Medical degradable zinc-based composite material and preparation method and application thereof

A composite material and zinc-based technology, applied in medical science, surgery, etc., can solve the problems of difficult cleaning, too fast corrosion of magnesium alloy, slow corrosion of zinc alloy, etc., and achieve the effect of moderate degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

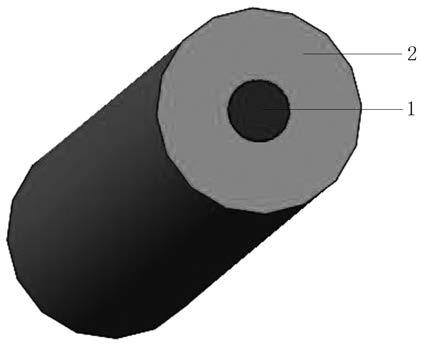

[0029] A medical degradable zinc-based composite material. The zinc-based composite material is cylindrical and includes an inner layer and an outer layer. The inner layer 1 is magnesium and the outer layer 2 is a zinc alloy; the zinc alloy is composed of metal Zn, The composition of metal Mg and element X, in terms of weight percentages, metal Zn 99.87%, metal Mg 0.01%, element X 0.1%, and the rest are inevitable impurities; the element X is Cu.

[0030] The preparation method of the medical degradable zinc-based composite material includes the following steps:

[0031] (1) Melting: smelting Zn5Mg and Zn9X master alloys using existing technology, and detecting the final composition content of the master alloy; then in a smelting mold with a cylindrical cavity, a magnesium rod with a diameter of 1 mm is fixed to the shaft of the cavity In the center, an inner layer is formed, and the diameter of the inner cavity is 27mm; then, taking the actual measured values of Zn5Mg and Zn9X a...

Embodiment 2

[0037] A medical degradable zinc-based composite material. The zinc-based composite material is cylindrical and includes an inner layer and an outer layer. The inner layer is magnesium and the outer layer is a zinc alloy; the zinc alloy is composed of metal Zn and metal Mg. And element X is composed of 99.83% metal Zn, 0.05% metal Mg, 0.1% element X, and the rest are unavoidable impurities; the element X is Li.

[0038] The preparation method of the medical degradable zinc-based composite material includes the following steps:

[0039] (1) Melting: smelting Zn5Mg and Zn9X master alloys using existing technology, and detecting the final composition content of the master alloy; then in a smelting mold with a cylindrical cavity, a magnesium rod with a diameter of 1 mm is fixed to the shaft of the cavity In the center, an inner layer is formed, and the diameter of the inner cavity is 27mm; then, taking the actual measured values of Zn5Mg and Zn9X as the standard, Zn, Zn5Mg, and Zn9X ...

Embodiment 3

[0045] A medical degradable zinc-based composite material. The zinc-based composite material is cylindrical and includes an inner layer and an outer layer. The inner layer is magnesium and the outer layer is a zinc alloy; the zinc alloy is composed of metal Zn and metal Mg. And element X, in terms of weight percentage, 99.78% metal Zn, 0.1% metal Mg, 0.1% element X, and the rest are inevitable impurities; the element X is Mn.

[0046] The preparation method of the medical degradable zinc-based composite material includes the following steps:

[0047] (1) Melting: smelting Zn5Mg and Zn9X master alloys using existing technology, and detecting the final composition content of the master alloy; then in a smelting mold with a cylindrical cavity, a magnesium rod with a diameter of 1 mm is fixed to the shaft of the cavity In the center, an inner layer is formed, and the diameter of the inner cavity is 27mm; then, taking the actual measured values of Zn5Mg and Zn9X as the standard, Zn, Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com