Mg-Sn-Mn system wrought magnesium alloy and preparation method thereof

A wrought magnesium alloy, mg-sn-mn technology, applied in the field of alloys, can solve problems such as toxicity, achieve the effects of low production cost, reduce the influence of impurity elements, and control the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

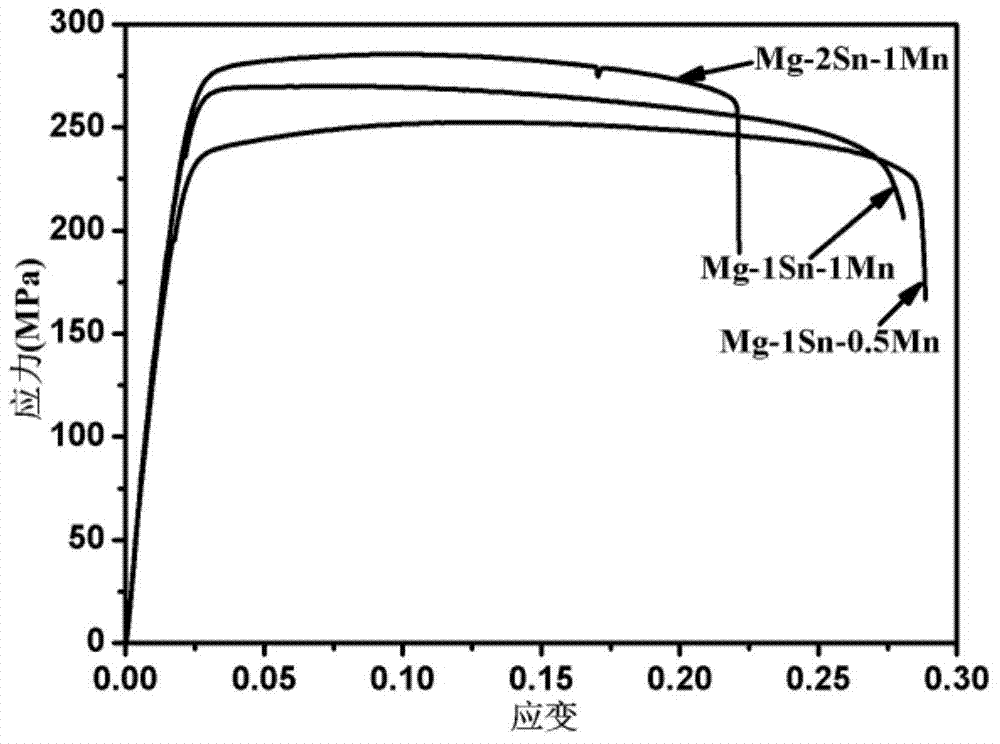

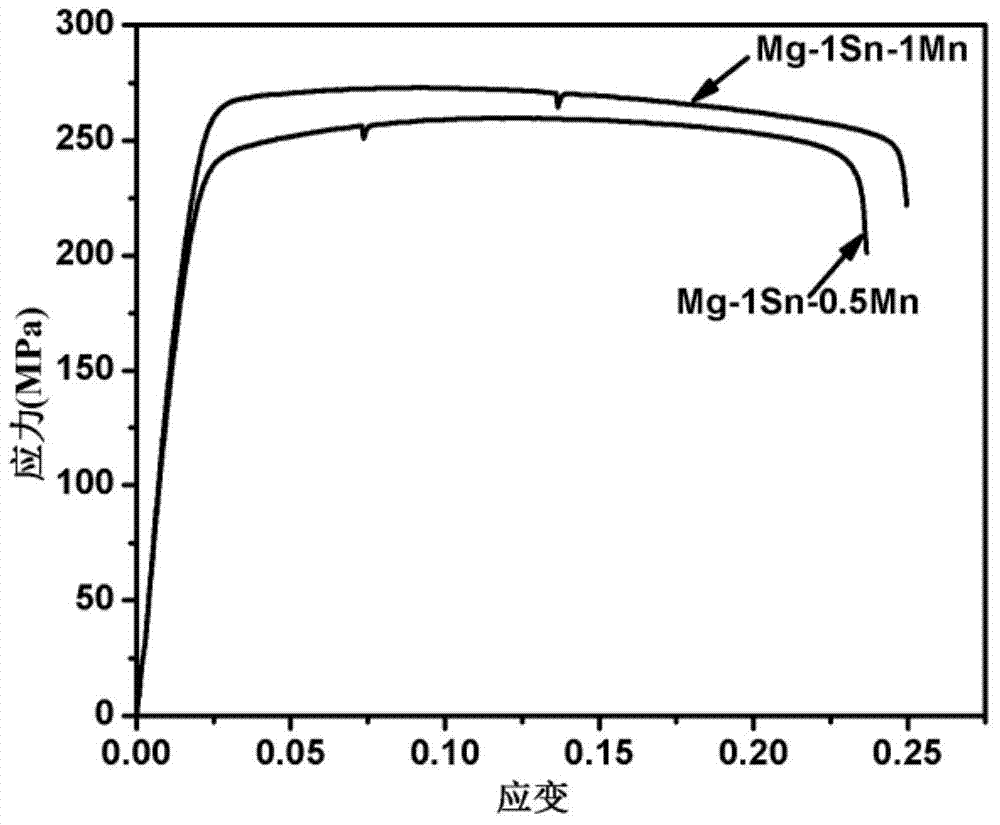

Embodiment 1

[0032] The method for preparing the Mg-Sn-Mn series deformed magnesium alloy in this embodiment comprises the following steps:

[0033] 1) Raw material preparation: select pure magnesium, pure tin and magnesium-manganese master alloy, wherein the mass percentage of manganese in the magnesium-manganese master alloy is 5%. Properly adjust the content of each raw material so that the alloy composition meets: Sn: 1%, Mn: 0.5%, and the rest is magnesium.

[0034] 2) Smelting: in SF 6 and CO 2 Under the protection of gas, the pure magnesium ingot is heated to 740°C to melt; then the pure tin and magnesium-manganese intermediate alloy preheated at 100-200°C are added to the magnesium melt for melting; finally, the alloy melt is kept at 740°C for 30 Minutes, after fully stirring for 3 minutes, let it stand for 5 minutes, and knock off the surface scum.

[0035] 3) Casting: in SF 6 and CO 2 Under the protection of mixed gas, the magnesium alloy melt is cast into an iron mold prehe...

Embodiment 2

[0039] The method for preparing the Mg-Sn-Mn series deformed magnesium alloy in this embodiment comprises the following steps:

[0040] 1) Raw material preparation: select pure magnesium, pure tin and magnesium-manganese master alloy, wherein the mass percentage of manganese in the magnesium-manganese master alloy is 5%. Properly adjust the content of each raw material so that the alloy composition satisfies: Sn: 1%, Mn: 1%, and the rest is magnesium.

[0041] 2) Smelting: in SF 6 and CO 2 Under the protection of gas, the pure magnesium ingot is heated to 740°C to melt; then the pure tin and magnesium-manganese intermediate alloy preheated at 100-200°C are added to the magnesium melt for melting; finally, the alloy melt is kept at 740°C for 30 Minutes, after fully stirring for 3 minutes, let it stand for 5 minutes, and knock off the surface scum.

[0042] 3) Casting: in SF 6 and CO 2 Under the protection of mixed gas, the magnesium alloy melt is cast into an iron mold pre...

Embodiment 3

[0046] The method for preparing the Mg-Sn-Mn series deformed magnesium alloy in this embodiment comprises the following steps:

[0047] 1) Raw material preparation: select pure magnesium, pure tin and magnesium-manganese master alloy, wherein the mass percentage of manganese in the magnesium-manganese master alloy is 5%. Properly adjust the content of each raw material so that the alloy composition meets: Sn: 2%, Mn: 1%, and the rest is magnesium.

[0048] 2) Smelting: in SF 6 and CO 2 Under the protection of gas, the pure magnesium ingot is heated to 740°C to melt; then the pure tin and magnesium-manganese intermediate alloy preheated at 100-200°C are added to the magnesium melt for melting; finally, the alloy melt is kept at 740°C for 30 Minutes, after fully stirring for 3 minutes, let it stand for 5 minutes, and knock off the surface scum.

[0049] 3) Casting: in SF 6 and CO2 Under the protection of mixed gas, the magnesium alloy melt is cast into an iron mold preheated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com