Biodegradable medical surgery anti-adhesion membrane and preparation method thereof

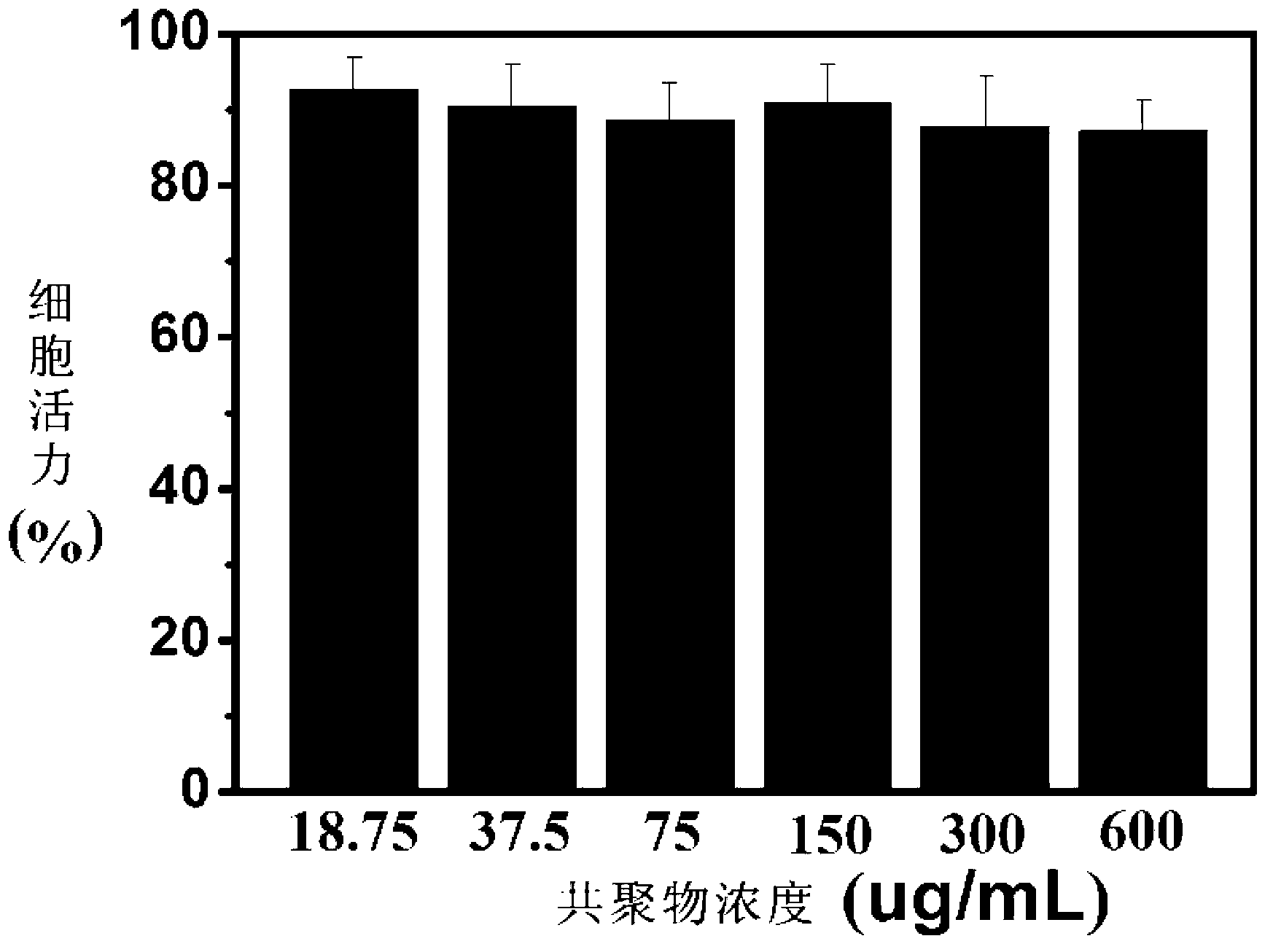

An anti-adhesion film and surgery technology, applied in the field of medical supplies, can solve the problems of unfavorable application, limited flexibility, poor controllability of degradation, etc., and achieve the effects of better application effect, better degradation time, and regulation of degradation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a preparation method of a biodegradable anti-adhesion film for medical operations, comprising the following steps:

[0056] The polyethylene glycol polymer is copolymerized with at least one of lactide and ε-caprolactone and glycolide to obtain a polyethylene glycol polymer with a number average molecular weight of 50,000 to 150,000- Polyester block copolymers;

[0057] Forming the polyethylene glycol polymer-polyester block copolymer into a film to obtain a biodegradable anti-adhesion film for medical operations;

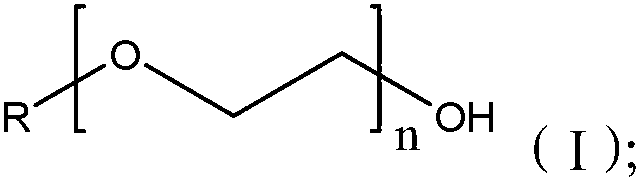

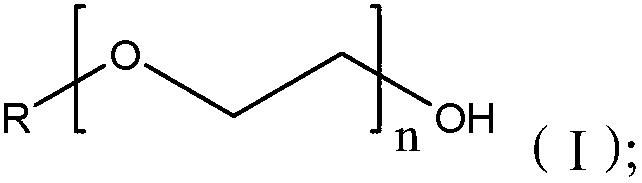

[0058] The polyethylene glycol polymer is shown in formula (I):

[0059]

[0060] Wherein, R is selected from any one of hydroxyl, methyl, ethyl, propyl, isopropyl, amino, propenyl, propynyl, mercapto, carboxyl and azido; n is the degree of polymerization.

[0061] In the present invention, the polyethylene glycol polymer represented by formula (I) is mixed with at least one of lactide and ε-caprolactone and glycolide...

Embodiment 1

[0083] Add 25g of polyethylene glycol monomethyl ether (MPEG) with a molecular weight of 5000 to a 1000mL round bottom flask, place it in an oil bath and heat it to 120°C for vacuum drying. After 5 hours, cool the system down to room temperature, and then Add 416g of lactide (LA) and 59g of glycolide (GA) under low temperature conditions, and continue vacuum drying at a temperature of 110°C. After 6 hours, add a catalyst amount of stannous octoate to carry out copolymerization at 130°C, and polymerize for 24 After 1 hour, the crude product was obtained;

[0084] Dissolve the obtained crude product in chloroform, then slowly pour it into ethanol for sedimentation, filter off the clear liquid, and after vacuum drying, obtain a white solid polymerization product, namely polyethylene glycol-polylactide glycolide block Copolymer, its number average molecular weight is 100,000, LA / GA=85 / 15;

[0085] Dissolve the obtained polymer product in chloroform, after fully dissolving, carefu...

Embodiment 2

[0087] Add 25g of polyethylene glycol monomethyl ether (MPEG) with a molecular weight of 5000 to a 1000mL round bottom flask, place it in an oil bath and heat it to 120°C for vacuum drying. After 5 hours, cool the system down to room temperature, and then 374g of lactide (LA) and 101g of glycolide (GA) were added under low temperature conditions, and the vacuum drying was continued at a temperature of 110°C. After 6 hours, a catalytic amount of stannous octoate was added to carry out a copolymerization reaction at 130°C, and the polymerization was carried out for 24 After 1 hour, the crude product was obtained;

[0088] Dissolve the obtained crude product in chloroform, then slowly pour it into ethanol for sedimentation, filter off the clear liquid, and after vacuum drying, obtain a white solid polymerization product, namely polyethylene glycol-polylactide glycolide block Copolymer, its number average molecular weight is 100,000, LA / GA=75 / 25;

[0089] Dissolve the obtained po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com