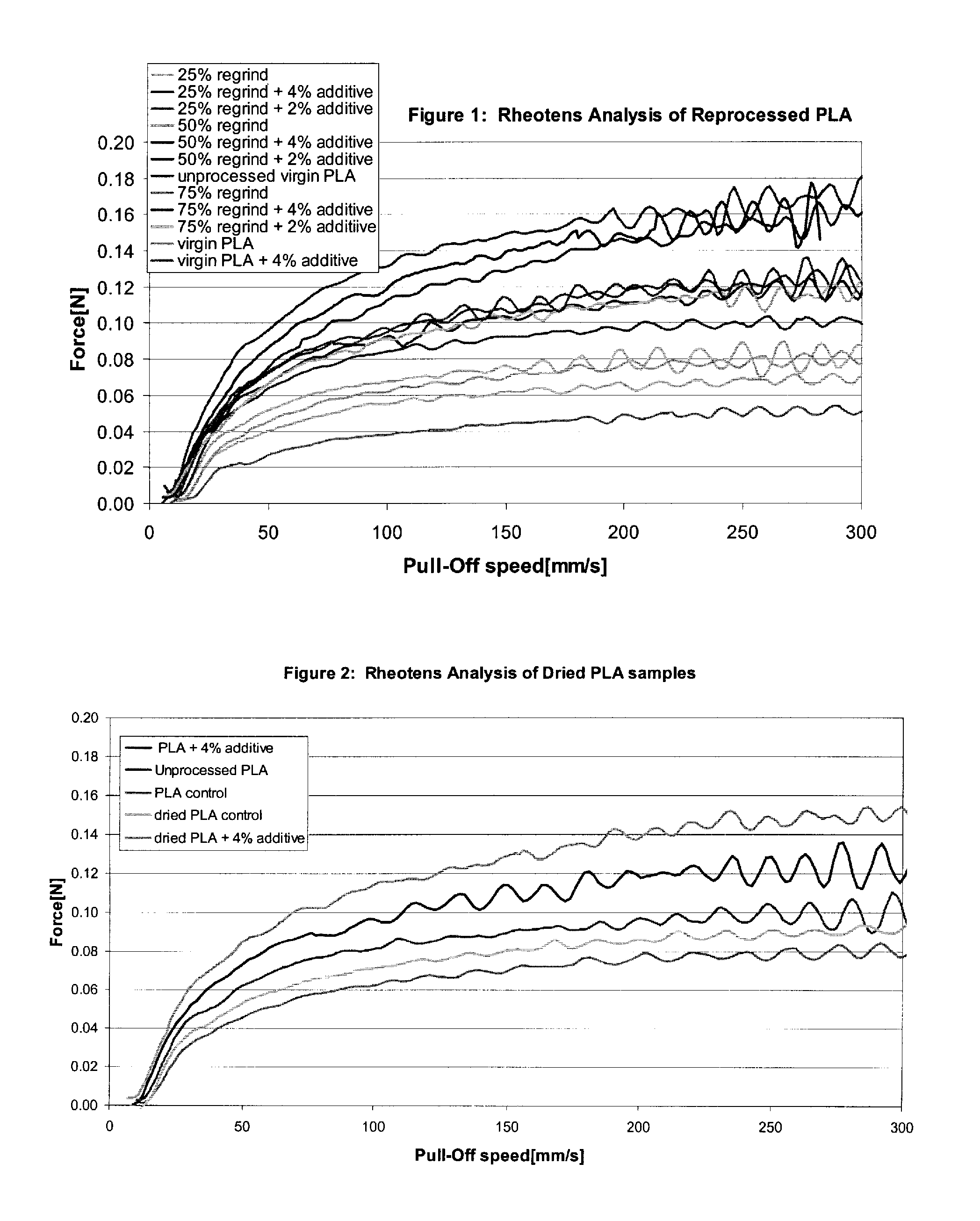

Blends of biodegradable polymers and acrylic copolymers

InactiveUS20100267867A1High strengthMinimize any hydrolysis or polymer degredationCosmetic preparationsToilet preparationsPolymer chemistryAcrylic acid

The invention relates to a blend of one or more biodegradable polymers with one or more acrylic copolymers, for the purpose of improving the properties of the biodegradable polymer(s). The biodegradable polymer contains at least 10 weight percent of a biopolymer that is in less than ideal condition for processing. The “compromised” biopolymer may be undried biopolymer, may have a heat history (be “reprocessed”, “regrind” or “recycled”), or both. The acrylic copolymer(s) are present in the blend at a level of 0.1 to 15 weight percent, based on the weight of the total blend.

Owner:ARKEMA INC +1

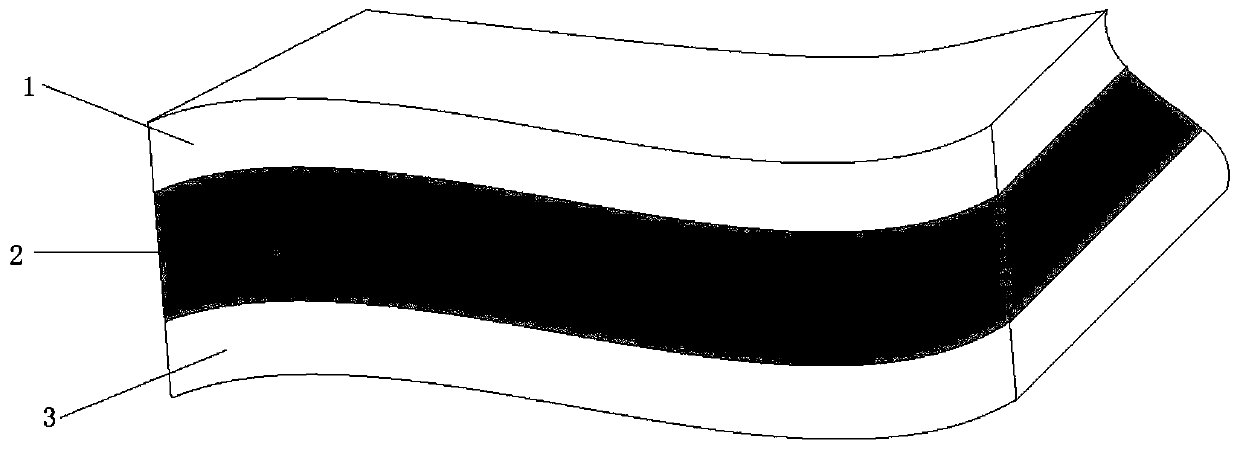

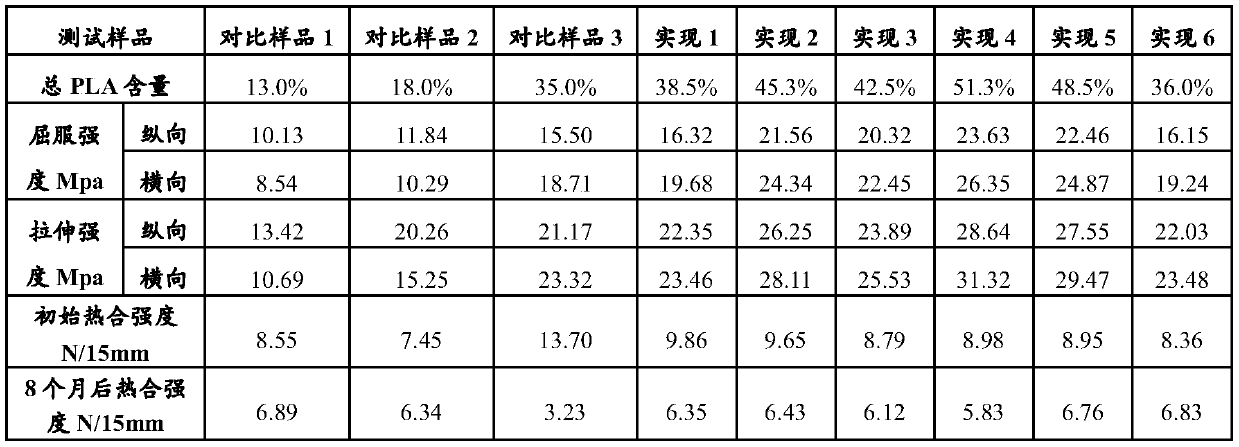

Biodegradable film and manufacturing method thereof

InactiveCN110654095AImprove melt strengthReduced melt strengthSynthetic resin layered productsComposite materialStarch

The invention provides a biodegradable film and a manufacturing method thereof. The biodegradable film comprises an inner layer, a middle layer and an outer layer; the middle layer is arranged betweenthe inner layer and the outer layer, and the outer layer or the inner layer is composed of the following components by the weight percentage: 40%-100% of PBAT, 0%-35% of PLA, 0%-30% of starch, 0%-30%of inorganic powder and 0%-15% of a modifying auxiliary agent. The middle layer is composed of the following components by the weight percentage: 35%-94.5% of PLA, 0%-64.5% of PBAT, 0%-30% of starch,0%-30% of inorganic powder and 0.5%-5% of a modifying auxiliary agent. The biodegradable film prepared by adding 35% or less of PLA into PBAT with high melt strength and stable heat sealing performance as an inner layer and an outer layer to drive the PBAT with low melt strength and high yield strength to be added with 35% or more of PLA as an intermediate layer is high in yield strength and longin heat sealing performance stable period.

Owner:深圳万达杰环保新材料股份有限公司

Polymer foam and method for preparing the same

ActiveUS20170029589A1Good foaming effectReduced melt strengthFlat articlesPolymer scienceFoaming agent

Polymer foam and a method for preparing the same are disclosed. In the present disclosure, the method sequentially comprises the following steps: providing a polymer body; performing a pressure-induced flow (PIF) process on the polymer body at a first predetermined temperature and a first predetermined pressure for a pressure holding time, to obtain a polymer sheet; and performing a foaming process on the polymer sheet by using a foaming agent at a second predetermined temperature and a second predetermined pressure for a saturation time, to obtain polymer foam.

Owner:LEE CHANG YUNG CHEM IND CORP +1

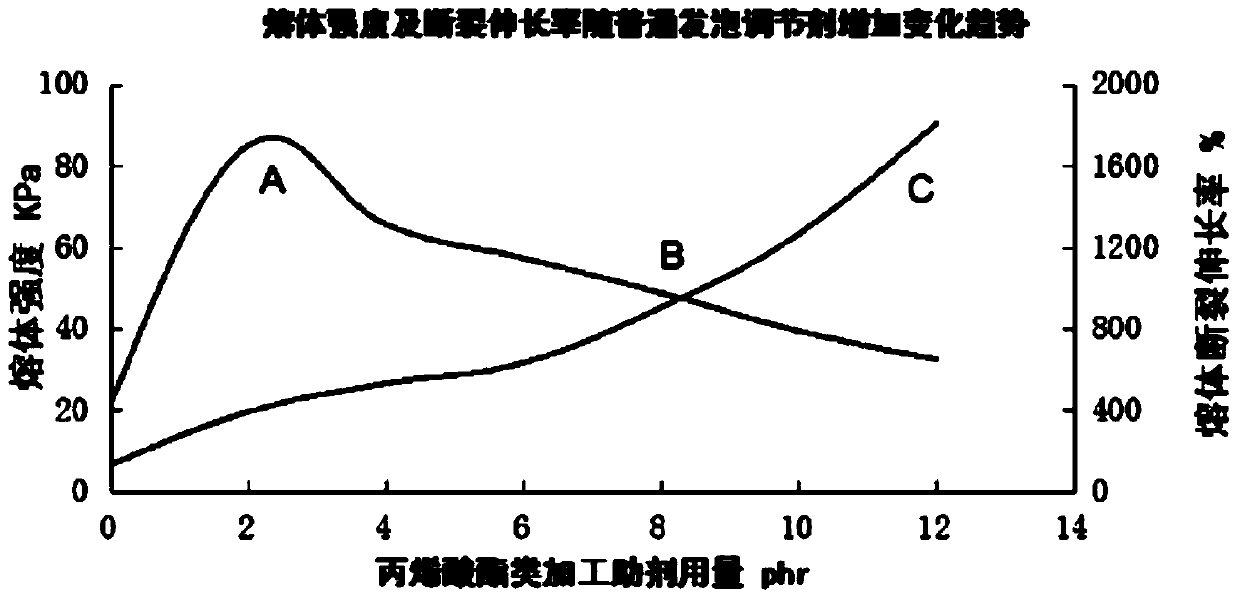

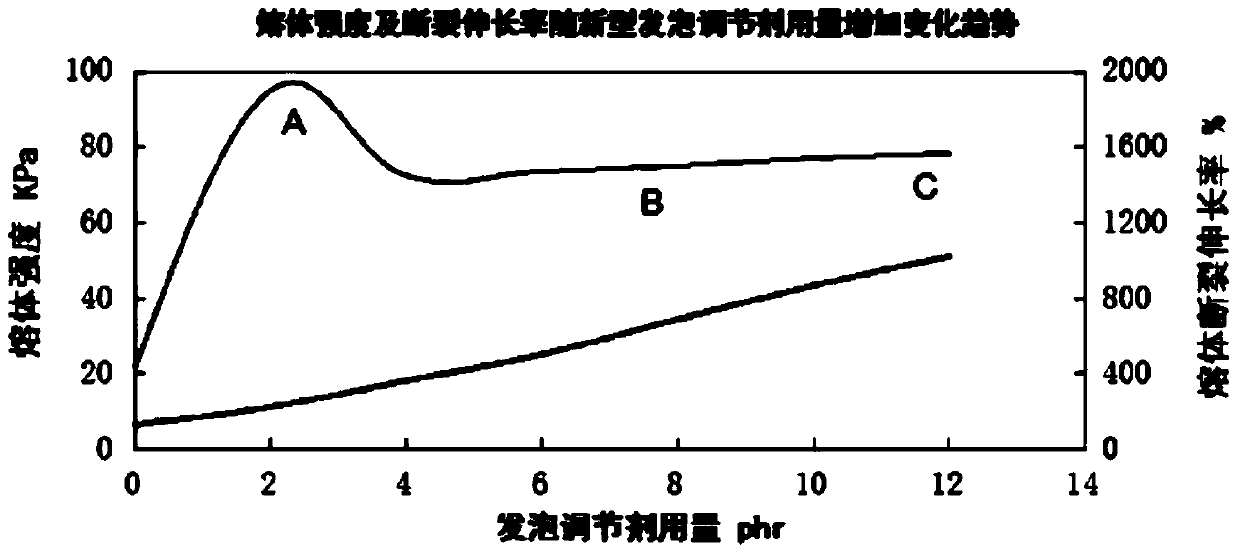

Low-density polyvinyl chloride foaming material and preparation method thereof

The invention discloses a low-density polyvinyl chloride foaming material with the density ranging from 0.10 g / cm<3> to 0.20 g / cm<3>. The low-density polyvinyl chloride foaming material comprises, by weight, 100 parts of polyvinyl chloride resin, 2 parts to 40 parts of foaming adjusting agents, 0.5 part to 5 parts of heat stabilizers, 0.5 part to 3 parts of thermal decomposition organic foaming agents, 0.5 part to 3 parts of thermal decomposition inorganic foaming agents, 1 part to 2 parts of lubrication type processing auxiliaries, 0 part to 30 parts of smoke suppression agents, 0 part to 30 parts of fire retardants, 0 part to 30 parts of filling agents, 0 part to 5 parts of lubricating agents and 0 part to 10 parts of pigment. The polyvinyl chloride replaces polystyrene in the prior art, and the foaming material with the low density is prepared to replace a polystyrene foaming material in the prior art. The production cost of the foaming material is reduced, and the low-density polyvinyl chloride foaming material can be used in the fields of building, packaging, furniture industries and the like.

Owner:SHANDONG RIKE CHEM

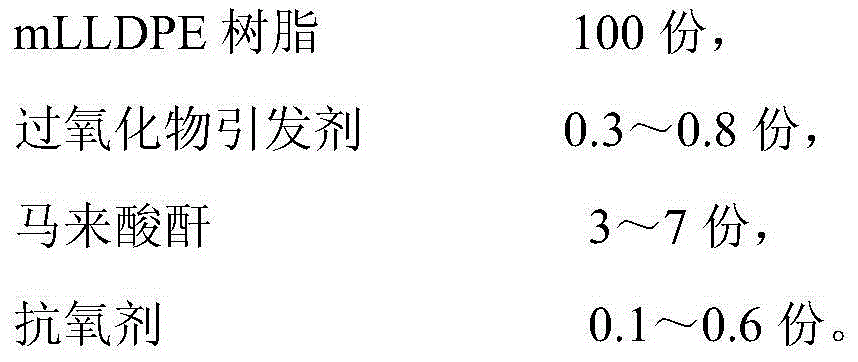

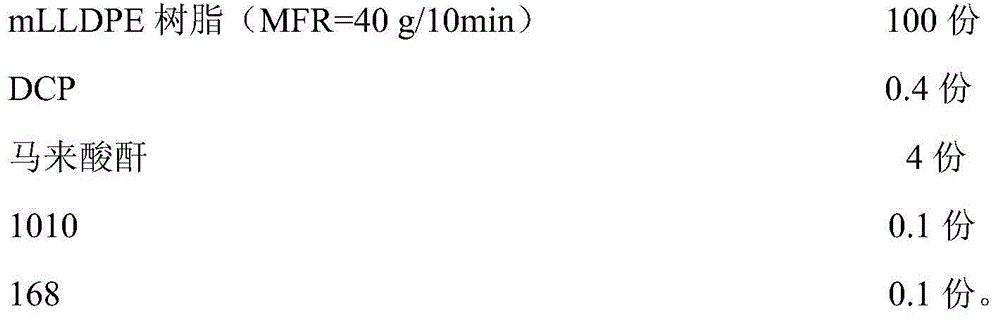

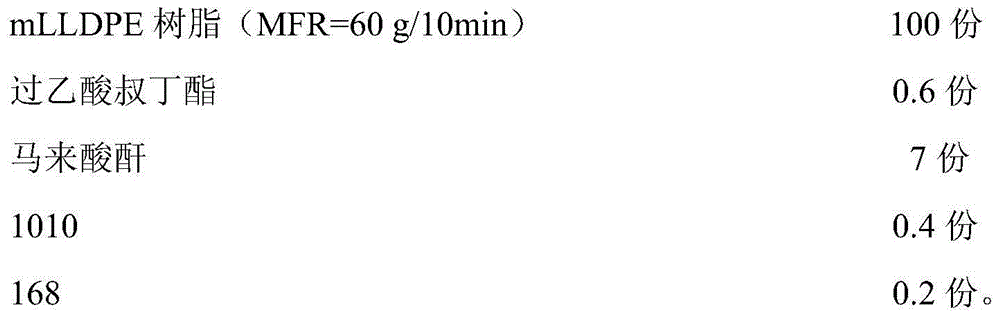

High-fluidity metallocene low-density polyethylene resin graft and preparation method thereof

ActiveCN105566573AImprove toughnessHigh transparencyLow-density polyethyleneLinear low-density polyethylene

The present invention belongs to the field of polymer material modification, and particularly relates to a high-fluidity metallocene low-density polyethylene resin graft, which comprises the following raw materials by weight: 100 parts of an mLLDPE resin, 0.3-0.8 part of a peroxide initiator, 3-7 parts of maleic anhydride, and 0.1-0.6 part of an antioxidant. The present invention further provides a preparation method of the graft. The preparation method comprises: feeding the materials into a co-rotating twin screw reaction extruder, and post-treating the reaction materials to obtain the grafted product, wherein the material drum of the extruder is divided into three sections, the first section is a melt mixing and dispersing section, the second reaction is a reaction section, and the third section is a metering molding section. According to the present invention, the maleic anhydride is successfully grafted onto the high-performance metallocene linear low-density polyethylene to prepare the high-fluidity metallocene low-density polyethylene resin graft, wherein the melt mass flow rate can achieve more than or equal to 15 g / 10 min, the tensile strength can achieve more than or equal to 17 MPa, and the high grafting rate is provided.

Owner:CHINA PETROLEUM & CHEM CORP

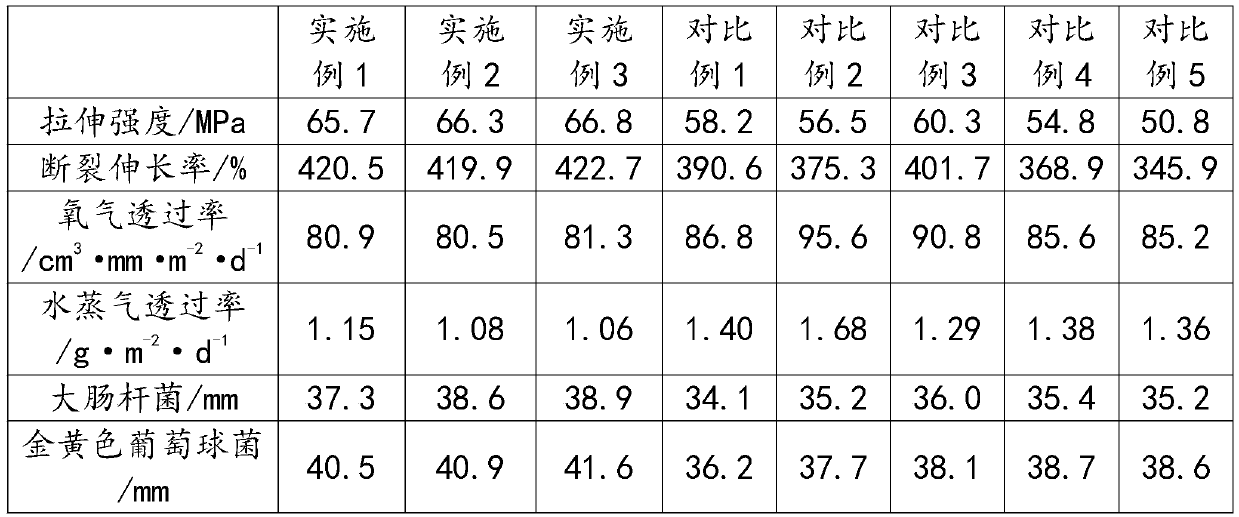

Environment-friendly beverage packaging bag and processing technology thereof

ActiveCN111117173AImprove antioxidant capacityImprove antibacterial propertiesPolymer scienceCarbon nanotube

The invention discloses an environment-friendly beverage packaging bag which comprises the following raw materials in parts by weight: 50-60 parts of polybutylene succinate, 16-18 parts of polybutylene terephthalate adipate, 2.6-3.2 parts of modified chitosan, 2.2-2.5 parts of carbon nanotube whiskers, 1.8-2 parts of mica powder and 0.5-0.7 part of a coupling agent. The invention further disclosesa processing technology of the packaging bag. According to the invention, the copolymer of polybutylene succinate and polybutylene terephthalate adipate is used as the polymer matrix of the packagingbag, so that the polymer matrix not only meets the environment-friendly performance of easy degradation, but also has good mechanical properties and heat resistance. By adding modified chitosan and carbon nanotube whiskers and carrying out coupling agent treatment before blending with a polymer matrix, the environment-friendly packaging bag which is easy to degrade, high in mechanical property and barrier property and antibacterial is obtained, and the environment-friendly packaging bag is suitable for packaging beverages.

Owner:广东丹青印务有限公司

Preparation method of foamed nylon plate

The invention discloses a preparation method of a foamed nylon plate. The preparation method comprises the following steps: premixing nylon, a toughening agent, a chemical foaming agent, a nucleating agent, a lubricant and a crosslinking agent according to a formula, adding the obtained mixture into an extensional rheological plasticization and extrusion device, using an extensional deformation-based flow field to make nylon melted and plasticized and a gas formed after decomposition of the foaming agent mixed and dispersed in a polymer melt, performing extrusion through a foamed sheet die, and carrying out three-roller pressing to obtain the foamed nylon sheet. Addition of a small amount of the crosslinking agent can significantly improve the melt strength of PA, and the nylon plate produced through the preparation method by adopting the extensional rheological plasticization and extrusion device has the advantages of uniform and fine cells, high foaming rate, low aperture ratio, excellent performances, good processing performance, simple process flow, high production efficiency, suitableness for industrial scale production, and wide application prospect.

Owner:SIIICO TECH CO LTD

A kind of open-cell polypropylene microcellular foam sheet and production method thereof

The invention relates to an open-celled polypropylene microcellular foaming sheet. The open-celled polypropylene microcellular foaming sheet comprises the following components: 100 parts by weight of polypropylene resin and 50-100 parts by weight of polyethylene resin. A production method of the open-celled polypropylene microcellular foaming sheet comprises the following steps: plastifying, mixing, sizing, cutting and forming a bicontinuous phase polypropylene / polyethylene blend foaming base material by virtue of a double-screw extruder, and then carrying out supercritical carbon dioxide solid foaming. The open-celled polypropylene microcellular foaming sheet has the advantages that the bicontinuous phase polypropylene / polyethylene blend base material is formed, and then the base material is foamed at a polypropylene foaming temperature by adopting a solid foaming technology, cells formed in a polyethylene phase in a complete molten state are completely cut-through and penetrate through cell walls of the cells formed in a polypropylene phase, and the open-celled polypropylene microcellular foaming sheet is formed; meanwhile, the obtained open-celled polypropylene microcellular foaming sheet is small in cell size, high foaming ratio and high porosity and can be widely applied to the fields of filtering, sound absorption, ventilation and the like.

Owner:ZHEJIANG XINHENGTAI ADVANCED MATERIAL

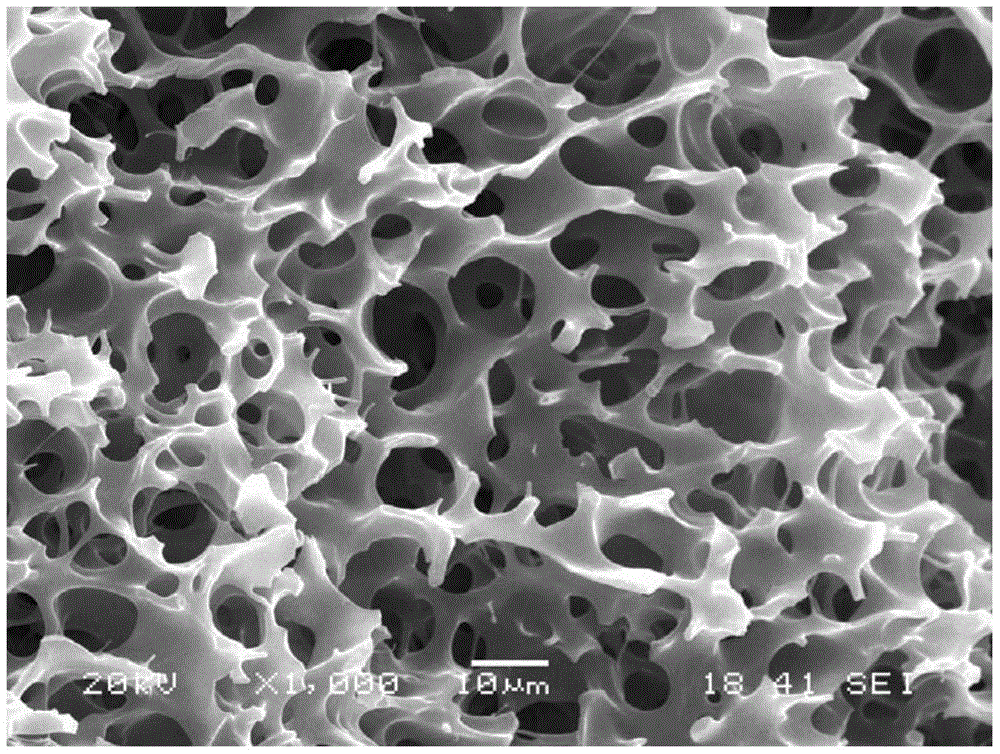

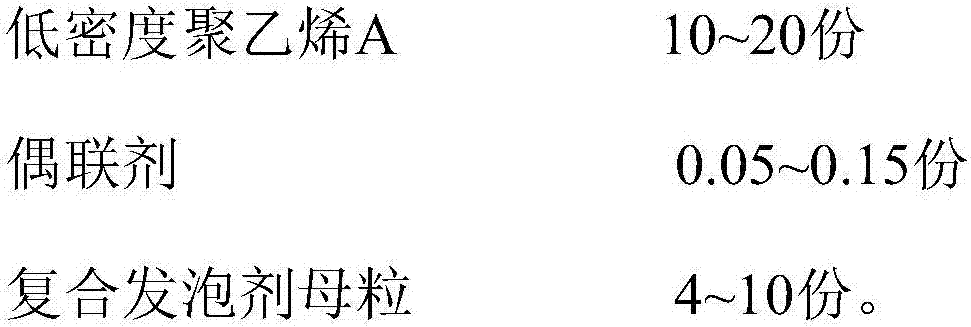

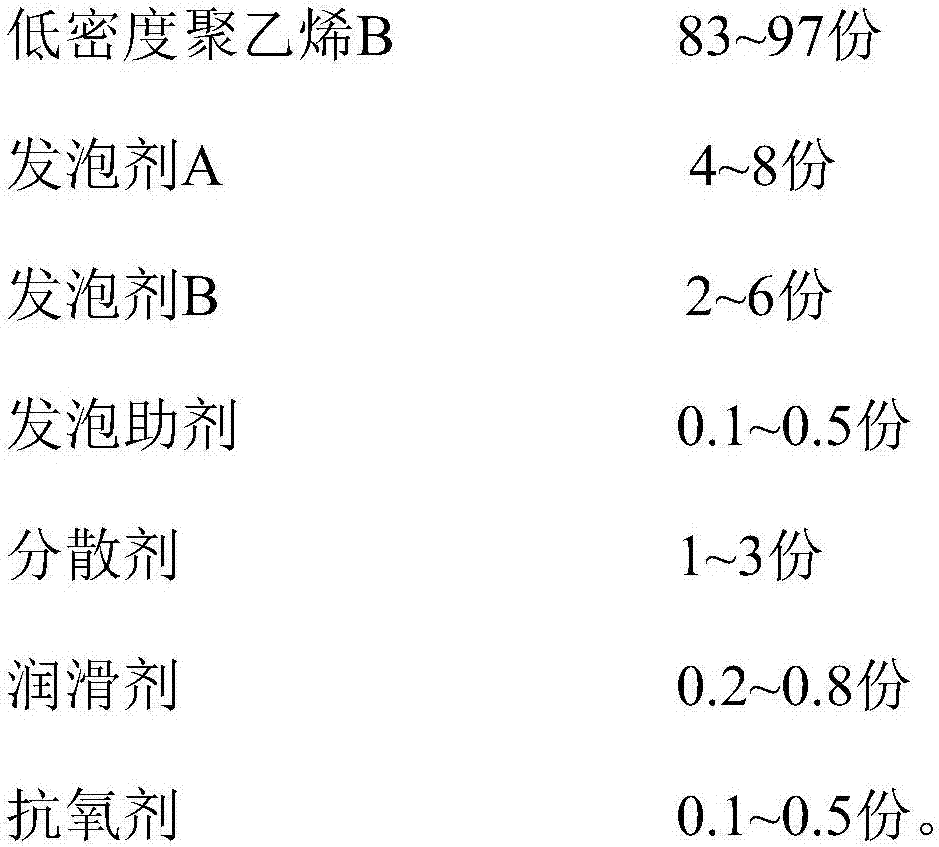

Chemical foaming polyethylene composition, preparation method and applications thereof

InactiveCN106947153AHigh foamingImprove mechanical propertiesPlastic/resin/waxes insulatorsLow-density polyethyleneFoaming agent

The present invention discloses a chemical foaming polyethylene composition, a preparation method and applications thereof, wherein the chemical foaming polyethylene composition is prepared from the following components by weight: 70-86 parts of high-density polyethylene, 10-20 parts of low-density polyethylene A, 0.05-0.15 part of a coupling agent, and 4-10 parts of composite foaming agent master batch. According to the present invention, the chemical foaming polyethylene composition retains the high foaming degree of the low-density polyethylene foaming material and the good mechanical property of the high-density polyethylene chemical foaming material so as to obtain the foaming insulation layer having the good electrical property. Another purpose of the present invention is to provide the preparation method of the chemical foaming polyethylene composition, wherein the preparation method is simple and is easy to operate. The present invention further provides uses of the chemical foaming polyethylene composition in preparation of communication cables.

Owner:广州敬信高聚物科技有限公司

Method for producing polyphenylene sulfide film

InactiveCN109957125ASmall polydispersity coefficientExcellent polydispersity coefficientWax coatingsChemical industryPolymer science

The invention discloses a method for producring a polyphenylene sulfide film. Sodium sulfide and p-dichlorobenzene are used as raw materials, N-methyl-2-pyrrolidone is used as a solvent, 1,3,5-trichlorobenzene and 2,4,6-trichlorobenzene molecular weight regulators are added to control the molecular weight distribution coefficient of polycondensation synthesized polyphenylene sulfide resin, an antioxidant is added to the synthetic polyphenylene sulfide resin, all above materials are mixed according to a certain ratio to form a raw material for the polyphenylene sulfide film, the material is extruded by a twin-screw extruder, goes through a T-shaped mold, and is biaxially drawn into the polyphenylene sulfide film, and the polyphenylene sulfide film undergoes corona and anti-adhesion agent treatment, and then is wound into a polyphenylene sulfide film roll. The film obtained in the invention can be widely used in the fields of electronic appliances, military industry, aerospace, machinery, chemical industry and the like.

Owner:德阳科吉高新材料有限责任公司

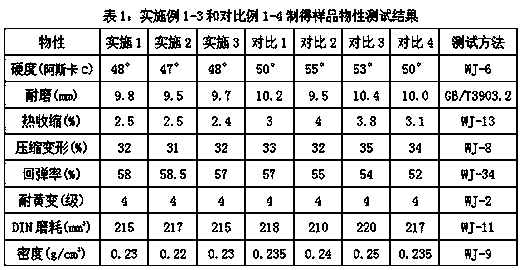

Anti-shrinkage modified EVA foam shoe material and preparation method thereof

InactiveCN109021375AGuaranteed stabilityReduce the value of the residual stressFootwearCross-linkFoaming agent

The invention relates to an anti-shrinkage modified EVA foam shoe material. The material comprises 40-43 parts of Formosa Plastics 7470, 5-6 parts of Formosa Plastics 7350, 6-8 pieces of Taiju 3312, 7-8 parts of Dow 3745, 10-12 an anti-shrinkage agent 203#, 1-1.5 parts of zinc oxide, 6-8 parts of an anti-wear agent, 2-3 parts of a filler, 0.3-0.5 part of an activator, 0.6-0.7 part of a cross-linking agent, 2-2.5 parts of a foaming agent and 3-4 parts of titanium dioxide. High-melting point and low-melt strength components are selected, so the product maintains molecular stability during use, the strain force required by the shrinkage deformation of the product is improved, the material has a low melt strength when the melting point of the material is reached in the production process of the product, the resistance to volume expansion is reduced, and the residual stress of the product after molding is reduced, thereby the shrinkage tendency is reduced, and the problem of heat shrinkagedeformation of the finished product is solved while ensuring "light, flexible, soft and elastic" basic characteristics.

Owner:林伟坤

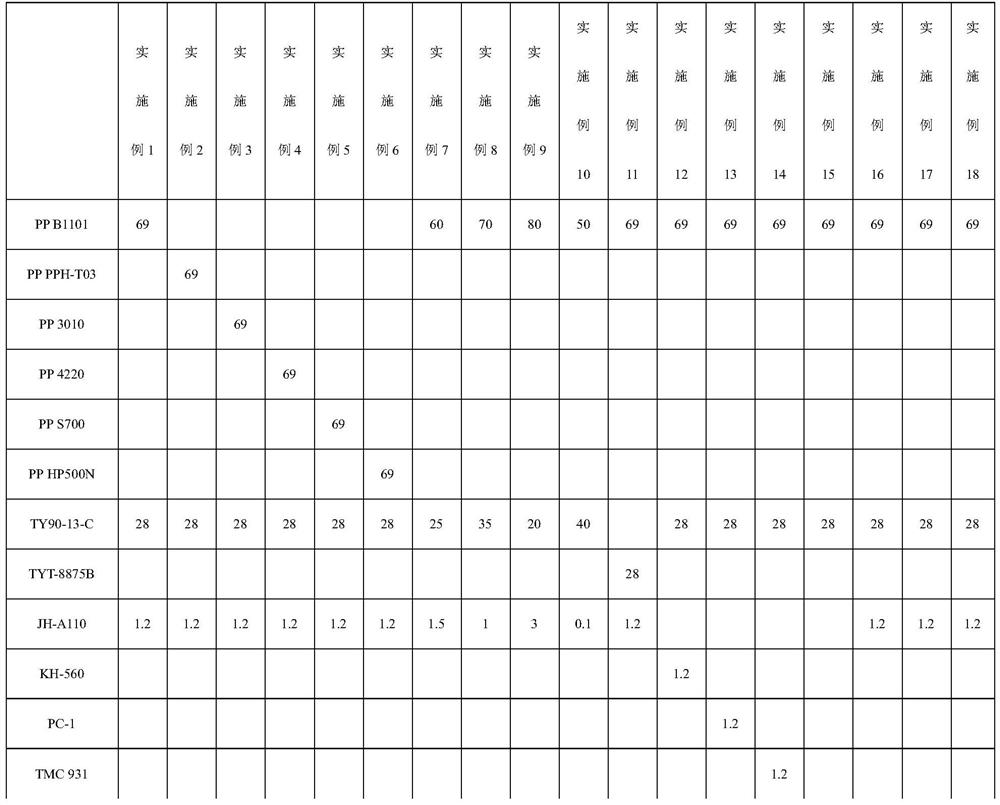

High-melt-strength polypropylene material resistant to cyclic processing as well as preparation method and application thereof

The invention discloses a high-melt-strength polypropylene material resistant to cyclic processing as well as a preparation method and application thereof, and belongs to the technical field of high polymer materials. The high-melt-strength polypropylene material resistant to cyclic processing comprises the following components in parts by weight: 50 to 80 parts of polypropylene, 20 to 40 parts of talcum powder, 0.1 to 3 parts of a modifier, 0.05 to 2 parts of a nucleating agent, 0.1 to 3 parts of a lubricant, and 0.2 to 2 parts of an antioxidant. The talcum powder increases the viscosity of the material and reduces chain scission in cyclic processing, the nucleating agent refines matrix crystal nucleuses, the modifier improves the dispersibility of the components and reduces interface defects, and the synergistic effect of the lubricant and the antioxidant is combined, so that the melt strength of the polypropylene material is effectively improved; and moreover, the melt strength reduction in the cyclic processing process is avoided, and the polypropylene material can be widely applied to cyclic processing preparation of polypropylene materials. The melt strength of the polypropylene material is 18-30 cN, and the retention rate of the melt strength is still 48-60% after three times of extrusion preparation.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

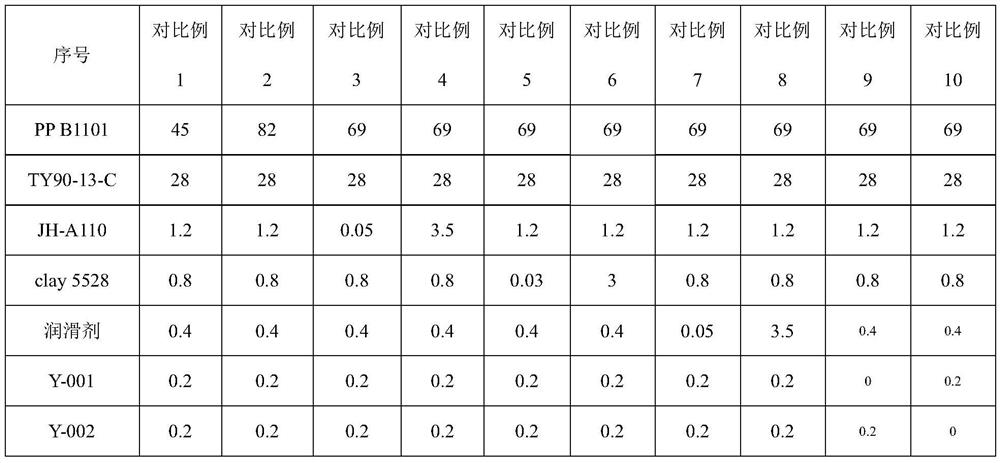

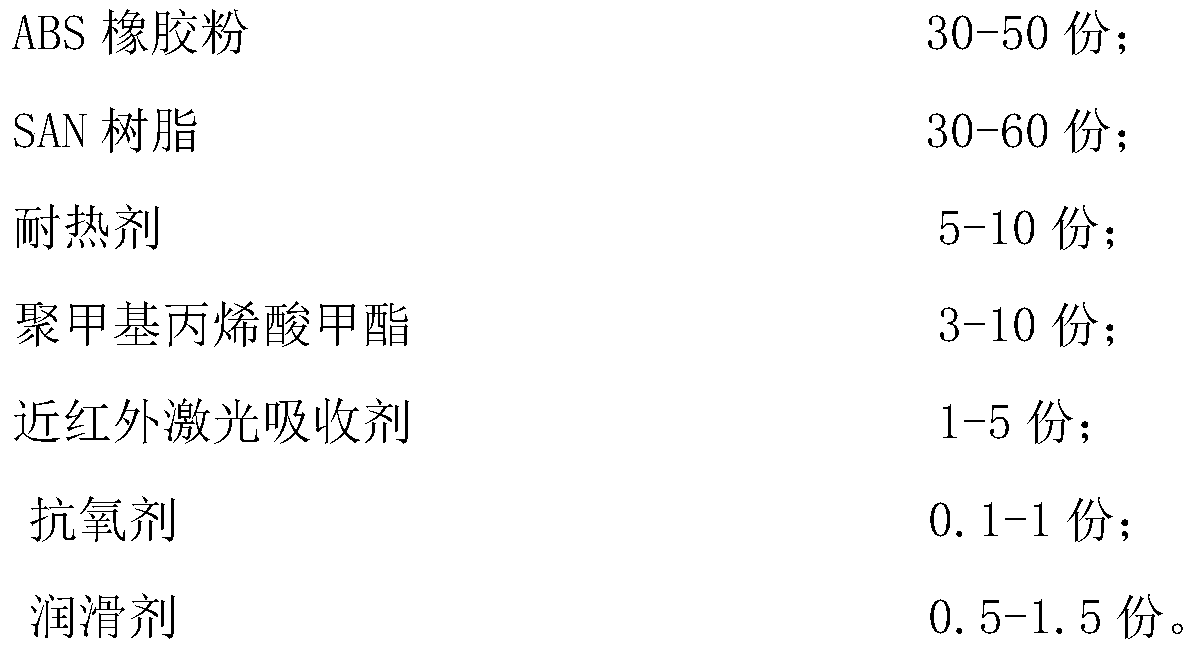

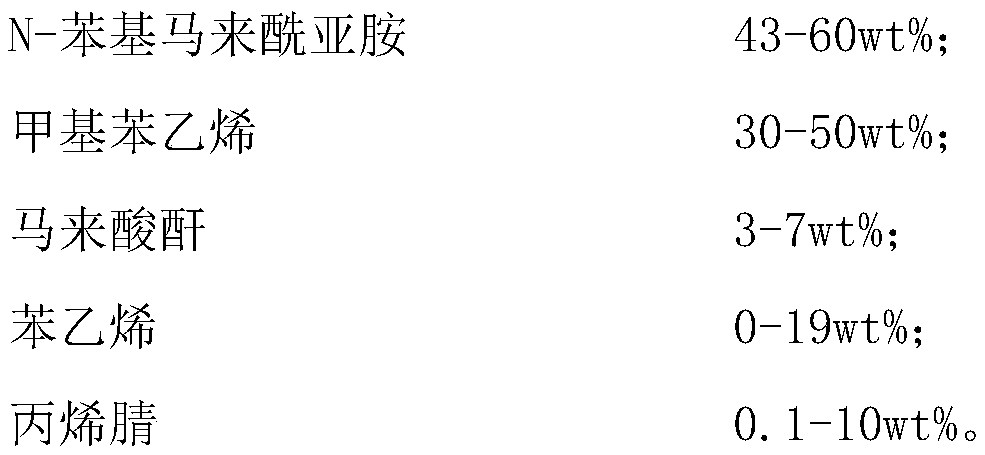

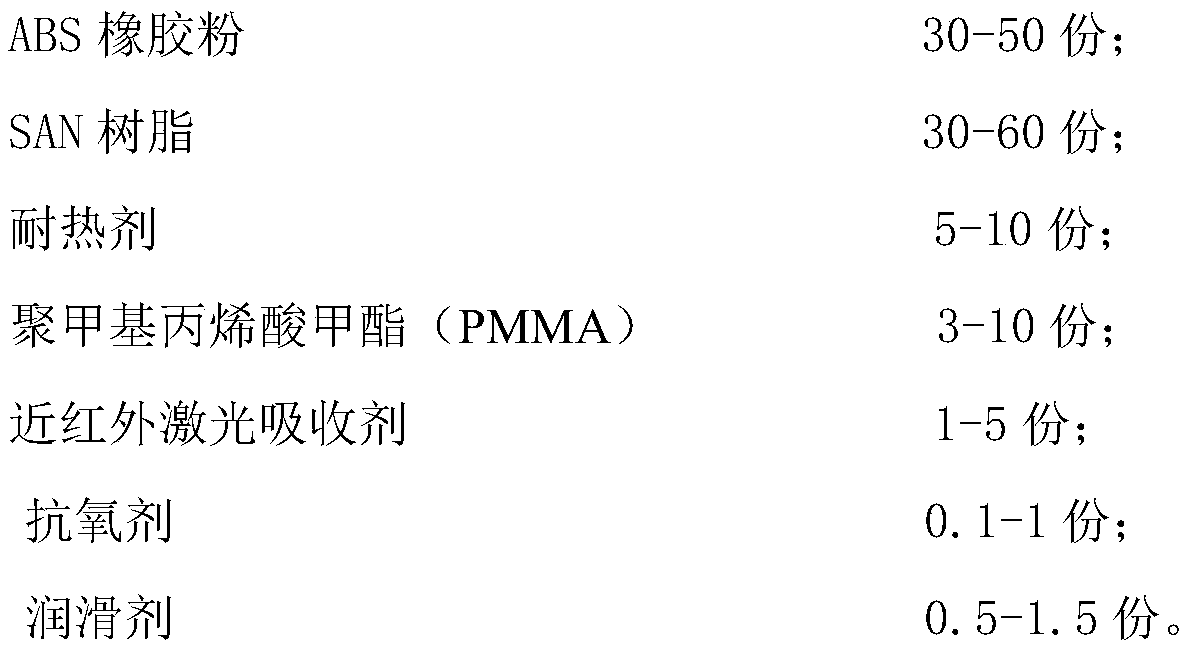

ABS composition suitable for being laser-welded and preparation method thereof

The invention provides an ABS resin composition capable of improving laser welding performance and a preparation method thereof. The ABS resin composition is prepared from the following components inparts by weight: 30-50 parts of ABS rubber powder, 30-60 parts of SAN resin, 5-10 parts of a heat resistant agent, 3-10 parts of polymethyl methacrylate, 1-5 parts of a near-infrared laser absorbent,0.1-1 part of an antioxidant, and 0.5-1.5 parts of a lubricant. The preparation method of the ABS resin composition comprises the following steps: the raw materials are pre-mixed in a high-speed mixerfor 3-10 minutes, then a pre-mixed material is extruded through a double-screw extruder to be pelletized, and then the ABS resin composition is obtained. The ABS resin composition and the preparationmethod thereof have the advantages that prepared ABS resin capable of improving laser welding can greatly improve the laser energy absorption capacity of an ABS substrate material, meanwhile, excellent tenacity and heat resistance and high melt strength are achieved, and the resin composition is very suitable for being laser-welded to PMMA.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Method for preparing low melt strength polyester / clay nanocomposites for CO2 foam

The invention relates to a method for preparing low melt strength polyester / clay nanocomposites for CO2 foam, and relates to three raw materials: a, a commercialized polyester chip or recycled polyester; b, multifunctional chain extender; c, organic modified clay. The method comprises three technology paths: A, premixing raw material a, raw material b and raw material c according to certain parts by mass, and then performing melt blending to obtain the nanocomposites; B, premixing the material a and the material b according to certain parts by mass, performing reactive extrusion to obtain the modified polyester; premixing the modified polyester and the raw material c according to certain parts by mass, and performing the melt blending to obtain the nanocomposites; C, premixing the raw material a and the raw material c according to certain parts by mass, and then performing the melt blending to obtain a master batch of the nanocomposites; premixing the master batch of the nanocomposites, raw material a and raw material b according to certain parts by mass, performing the reactive extrusion to obtain the nanocomposites. The polyester / clay nanocomposites prepared by the method can be directly used in a CO2 foaming process, and no need to further enhance the melt strength.

Owner:EAST CHINA UNIV OF SCI & TECH

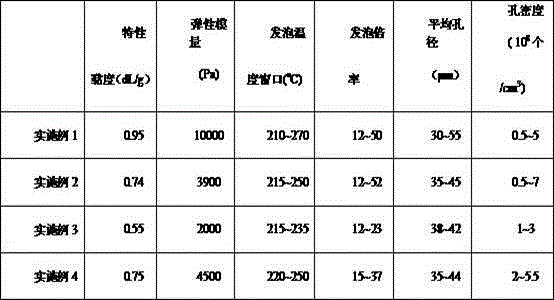

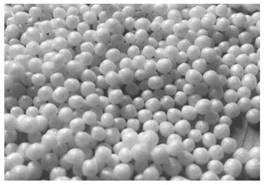

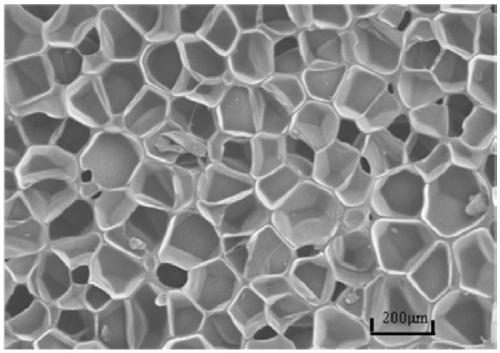

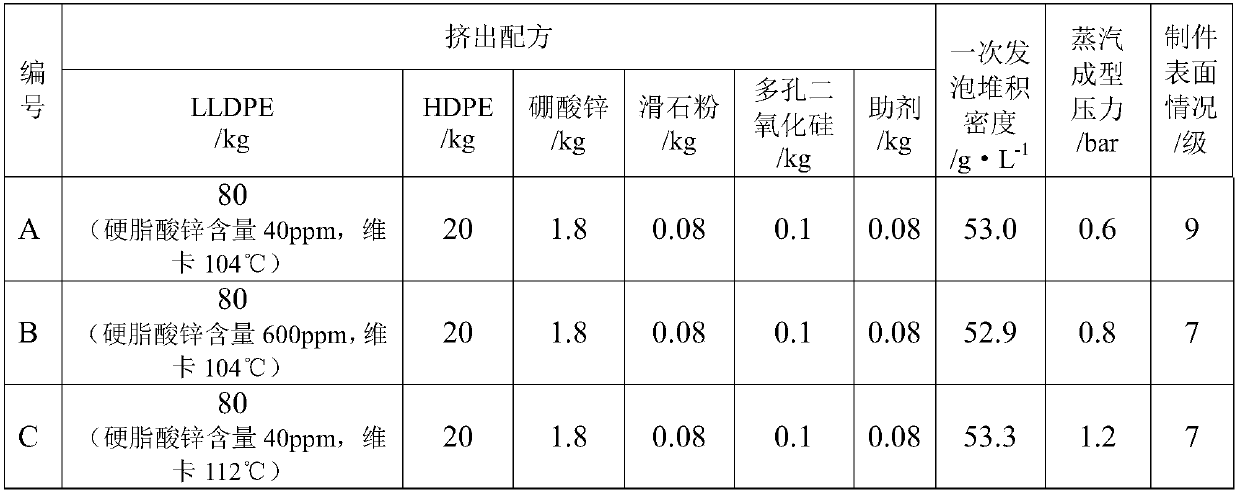

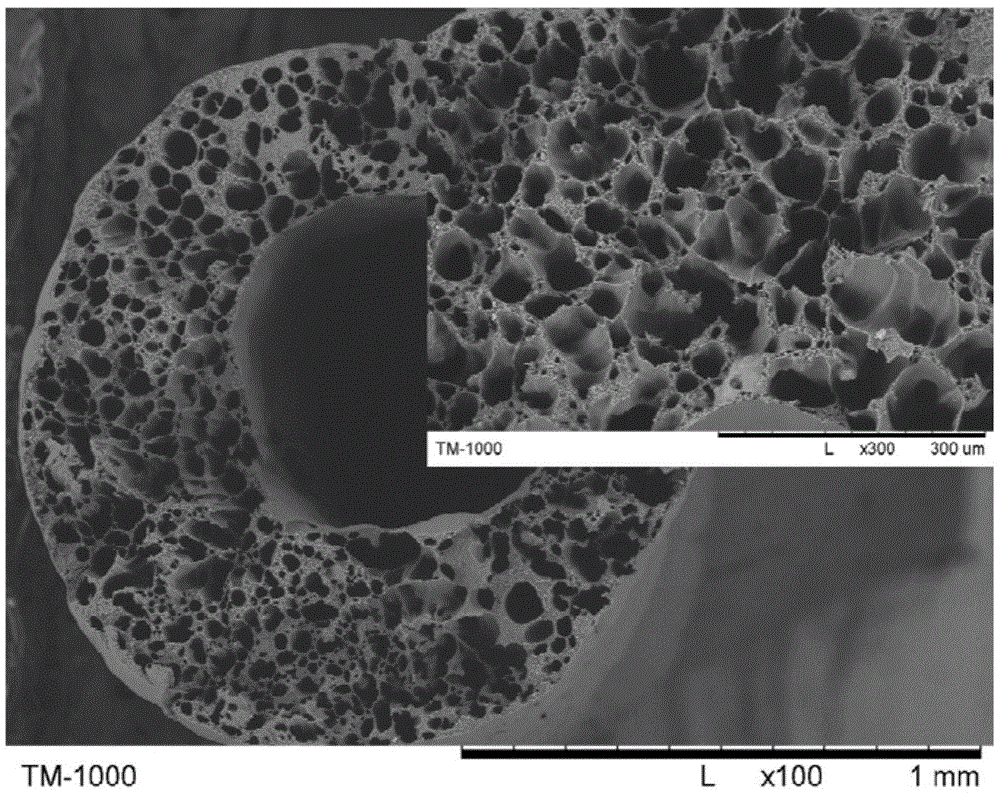

Easily melted foamed polyethylene bead with strong temperature tolerance and preparation method thereof

ActiveCN109651695AIncrease elasticityImprove temperature resistanceLow-density polyethyleneThermal insulation

The invention discloses an easily melted foamed polyethylene bead with strong temperature tolerance and a preparation method thereof. Low density polyethylene with a Vicat softening point of 90 to 105DEG C and high density polyethylene are compounded, at the same time, an inorganic compounding foaming aid is adopted, and through the synergistic effect generated by three components, goals of easily melting and high temperature tolerance are realized. Through the cooperation of formula and technology, the size of inner pores of primarily foamed EPE beads is controlled in a range of 200 to 230 [mu]m, after foaming, no thermal insulation device is needed, and a step of introducing steam with a certain air pressure into a pipe for delivering polypropylene resin particles is not needed either.The moulding steam pressure is obviously reduced, the melting stability between particles is excellent, and the curing degree is 95% or more. Because the inner pores in the beads are increased, and the pore uniformity is increased, the polyethylene bead can tolerate a certain moulding temperature, the stiffness of pores in the surface of a moulded product is improved, and the beauty of the surfaceof a EPE bead moulded product is obviously improved.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

Poly(L-lactic acid) foaming material with rapid crystallization capacity and preparation method of poly(L-lactic acid) foaming material

The invention provides a polylactic acid foaming material. The polylactic acid foaming material is obtained by injection molding of raw materials. The raw materials comprise the following components in parts by mass: 90-98 parts of poly(L-lactic acid) resin, 1-9.9 parts of a PLLA-b-PDLA block copolymer, and 0.1-1 part of a nano bubble nucleating agent, wherein the poly(L-lactic acid) comprises end-capped poly(L-lactic acid); and the end-capped group comprises one or more of a benzene ring structure, a carbon chain structure with the number of carbon atoms greater than or equal to 4 and a polyalkylene oxide structure. According to the polylactic acid with the rapid crystallization capacity, the corresponding foaming material formula and the light-weight injection molding technology, a new direction is provided for preparation of a high-strength and low-gram-weight full-degradable material and subsequent research of the polylactic acid material, and the polylactic acid foaming material has the advantages of being high in heat-resistant temperature, has the characteristics of stable foaming, high cell density and the like at the same time, and is suitable for large-scale continuous production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

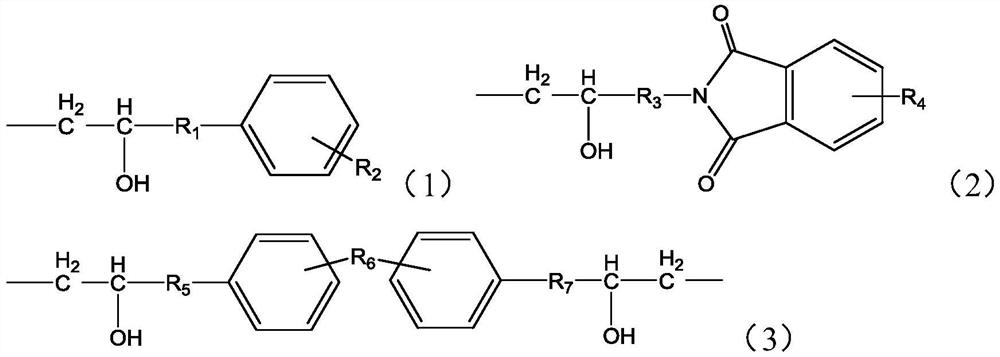

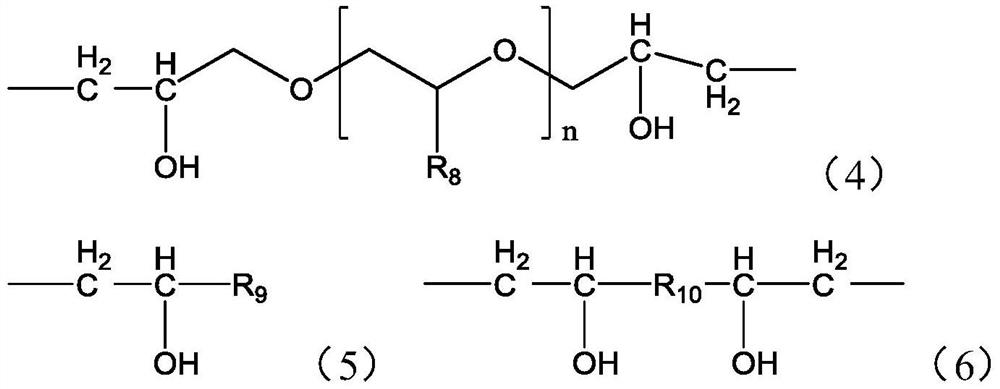

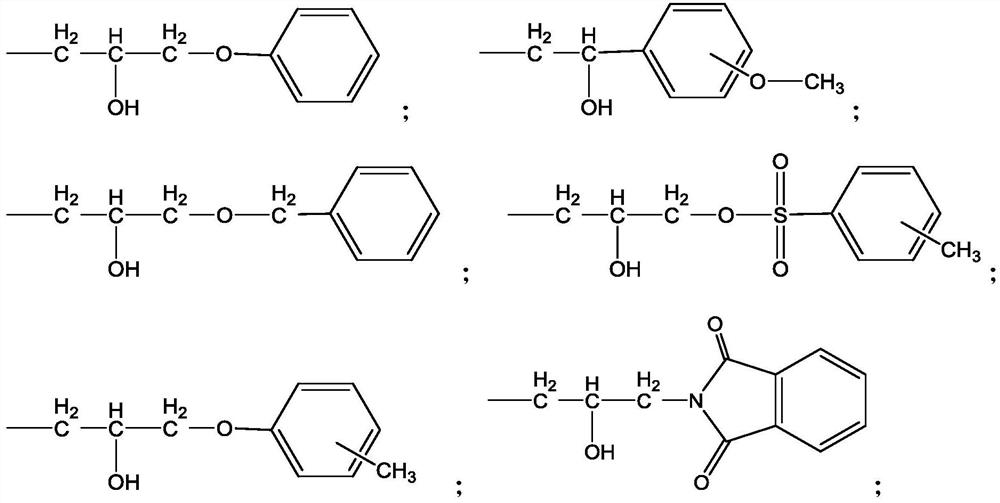

Polypropylene with low gel content and high melt strength, preparation method and application thereof

The invention relates to the technical field of high polymer materials, and discloses polypropylene with low gel content and high melt strength, a preparation method and application thereof. According to the method, a polypropylene raw material is grafted through unsaturated alcohol to obtain grafted polypropylene, and the grafted polypropylene is cross-linked through a multi-epoxy compound to obtain cross-linked polypropylene, namely the polypropylene with low gel content and high melt strength; According to the invention, unsaturated alcohol is used for grafting a polypropylene raw material, and is only grafted with polypropylene and cannot be cross-linked, and then a multi-epoxy compound reacts with the grafted alcohol to generate an ether bond, and does not directly react with the polypropylene, so that the generation of gel is effectively avoided; and the obtained polypropylene is low in gel content and high in melt strength, and can be used in foaming materials.

Owner:中化石化销售有限公司

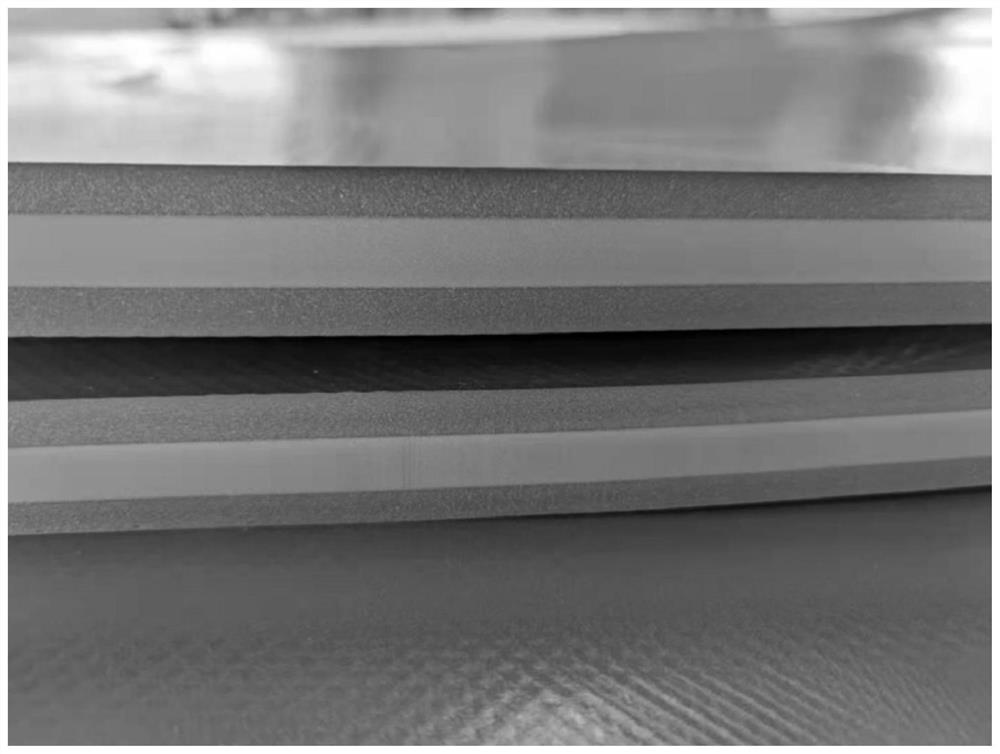

Method for preparing double-color foamed sheet based on temperature control

The invention relates to a method for preparing a double-color foamed board based on temperature control, and belongs to the technical field of foaming. The invention provides a method for preparing a double-color foamed sheet based on temperature control, which comprises the following steps of: putting a foamed mother board into a mold cavity of a foaming mold, raising the temperature in the mold cavity to a first saturation temperature, injecting a foaming agent into the mold cavity, and dissolving the foaming agent into the foamed mother board, and after the foaming agent reaches a saturation state at the first saturation temperature in the foaming mother board, raising the temperature in the mold cavity to a second saturation temperature and keeping the second saturation temperature for a preset length of time, so that the foaming mother board forms a temperature gradient in the thickness direction, and after the temperature gradient is formed, releasing the pressure in the mold cavity to the environmental pressure, so that the foaming mother board expands and foams. According to the method, a temperature gradient is formed in the thickness direction of a foaming mother board by controlling the temperature in a mold cavity, so that the foaming mother board forms a melt strength difference in a foaming environment, and finally chromatic aberration is formed.

Owner:SHINCELL NEW MATERIAL CO LTD

A preparation method of high temperature resistant fluoropolymer microporous material

The invention discloses a preparation method of a high-temperature-resisting fluorine-containing polymer cellular material. The preparation method comprises the following steps of uniformly mixing fluorine-containing polymer, micro-phase separation induction polymer, a pore-foaming agent and an auxiliary induction agent at a high speed, carrying out extrusion molding on the mixture through a supercritical-double-screw extruder film forming system to obtain a primary cellular material, immersing the primary cellular material in a coagulating bath, drawing and stretching the primary cellular material at a given speed, and soaking the primary cellular material in a washing bath to be oscillated and washed to obtain the high-temperature-resisting fluorine-containing polymer cellular material. The supercritical carbon dioxide is used as a plasticizing additive of the system, so that the melt viscosity of the fluorine-containing polymer can be reduced, and the processing temperature of the fluorine-containing polymer can be at least reduced by 20 DEG C; the supercritical carbon dioxide is used as green solvent, so that a great amount of organic solvent can be avoided, the problem of the prepared cellular material has no solvent residual can be avoided, and the environmental pollution can be avoided.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

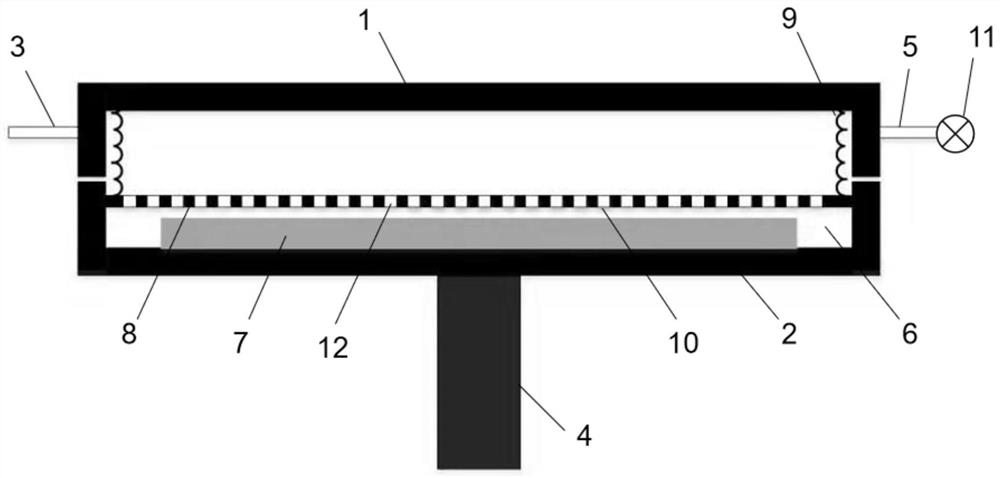

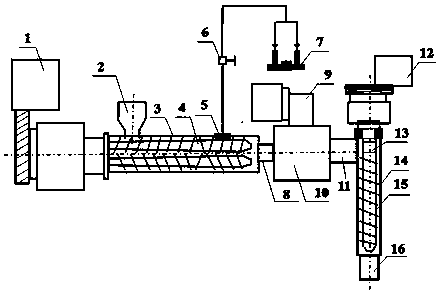

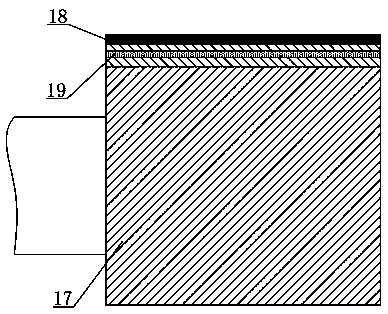

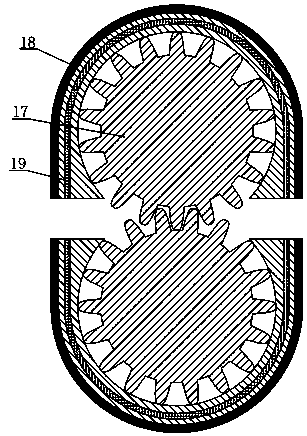

Isotatic polypropylene extrusion foaming device and process

The invention discloses an isotatic polypropylene extrusion foaming device and process. The device comprises a double-screw extruder, a duplex air pump, a melt pump and a single screw extruder which are arranged in sequence. According to the isotatic polypropylene extrusion foaming device and process, through temperature and pressure control of the melt pump and the single screw extruder, the isotatic polypropylene melt strength is enhanced online; and by adopting the structural design of a screw of the single screw extruder in a matched mode, isotatic polypropylene extrusion foaming forming is achieved.

Owner:ZHENGZHOU UNIV

Melt fabrication of fiber-filled fluoropolymer

A molding process is provided for a composition comprising fiber, such as glass, aramid, PTFE fiber, or carbon fiber, and melt-fabricable fluoropolymer, wherein the decrease in melt flowability of the composition as arises when the composition is provided to the process as conventional size melt-formed pellets is minimized by providing the composition to the process in the form melt-formed particles, at least 80 wt % of these particles having a width no greater than about 70 mils (1784 micrometers).

Owner:EI DU PONT DE NEMOURS & CO

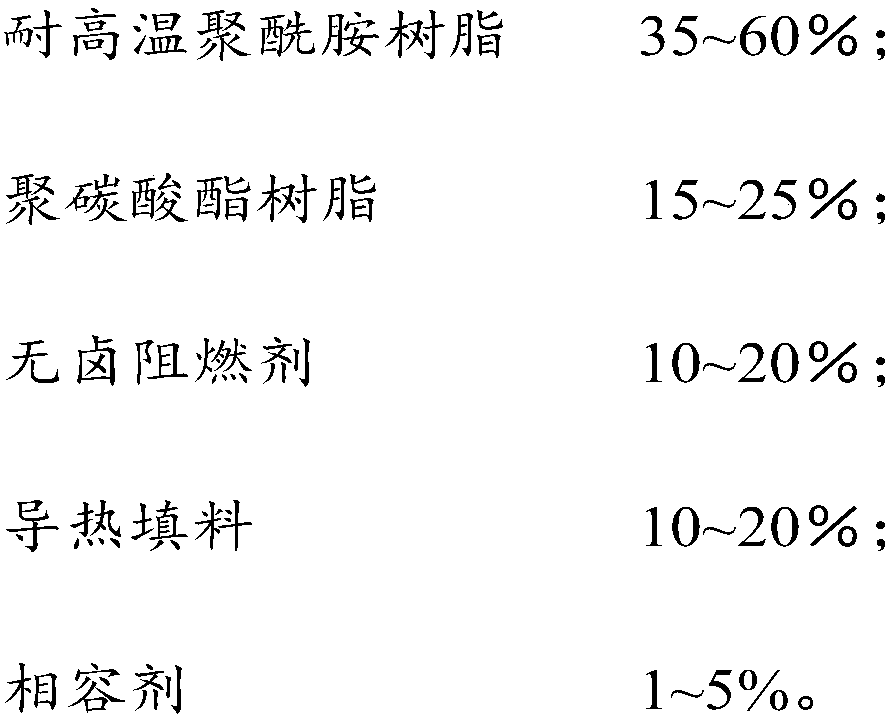

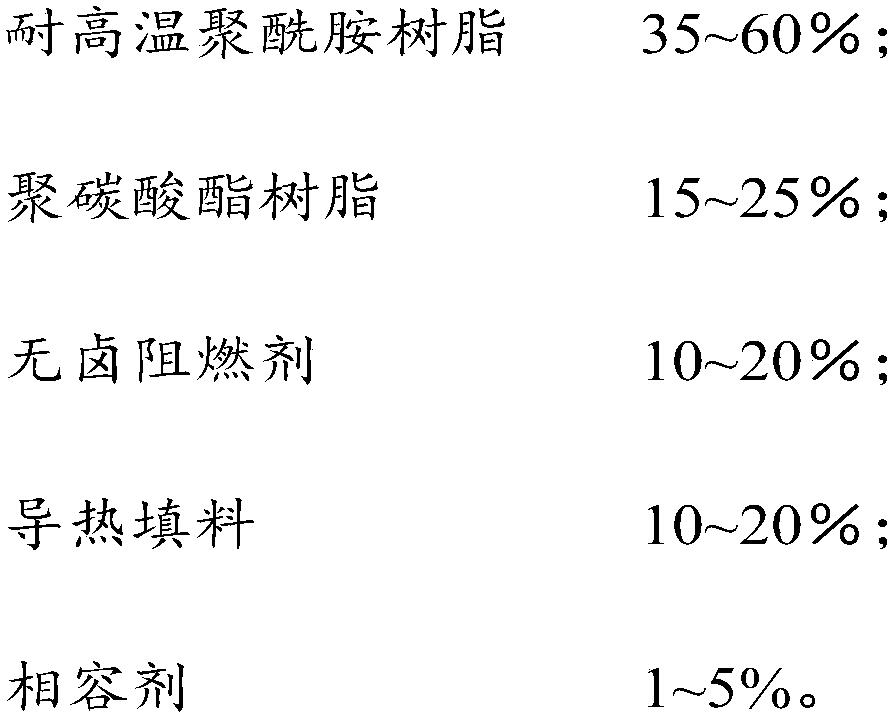

Halogen-free flame-retardant thermal-conductive plastic alloy and preparation method thereof

ActiveCN108102362AImprove mechanical propertiesNo significant reduction in mechanical propertiesPolyamideAlloy

The invention provides halogen-free flame-retardant thermal-conductive plastic alloy and a preparation method thereof and relates to the field of plastic alloy materials. The halogen-free flame-retardant thermal-conductive plastic alloy is prepared from the materials in mass percent: 35 to 60% of high-temperature-resistant polyamide resin, 15 to 25% of polycarbonate resin, 10 to 20% of halogen-free flame-retardant agent, 10 to 20% of thermal-conductive filler and 1 to 5% of compatilizer. The preparation method comprises the steps: mixing the dried high-temperature-resistant polyamide resin andthe halogen-free flame-retardant agent, then stirring and mixing with the polycarbonate resin, the thermal-conductive filler and the compatilizer and warming to 100 to 120 DEG C in a stirring processto obtain a mixed base materail; melting and blending the mixed base material under 300 to 320 DEG C and extruding and granulating. The halogen-free flame-retardant thermal-conductive plastic alloy has the advantages of excellent flame retardance, thermal conductivity, mechanical property and high temperature resistance.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

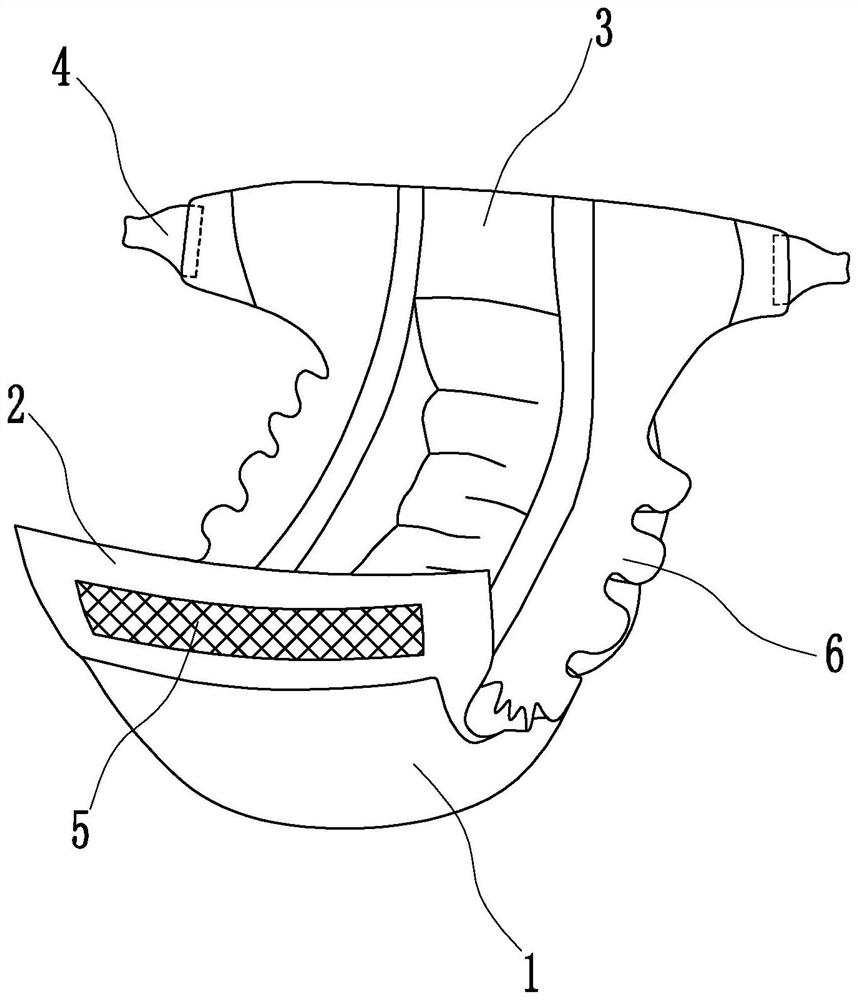

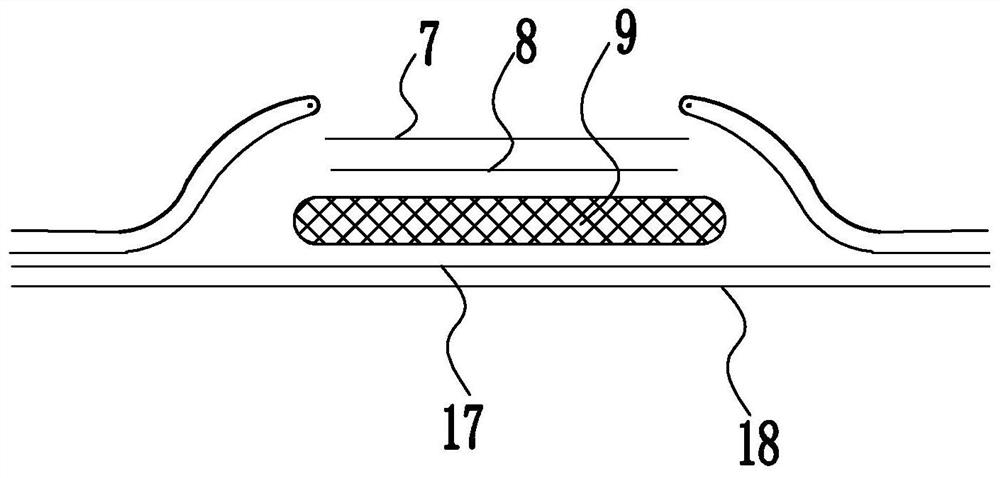

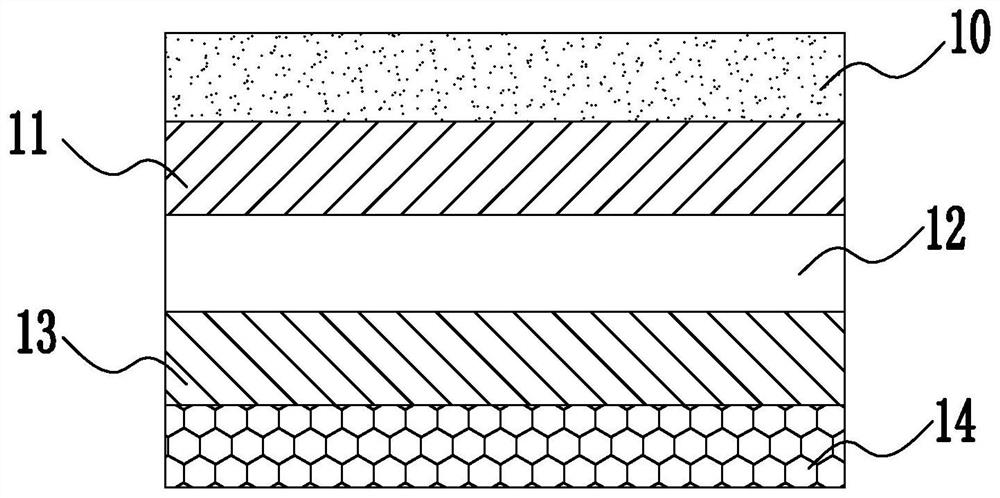

A reinforced structure paper diaper with a composite core

The invention relates to the field of disposable hygiene products, and discloses a reinforced structural diaper with a composite core, which includes a diaper body, and the diaper body is composed of an air-permeable surface layer, a diversion layer, a composite core body, and a leak-proof bottom layer. Bonded with degradable hot-melt adhesive, the composite core consists of a dust-free paper, an upper absorbent layer, an elastic layer, a lower absorbent layer, and a spun-bonded non-woven fabric from top to bottom, and the upper absorbent layer includes a middle area and a Anti-side leakage areas on both lateral sides of the middle area, the middle area has several upper absorption sections distributed along the longitudinal direction, each of the upper absorption sections is arranged at intervals, and the distribution density of the superabsorbent resin on the anti-side leakage area is greater than The upper absorbing section, the lower absorbing layer is longitudinally distributed with several lower absorbing sections, each of the lower absorbing sections is arranged at intervals, and the layers of the composite core are bonded by degradable hot-melt adhesives. It solves the problem that the existing paper diapers are easy to agglomerate, break and delaminate, and the hot melt adhesive used for bonding has good bonding effect and is degradable.

Owner:GUANGDONG YINYIN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com