Halogen-free red phosphorus-free flame-retardant heat shrinkage material, heat shrinkage tube and preparation method and application

A heat-shrinkable tube and heat-shrinking technology, applied in conductors, electrical components, circuits, etc., can solve the problems of narrow use range, poor mechanical properties, and unsatisfactory halogen-free flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Synthesis of polyphosphazene flame retardant hexaphenoxycyclotriphosphazene:

[0080] The specific operation process is:

[0081] 1), the preparation of sodium phenolate: in a 50L stainless steel reaction kettle, add 5Kg phenol, 25L chlorobenzene, 500g polyethylene glycol, 45% sodium hydroxide solution under nitrogen protection, which contains 5.0mol of sodium hydroxide , the reaction temperature is 120-130°C, and the reaction time is 8-12 hours. After the reaction is completed, the water is separated by azeotropic distillation, and the reactant is cooled to room temperature for use.

[0082] 2), the preparation of hexaphenoxycyclotriphosphazene: in step 1) in the phenol sodium salt of preparation, add the 30% chlorobenzene solution that contains the hexachlorocyclotriphosphazene of commercially available 3.0Kg under nitrogen protection, in React at 130-132°C for 6-12 hours, cool, filter, distill the filtrate under reduced pressure, recover the solvent chlorobenzene, a...

Embodiment 2

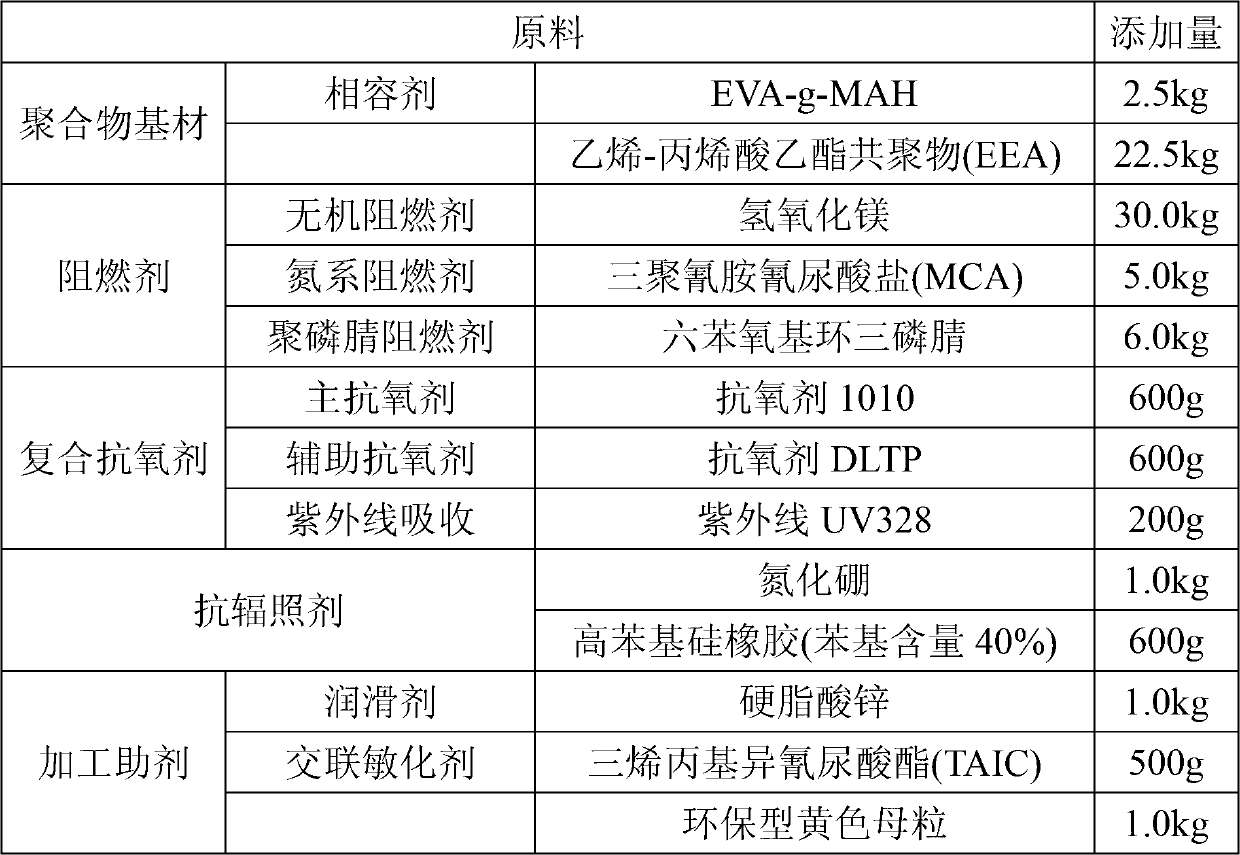

[0084] raw material:

[0085]

[0086] Wherein, the polyphosphazene flame retardant used is the hexaphenoxycyclotriphosphazene prepared in Example 1.

[0087] Steps:

[0088] The compatibilizer EVA-g-MAH, ethylene-ethyl acrylate copolymer (EEA), antioxidant 1010, antioxidant DLTP, ultraviolet UV328, boron nitride, magnesium hydroxide, melamine cyanurate (MCA) , polyphosphazene flame retardant hexaphenoxycyclotriphosphazene, and environmentally friendly yellow masterbatch, put them into a 55-liter internal mixer, and when the internal mixer reaches 130°C, add high-phenyl silicone rubber (phenyl content 40 %), zinc stearate, triallyl isocyanurate (TAIC), after mixing for 10 minutes (mixing temperature 120-140 ℃), turn over the internal mixer, pour the material into the hoist and raise it to Two-stage twin-screw extruder, extruding and granulating at 110-150°C, and air-cooled to obtain a yellow halogen-free and red phosphorus-free flame-retardant heat-shrinkable material. ...

Embodiment 3

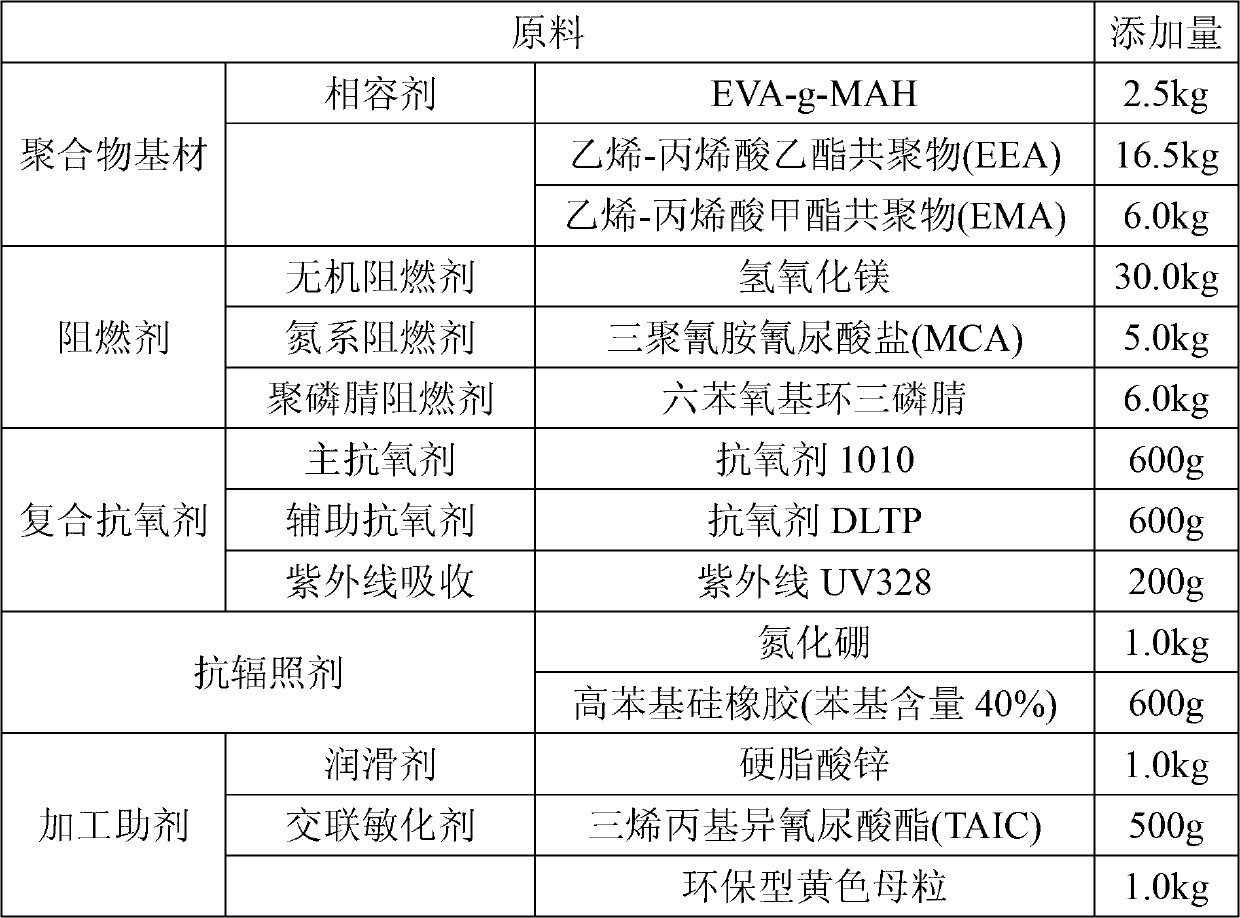

[0090] raw material:

[0091]

[0092] Wherein, the polyphosphazene flame retardant used is the hexaphenoxycyclotriphosphazene prepared in Example 1.

[0093] Steps:

[0094] The compatibilizer EVA-g-MAH, ethylene-ethyl acrylate copolymer (EEA), ethylene-methyl acrylate copolymer (EMA), antioxidant 1010, antioxidant DLTP, ultraviolet UV328, boron nitride, hydrogen Magnesium oxide, melamine cyanurate (MCA), polyphosphazene flame retardant hexaphenoxycyclotriphosphazene, and environmentally friendly yellow masterbatch are put into a 55-liter internal mixer, and when they are mixed to 130°C, Add high phenyl silicone rubber (40% phenyl content), zinc stearate, triallyl isocyanurate (TAIC), knead for 10 minutes (mixing temperature 120-140°C), turn over and knead machine, pour the material into the hoist and lift it to Two-stage twin-screw extruder, extruding and granulating at 110-150°C, and air-cooled to obtain a yellow halogen-free and red phosphorus-free flame-retardant hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com