Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202results about How to "Control degradation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

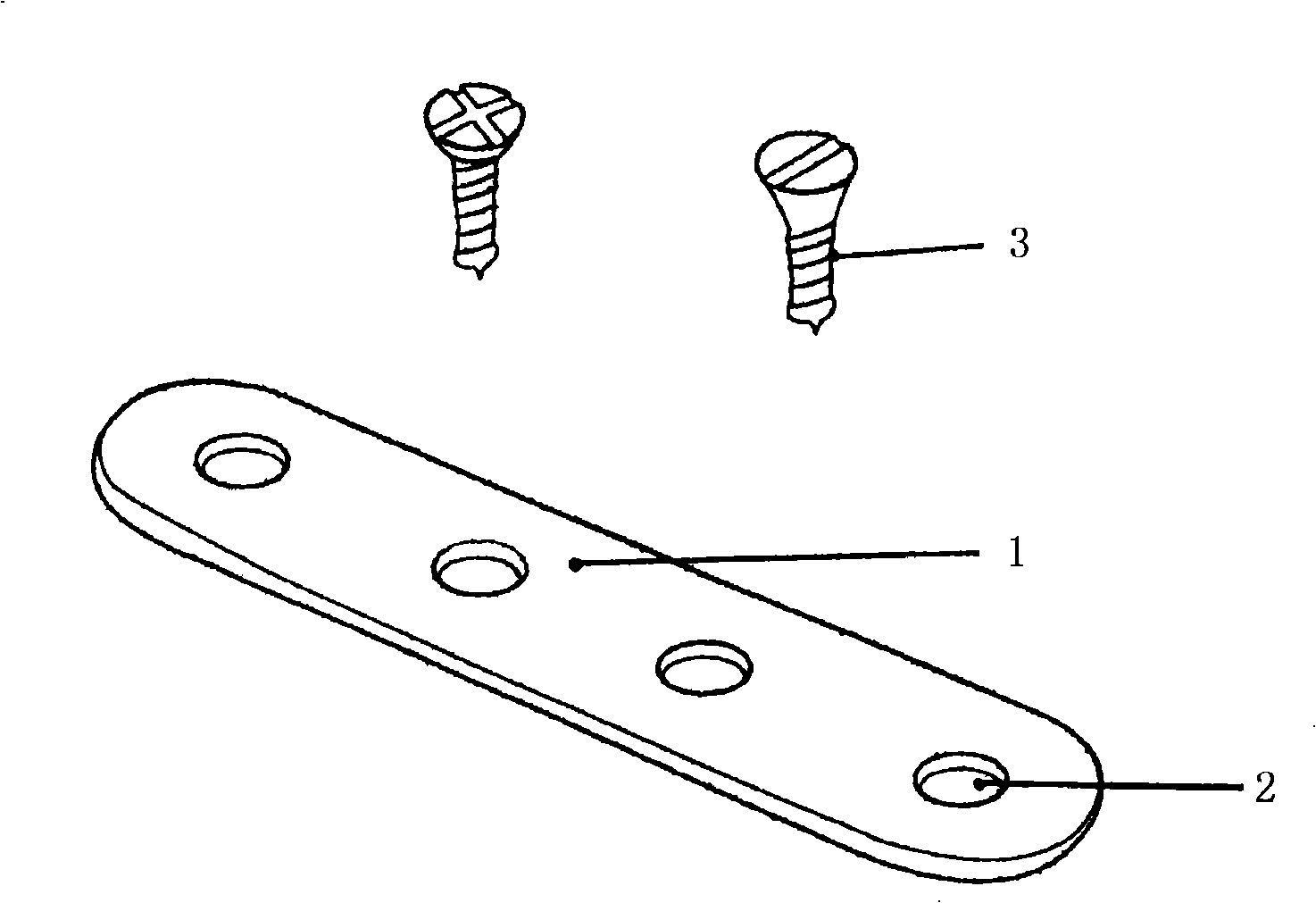

Biological and adsorbable bone internal fixation implantation instrument

InactiveCN101283922APromote healingUniform corrosion degradationInternal osteosythesisProsthesisInternal bone fixationReconstructive surgery

The invention relates to a bone implanting and internal fixation appliance with bioactivity and absorbability, which belongs to the field of bio-medical appliances, particularly to the field of medical appliances used for bone wound surgery, reparative and reconstructive surgery and plastic and cosmetic surgery. The appliance includes bone nails and a bone plate made of magnesium and the alloy thereof with bioactivity and absorbability. The bone implanting and internal fixation appliance is a bone internal fixation device, which comprises a blade plate and matched screws, intramedullary nails, a fracture and dislocation fixing device of vertebral column, bone nails or screws having individual fixation effect, wherein the bone internal fixation device is made of magnesium and the alloy thereof with bioactivity and absorbability. The bone internal fixation device can solve the problem in bioactivity of prior bone internal fixation device and promote healing the tissue where the device in implanted. The device also includes a protection layer prepared on the surface of the internal fixation device for controlling the degradation rate of magnesium alloy and the dissolution rate of magnesium ions, thus controlling the bioactivity and the absorption speed of the magnesium alloy device in an organism.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

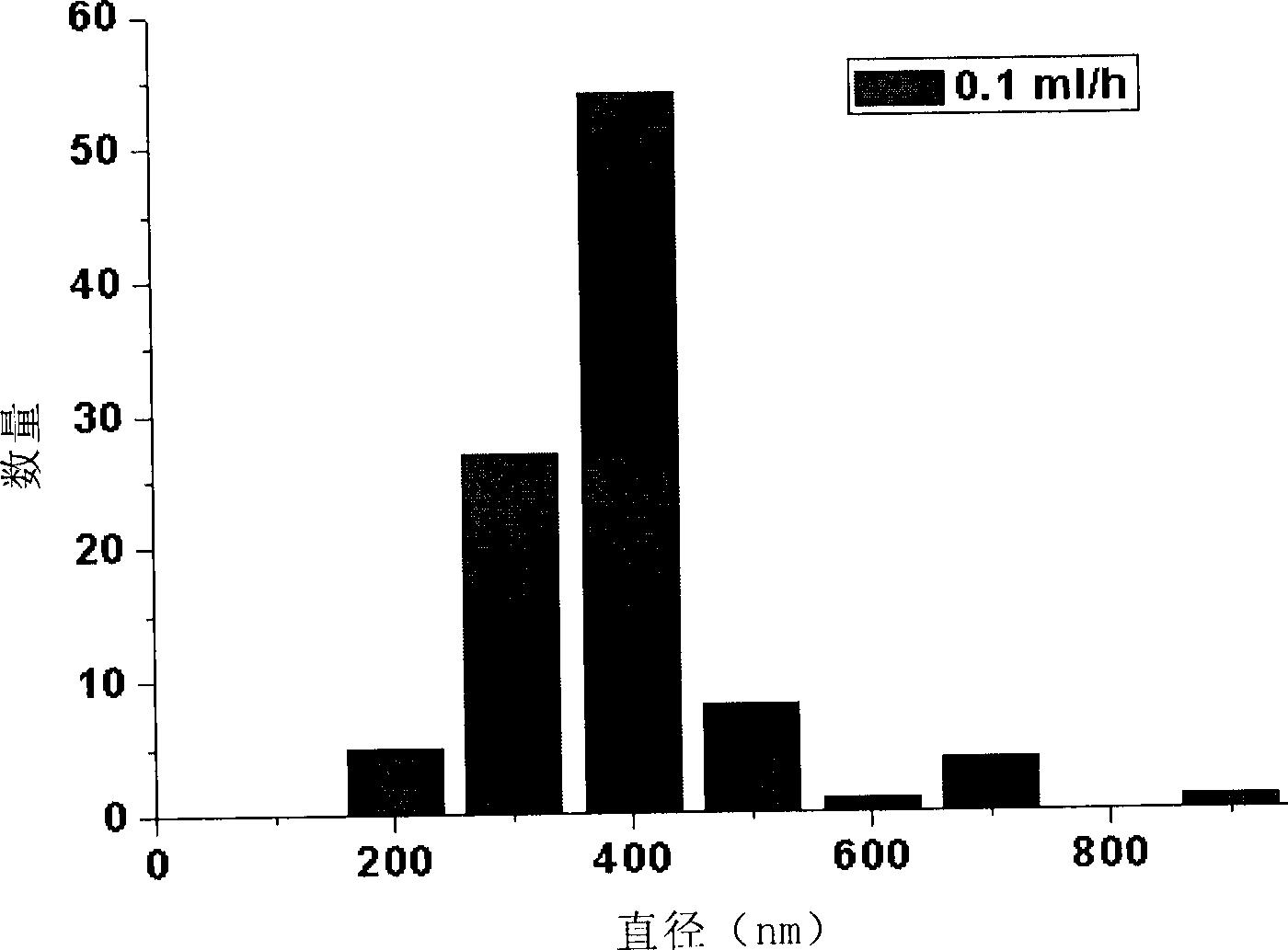

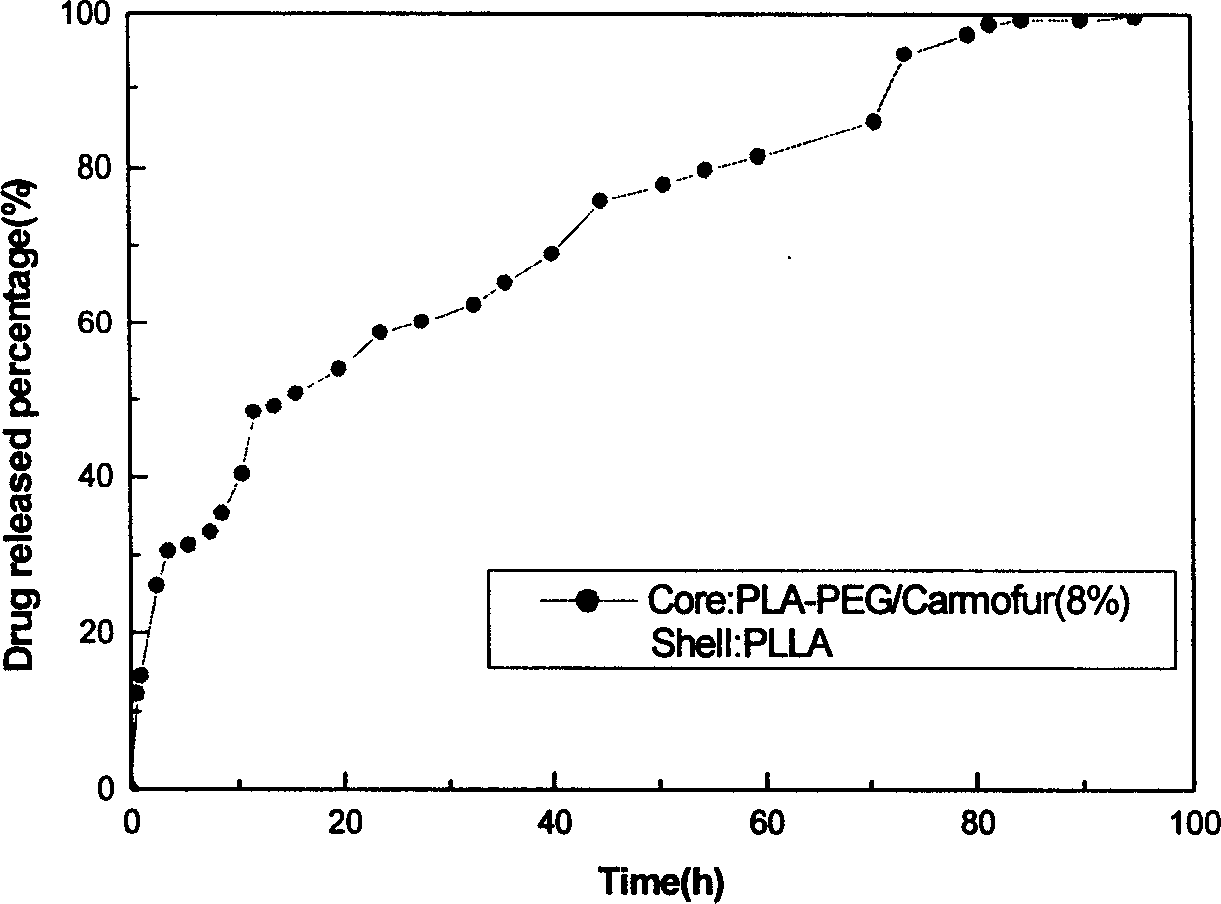

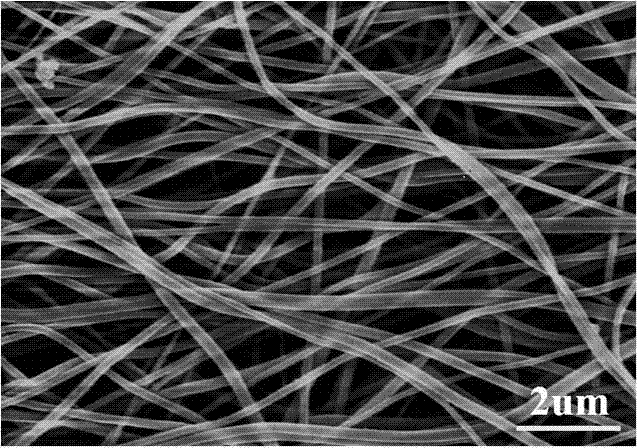

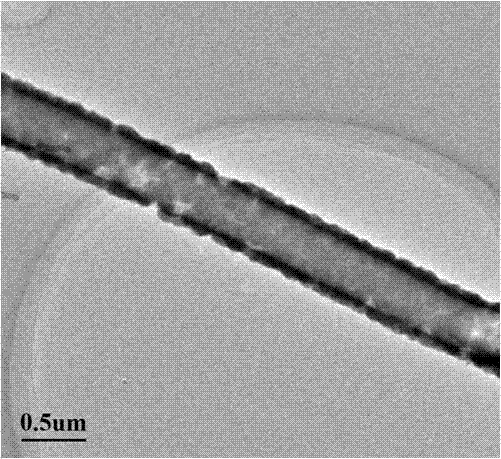

Nerve catheter as well as preparation method and application thereof

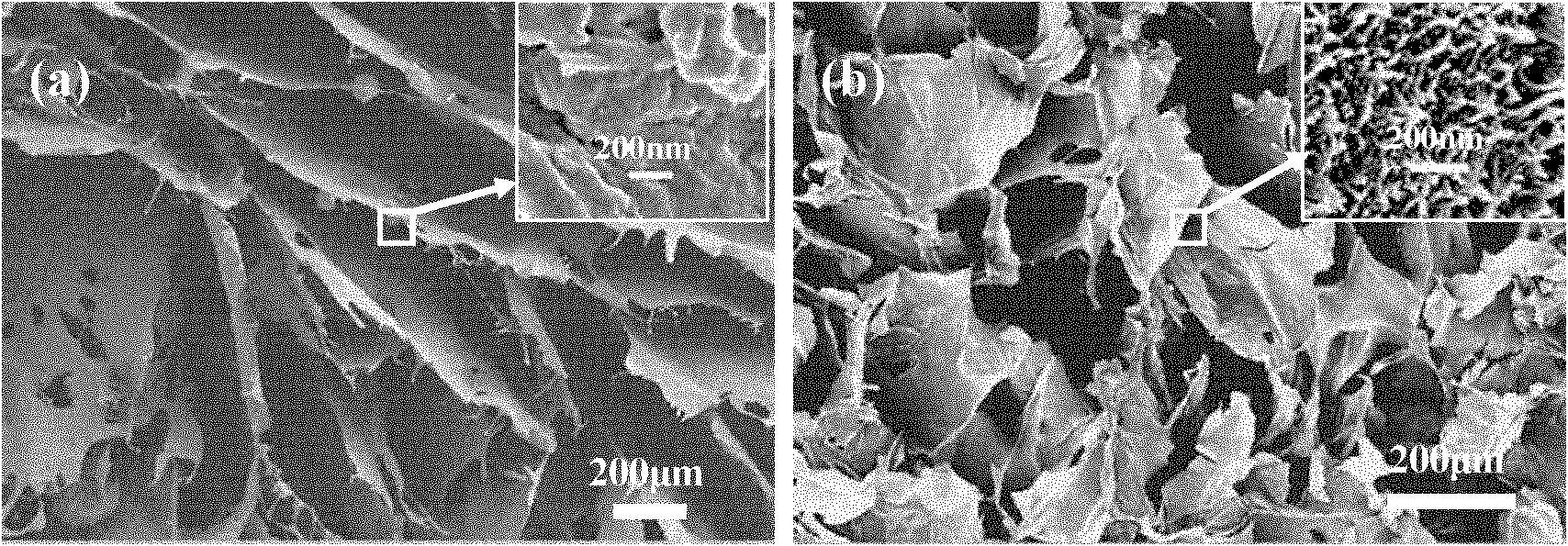

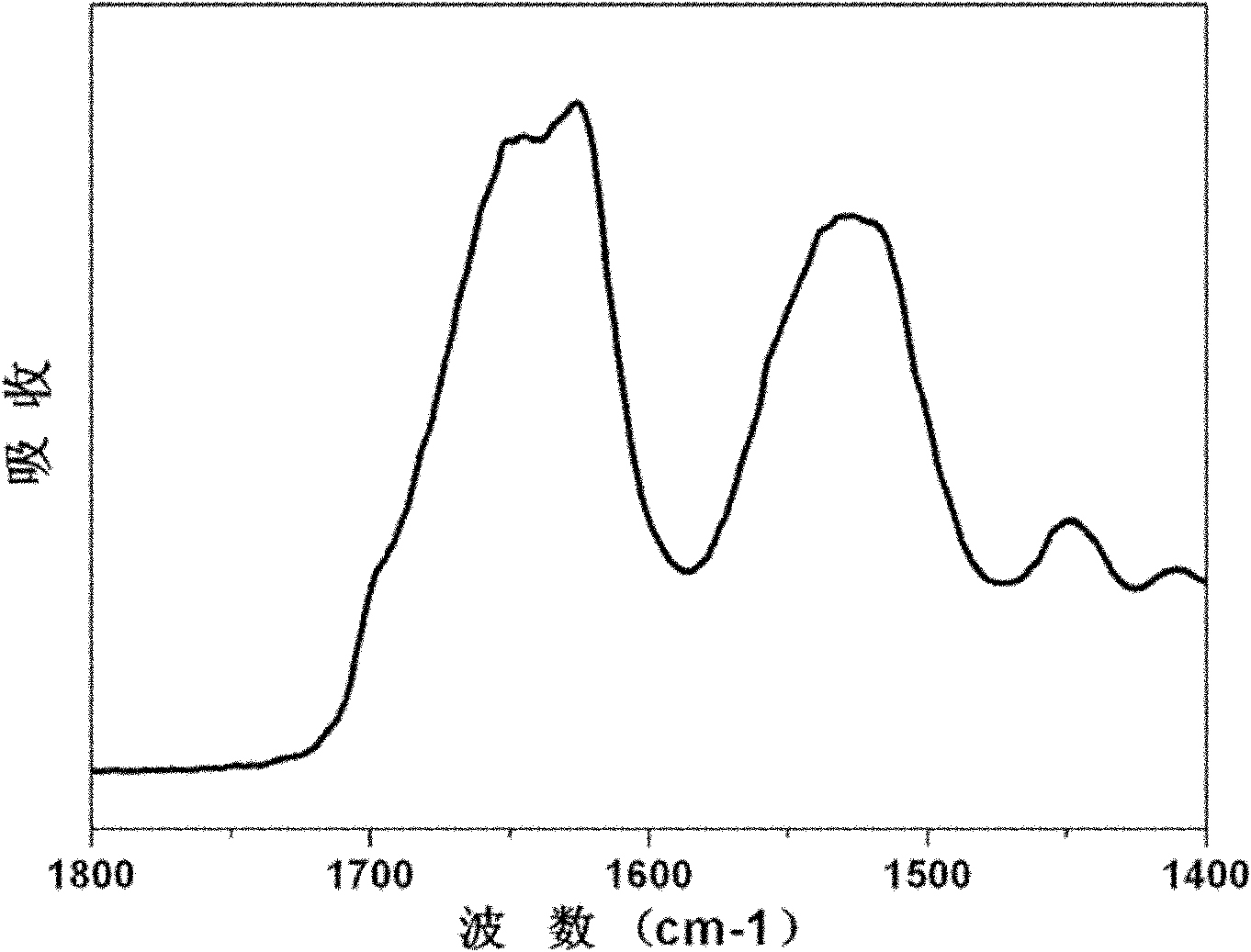

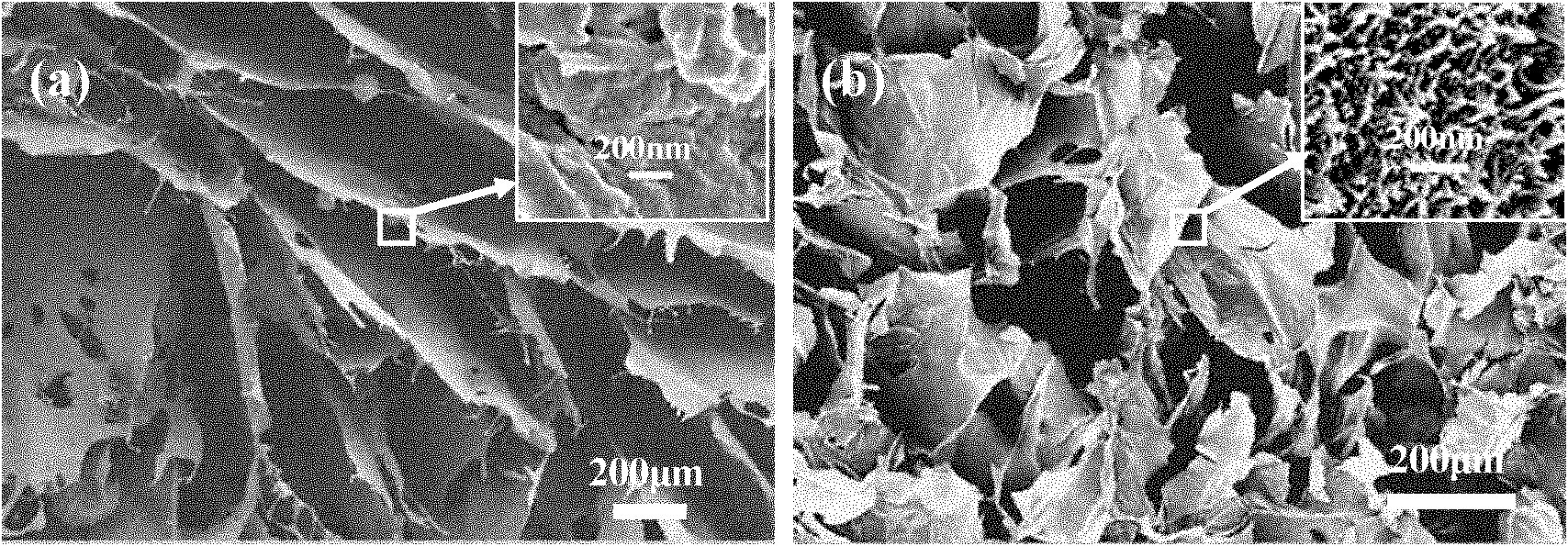

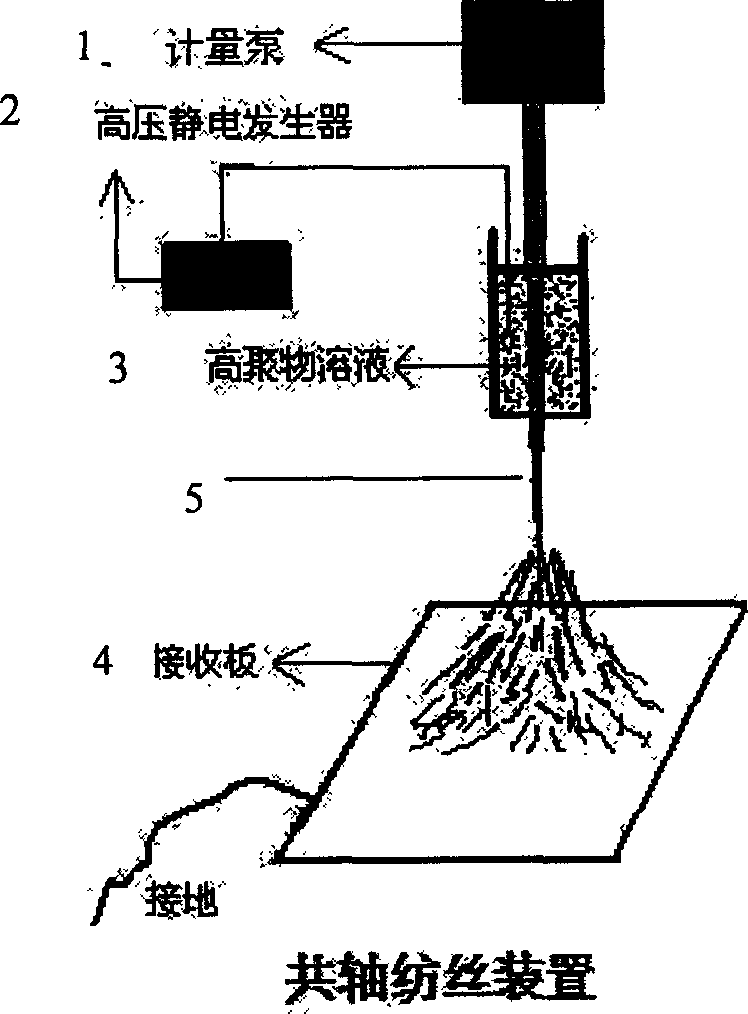

InactiveCN101439205APromote regenerationHigh porosityFilament/thread formingCatheterMedicineActive component

The invention discloses a nerve duct and a preparation method as well as use thereof. The nerve duct is composed of 'shell-core' structured nanofiber, a core layer of the 'shell-core' structured nanofiber contains a biological active component, and a shell layer of the 'shell-core' structured nanofiber contains a biodegradable material; the inside diameter of the nerve duct is 0.5-5.0mm, and the outside diameter thereof is 1.0-6.0mm; the biological active component is a neurotrophic factor; and the biodegradable material is selected from one or more than one of the following components: polylactic-co-glycolic acid (PLGA), poly(lactic acid-caprolactone copolymer) (P (LLA-CL)) and poly(3-hydroxybutyrate) (PHB) or polyphosphoester (PPE).

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL

Preparation method of controlled-degradation high-hygroscopicity resin

The invention discloses a preparation method of controlled-degradation high-hygroscopicity resin. The preparation method comprises the following steps of: adding an acrylic acid monomer, a host / guest identification monomer and a functional monomer to a dispersion medium, uniformly mixing, then adding a cross-linking agent and an initiator, and polymerizing under a certain condition to obtain the high-hygroscopicity resin. The preparation method has the advantages that: the identification effect among the host and guest molecules in the polymer chain of the prepared resin can be controlled by changing the external conditions, and the degradation speed of the high-hygroscopicity resin is further controlled, therefore, the degradation time of the high-hygroscopicity resin can be adjusted to be adapted to different completion time during the oil-gas field construction; and under certain conditions, the host and guest molecules in the molecular chain of the degraded resin are compounded to form the high-hygroscopicity resin, thereby achieving the recycling effect. The obtained product can be applied to oil-gas field plugging agents, agricultural water-retaining corrosion inhibitors, soil improvement agents and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Plant fiber-reinforced polylactic acid foam material and preparation method thereof

The invention discloses a plant fiber-reinforced polylactic acid foam material, which is prepared from the following components: 20 to 95 percent of polylactic acid, 1 to 60 percent of plant fiber powder, 1 to 5 percent of foaming agent, 1 to 5 percent of nucleating agent, 1 to 5 percent of antioxidant and 1 to 5 percent of bulking agent. The invention also discloses a preparation method for the material. The foam material has the advantages of low apparent density, biodegradability, no environmental pollution, capacity of replacing polyolefin foam materials, wide application in the fields of heat insulation, buffer and packaging, simple preparation process and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

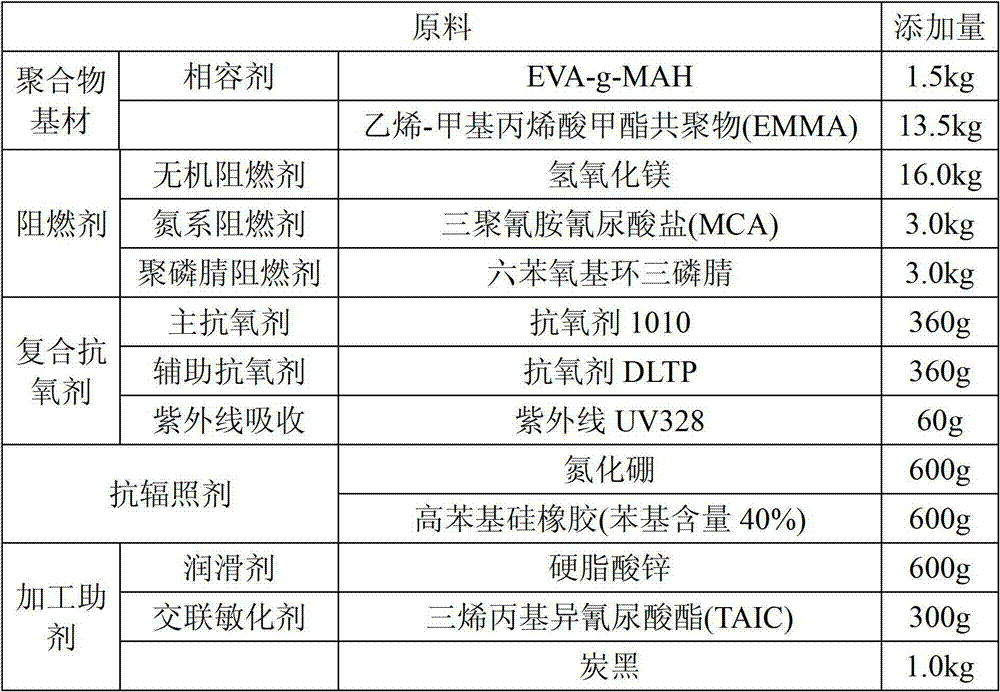

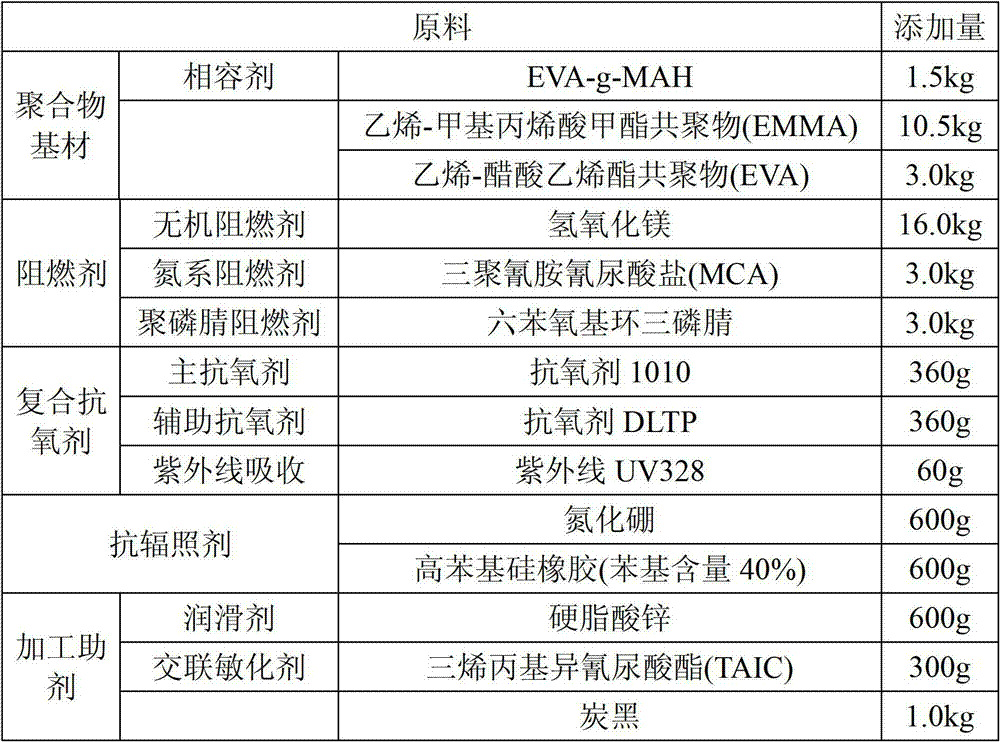

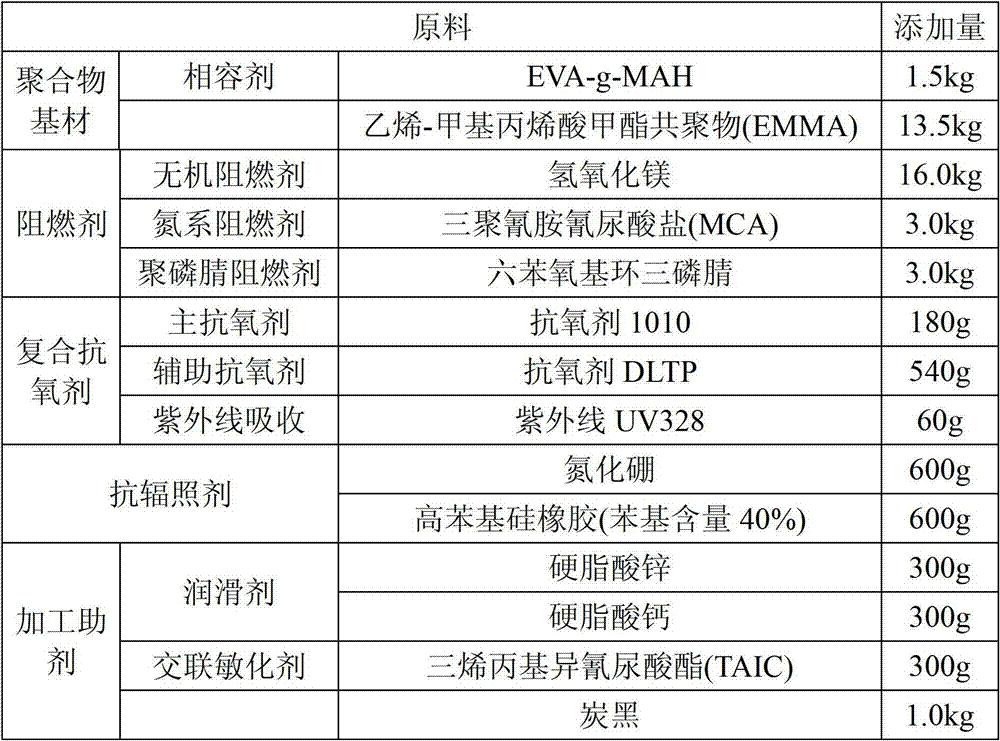

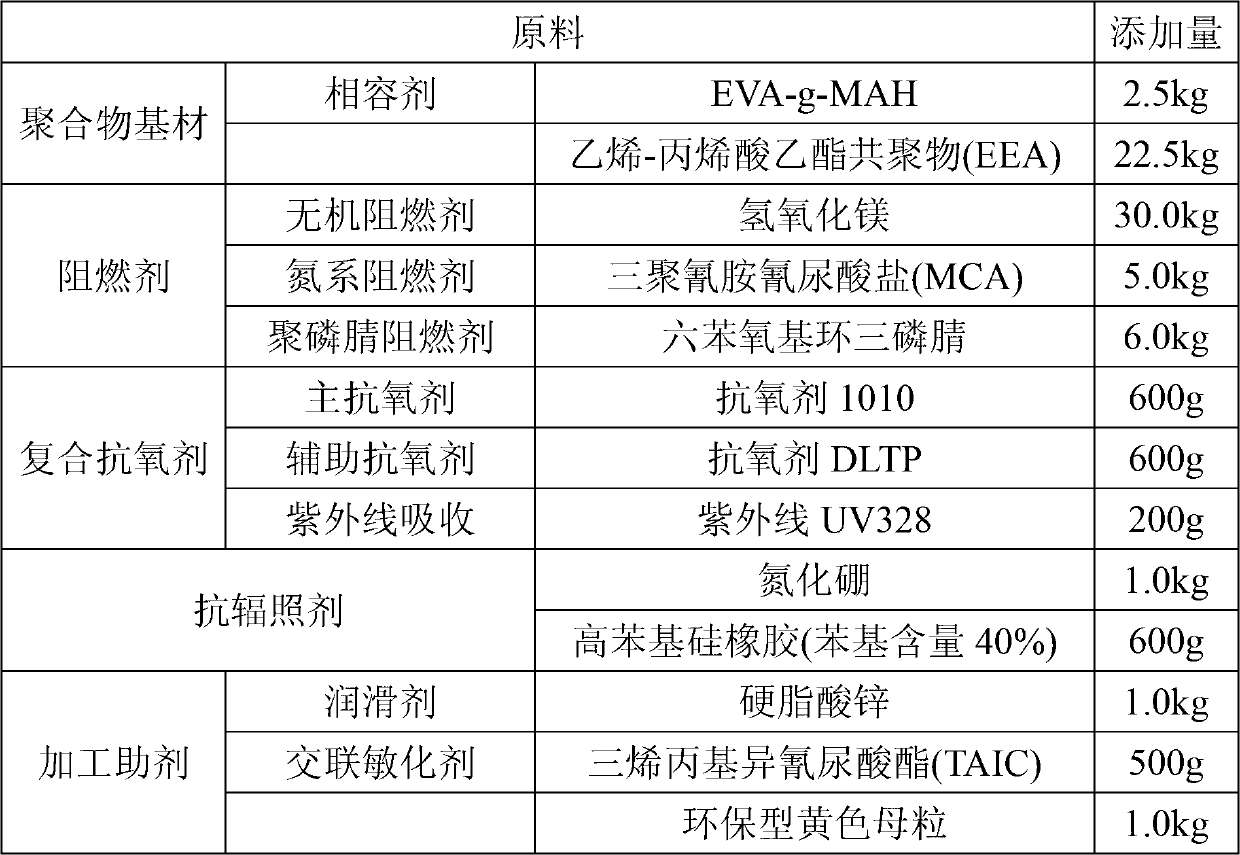

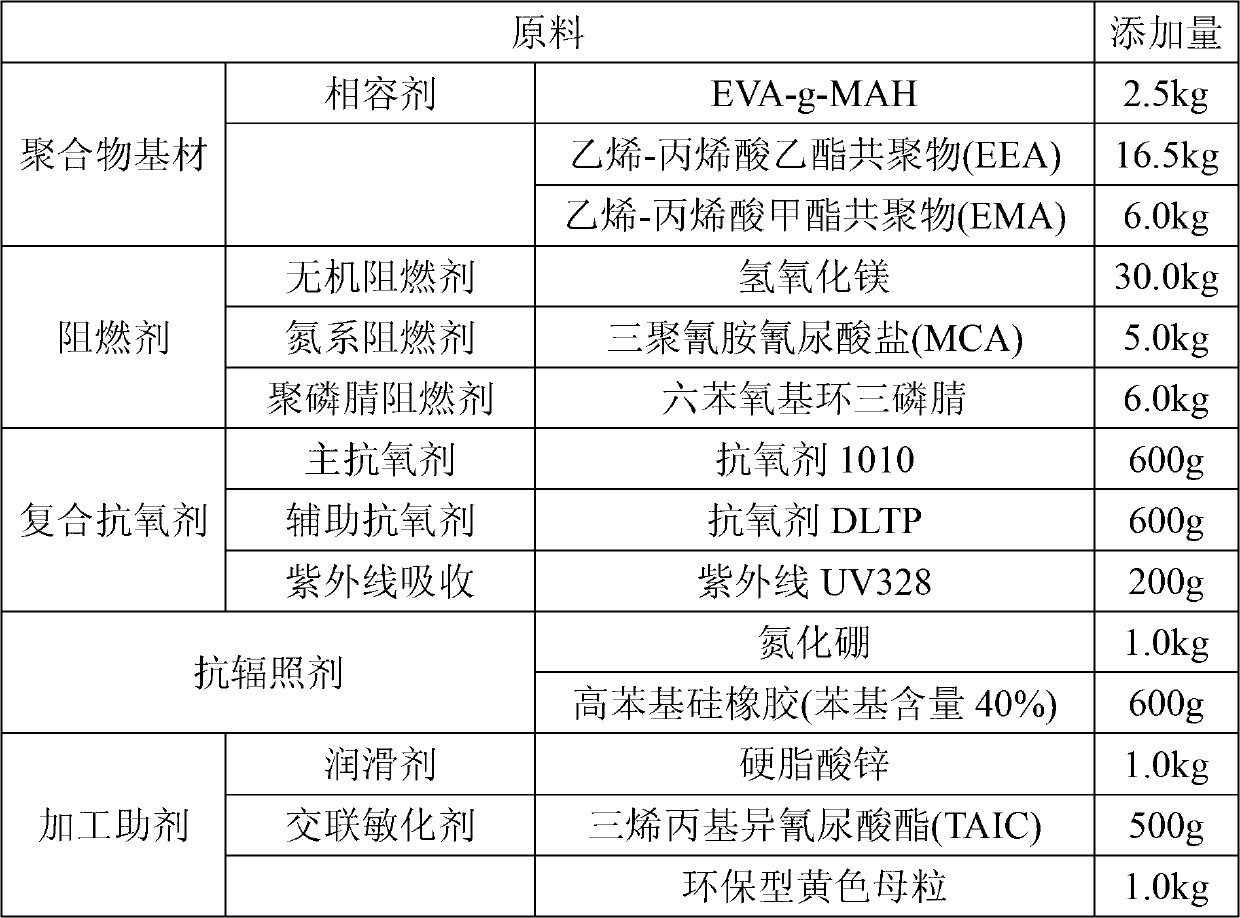

Halogen-free flame retardant sheath material for nuclear cable, cable sheath, preparation method and application

ActiveCN102875947AImprove performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention discloses a halogen-free flame retardant sheath material for a nuclear cable, a cable sheath, and a preparation method and an application of the cable sheath. The halogen-free flame retardant sheath material for the nuclear cable comprises the following raw materials: 100 parts of a polymer base material comprising ethylene vinyl acetate copolymer and ethylene methyl methacrylate copolymer, 100-140 parts of an inorganic fire retardant comprising magnesium oxide, 15-25 parts of phenoxycycloposphazene; 15-30 parts of nitrogen fire retardant comprising melamine cyanurate, 4-8 parts of a compound antioxidant comprising a main antioxidant, an auxiliary antioxidant and an ultraviolet light absorber, 5-15 parts of an anti-radiation agent comprising high phenyl siloxane rubber and an anti-radiation agent A, and 6-12 parts of a processing aid comprising a cross-linking sensitizing agent and a lubricant, wherein the anti-radiation agent A is boron carbide and / or boron nitride. The halogen-free sheath material for the nuclear cable disclosed by the invention is good in superior performance, good fire retardant performance, and stable anti-radiation performance, electrical performance and mechanical performance.

Owner:青岛中科汉缆高分子材料有限公司

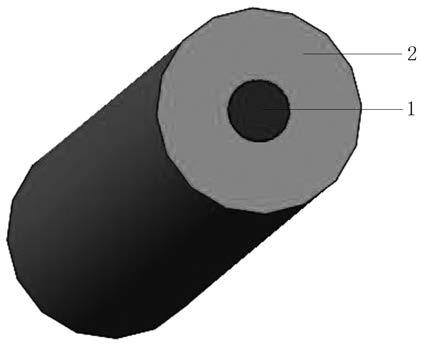

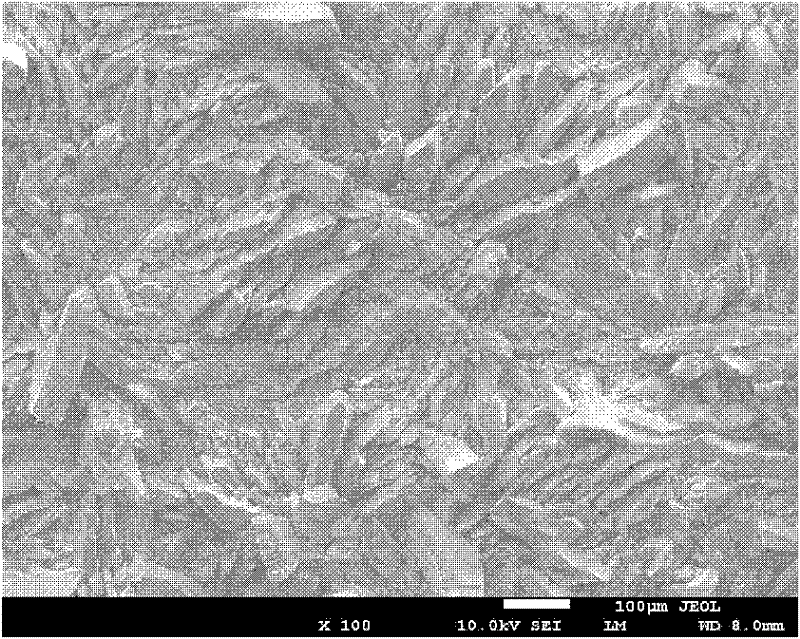

Medical degradable zinc-based composite material and preparation method and application thereof

The invention discloses a medical degradable zinc-based composite material. The medical degradable zinc-based composite material is cylindrical and comprises an inner layer and an outer layer, whereinthe inner layer is magnesium and the outer layer is zinc alloy; and the zinc alloy is composed of metal Zn, metal Mg, element X and inevitable impurities and is prepared from the components in percentage by weight: 96-99.87% of metal Zn, 0.01-1% of metal Mg, 0.1-3% of element X and 0.005-0.02% of inevitable impurities, wherein the element X is any one of Cu, Fe, Mn, Ca, Sr or Li. Meanwhile, the invention further discloses a preparation method of the medical degradable zinc-based composite material and application of the medical degradable zinc-based composite material in preparing orthopedicimplantation instruments. The medical degradable zinc-based composite material takes magnesium as the inner layer and zinc alloy as the outer layer, can be degraded in layers and can be used for the orthopedic implantation instruments, and degradation speed is moderate in the environment of simulated human body fluid at 37 DEG C.

Owner:湖南华翔医疗科技有限公司

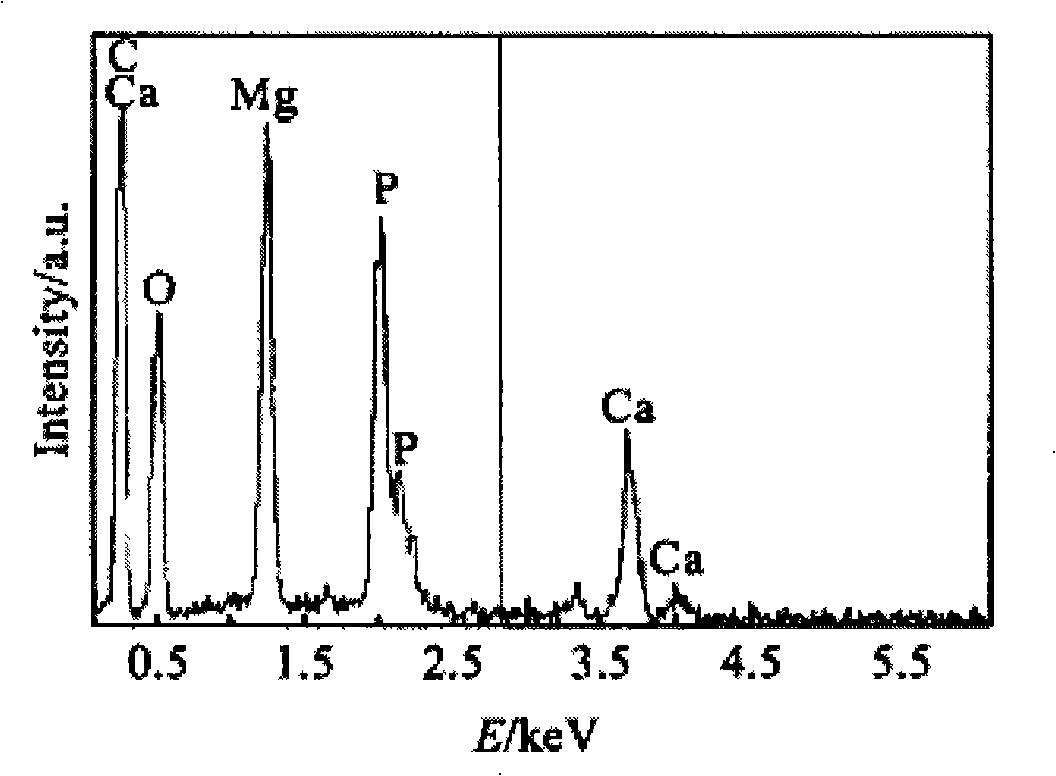

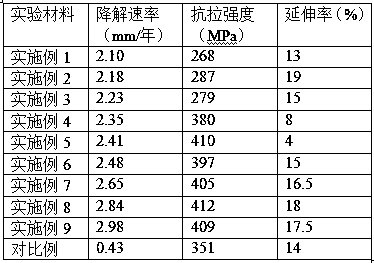

Method for preparing bioactive calcium phosphate coating on magnesium alloy surface for endosseous implant

ActiveCN102206819AControl degradation rateReduce corrosion rateMetallic material coating processesProsthesisCalcium phosphate coatingChemical reaction

The invention belongs to the technical field of medical material, and relates to a method for preparing a bioactive calcium phosphate coating on a magnesium alloy surface for an endosseous implant. The method comprises: sequential soaking the magnesium alloy surface layer for the endosseous implant in hydrofluoric acid and a mixed solution containing phosphate at a constant temperature to preparethe bioactive calcium phosphate coating. With adopting a chemical deposition method provided by the present invention, surface bioactivity of the magnesium alloy is improved, and corrosion rate of the magnesium alloy substrate is reduced. The method has simple operation process, easy operation and no requirement of special equipment. The bioactive calcium phosphate coating prepared by the method has strong combining power with the magnesium alloy substrate, and has controllable thickness.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

Novel nerve duct bracket and preparation method and application thereof

ActiveCN109847105ASimple manufacturing methodRaw material safetyFilament/thread formingNon-woven fabricsFiberCross-link

The invention relates to a novel nerve duct bracket and a preparation method and application thereof. Three-dimensional graphene or graphene derivative multichannel active nanofiber sponge is used asa stuffing inner core, and nanofibers in an axial direction are used as an outer pipe. The preparation method comprises the steps of performing ultrasonic dispersion on graphene or a graphene derivative into spinning liquid, performing electrostatic spinning, and performing drying so as to obtain a nanofiber film; performing shearing, and performing homogenization and crushing so as to obtain broken fiber mixed liquid; pouring the broken fiber mixed liquid into a multichannel mold, and performing freeze drying; performing cross-linked shaping; performing drying and shaping so as to obtain thethree-dimensional graphene or graphene derivative multichannel nanofiber sponge; and performing fixing in an axial direction spinning receiver, and performing axial direction spinning on an outer layer so as to obtain the novel nerve duct bracket. The novel nerve duct bracket is used for inducing repair and regeneration of nerve tissue. The novel nerve duct bracket disclosed by the invention is simple to operate and good in repeatability, and a new thinking is provided for repairing neurological deficits.

Owner:DONGHUA UNIV

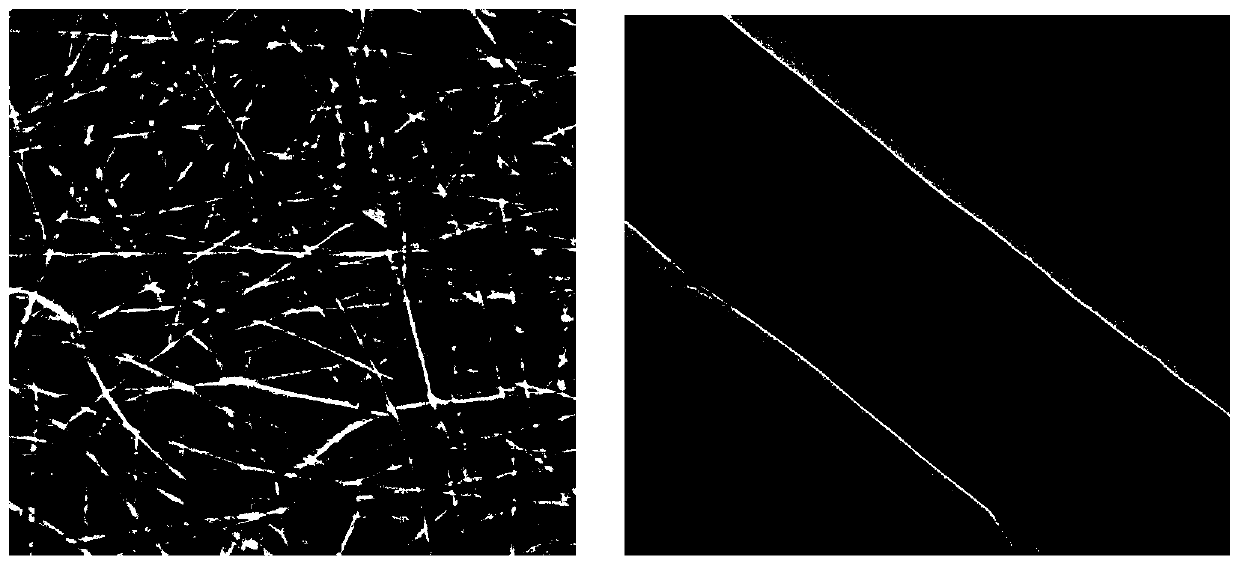

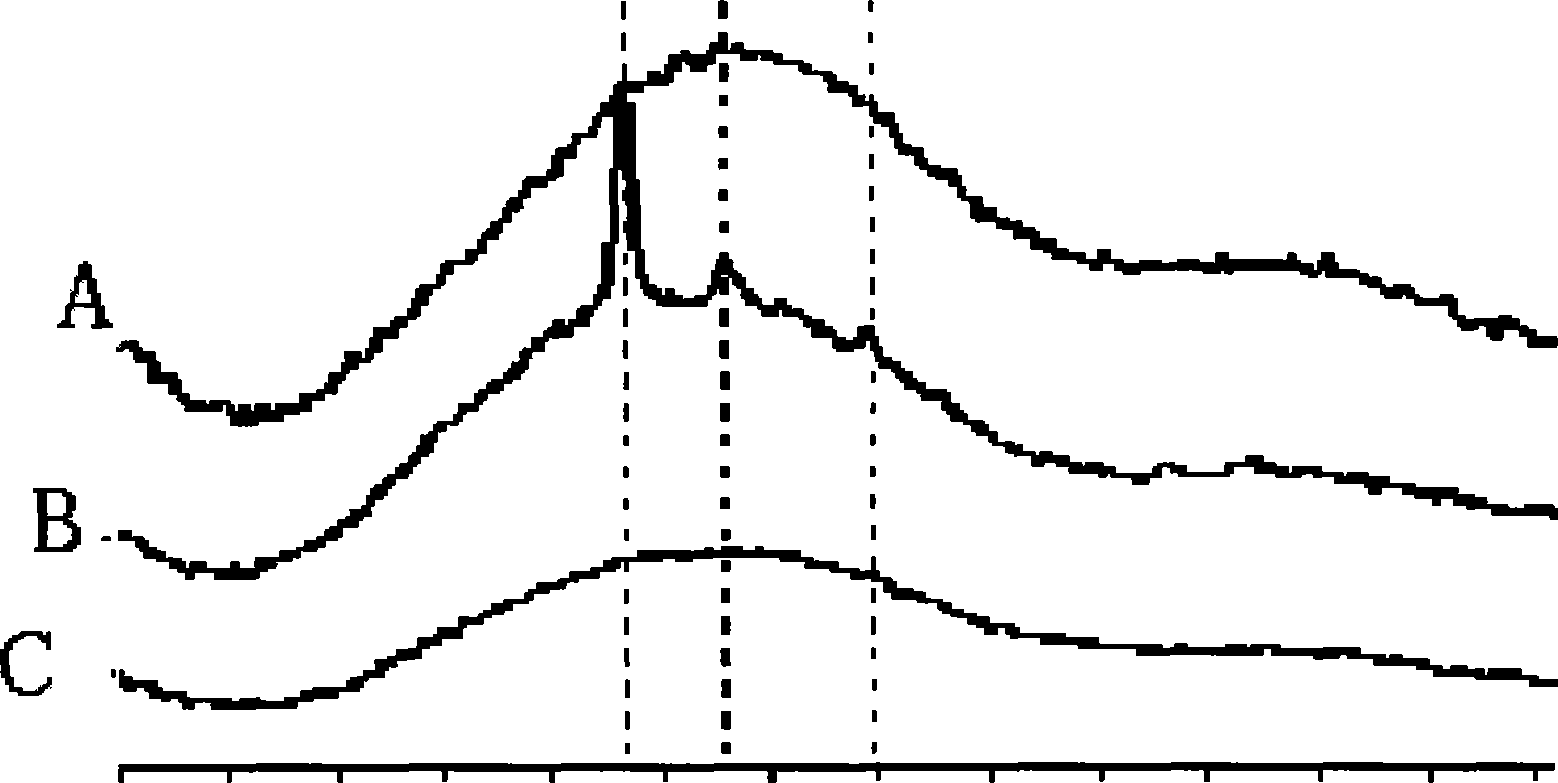

Preparation method of surface coating capable of lowering degradation rate of fully-degradable magnesium alloy vascular stent

ActiveCN104189963AReduce the degradation rateReduce sheddingSurgeryCoatingsMg alloysBiocompatibility

The invention relates to a preparation method of a surface coating capable of lowering the degradation rate of a fully-degradable magnesium alloy vascular stent. The method comprises the following steps: preparing a silane coupling agent on a magnesium alloy surface in a way that a silane coupling agent and an organic solvent are mixed, the silane coupling agent is grafted to the magnesium alloy surface of a biodegradable vascular stent by adopting a dip coating method and heating and curing are performed to form a coating; and preparing a polymer coating on the surface pre-treated by the silane coupling agent in a way that a spin-coating method is adopted to coat a polymer on a sample surface treated by the silane coupling agent, vacuum drying is realized and the polymer coating is formed after solvent volatilization. Through the technical scheme, a strong binding force exists between the polymer coating on the magnesium alloy surface pre-treated by the silane coupling agent and the surface of the fully-degradable magnesium alloy vascular stent, so that the magnesium alloy base body is prevented from excessively quick degradation, and the biocompatibility is improved; and as the coating is completely degraded with the base body at last, no toxic or side effects are brought to a human body.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

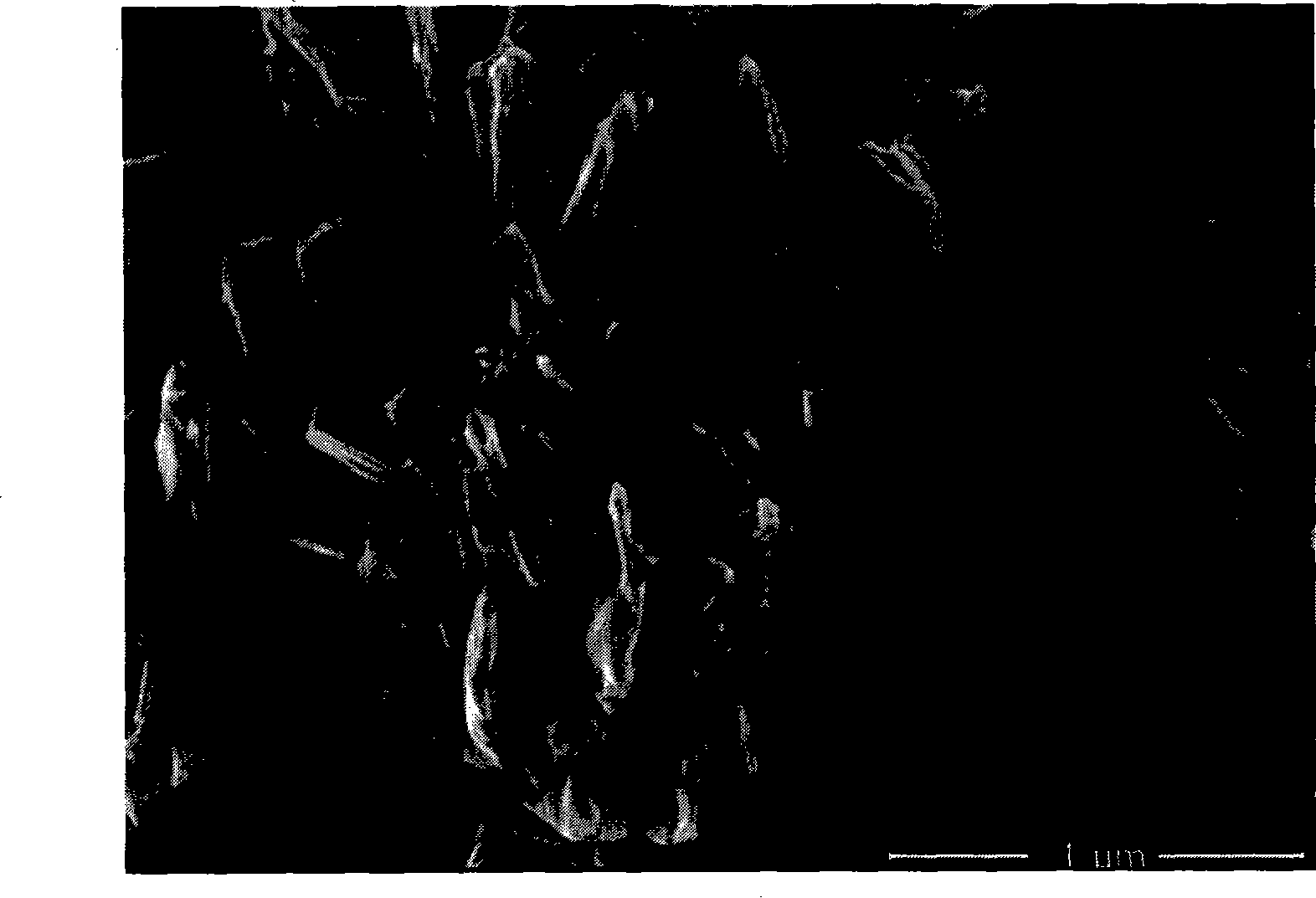

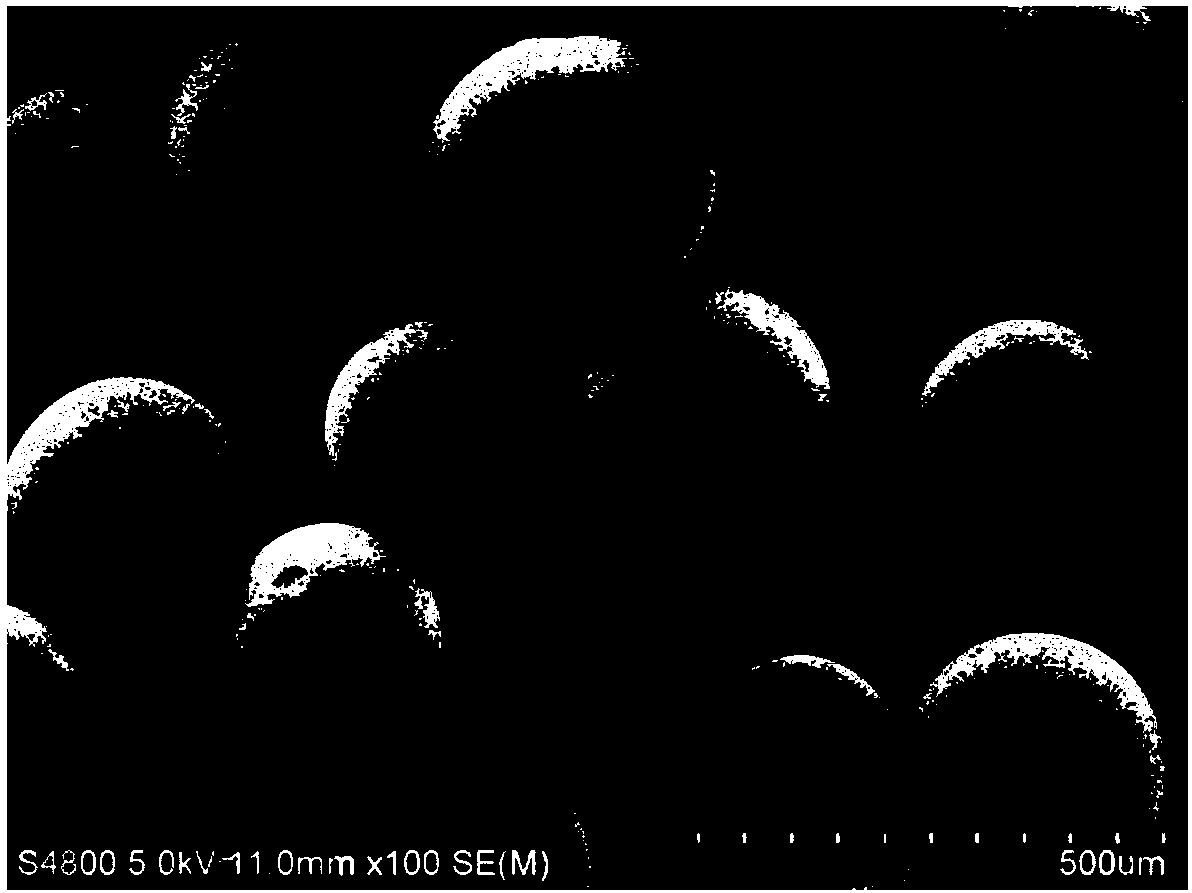

Preparation method of nano-fibrous silk fibroin-based porous scaffold

InactiveCN102008756APromote formationDegradation controllableProsthesisFiberCell-Extracellular Matrix

The invention relates to a preparation method of a porous scaffold material and discloses a preparation method of a nano-fibrous silk fibroin-based porous scaffold. The preparation method comprises the following steps: blending a silk fibroin solution and a collagen solution under the temperature of 0-20 DEG C, standing to ensure the complete reaction of collagen and silk fibroin and generate nano-fiber; freezing the mixed solution to obtain a freezing body; performing freeze drying treatment on the freezing body to obtain a nano-fibrous porous scaffold material; and placing the nano-fibrous porous scaffold material in a vacuum drier with water and methanol, or an ethanol aqueous solution at the bottom, vacuumizing, and then standing to obtain the water-insoluble nano-fibrous porous scaffold. The obtained porous scaffold has 10-1000 microns of communicated pores. The pore walls consist of 10-100nm of nano-fibers; and the porous scaffold has similar nanoscale structures and micronscalestructures to extracellular matrix, is suitable for the adhesion and growth of cells and has good biocompatibility.

Owner:SUZHOU UNIV +1

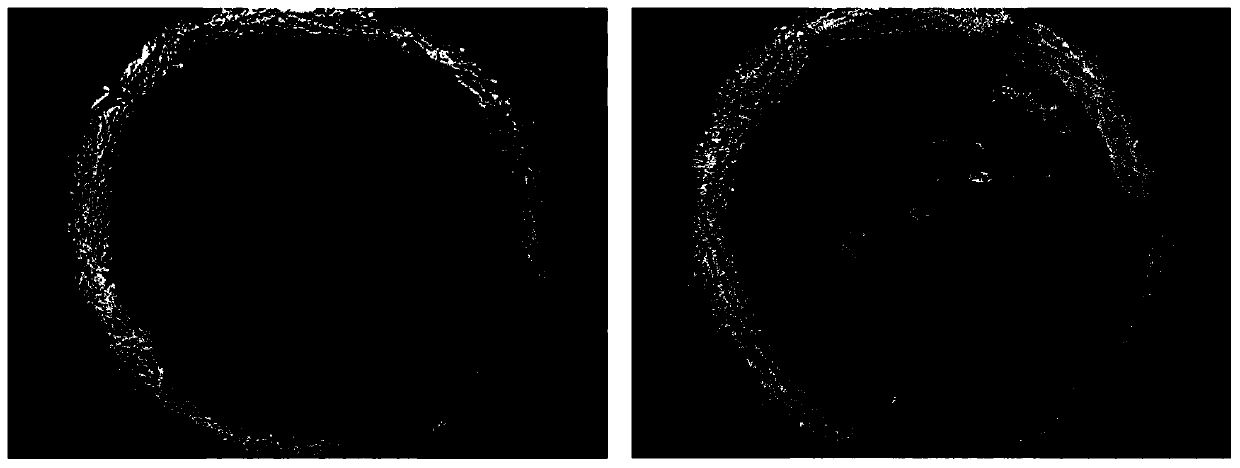

Preparation method of surface coating capable of regulating degradation rate of magnesium alloy intravascular stent

ActiveCN103418035AReduce corrosion rateImprove the acidic microenvironmentSurgeryCoatingsSpray methodMetallurgy

The invention relates to a preparation method of a surface coating capable of regulating the degradation rate of a magnesium alloy intravascular stent. The preparation method comprises the following steps: step one, preparing a polymer solution : dissolving biodegradable high polymer material into organic solvent; step two: preparing dispersion liquid containing an additive: adding additive particles into the polymer solution, and performing ultrasonic dispersion; step 3: coating the dispersion liquid containing the additive on the surface of the biodegradable magnesium alloy intravascular stent by adopting a dip coating method or a spraying method so as to form a coating, and obtaining the surface coating after the coating is dried and baked. The coating containing the additive, which is prepared through the preparation method provided by the invention, has the advantages that acidic micro-environment at the periphery of the coating can be improved, the degradation of a basal body is inhibited, the basal body together with the coating is completely degraded in a human body finally, the side effects to human body are not be generated, meanwhile, the degradation speed of the coating can be controlled through regulating the content of the additive. Therefore, the degradation speed of the intravascular stent can be controlled.

Owner:SHANGHAI JIAO TONG UNIV

Process for preparing nanometer fiber for packaging medicine or growth factor

InactiveCN1733311ALarge specific surface areaHigh porosityPeptide/protein ingredientsPharmaceutical delivery mechanismFiberElectrospinning

Disclosed is a process for preparing nanometer fiber for packaging medicine or growth factor, which comprises compounding biologically degradable polymer material with medicament or growth factor, coating the medicament or growth factor into nano fabrics by utilizing electrostatic spinning technology, thus forming nano fabric slow release system with an axial structure.

Owner:TONGJI UNIV

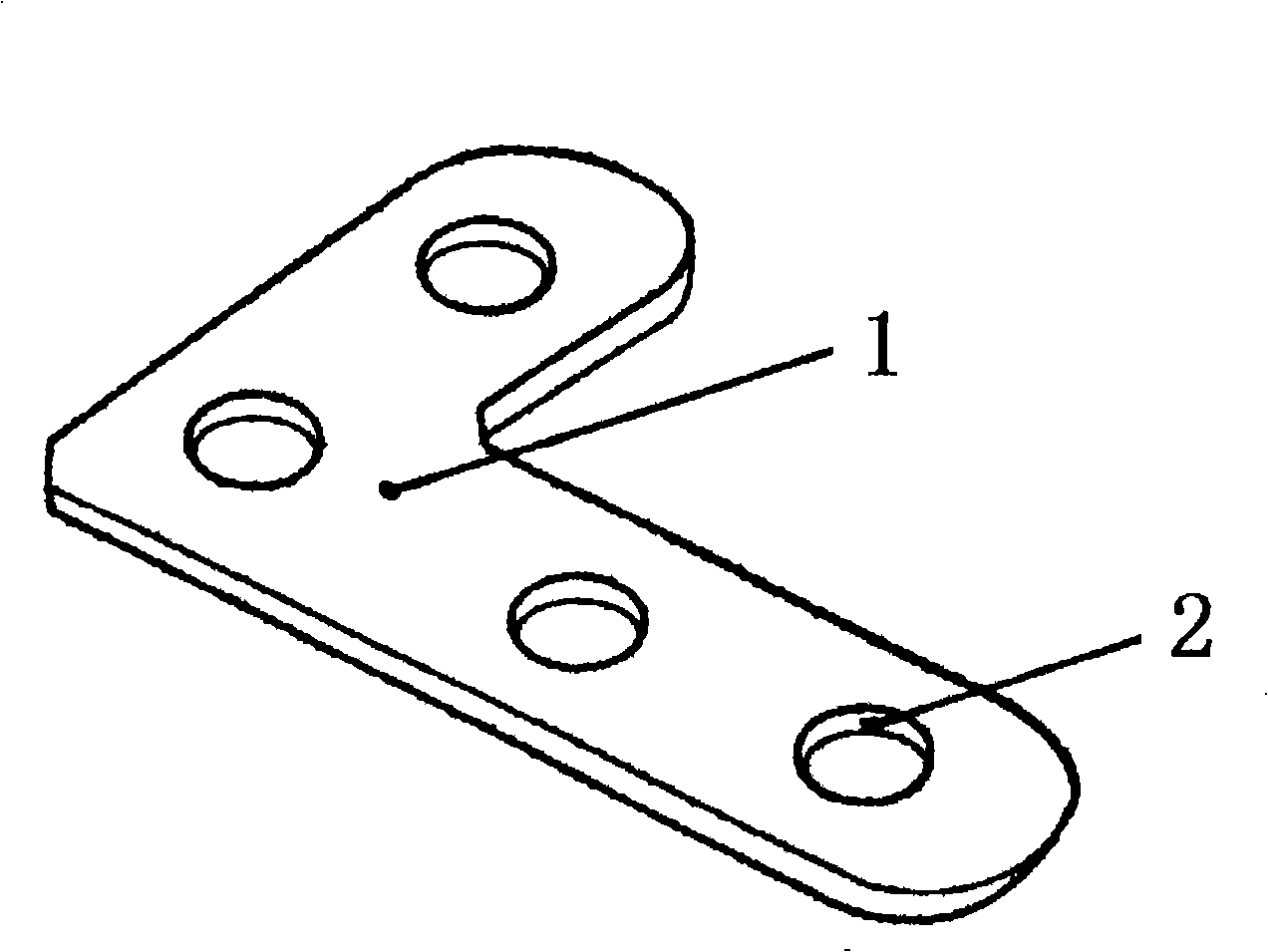

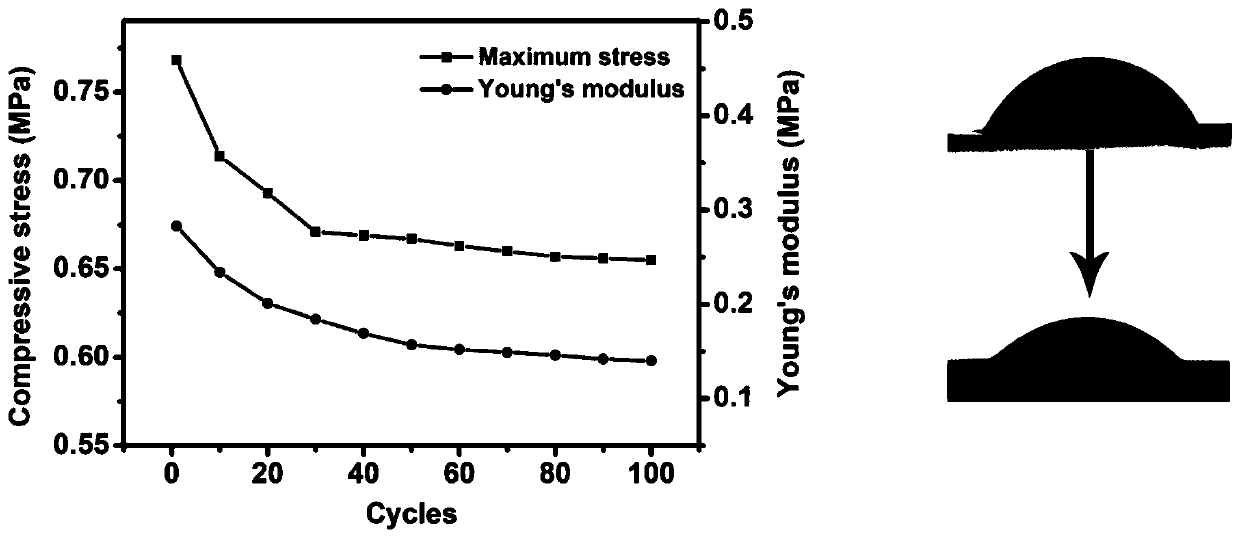

High-strength absorbable magnesium substrate composite orthopedic fixing device and preparation method thereof

InactiveCN102908672AHigh strength requirementsMeet mechanical safety requirementsInternal osteosythesisCoatingsPlastic surgeryPolylactic acid

The invention relates to a high-strength absorbable magnesium substrate composite orthopedic fixing device and a preparation method thereof. The fixing device is mainly formed by bonding and solidifying a low-porosity porous magnesium alloy substrate of which a pore structure presents a regular gradient distribution and a lower-content polylactic acid high-polymer material filled in the pore structure of the low-porosity porous magnesium alloy substrate, wherein the pore structure in the porous magnesium alloy substrate presents a gradient distribution that the porosity is gradually reduced from the surface of the magnesium alloy substrate to a core part or from the edge to the center, and the size of a pore is gradually diminished; and according to the calculation in percentage by weight, the polylactic acid of the high-polymer material for filling accounts for 5-49.9 percent of total weight, and the porous magnesium alloy substrate accounts for 50.1-95 percent of total weight. The fixing device is closer to magnesium alloy in strength, has the advantages of controllable in-body adsorption speed, slow-quick degradation, less hydrogen evolution moderate quantity and the like, is particularly suitable for the bone trauma surgery with high strength requirement and big volume, the bone defect repair surgery, the plastic surgery and other absorbable orthopedic fixed implantable devices applied to the clinical.

Owner:SOUTHEAST UNIV

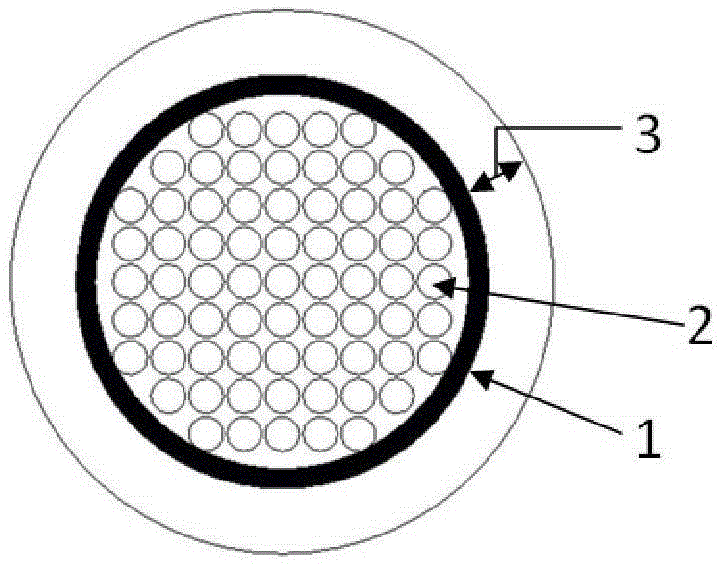

Prestress-reinforced light high-strength controllable-degradation medical composite material and preparation method thereof

InactiveCN103330959AMake full use of the strengthening effectReduce dosageSurgeryAbsorbable polymersProtection layer

The invention relates to a prestress-reinforced light high-strength controllable-degradation medical composite material and a preparation method thereof. The medical composite material is characterized in that a magnesium alloy wire subjected to prestress processing is taken as a reinforced phase to improve strength and stiffness of the composite material, an absorbable high polymer material is taken as a matrix, and meanwhile, the early-stage degradation velocity of the composite material can be further regulated and controlled by regulating the thickness of a shell protection layer formed by the high polymer material of the matrix. According to the composite material, bars or plates are manufactured by utilizing methods of thermal die pressing, extrusion or drawing or the like, and various degradable high-toughness bone repairing and fixing instruments such as bone nails and bone plates can be obtained by carrying out subsequent machining; and compared with the conventional absorbable polymer bone surgery instruments, the composite material has the advantages that the mechanical fixing effect is relatively good, and furthermore, the problems that the degradation speed of the absorbable magnesium alloy bone surgery instruments is difficult to control and the hydrogen release quantity during degradation is large and the like can be overcome.

Owner:SOUTHEAST UNIV

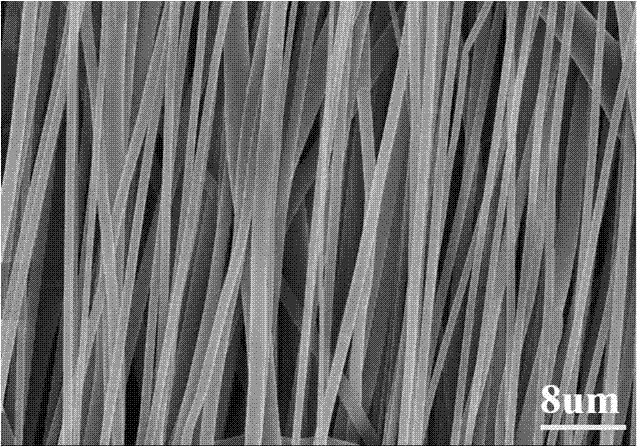

Nerve tissue engineering electric conduction nano-fiber tubular stent and preparation method thereof

The present invention relates to a nerve tissue engineering electric conduction nano-fiber tubular stent and a preparation method thereof. The nerve tissue engineering electric conduction nano-fiber tubular stent comprises an electric conduction nano-fiber tube and an electric conduction hydrogel filling material, wherein the electric conduction nano-fiber tube is formed by compounding an inner layer and an outer layer, the inner layer is an electric conduction nano-fiber film arranged in a parallel manner and oriented along the axial direction of the catheter, the outer layer is a non-electric conduction non-woven arrangement nano-fiber film, and the filling material is formed by compounding a natural macromolecular hydrogel and growth factor-loading electric conduction nano-tubes. According to the present invention, the catheter stent material can provide the multifunctional bionic microenvironment for nerve tissue engineering, has good biocompatibility, and can provide nutrients for nerve repair, wherein the two-dimensionally oriented fiber morphology can promote the differentiation and growth of nerve cells, and with the adding of the electric conduction material, the differentiation degree of nerve cells can be further improved, the cell proliferation can be promoted, and the conditions required by nerve regeneration can be well met.

Owner:BEIJING UNIV OF CHEM TECH +1

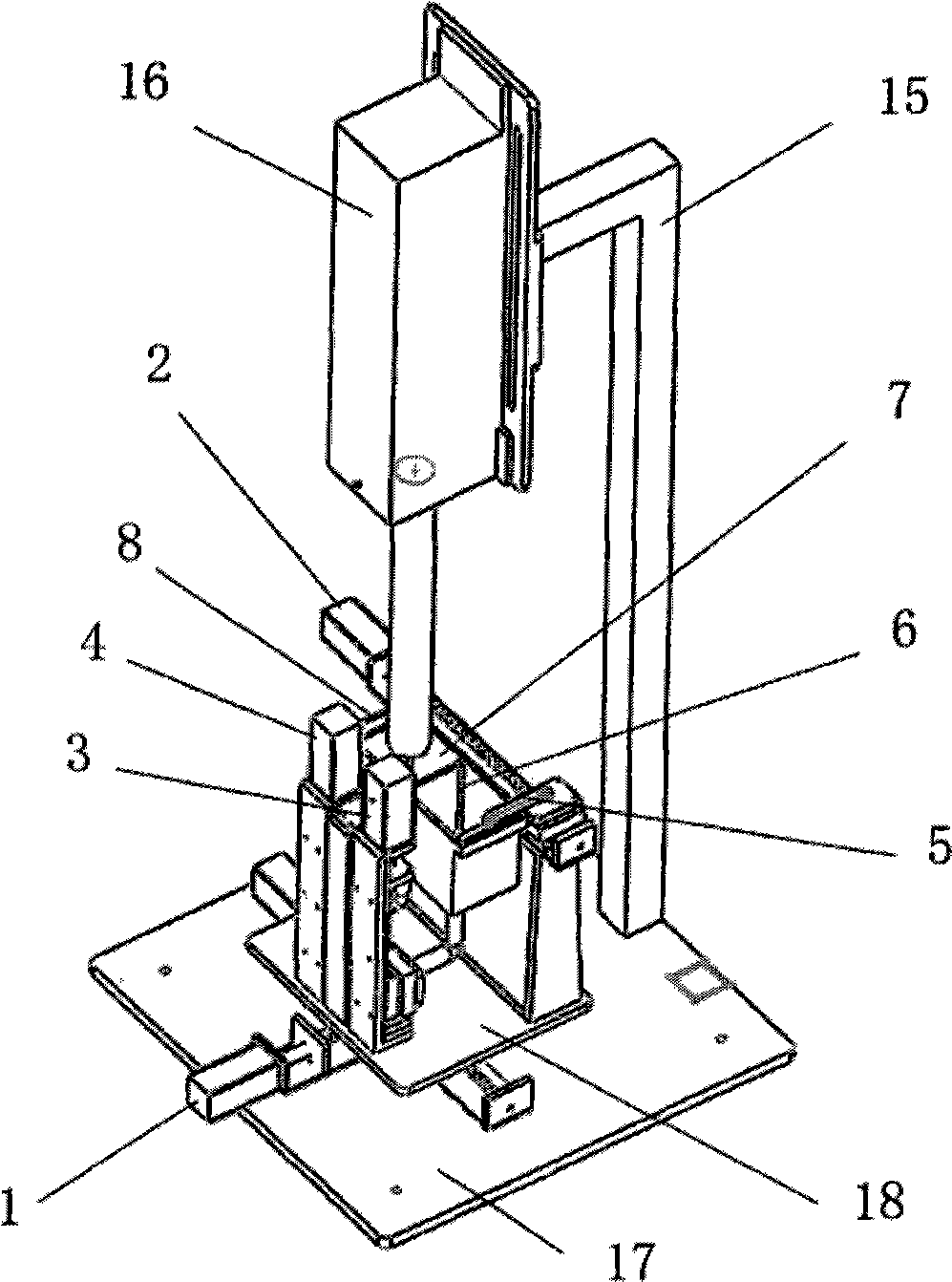

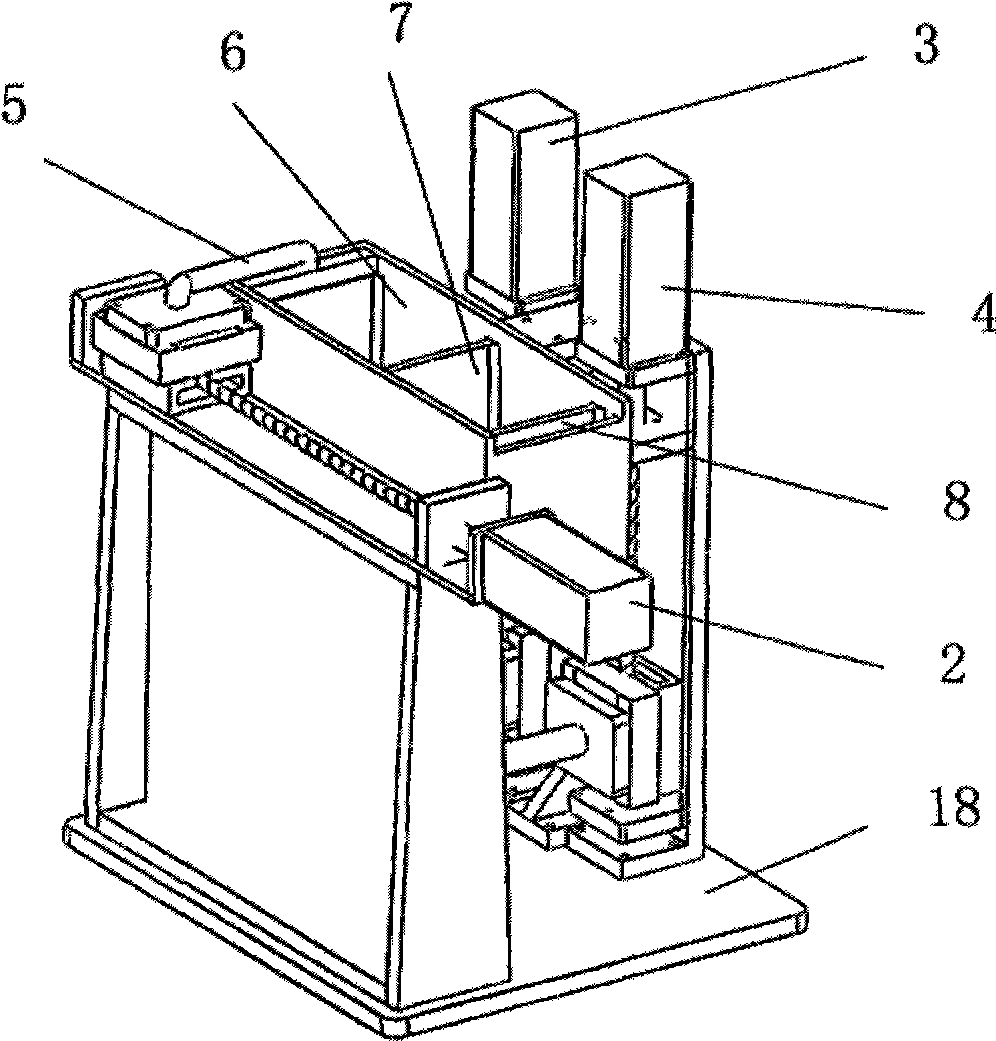

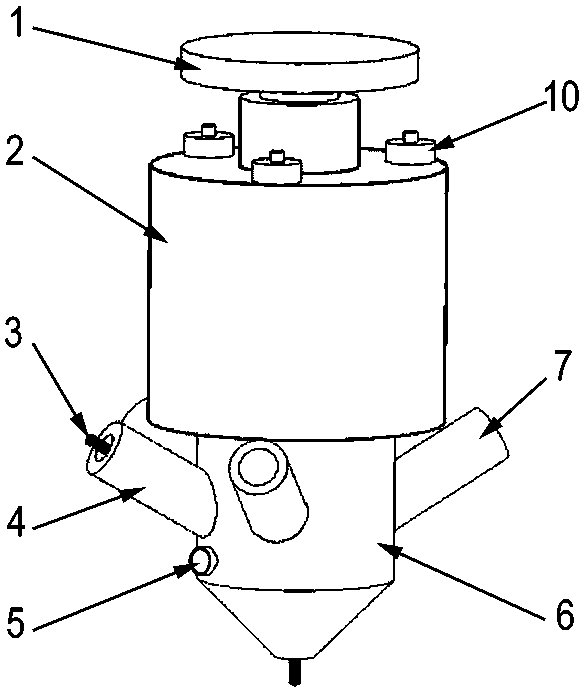

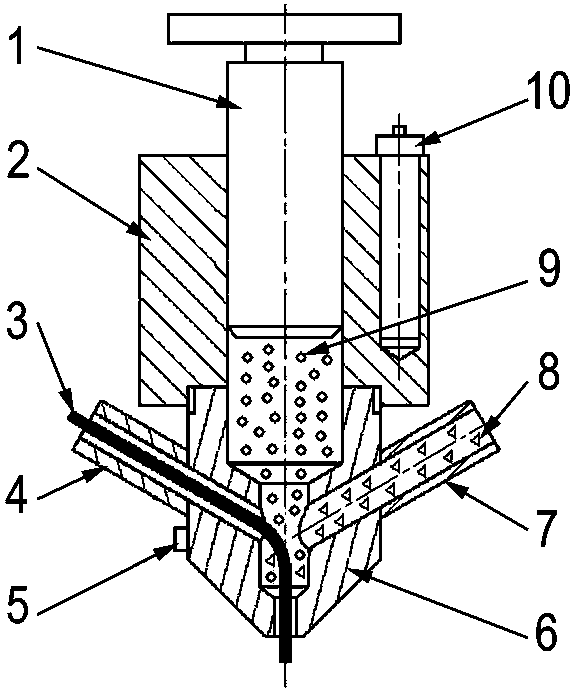

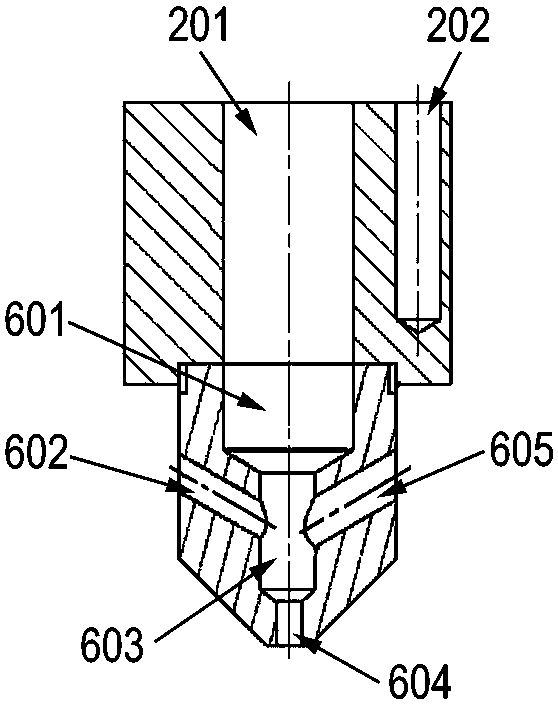

Laser sintering machine based on nano hydroxyapatite and used for manufacturing absorptive artificial bone

InactiveCN101530950AConvenience and precise controlControl degradation rateProsthesisLaser beam welding apparatusLaser scanningNano hydroxyapatite

The invention discloses a laser sintering machine based on nano hydroxyapatite and used for manufacturing an absorptive artificial bone. An X / Y motion mechanism (1) is arranged on a frame (17). A sintering support plate (18) is arranged on the X / Y motion mechanism (1). A raw material box up-down motion machine (3), a raw material box (6), a sintering table up-down motion machine (4) and a sintering table (7) are arranged on the sintering support plate (18). A feeding left-right motion mechanism (2) and a feeding rod (5) are arranged on the sintering support plate (18). A laser and laser focusing system (16) which is corresponding to the sintering table (7) is arranged on a bracket (15) of the frame (17). Nano hydroxyapatite powder (10-100nm) is arranged on the sintering table (7). Laser energy is assembled into a 50-100micron light spot by a focusing system such as a convex lens. A motion table is moved according to the requirement of section profile and certain sintering distance interval (150-500mum), partial powder is subjected to laser scanning, and a three-dimensional artificial bone is formed finally.

Owner:CENT SOUTH UNIV

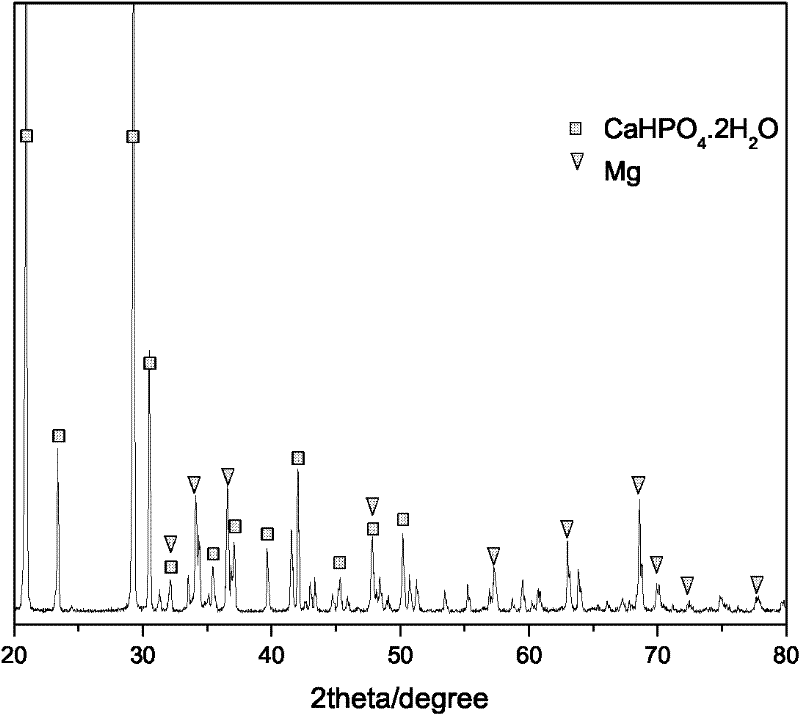

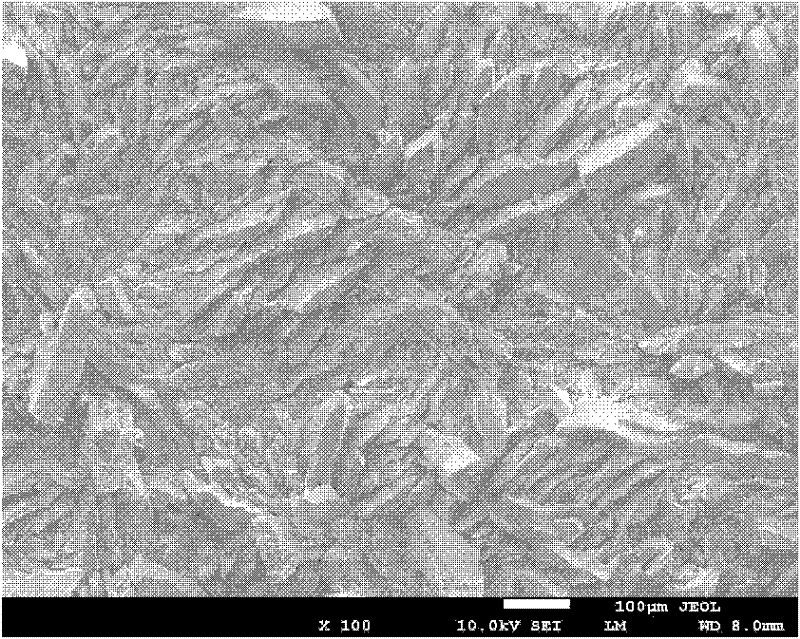

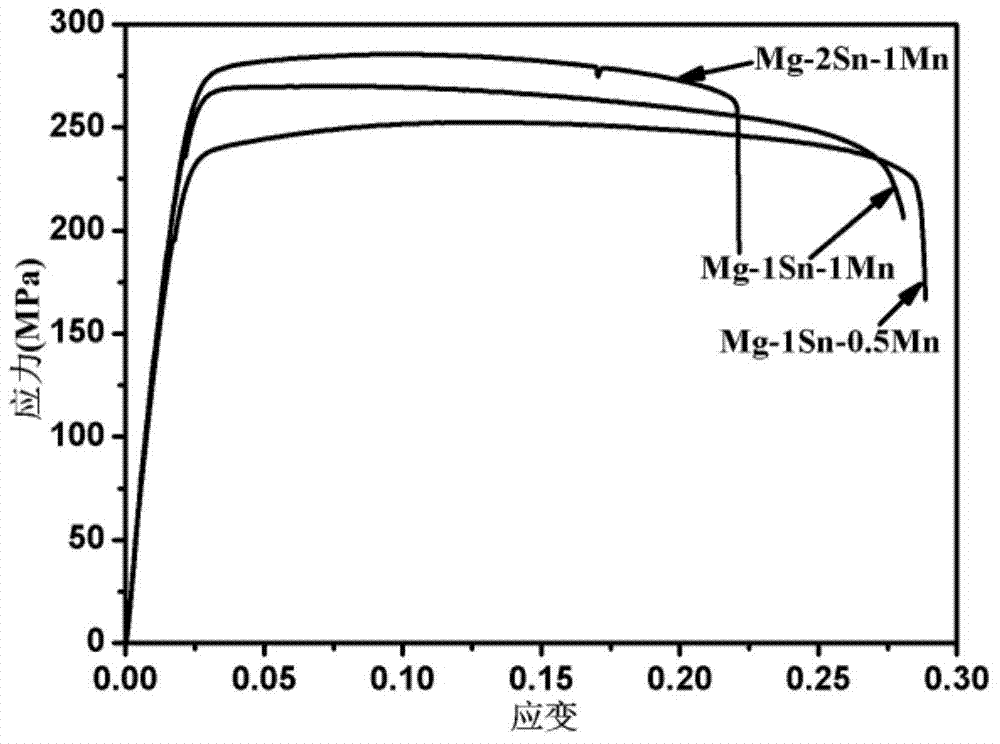

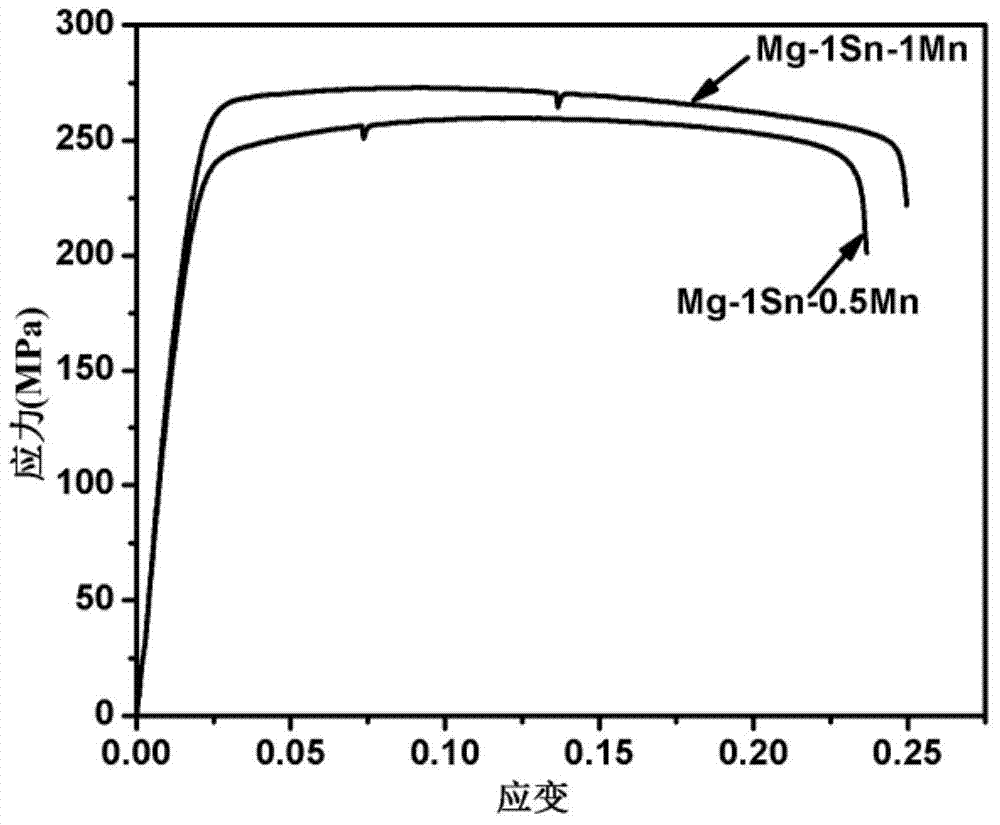

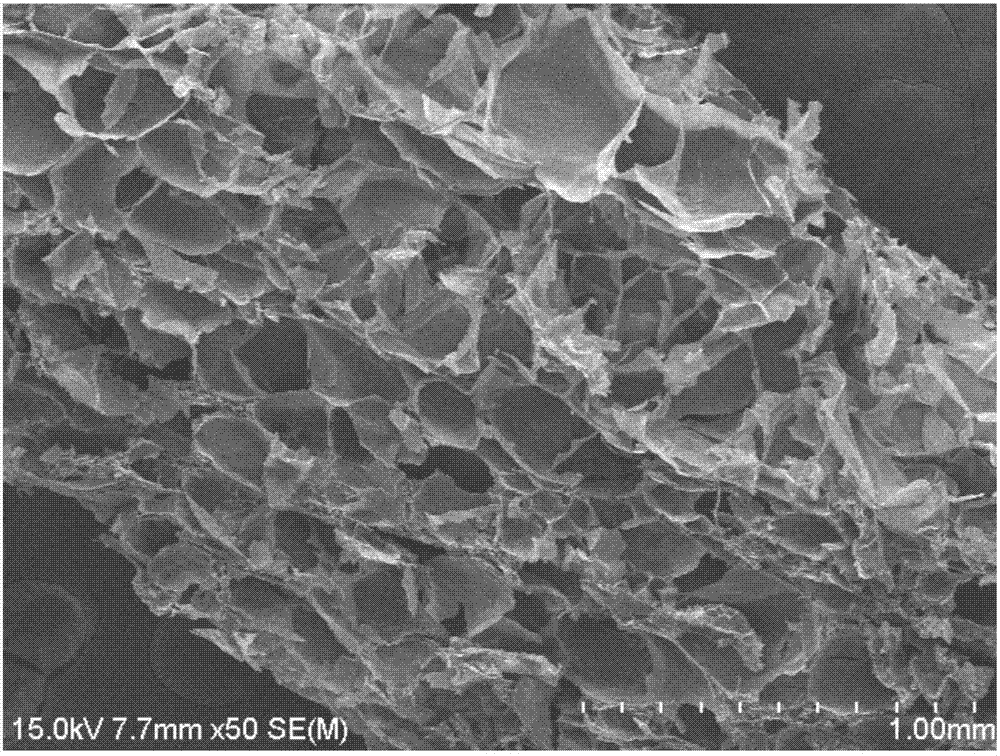

Mg-Sn-Mn system wrought magnesium alloy and preparation method thereof

The invention discloses Mg-Sn-Mn system wrought magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by weight: 0.5 to 2 percent of tin, 0.5 to 1.5 percent of manganese and the balance of magnesium. The preparation method comprises the following steps of 1) preparing raw materials according to the alloy components; 2) smelting the selected raw materials, pouring the selected raw materials, or directly cooling the melt to obtain cast ingot; 3) homogenizing the obtained cast ingot; 4) extruding the homogenized cast ingot to obtain the wrought magnesium alloy finished product. The preparation method of the wrought magnesium alloy is simple, the cost is low, the comprehensive mechanical property is excellent, the biological compatibility is good, and the degradation speed and the mechanical performance are adjustable. The Mg-Sn-Mn system wrought magnesium alloy can be used as a medical material and also can be used as an ordinary structural material.

Owner:CHONGQING UNIV

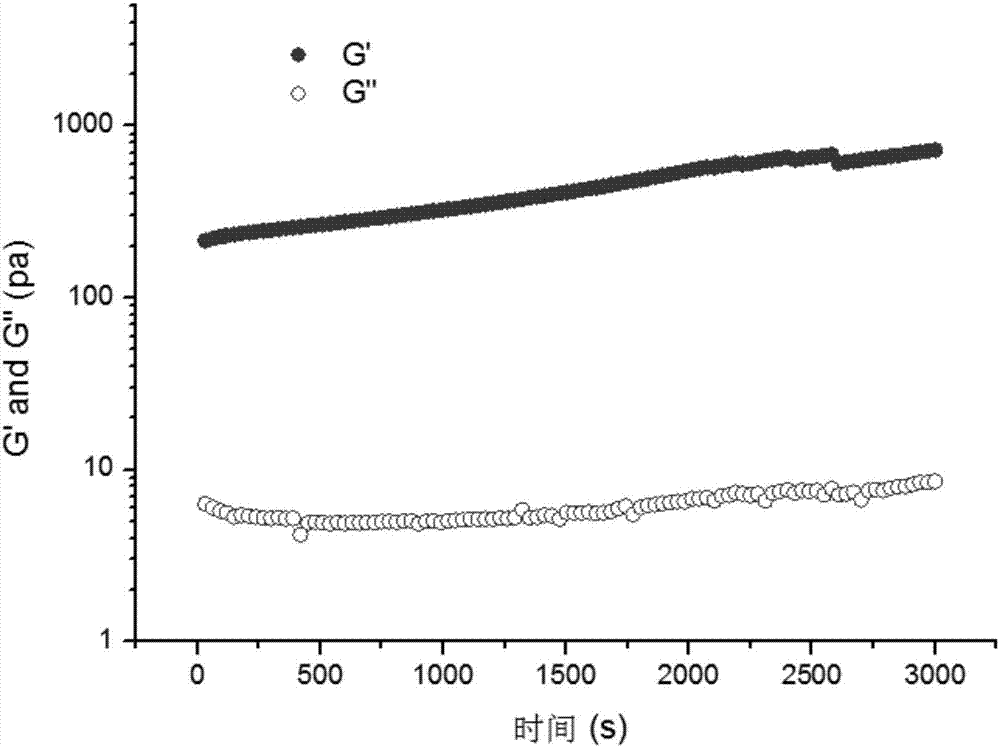

Injectable hydrogel and preparation method and application thereof

ActiveCN107233629AEasy to adjust intensityEasy to adjust the degradation rateAerosol deliverySurgeryImideDrug carrier

The invention discloses injectable hydrogel and a preparation method and application thereof. The injectable hydrogel is composed of a raw material A, a raw material B and gelling liquid, a mass sum of the raw material A and the raw material B accounts for 5-50% of mass of the hydrogel, the raw material A is butyraldehyde-polyethylene glycol-butyraldehyde, and the raw material B is four-arm-terminated amino modified polyethylene glycol. The injectable hydrogel is obtained by mainly utilizing imide dynamic bonds formed by amino of four-arm-terminated amino modified polyethylene glycol and aldehyde of butyraldehyde-polyethylene glycol-butyraldehyde. The injectable hydrogel can be applied as a drug carrier, an embolization material or a tissue engineering material. The preparation method includes steps: adding the gelling liquid into the raw material A and the raw material B, and well mixing to obtain the injectable hydrogel. The injectable hydrogel has the advantages of simple, convenient and quick preparation process and easiness in large-scale production.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

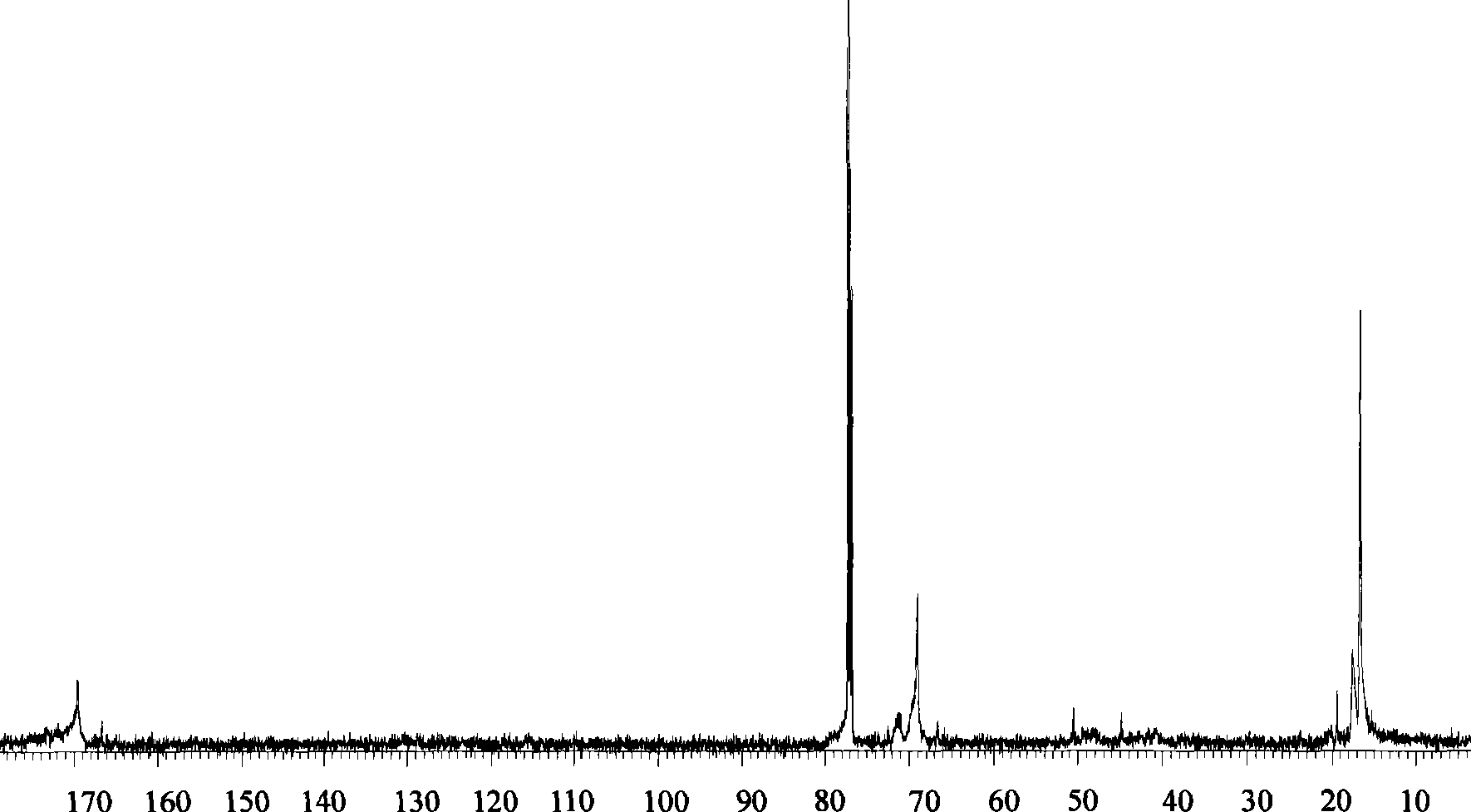

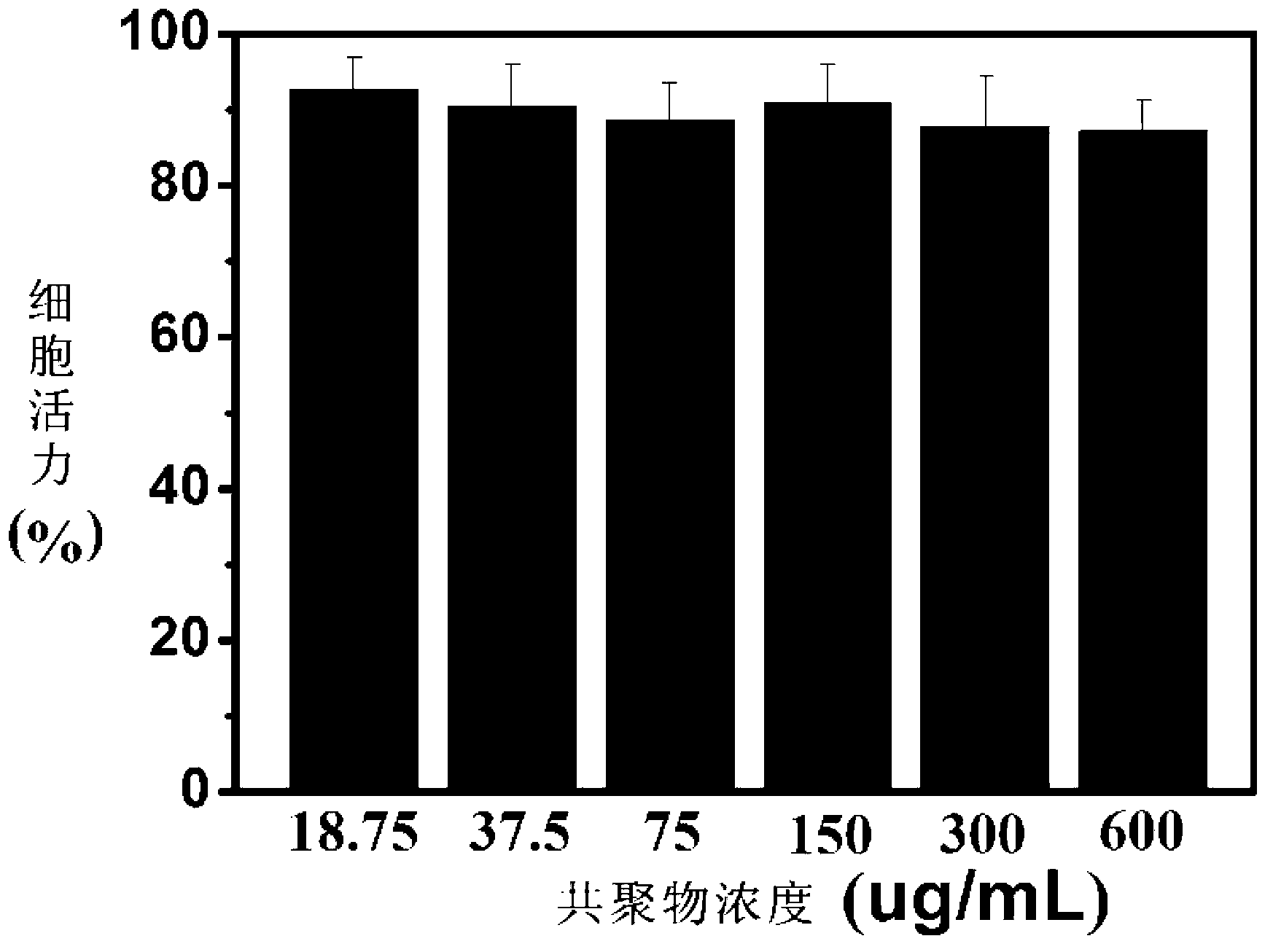

Copolymer of fibroin and poly D,L-lactic acid, preparation method and application thereof

The invention discloses a copolymer of fibroin and a poly D,L-lactic acid. The molecular weight of the copolymer having the structure is 5,000 to 180,000, and the mass ratio of the fibroin chain segment and the poly L-lactic acid chain segment is 0.5 / 99.5-99 / 0.5. The invention also discloses a solid phase polymerization preparation method thereof, the application thereof in biomedical materials, nano material thereof and a preparation method of nano materials. Copolymer of fibroin and poly D,L-lactic acid is prepared by adopting melt ring opening polymerization, and solvent is not used in the synthesis technique; therefore, the invention has the advantages that the process is simple, and the product cost is low. Through the invention, copolymer of fibroin and poly D,L-lactic acid with different number average molecular weight can be prepared. Copolymer of fibroin and poly D,L-lactic acid prepared by the invention can improve the hydrophilicity, the biocompatibility and the cellualar affinity of lactic acid material and control the degradation speed of the material.

Owner:NANJING FORESTRY UNIV

Absorbable orthopedic apparatus material having antibiosis and bone growth promotion functions, and preparation method thereof

ActiveCN104127916AAbsorbablePromote growthSurgeryElectrophoretic coatingsOrthopaedic deviceBone growth

The invention relates to an absorbable orthopedic apparatus material having antibiosis and bone growth promotion functions, and a preparation method thereof. The orthopedic apparatus material is obtained by compounding medical pure magnesium or magnesium alloy with an absorbable high-molecular polymer, the surface of the pure magnesium or magnesium alloy has a porous ceramic layer, the surface of the porous ceramic layer is a functional load layer loaded with bone morphogenetic proteins and copper ions with B-type gelatin as a carrier by adopting an electrophoresis-electrodeposition process, the volume fraction of the pure magnesium or magnesium alloy is 1-99%, the micropore aperture and the thickness of the porous ceramic layer on the surface of the pure magnesium or magnesium alloy are 1-100[mu]m and 1-100[mu]m respectively, and the surface of the porous ceramic layer is the functional load layer loaded with bone morphogenetic proteins and copper ions with B-type gelatin as the carrier by adopting the electrophoresis-electrodeposition process. An orthopedic apparatus can slowly release copper ions having a sterilizing effect and bone morphogenetic proteins having a bone growth promotion effect in the use process, can be applied to restore and fix various bone injuries, and has a wide application prospect.

Owner:SOUTHEAST UNIV

High strength starch-based degrading and environment-protecting material and preparation method

The invention provides a high-intensity starch-based degradation environmental protection material and a manufacturing method thereof, which relates to a rapid degradation raw material used for manufacturing disposable tableware and disposable wrappage and the manufacturing method thereof. The present disposable foaming plastic tableware has the disadvantages of hard heat insulation, complicated process line, high production cost, undesirable production quality and white pollution. The components of the product include macromolecular natural starch, polyvinyl alcohol, plant sugar, polyvinyl alcohol, a degradation control agent, a multipolymer of polycaprolactone and poly-beta-hydroxybutyrate and hexa-butyl ester hexa-butyl glycan; wherein, the starch is 51-80 weight portions, the polyvinyl alcohol is 12-20 weight portions, the plant sugar is 2-10.5 weight portions, plasticizer is 2.5-8 weight portions, the degradation control agent is 0.2-1 weight portions, the multipolymer of polycaprolactone and poly-beta-hydroxybutyrate is 5-9 weight portions and the hexa-butyl ester hexa-butyl glycan is 0.2-0.5 weight portions. The high-intensity starch-based degradation environmental protection material of the invention is used for manufacturing the disposable tableware and the disposable warppage.

Owner:季国良

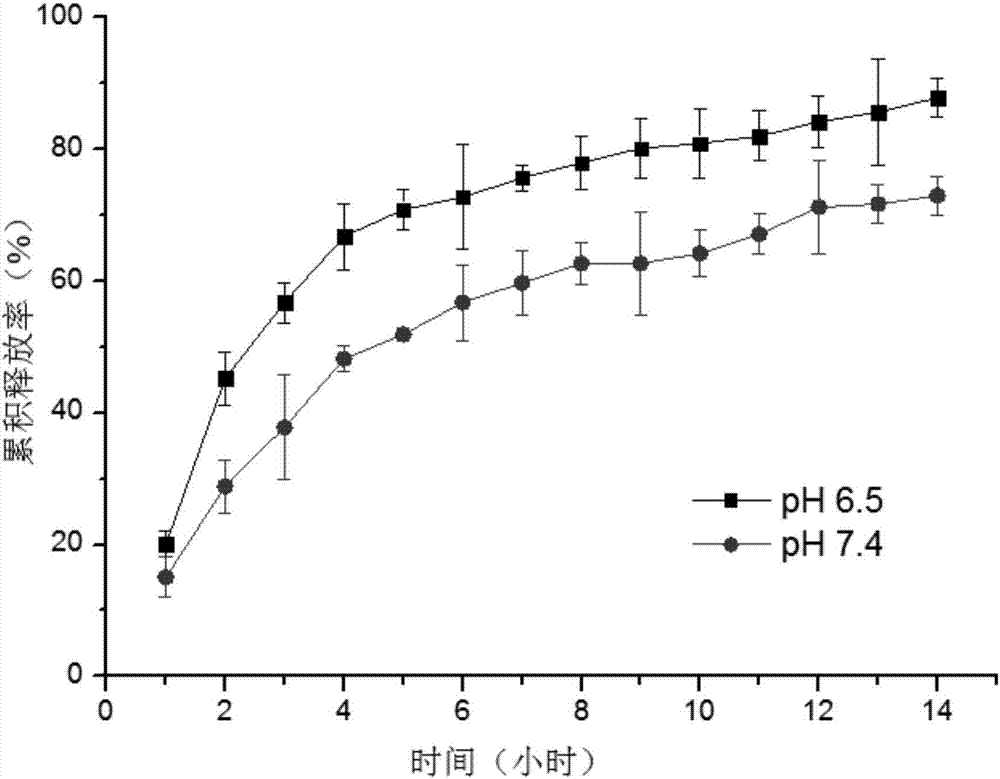

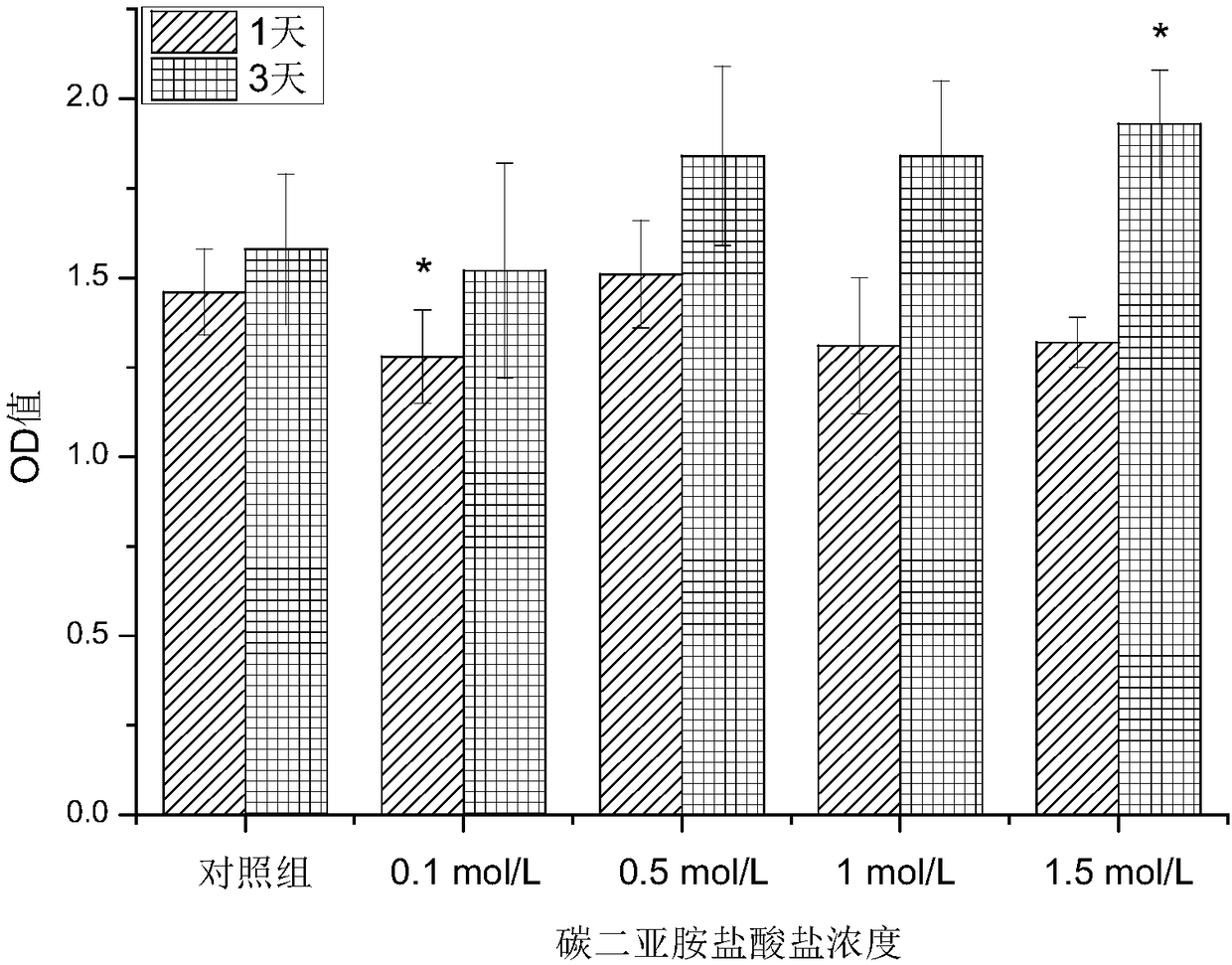

Gelatin microsphere/magnesium phosphate-based bone cement medicine slow-release carrier and preparation method thereof

ActiveCN108379666AGood biocompatibilityReduce adverse reactionsMicrocapsulesProsthesisMagnesium orthophosphateDrug

The invention discloses a gelatin microsphere / magnesium phosphate-based bone cement medicine slow-release carrier and a preparation method thereof. Firstly, medicine carried gelatin microspheres crosslinked by 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride are prepared; then, the medicine carried gelatin microspheres are uniformly mixed with magnesium phosphate-based bone cement powderand are then subjected to liquid phase conditioning curing with the magnesium phosphate-based bone cement to obtain the gelatin microsphere / magnesium phosphate-based bone cement medicine slow-releasecarrier. The 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride is used as a gelatin crosslinking agent; the obtained gelatin microsphere has good compatibility; the gelatin microspheres can carry various kinds of medicine; the degradation speed of the microspheres can be controlled through the concentration of the crosslinking agents; the medicine release speed is further controlled; the gelatin microsphere / magnesium phosphate-based bone cement medicine slow-release carrier has the excellent medicine slow release effect, and realizes the continuous release of medicine as long as several months.

Owner:WUHAN UNIV OF TECH

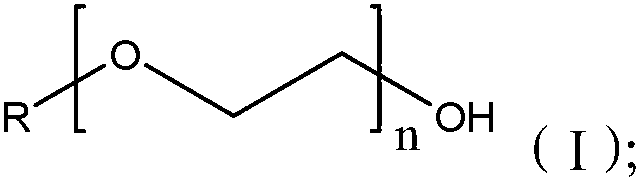

Biodegradable medical surgery anti-adhesion membrane and preparation method thereof

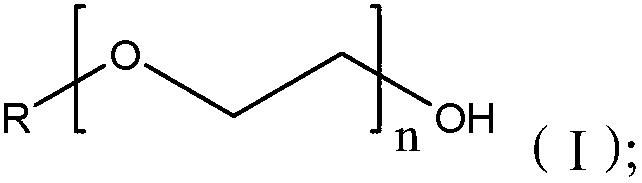

The invention provides a biodegradable medical surgery anti-adhesion membrane and a preparation method thereof. According to the method, polyethylene glycol compound, at least one of lactide and epsilon-caprolactone and glycolide are subjected to copolymerization so as to obtain a polyethylene glycol compound-polyester segmented copolymer of which the number-average molecular weight is 50000 to 150000; and a polymer material containing the polyethylene glycol compound-polyester segmented copolymer is made into a membrane so as to obtain the biodegradable medical surgery anti-adhesion membrane, wherein the polyethylene glycol compound is shown in formula (I) shown in the specification, R is any one selected from hydroxyl, methyl, ethyl, propyl, isopropyl, amino, allyl, propinyl, sulfydryl, carboxyl and azide; and n is the polymerization degree. Through double modulation of the polyethylene glycol compound and glycolid, the anti-adhesion membrane is better in controllability and good in flexibility, has certain tension resistance strength and is beneficial for application.

Owner:CHANGCHUN SINOBIOMATERIALS

Biodegradable hydroxylapatite-magnesium and calcium metallic matrix composite

InactiveCN101524558AGood biocompatibilityImprove creep resistanceProsthesisPowder metallurgyBone tissue engineering

The invention relates to a biodegradable hydroxylapatite-magnesium and calcium metallic matrix composite, belonging to the field of biomedical materials. The material of the invention is composed of the composite of magnesium-calcium alloy and hydroxylapatite particles, the components and mass percent thereof are: 0.01-5% of Ca, 0-1% of Zn and Mg as the balance; the mass ratio of the hydroxylapatite to magnesium-calcium alloy is 0.01-50:100. In the invention, powder metallurgic method is adopted. The material matrix of the invention has close bonding with strengthened nano particles which areevenly distributed. The composite of the invention can be biologically degradable and has fine mechanical property and biological activity, and wide application prospect in medical material field such as repairing impairment of scaffold for bone tissue engineering, fixed fasteners within bones and weight-bearing parts of bones.

Owner:CHONGQING UNIV

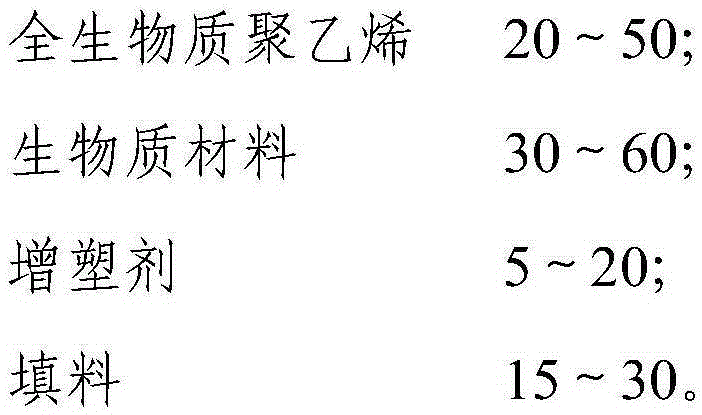

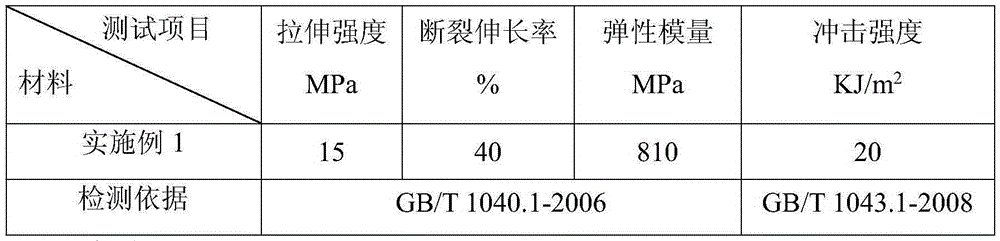

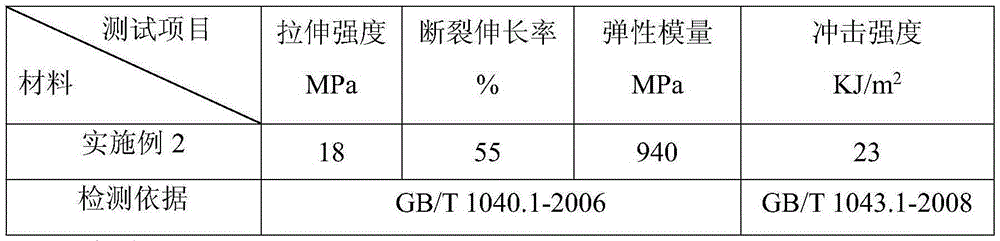

Total biomass composite injection moulding material and preparation method thereof

The invention discloses a total biomass composite injection moulding material and a preparation method thereof. The raw materials of the total biomass composite injection moulding material contain the following components in part by weight: 20-50 parts of total biomass polyethylene; 30-60 parts of a biomass material; 5-20 parts of a plasticizer; 15-30 parts of a filling material. The preparation method comprises the following steps: raw materials are uniformly mixed and added into a double screw extruder, a mixing is carried out at 150-220 DEG C, a granulation is carried out, and the product is obtained. Raw materials of the products are totally selected from natural renewable substances, thermoplastic renewable substances are blended with the total biomass polyethylene for granulation, along with biodegradation of renewable substances, the whole material is disintegrated into fragments, so that the material has a certain degradation performance.

Owner:WUHAN HUALI BIOLOGY CO LTD

Application of collagen matrix as tissue engineering scaffold

InactiveCN102772822AImprove mechanical propertiesControl degradation rateProsthesisAcetic acidFreeze-drying

The invention discloses novel application of a collagen matrix as a tissue engineering scaffold. The collagen matrix comprises the following substances expressed in mass parts: 50 to 90 of collagen, 8 to 48 of chitosan and 0.5 to 5 of glycerin. A preparation method for the collagen matrix comprises the following steps: 1) dissolving collagen in an acetic acid aqueous solution with a concentration of 0.01 to 0.1% to prepare a collagen solution with a concentration of 1 to 3%; 2) dissolving chitosan in the acetic acid aqueous solution with a concentration of 0.01 to 0.1% to prepare a chitosan solution with a concentration of 1 to 3%; 3) mixing the collagen solution, the chitosan solution (in terms of dry weight) and glycerin according to a mass ratio of 50-90: 8-48: 0.5-5 and carrying out freeze drying at a temperature of -80 DEG C to -10 DEG C for 1 to 5 d so as to obtain a spongy material; 4) immobilizing the spongy material with an aldehyde cross-linking agent at a temperature of 40 to 50 DEG C for 20 to 100 min; and 5) rinsing the spongy material with an aqueous solution of glycerin and drying the spongy material in vacuum so as to obtain the collagen matrix. According to results of cell culture experiments, the collagen matrix provided by the invention can promote cell growth and can be used as a tissue engineering scaffold.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

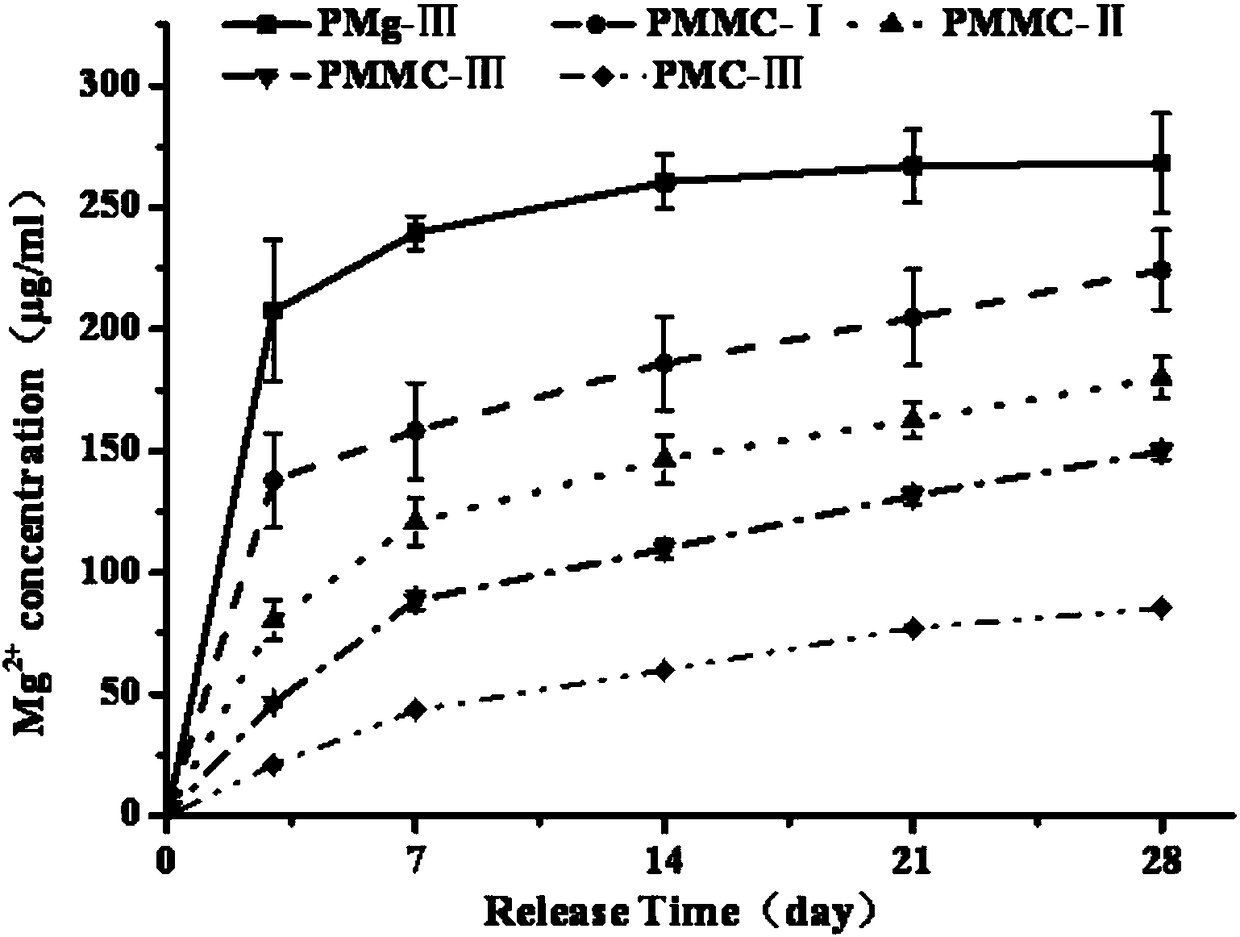

Injectable bone repair material with controllable magnesium ion release behavior and preparation method of material

ActiveCN108283729AImprove surface roughnessHigh affinityPharmaceutical delivery mechanismTissue regenerationPolyesterHuman body

The invention discloses an injectable bone repair material with a controllable magnesium ion release behavior and a preparation method of the material, relates to the field of injectable bone repair materials, and aims at developing an injectable microsphere cell carrier loaded with magnesium-containing inorganic components. Different from common microcarriers such as sephadex in a large-scale cell culture technology, microphseres are prepared from aliphatic polyester with adjustable rate of biodegradation and can be injected into defect parts in a human body together with cells performing adhesive growth on the surfaces by serving as cell carriers, and along with tissue regeneration, a polyester microsphere support is gradually degraded and absorbed by an organism and gives way to regenerated tissue. The magnesium-containing inorganic components are introduced in the microcarriers, by selecting different magnesium-containing inorganic components and changing the proportion and intakeof the magnesium-containing inorganic matter in the microspheres, the release behavior of magnesium ions is regulated and controlled, and then the bioactive microsphere type bone repair material withthe excellent osteogenesis promoting capacity is developed by means of the biological effect of the magnesium ions in the new bone formation process.

Owner:BEIJING UNIV OF CHEM TECH

Halogen-free red phosphorus-free flame-retardant heat shrinkage material, heat shrinkage tube and preparation method and application

ActiveCN102952325AImprove performanceImprove flame retardant performanceInsulated cablesInsulated conductorsPolymer scienceAntioxidant

The invention discloses a halogen-free red phosphorus-free flame-retardant heat shrinkage material, a heat shrinkage tube and a preparation method and application. The heat shrinkage material comprises the following raw materials: 100 parts of polymer base materials including ethylene-vinyl acetate copolymer and ethylene-ethyl acrylate copolymer in radiation grafting with maleic anhydride, 120-160 parts of inorganic flame retardant including magnesium hydroxide, 15-30 parts of polyphosphazene flame retardant including hexaphenoxy cyclotriphosphazene, 15-30 parts of nitrogen flame retardant including melamine cyanurate, 4-8 parts of composite antioxidants including a main antioxidant, an auxiliary antioxidant and an ultraviolet light absorber, 5-15 parts of anti-radiation agents including high-phenyl silicon rubber and anti-radiation agent A, and 6-12 parts of processing aids including a crosslinking sensitizer and a lubricant, wherein the anti-radiation agent A is boron carbide and / or boron nitride. The shrinkage material provided by the invention has excellent performance, good flame retardation and stable radiation resistance, electric performance and mechanical performance.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

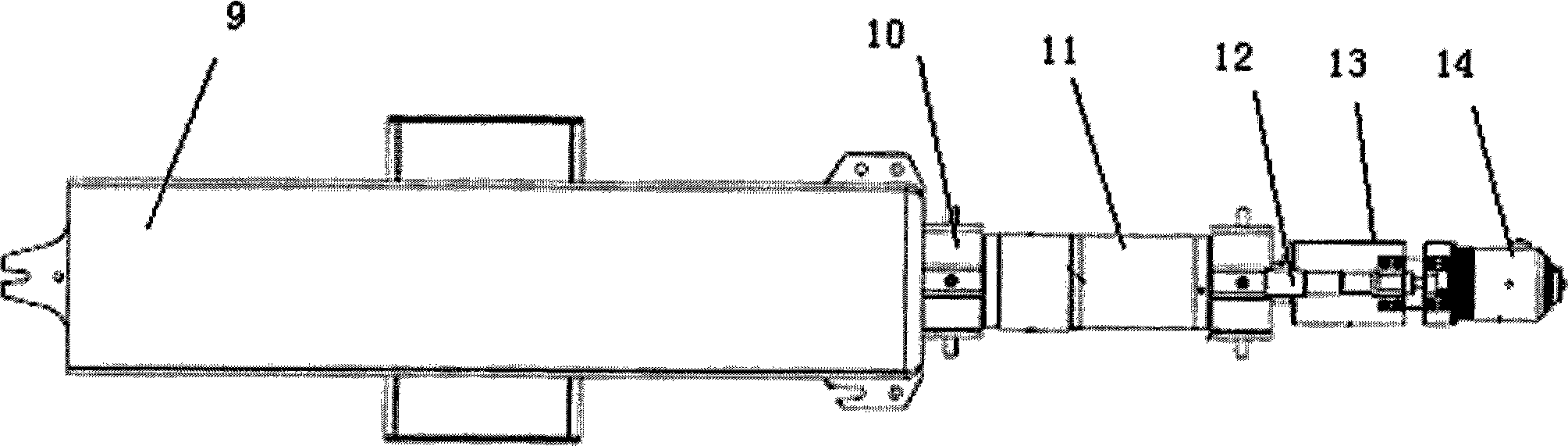

Three-dimensional (3D) printing head for biological composite material

ActiveCN108381924AControl degradation rateImprove mechanical propertiesManufacturing heating elementsCeramic shaping apparatusFiberEngineering

The invention relates to a three-dimensional (3D) printing head for a biological composite material. The 3D printing head for the biological composite material comprises a push rod, a coaxial heatingjacket, a wire feeding pipe, a thermoelectric couple, a mixed extrusion head, powder feeding pipes and electric heating pipes. The mixed extrusion head is connected with the coaxial heating jacket through a screw thread; the push rod is arranged in an inner hole of a feeding cavity of the coaxial heating jacket; a degradable polymer is filled in an inner hole of the feeding cavity; and the three electric heating pipes are arranged on the coaxial heating jacket. The three powder feeding pipes and the wire feeding pipe are arranged on the mixed extrusion head; and the thermoelectric couple is arranged on an outer wall of the thermoelectric couple. The printing head can be used for manufacturing a 3D printing piece made of the continuous fiber-reinforced degradable polymer-biological ceramiccomposite material, the mechanical performance and the bone binding force of the printing piece can be effectively improved, the degradation speed of the printing piece can be controlled, and the riskof aseptic inflammation can be reduced.

Owner:XINJIANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com