Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

248 results about "Distance interval" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

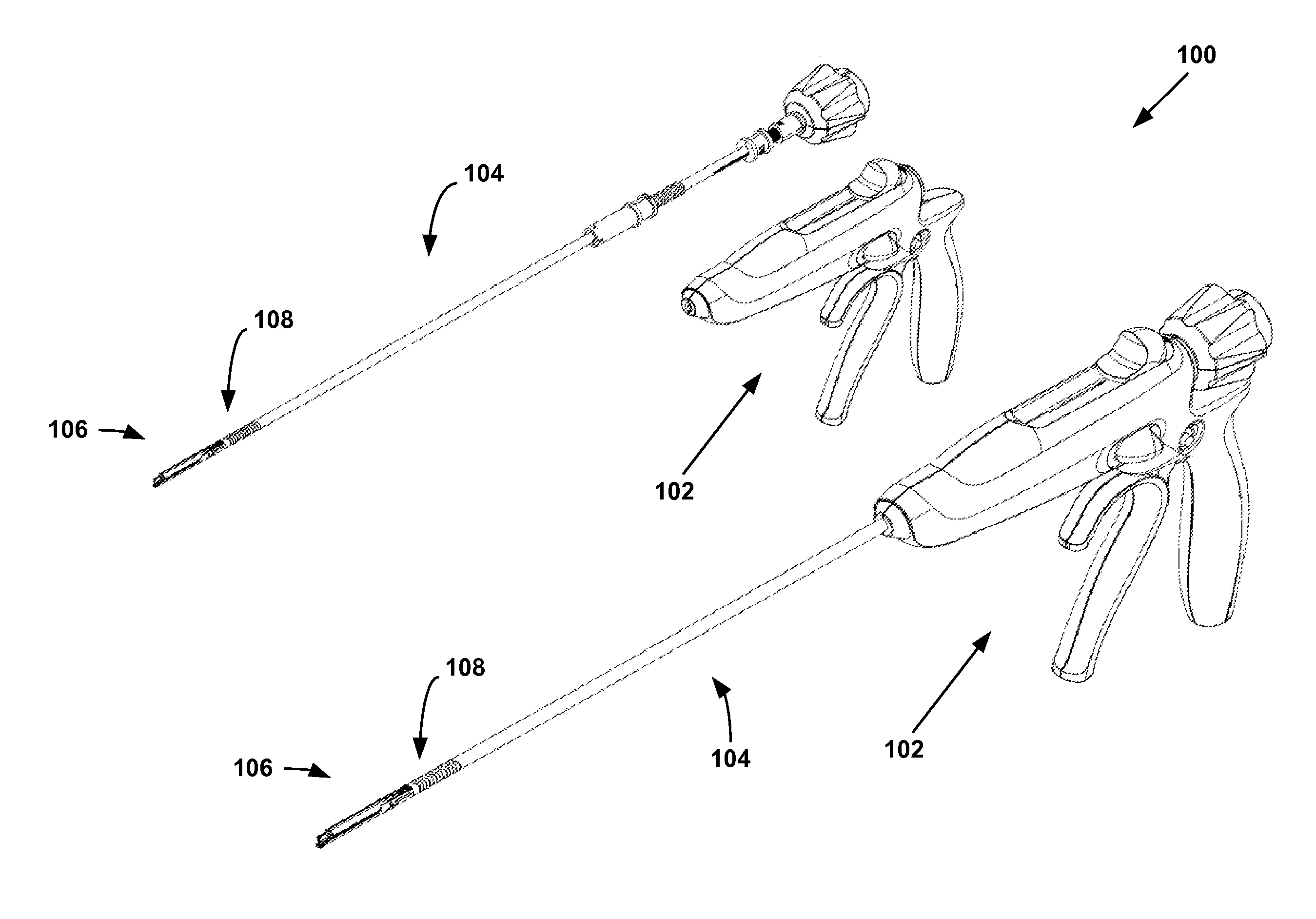

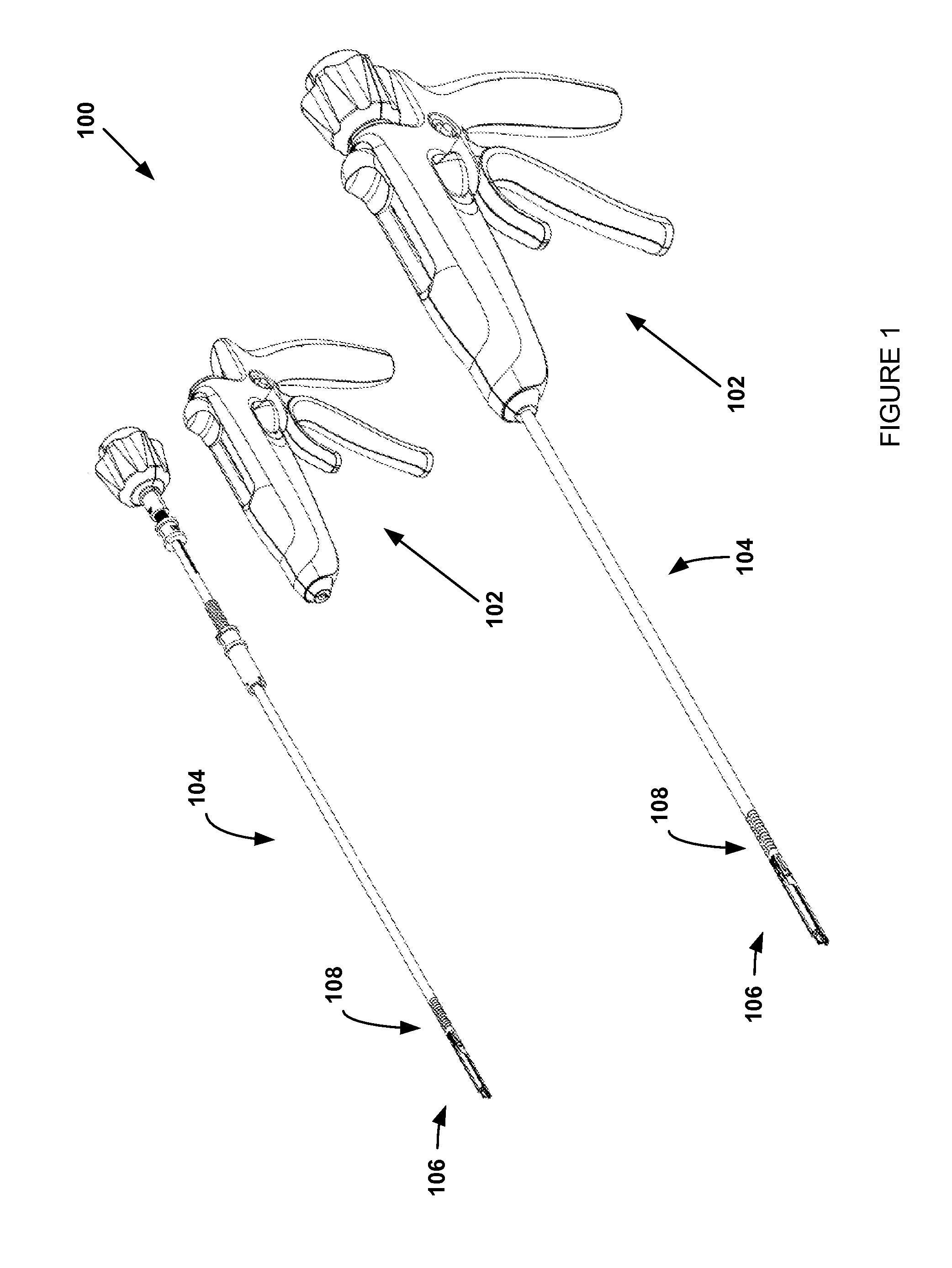

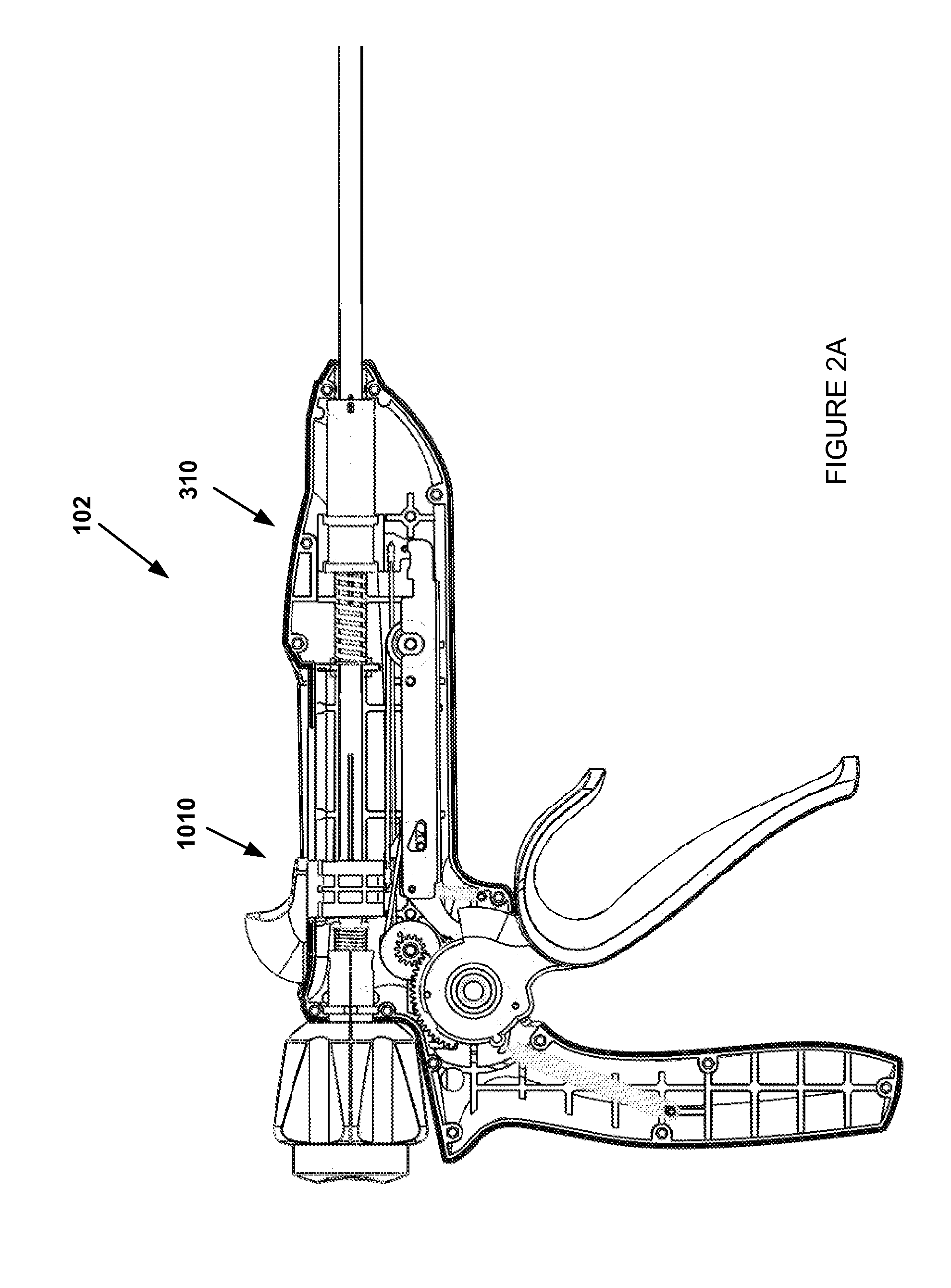

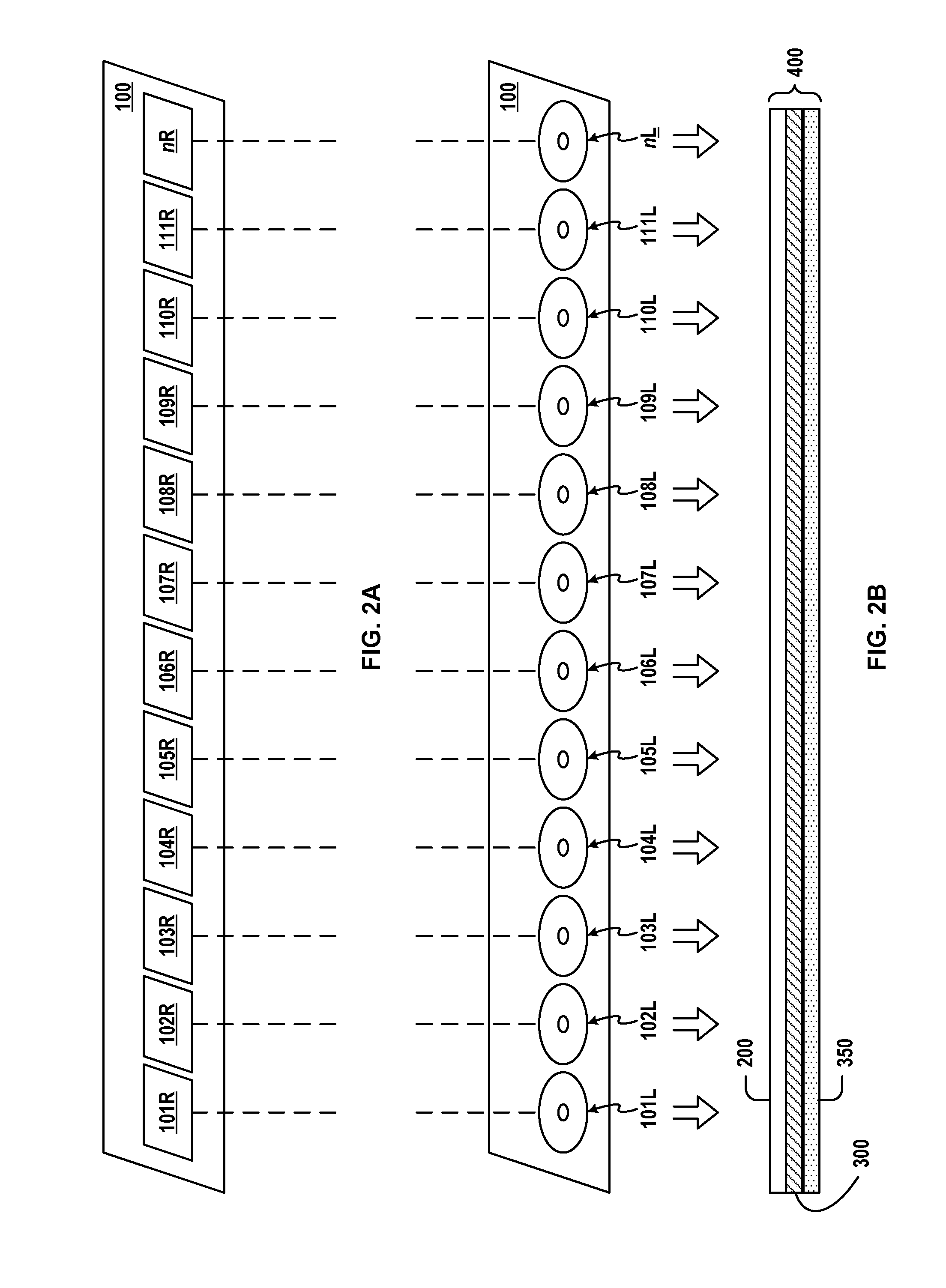

Microcutter stapling apparatus clamp and deploy mechanisms systems and methods

A surgical stapling apparatus configured to perform stapling and / or cutting operations on a target tissue of a patient. The surgical stapling apparatus comprises of a mode selection switch to place the apparatus in either a clamping operational phase or a deployment operational phase. In the clamping operational phase, various clamp components are operated to facilitate loading of surgical staples into the stapling apparatus, if not preloaded, placement of the stapling apparatus to a target surgical site, and clamping of target tissue to be stapled and / or cut. In the deployment operational phase, various deployment components are operated to staple and / or cut the target tissue to one or more desired distance intervals to achieve the desired outcome for the surgical procedure.

Owner:AESCULAP AG

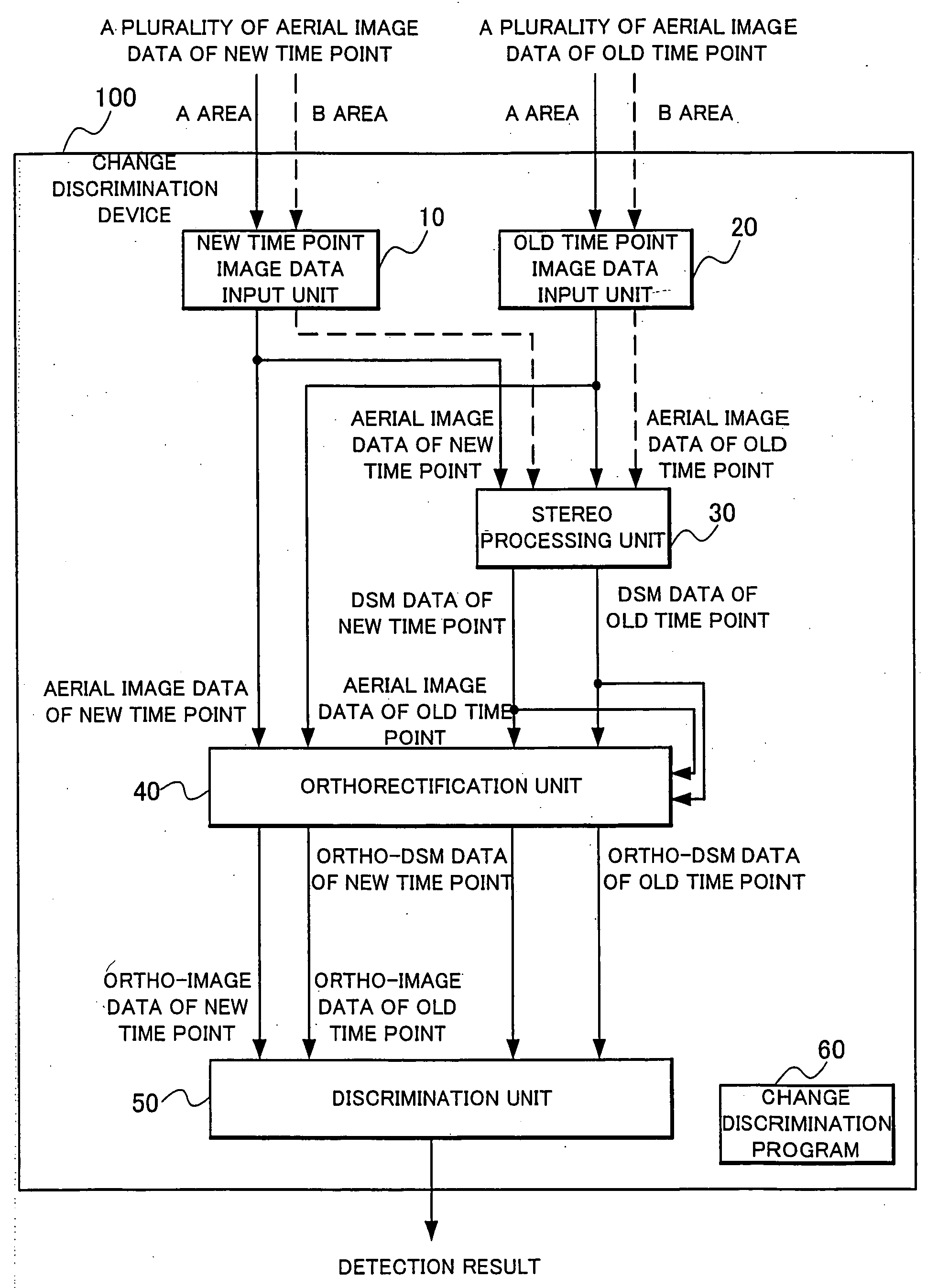

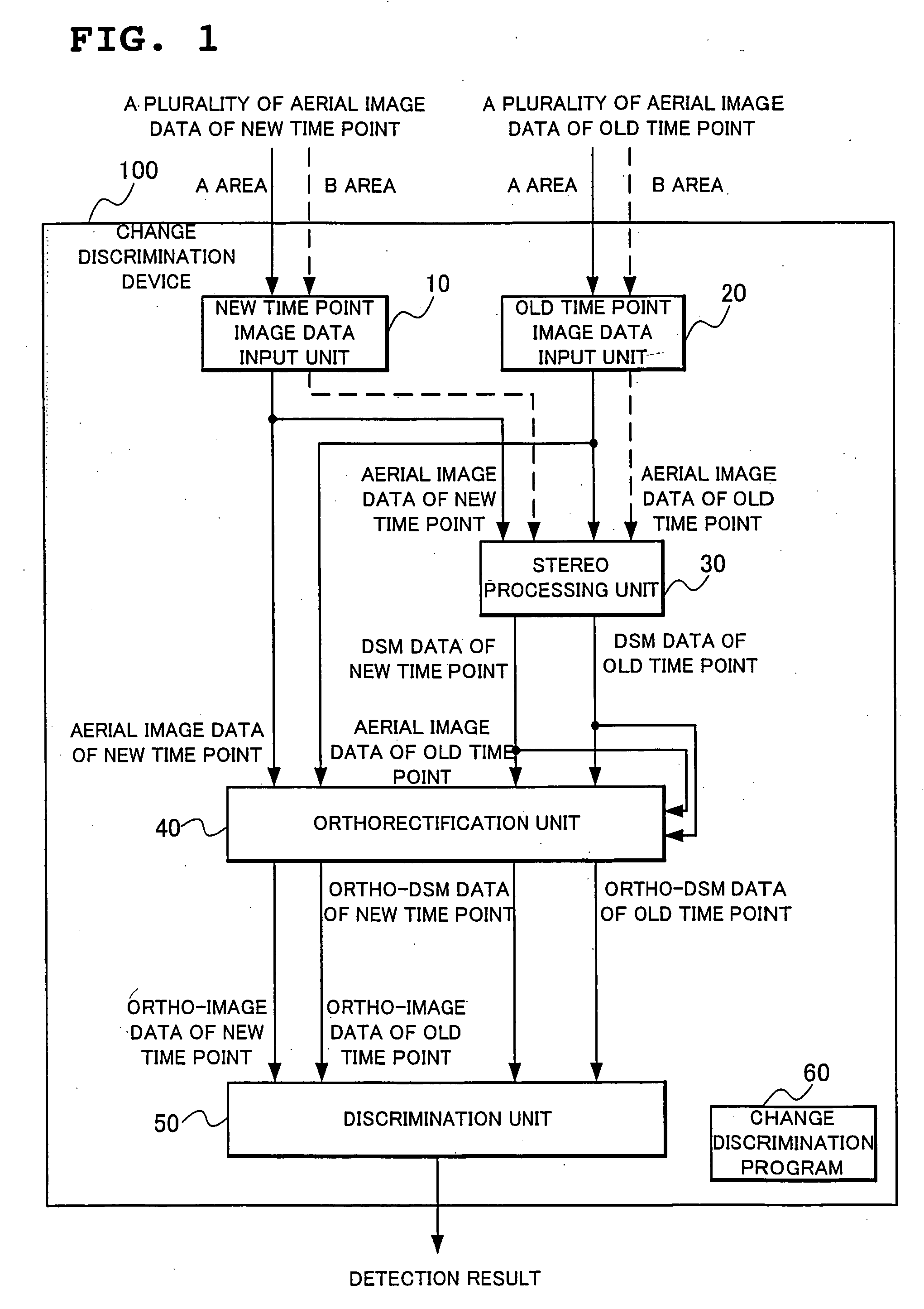

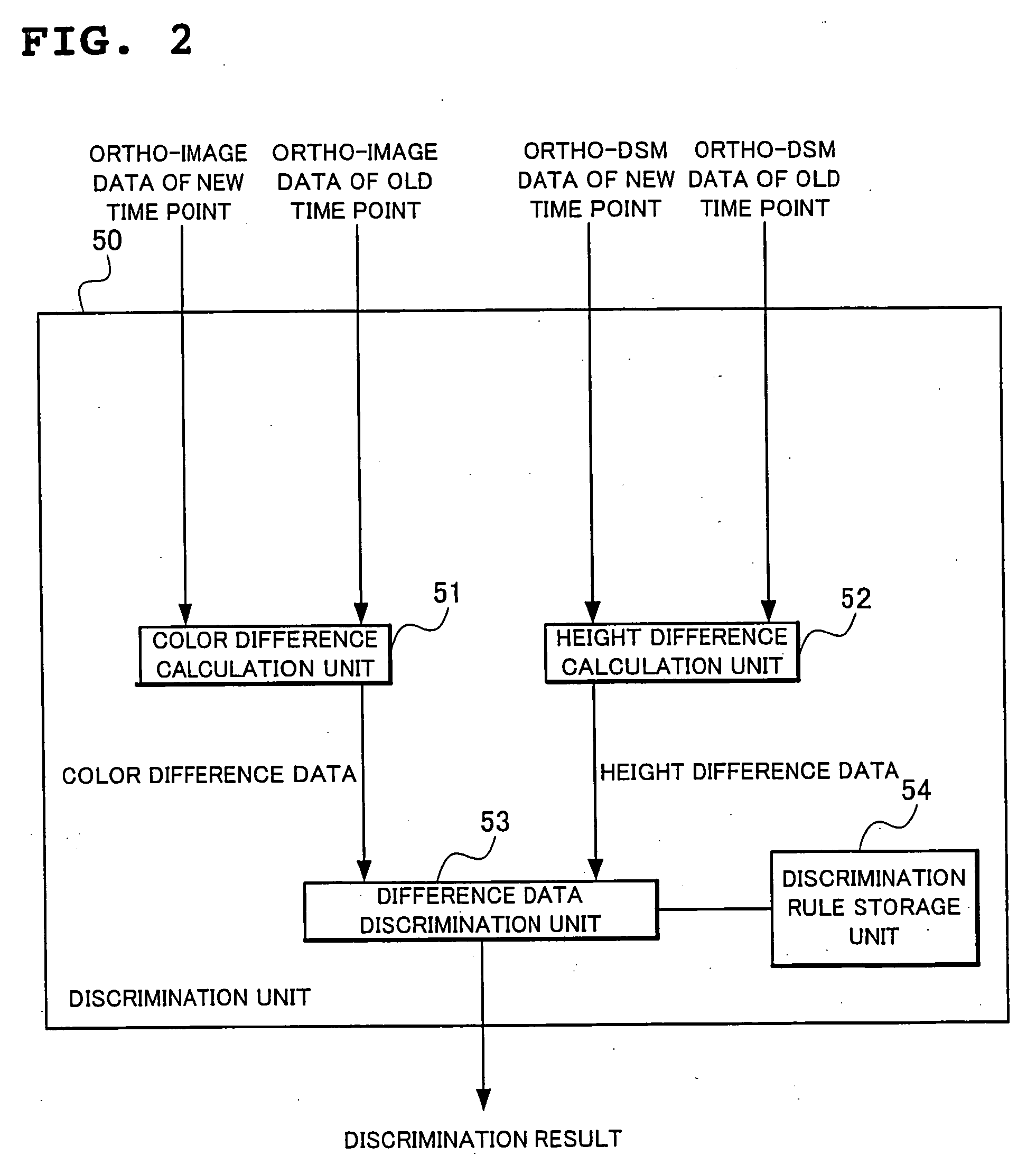

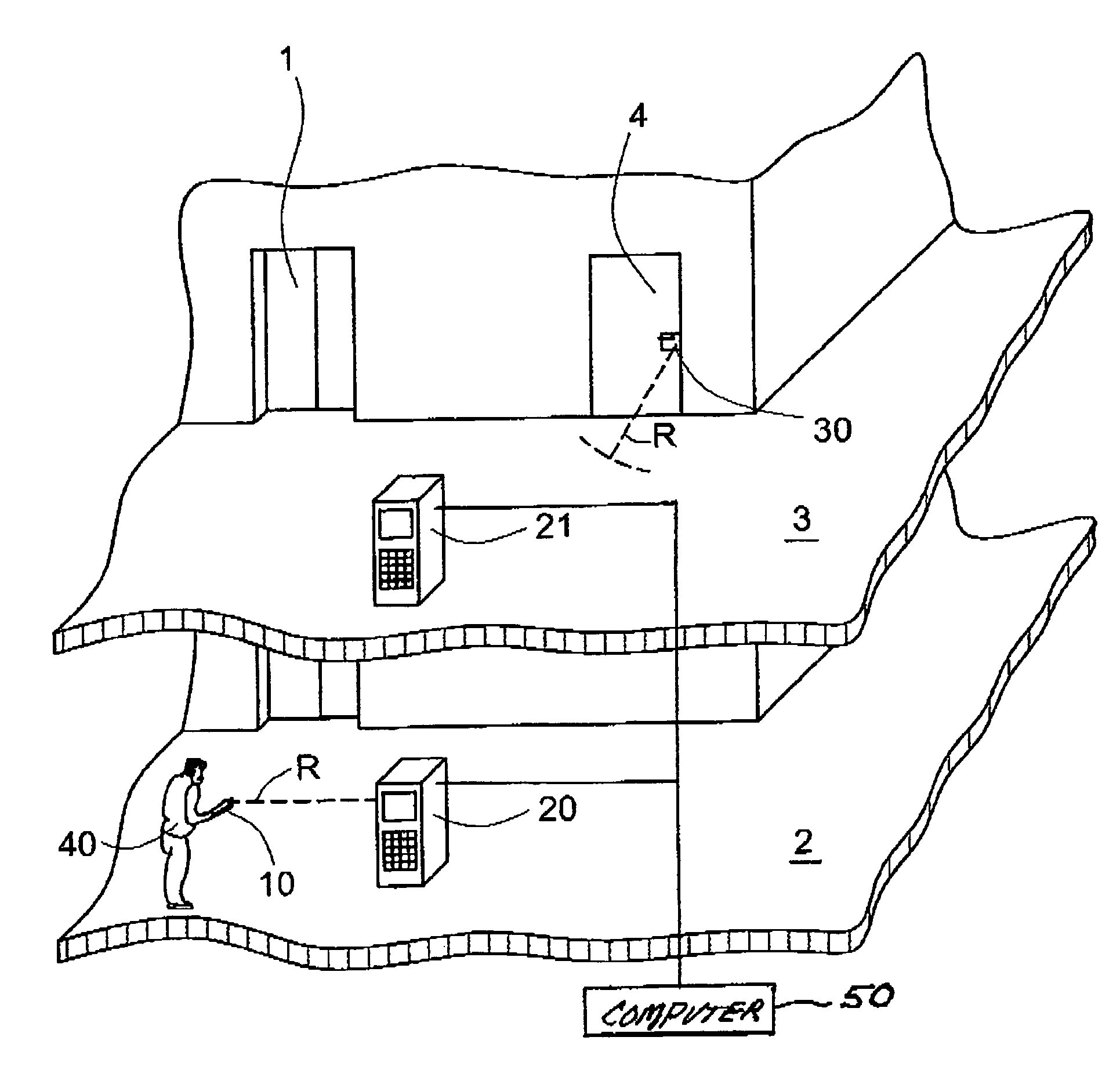

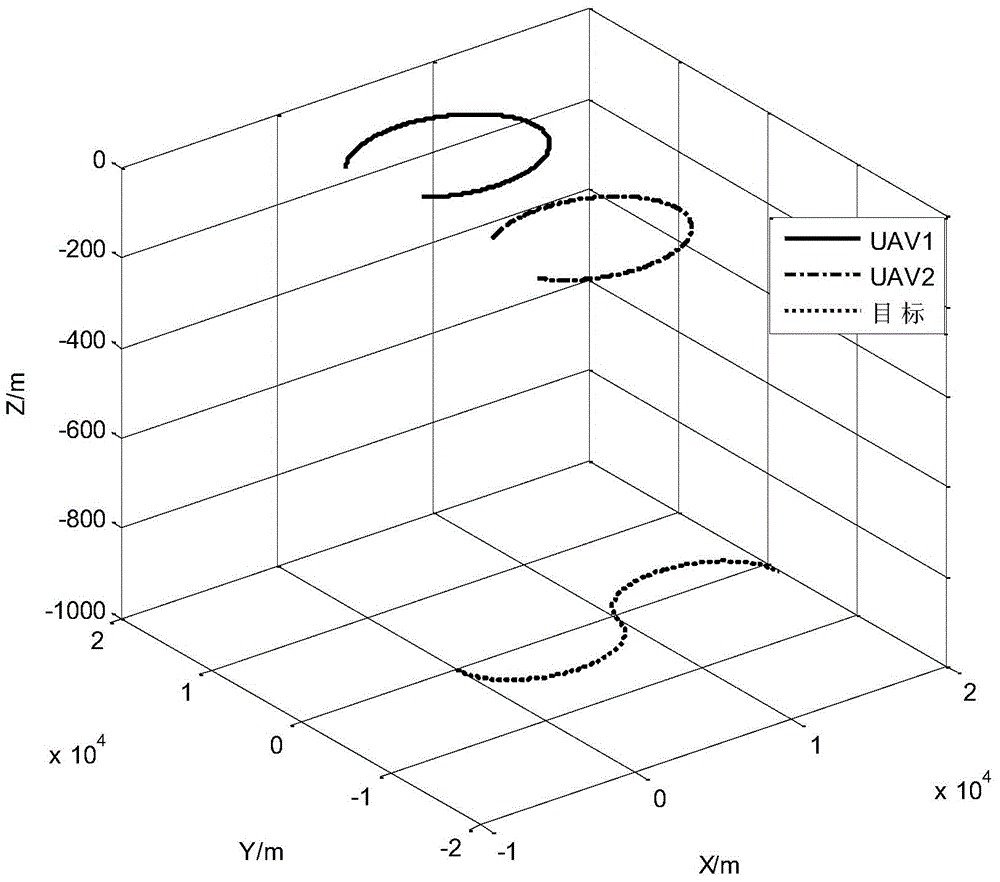

Change discrimination device, change discrimination method and change discrimination program

ActiveUS20070025595A1Improve accuracyLow costScene recognitionPicture interpretationPattern recognitionStereo matching

A change discrimination device capable of discriminating an alteration of a photographing target only from an aerial photograph or irrespectively of a difference in lighting conditions or photographing conditions at the time of taking a photo, and at minute distance intervals on a pixel basis, which receives input of a plurality of aerial image data at a new time point and an old time point, generates three-dimensional data (DSM) by subjecting the applied aerial image data to stereo-matching processing, generates ortho-image data and ortho-DSM data by normalizing the aerial image data and the generated DSM data, compares colors by using the generated ortho-image of the new time point and ortho-image of the old time point and compares heights by using the generated ortho-DSM data of the new time point and ortho-DSM data of the old time point to discriminate an alteration of a feature on the earth.

Owner:NEC SOLUTION INNOVATORS LTD

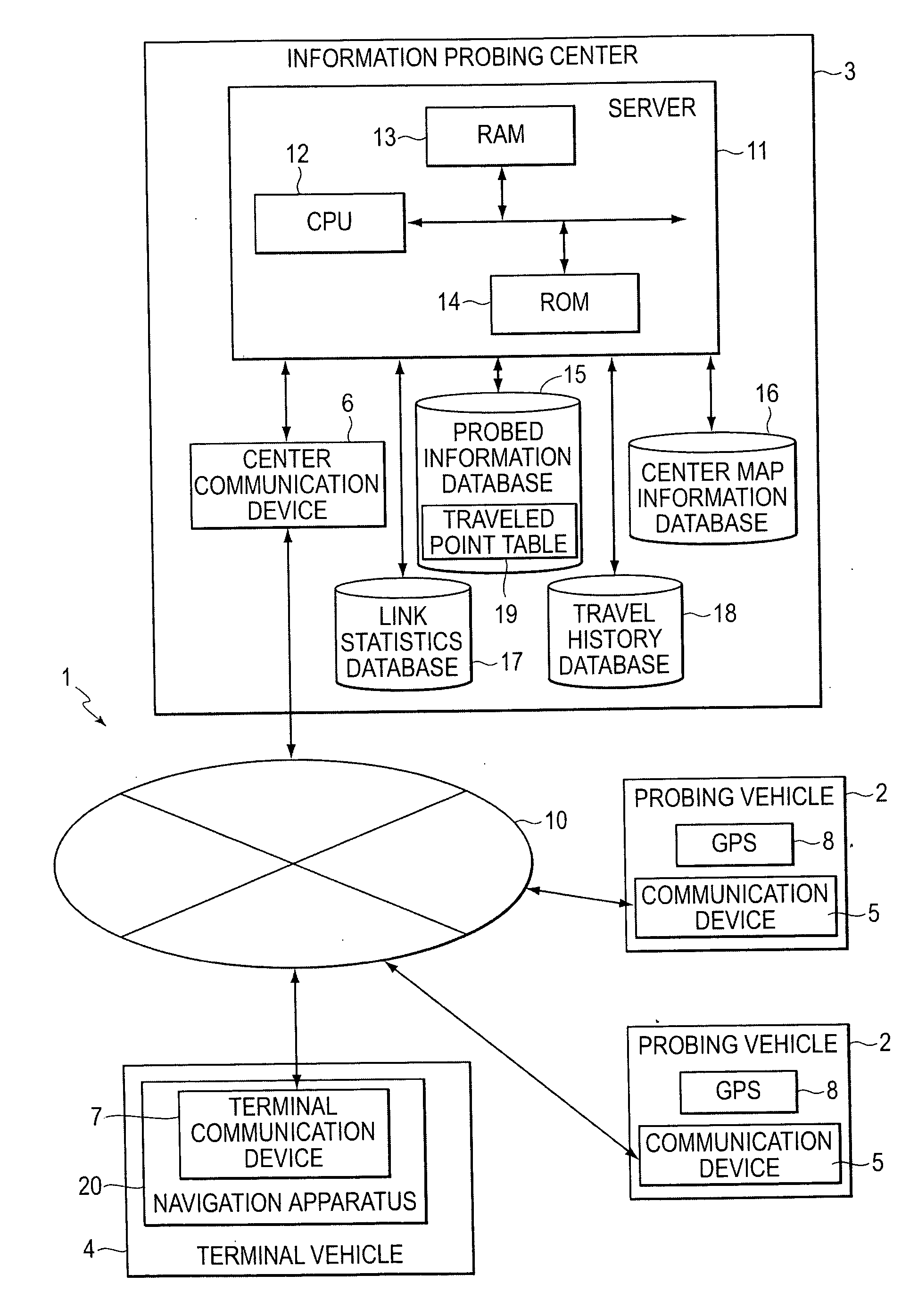

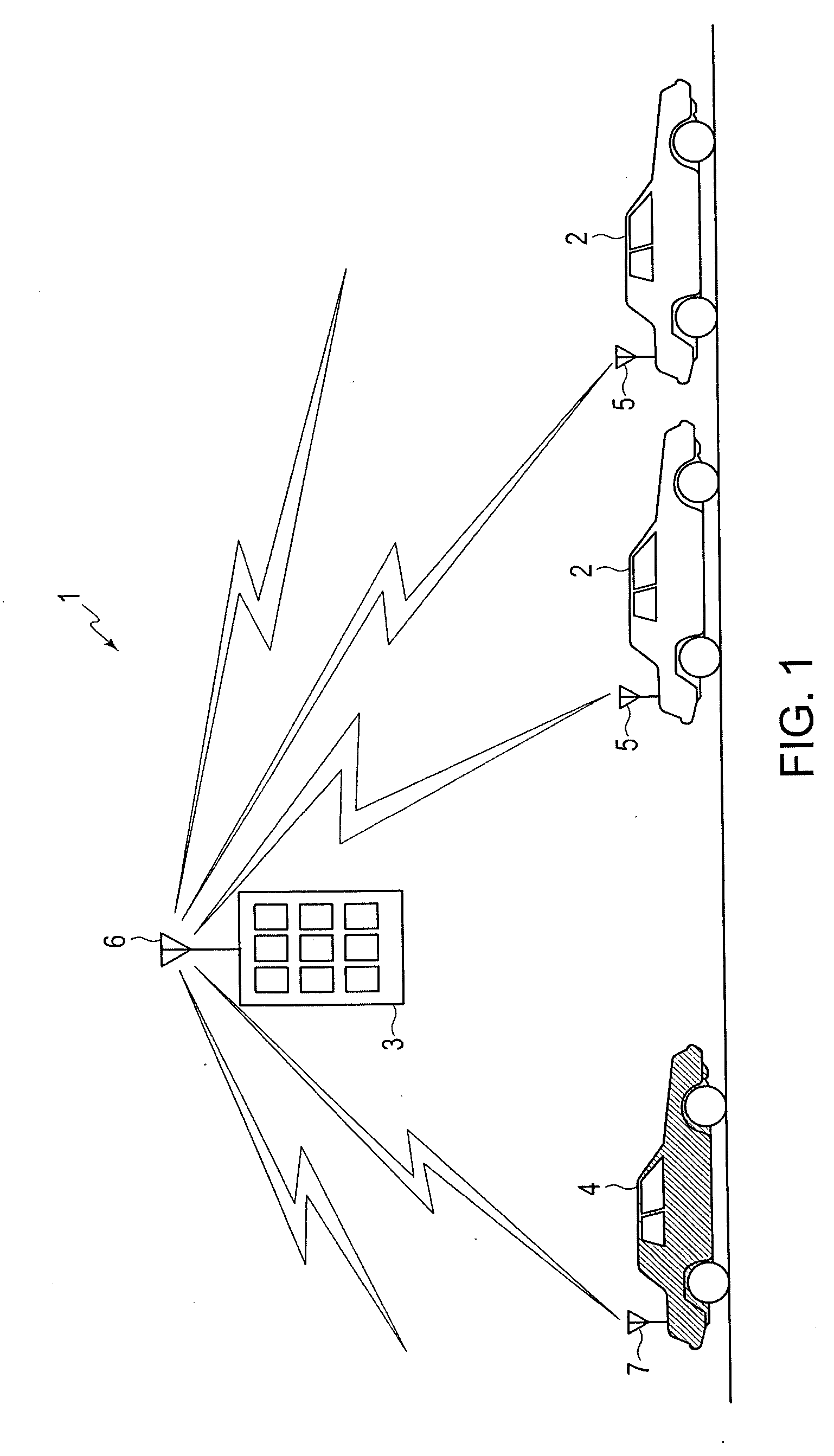

Traveled link identifying systems, methods, and programs

ActiveUS20070150185A1Instruments for road network navigationDetection of traffic movementSystems approachesPath recognition

Traveled link identifying system systems, methods, and programs receive information representing current positions of probe vehicles, the information acquired from each probe vehicle at predetermined distance intervals or at predetermined time intervals. The systems, methods, and programs store connection relationships between links, the links representing portions of roads within map data, and acquire position information from the communication device. The systems, methods, and programs detect links traveled by a probe vehicle on the basis of the acquired position information and determine, based on the stored connection relationships, whether it is possible to uniquely identify one combination of links connecting the detected traveled links. The systems, methods, and programs identify a path traveled by the probe vehicle as being a path between the detected travel links along the unique combination of links.

Owner:AISIN AW CO LTD

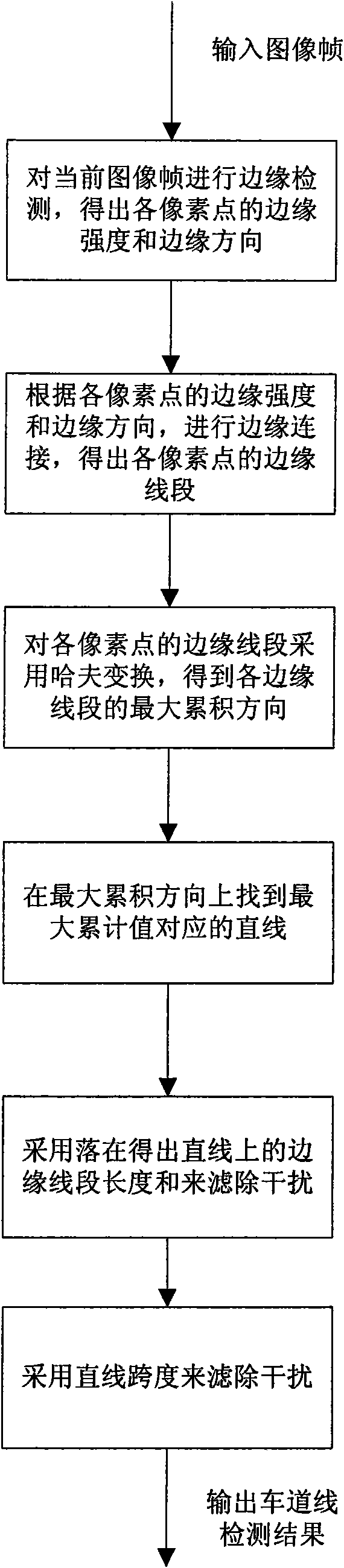

Method of lane line detection and equipment thereof

The invention discloses a method of lane line detection and an equipment thereof. The method comprises the following steps of: carrying out edge detection on images and calculating edge strength and edge direction of all pixel points in the images; carrying out edge connection on all the pixel points according to the edge strength and edge direction and obtaining edge line segments in the images; carrying out Hough transform on the edge line segments and calculating the maximum accumulative direction thereof in a Hough transform accumulative column diagram including a directional interval and a distance interval; and in the interval of the maximum accumulative direction, finding a distance interval corresponding to a larger accumulative value, thus determining the lane line according to the maximum accumulative direction and the distance interval corresponding to the larger accumulative value. The invention filters and removes interference of point edges by edges which are connected and detected, and eliminates strong interference in the scene with multiple parallel lane lines by finding the maximum accumulative direction.

Owner:VIMICRO ELECTRONICS CORP

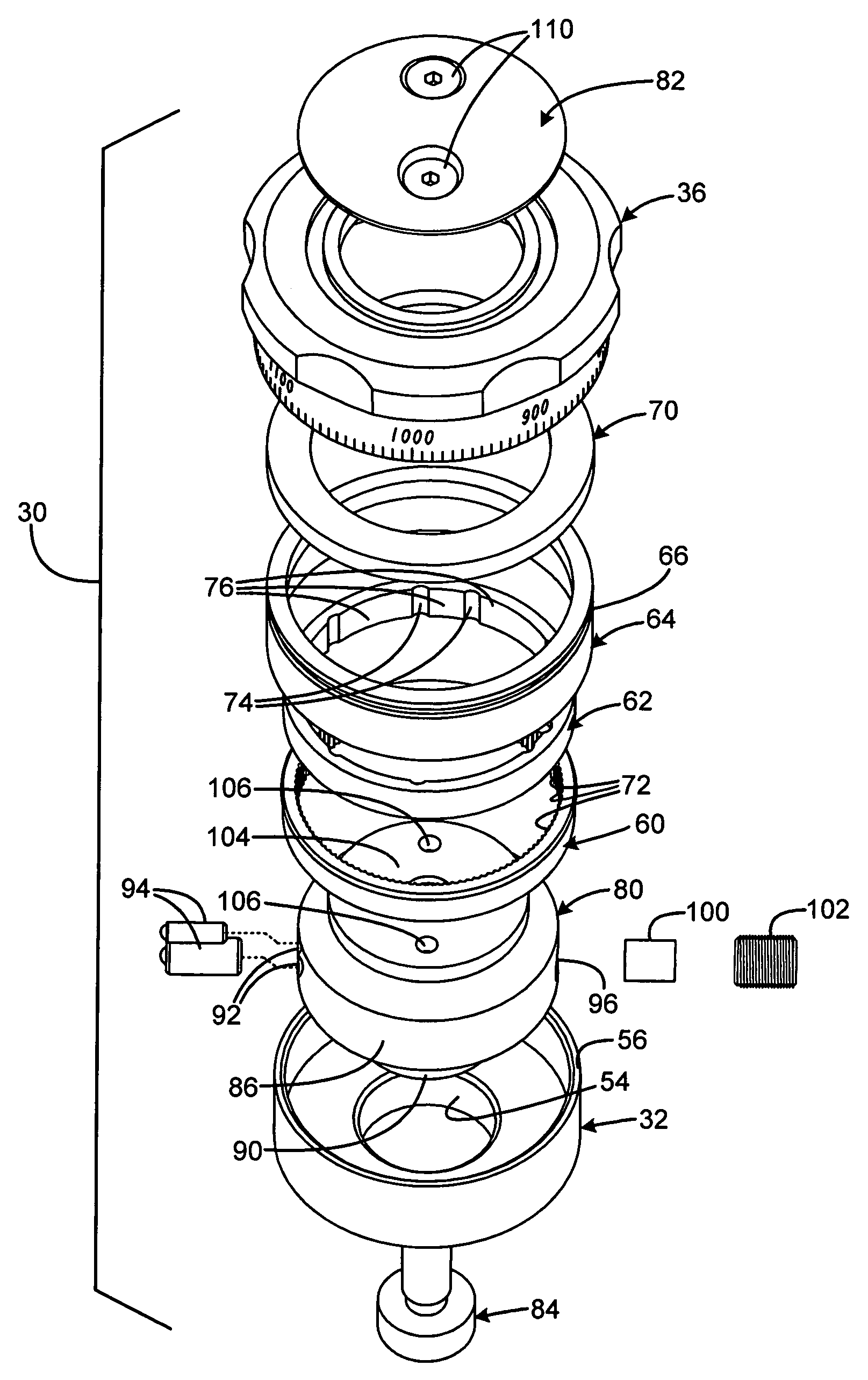

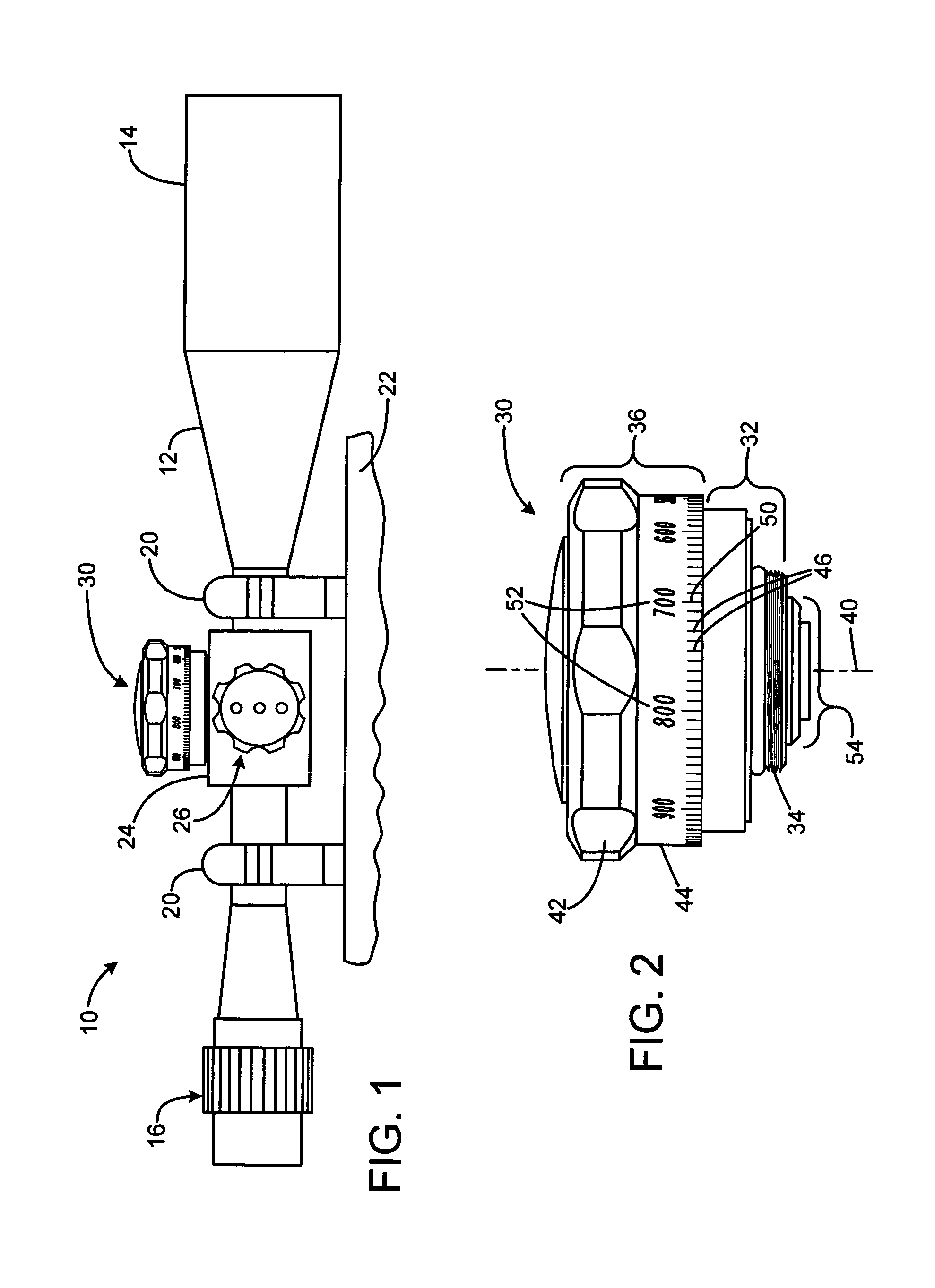

Rifle scope with adjustment knob having multiple detent forces

A rifle scope has a body with a number of optical elements. An adjustment knob is rotated we connected to the body and interacts with at least one of the optical elements to provide an image shift in response to rotation of the knob. A detent mechanism interacts with the knob, and has a number of detent positions. Many of the detent positions have a first detent force, and a selected subset the detent positions have a greater second force. The selected subset of detent positions may correspond to selected major distance intervals.

Owner:DOWN RANGE SOLUTIONS GRP LLC

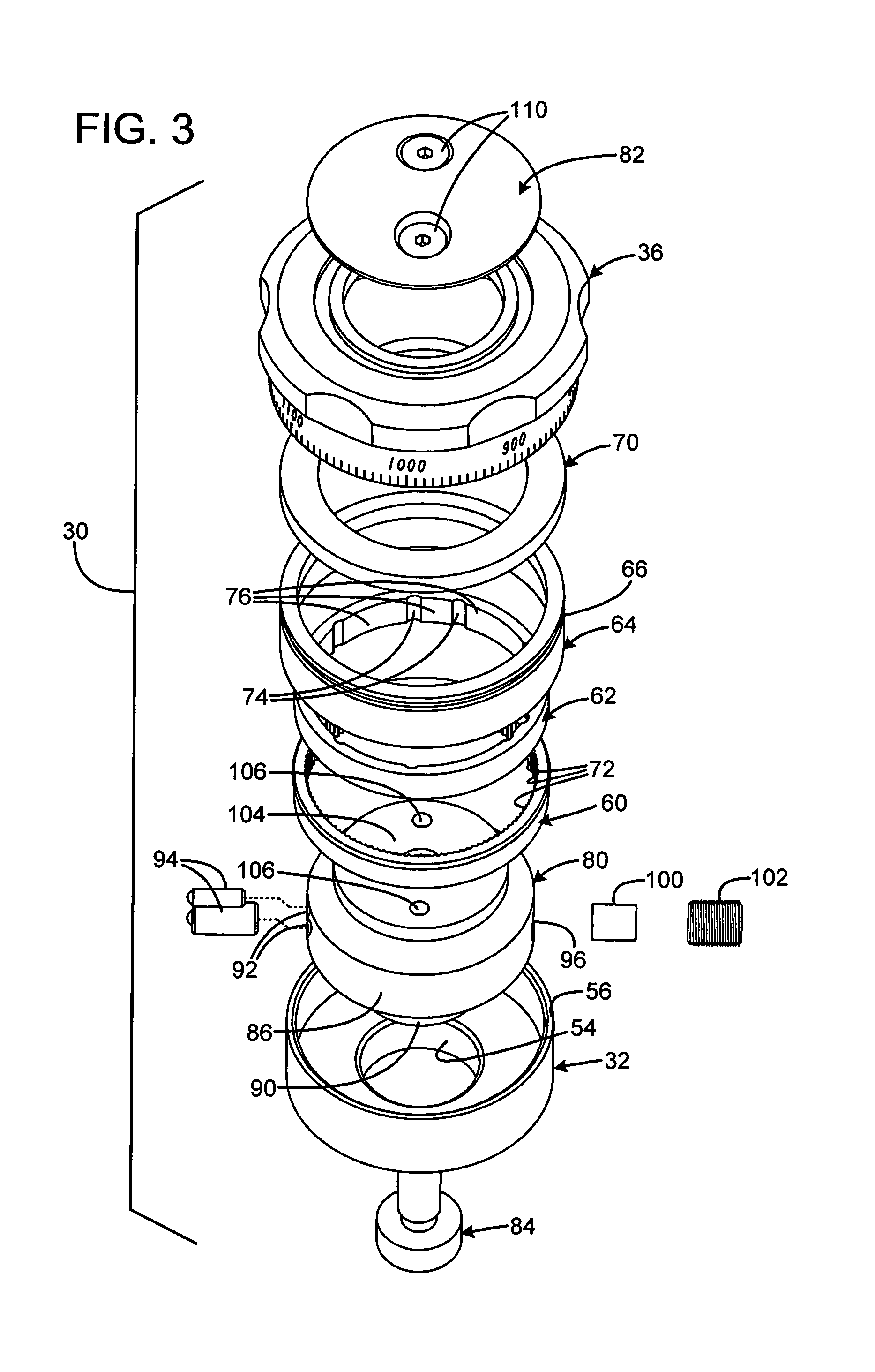

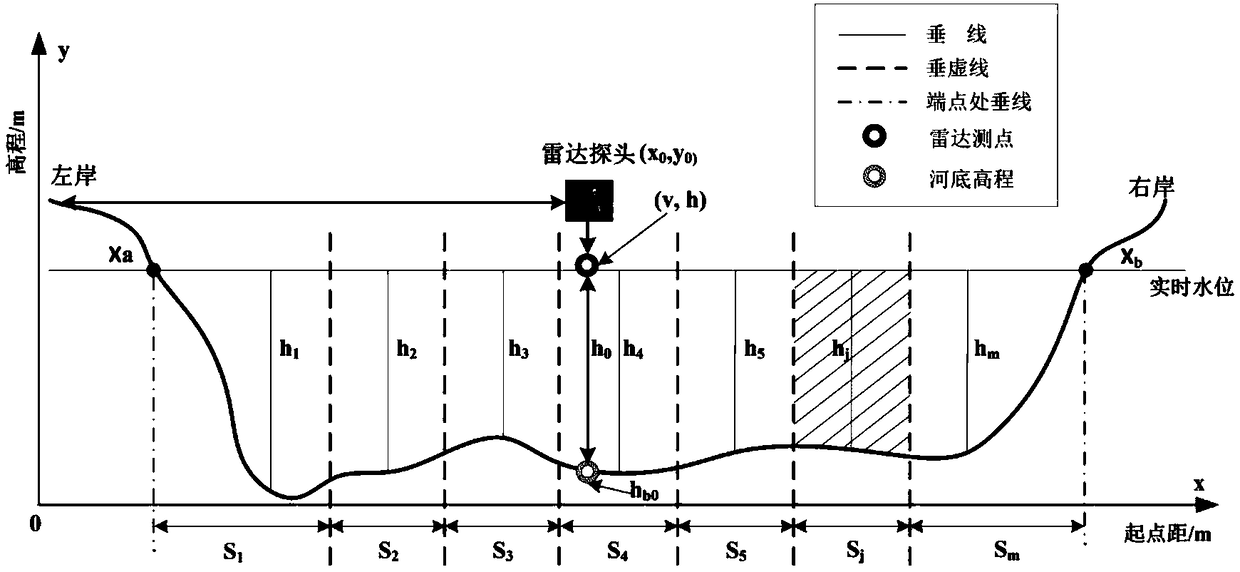

Method for calculating riverway cross-section flow measured by non-contact radar

ActiveCN109060056ASolve the problem that it is difficult to obtain cross-sectional flowMeet the requirements of high real-time traffic monitoringVolume/mass flow measurementWater resource assessmentBed roughnessMeasurement point

The invention provides a method for calculating the riverway cross-section flow measured by a non-contact radar. On a riverway cross-section on which a radar probe measurement point is located, cross-section measurement is carried out at a certain distance interval, based on the measured cross-section data, the cross-section polynomial curve fitting is carried out, and the riverway cross-section water surface slope is calculated by combining with a hydraulics manning formula according to the position of a probe, the actually-measured water level, the surface flow velocity and the bed roughness, then based on a hydraulics natural riverway flow calculation principle, a certain number of vertical lines are chosen to divide the riverway cross-section evenly, the depth of water of the verticallines and the corresponding vertical line flow velocity are calculated in sequence, and then virtual vertical lines are made in interval midpoint of each vertical line, a plurality of virtual verticallines and cross-section fitted curves and a riverway water line form a plurality of irregular polygons, the area of each polygon is calculated in sequence, and finally, a weighted area method is usedfor calculating the flow of a riverway large section. The method for calculating the riverway cross-section flow measured by the non-contact radar has important practical value for the popularizationof online flow measurement technology and the high real-time flow monitoring of flood prevention.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

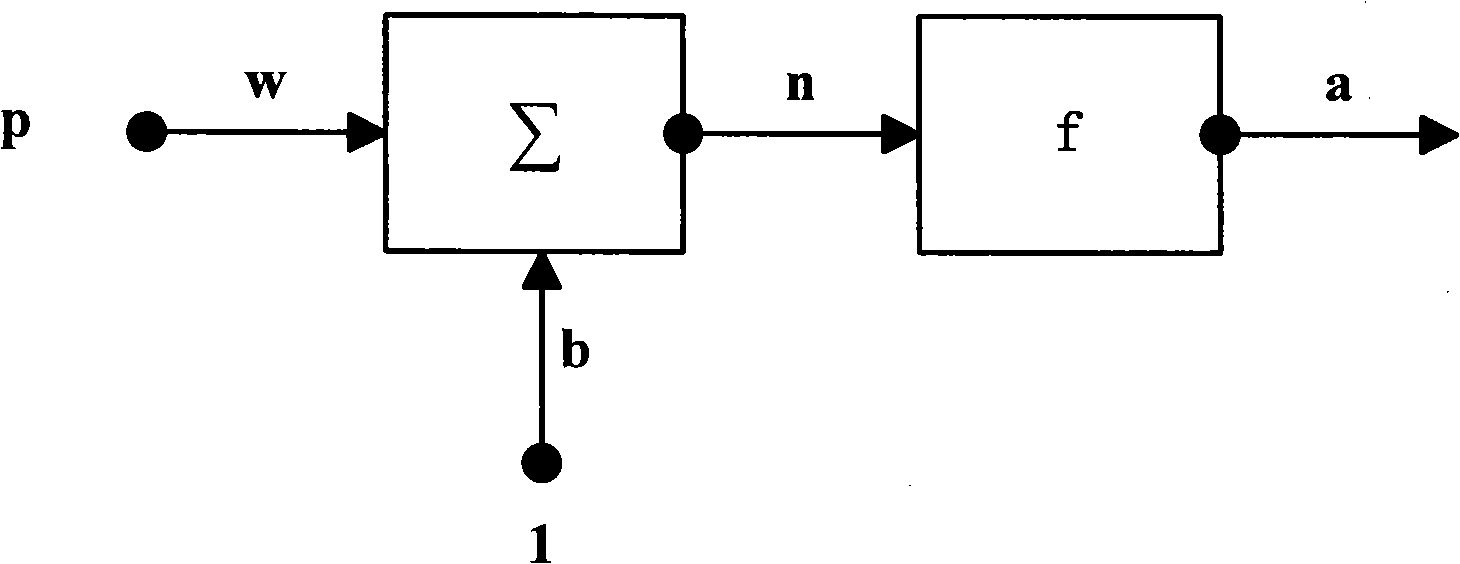

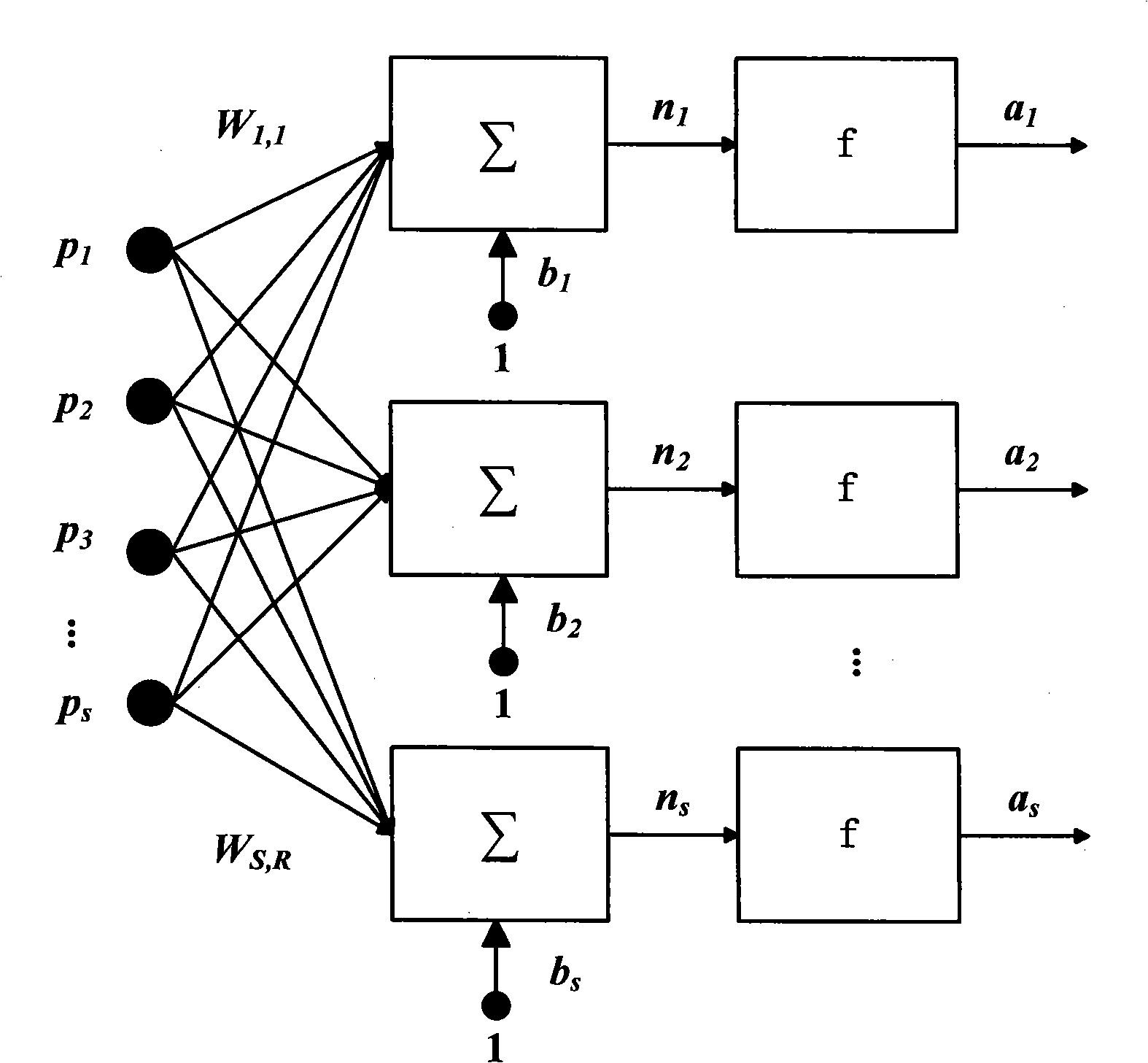

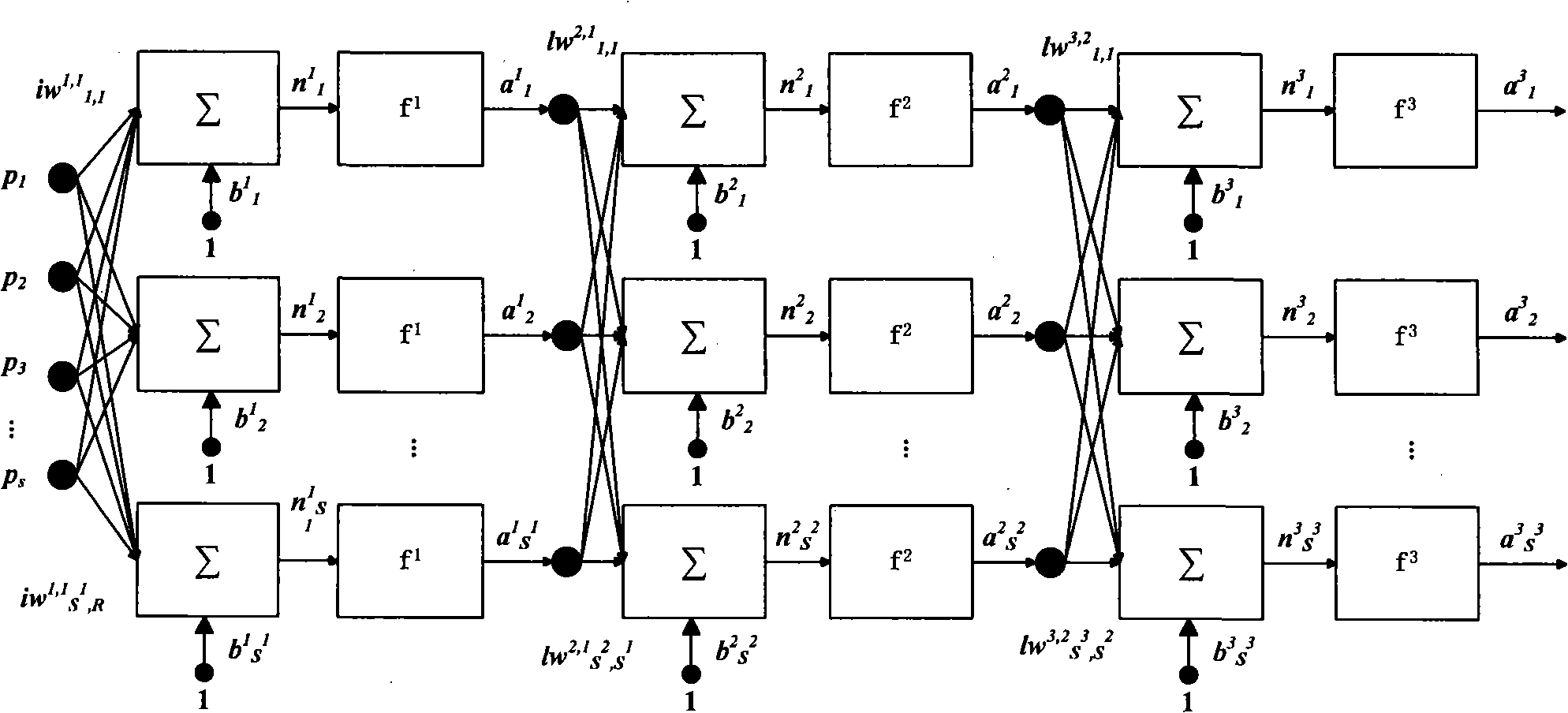

2.5D location method based on neural network and wireless LAN infrastructure

InactiveCN101267374AReduce positioning errorsThe sampling point interval is reducedData switching by path configurationPhysical realisationNerve networkData acquisition module

A positioning method based on neural network and wireless local area network basic structure is proovided, belonging to the wireless local area network client positioning. The data collecting module, database, positioning request module, positioning calculating module and positioning displaying module are arranged on the positioning server of the wireless local area network; the positioning server is accessed to AP via wireless accessing point obtaining the signal intensity information transmitted by a laptop of the client in a period of time under the predetermined distance interval and measuring time interval, and obtaining the floor number of the client and plane coordinate in real-time way by using Matlab Neural Network kit and displaying the floor number of the client and plane coordinate for the laptop of the client via web page; the signal intensity information comprises date, measuring time, identification of the wireless accessing point, client MAC and signal intensity. The average positioning error is 4.44m while the average sampling distance interval is 6.6m; the average positioning error is 2.98m while the average sampling distance interval is 3.7m, which is better than the effect of the Radar method.

Owner:TSINGHUA UNIV

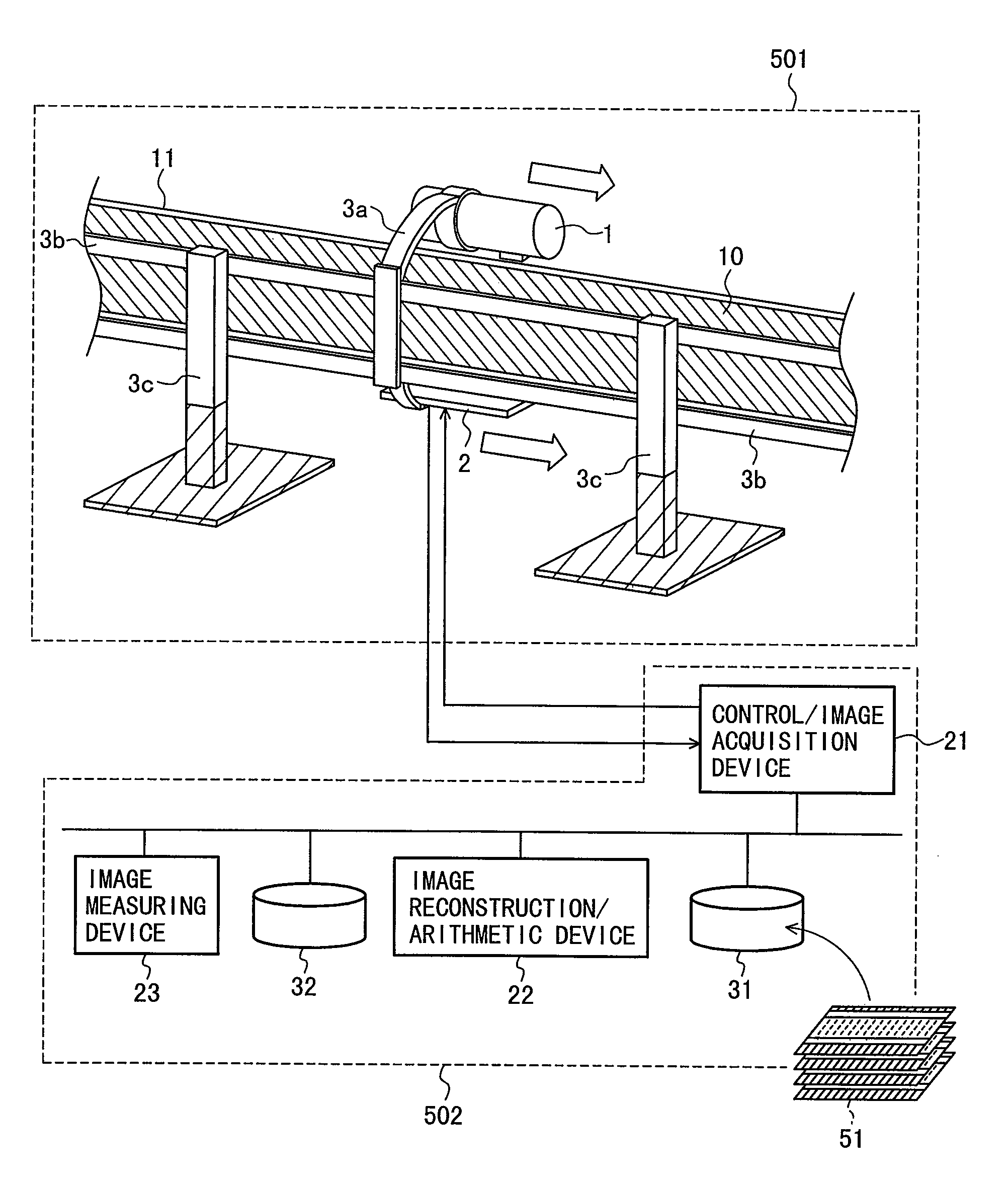

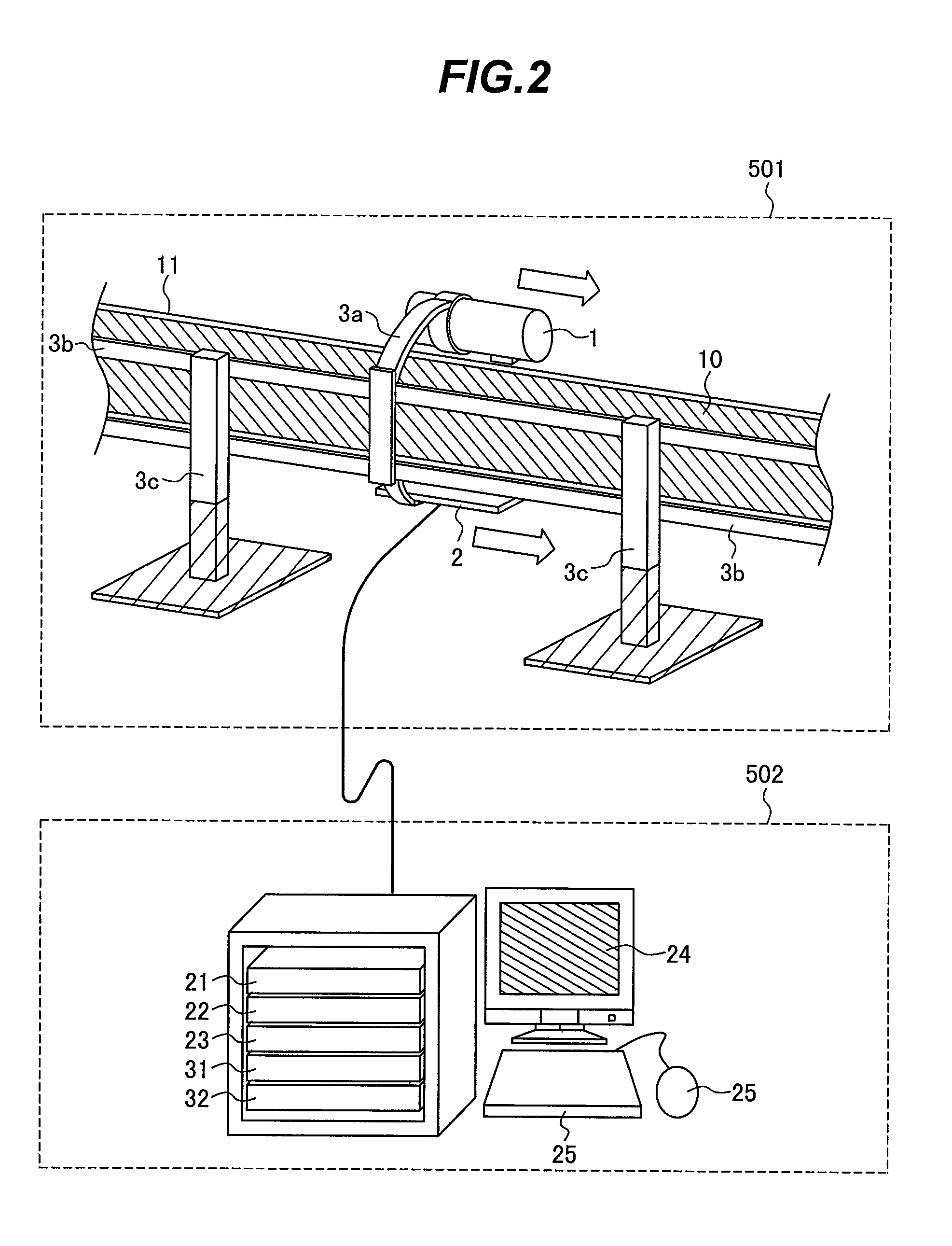

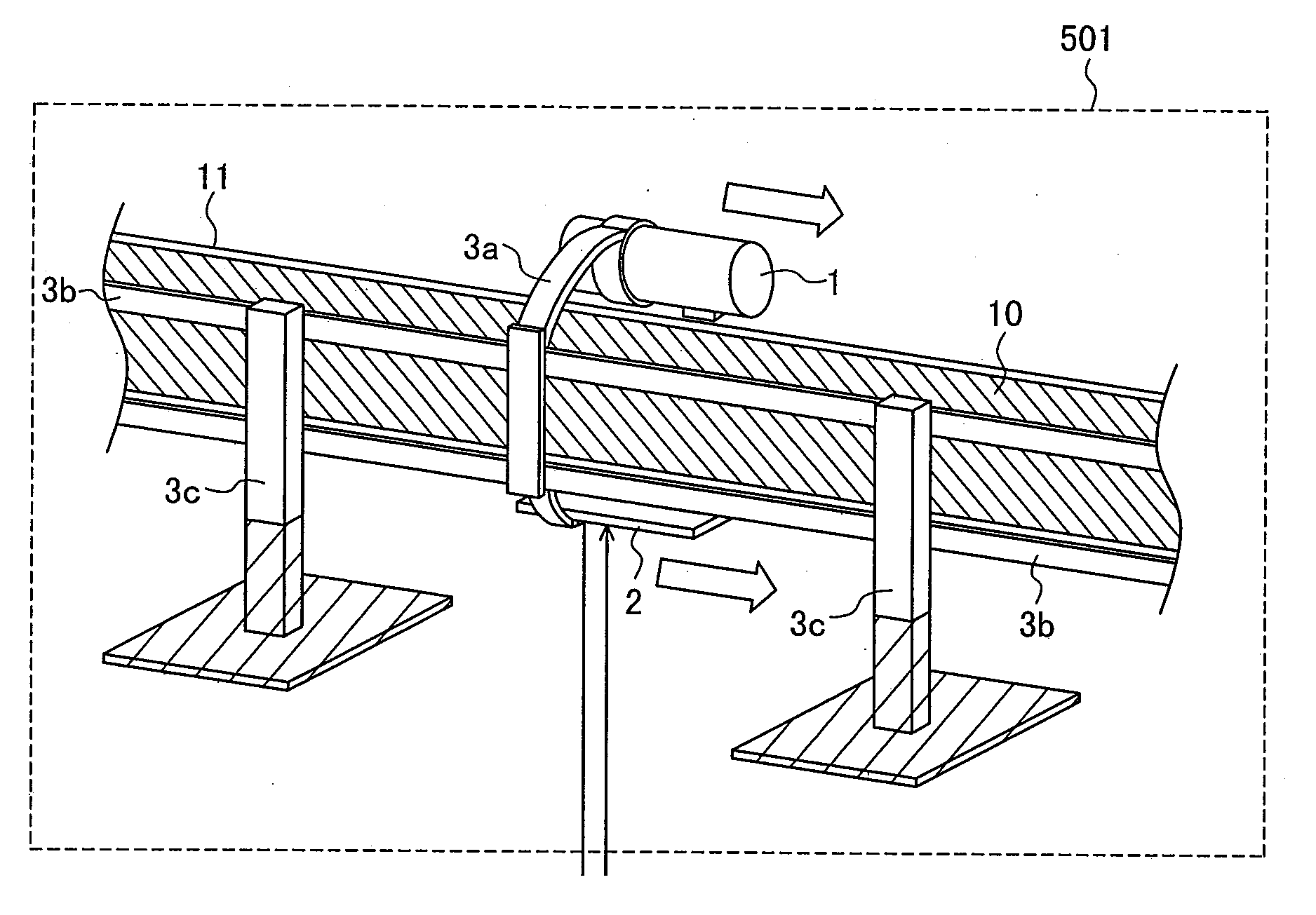

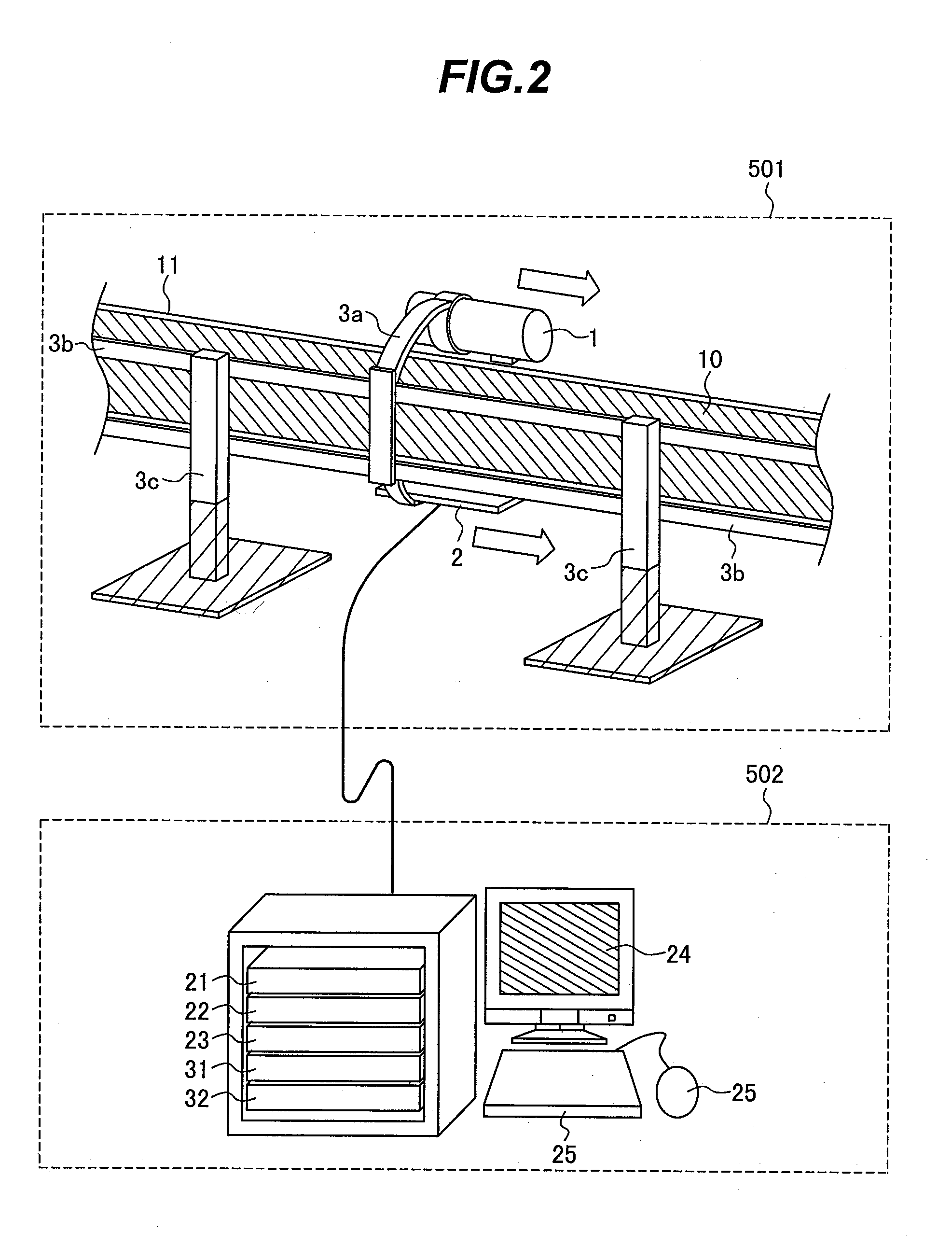

Method for inspecting pipes, and radiographic non-destructive inspection apparatus

ActiveUS7885381B2Improve inspection efficiencyX-ray/infra-red processesRadiation/particle handlingNon destructiveFractography

The pipe inspection method and apparatus can be used to implement rapid, tomographic inspection of a pipe set up at a narrow location. The pipe inspection method includes: a first step for scanning the pipe by translating a radiation source and radiation detector arranged opposedly to the pipe; a second step for the radiation detector to detect radiation that the radiation source has emitted, at given scanning distance intervals; a third step for creating a transmission image of the pipe, based on a radiation dose that the radiation detector has detected; and a fourth step for constructing a tomogram or stereoscopic image of the pipe, based on the transmission image. Thus, it is possible to provide the pipe inspection method and apparatus that can be used to implement rapid, tomographic inspection of the pipe set up at a narrow location.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Method for inspecting pipes, and radiographic non-destructive inspection apparatus

ActiveUS20080267345A1Improve inspection efficiencyX-ray/infra-red processesRadiation/particle handlingNon destructiveFractography

The pipe inspection method and apparatus can be used to implement rapid, tomographic inspection of a pipe set up at a narrow location. The pipe inspection method of the present invention includes: a first step for scanning the pipe by translating a radiation source and radiation detector arranged opposedly to the pipe; a second step for the radiation detector to detect radiation that the radiation source has emitted, at given scanning distance intervals; a third step for creating a transmission image of the pipe, based on a radiation dose that the radiation detector has detected; and a fourth step for constructing a tomogram or stereoscopic image of the pipe, based on the transmission image. According to this invention, it is possible to provide the pipe inspection method and apparatus that can be used to implement rapid, tomographic inspection of the pipe set up at a narrow location.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

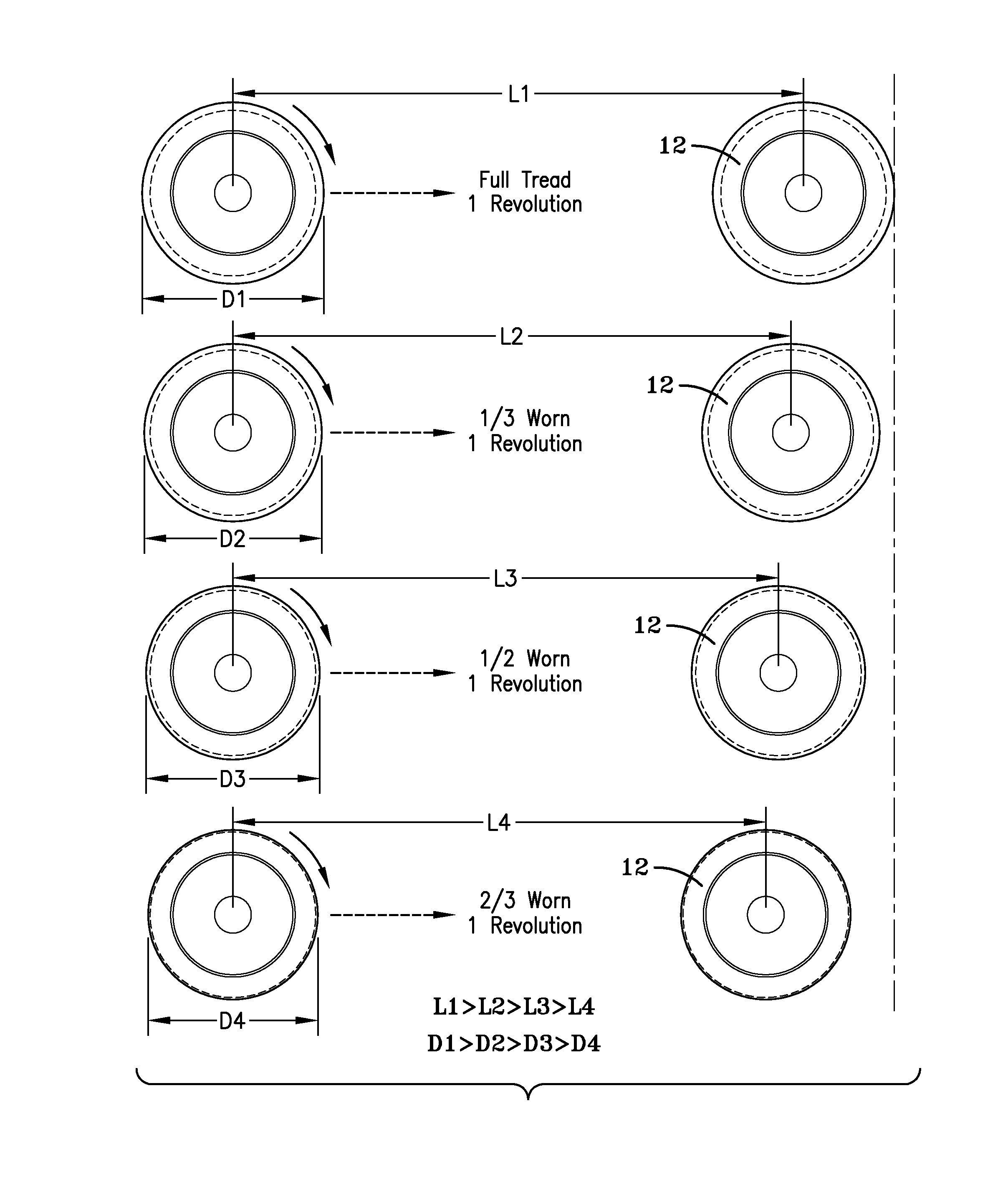

Tread wear estimation system and method

ActiveUS20170023441A1Great tractionError minimizationTyre measurementsTyre tread bands/patternsLow speedEffective radius

A tire wear state estimation system for a tire calculates tire effective radius during measured distance intervals travelled by the tire from vehicle speed and tire rotation counters. The system includes a filter for selecting slow-speed effective radius measuring intervals and an estimator for estimating the tire effective radius during only those intervals in which the vehicle is travelling below a threshold speed.

Owner:THE GOODYEAR TIRE & RUBBER CO

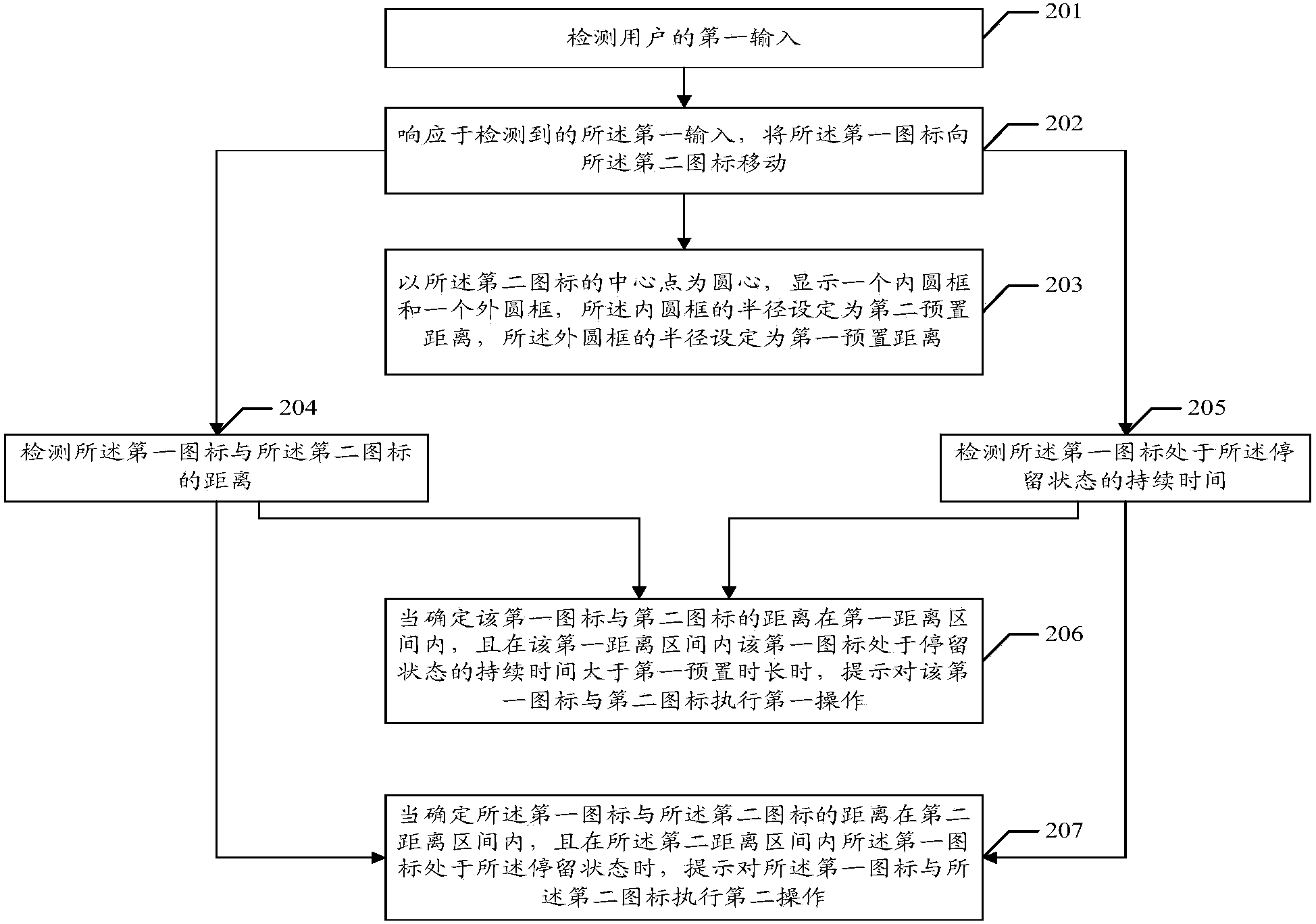

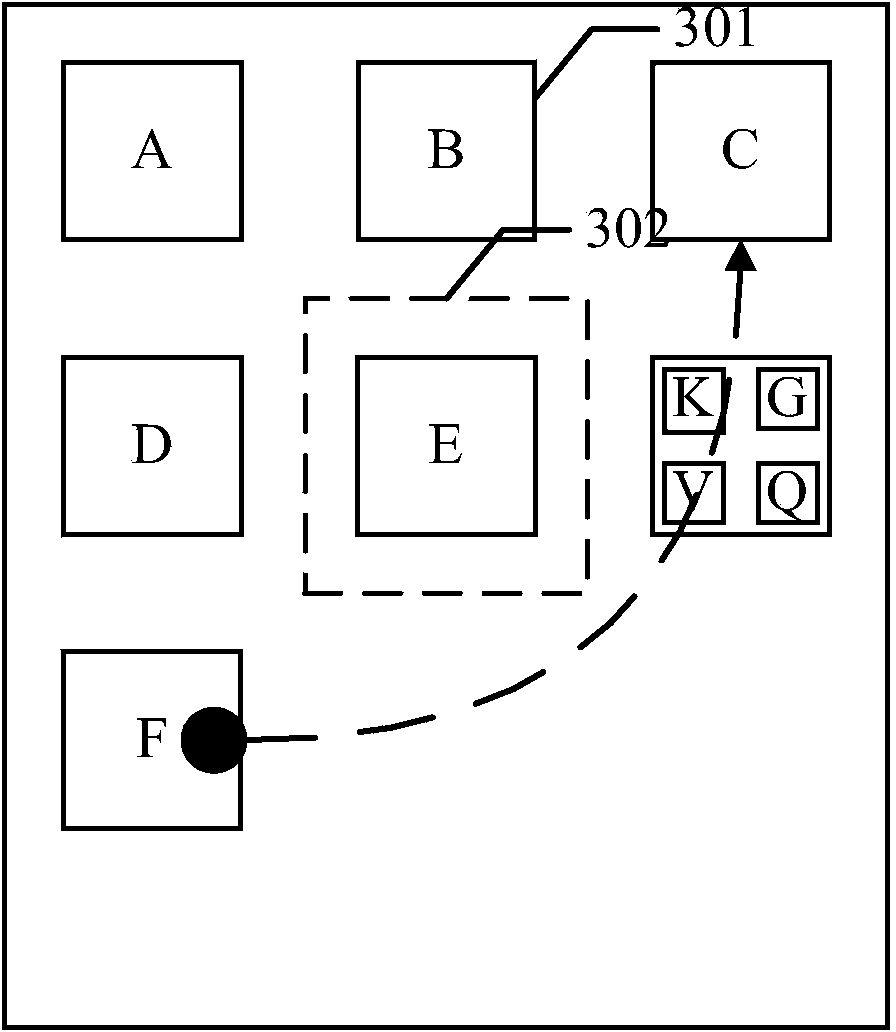

Icon control method and terminal

ActiveCN104238877AReduce the probability of false responsesImprove interactivityInput/output processes for data processingHabitComputer terminal

The embodiment of the invention discloses an icon control method and a terminal, which are used for solving the problem of terminal error response during the icon dragging by a user on the precise of not influencing the existing operation habit of the user. The method provided by the embodiment of the invention comprises the following steps that a first input of the user is detected, the detected first input is responded, a first icon moves to a second icon, when the distance between the first icon and the second icon is determined to be in a first distance interval, and in addition, the duration of the first icon in the first distance interval in the retaining state is greater than the first preset duration, the operation of executing a first operation on the first icon and the second icon is prompted, and when the distance between the first icon and the second icon is determined to be in a second distance interval, and in addition, the first icon in the second distance interval is in the remaining state, the operation of executing a second operation on the first icon and the second icon is prompted.

Owner:HUAWEI TECH CO LTD

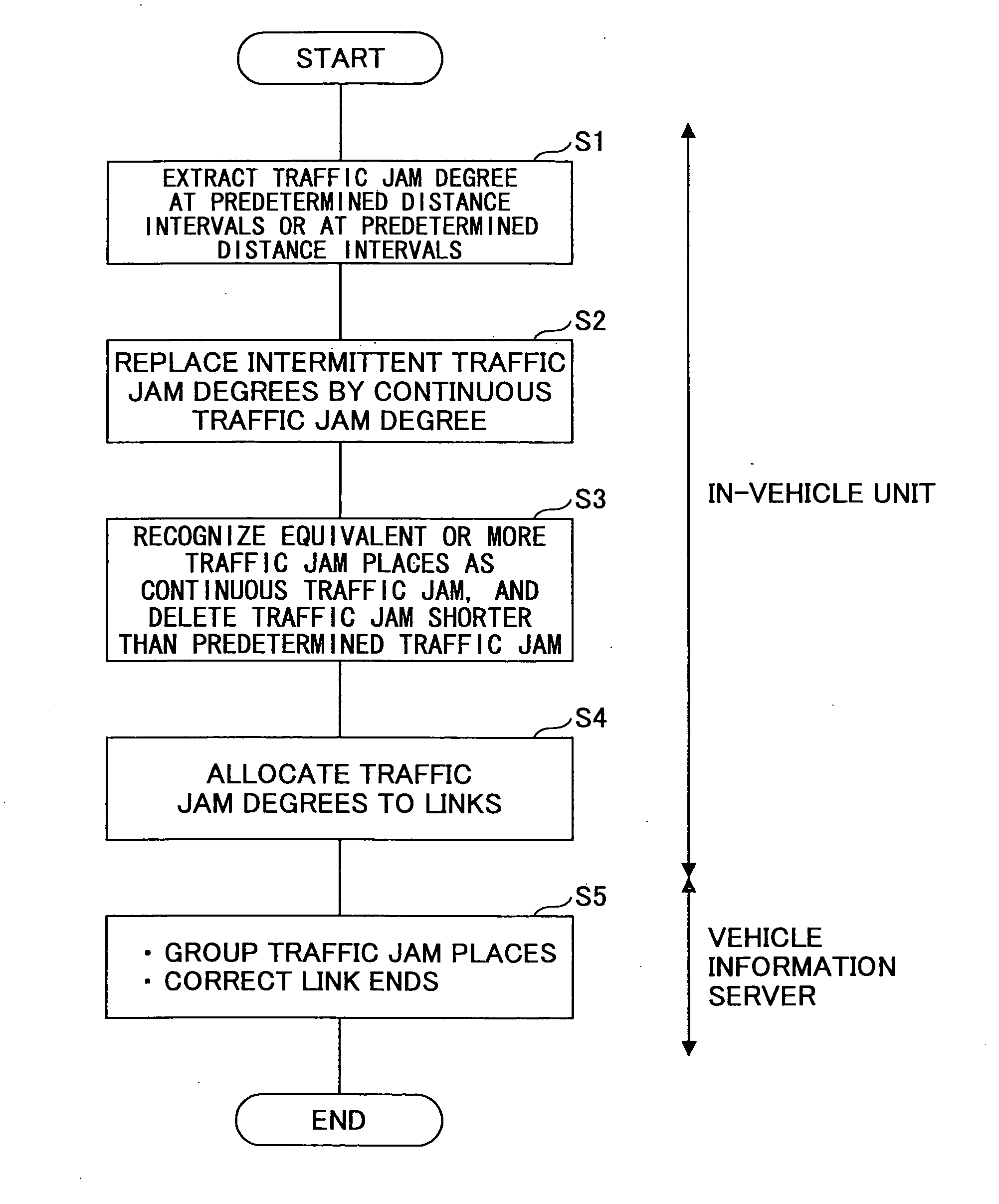

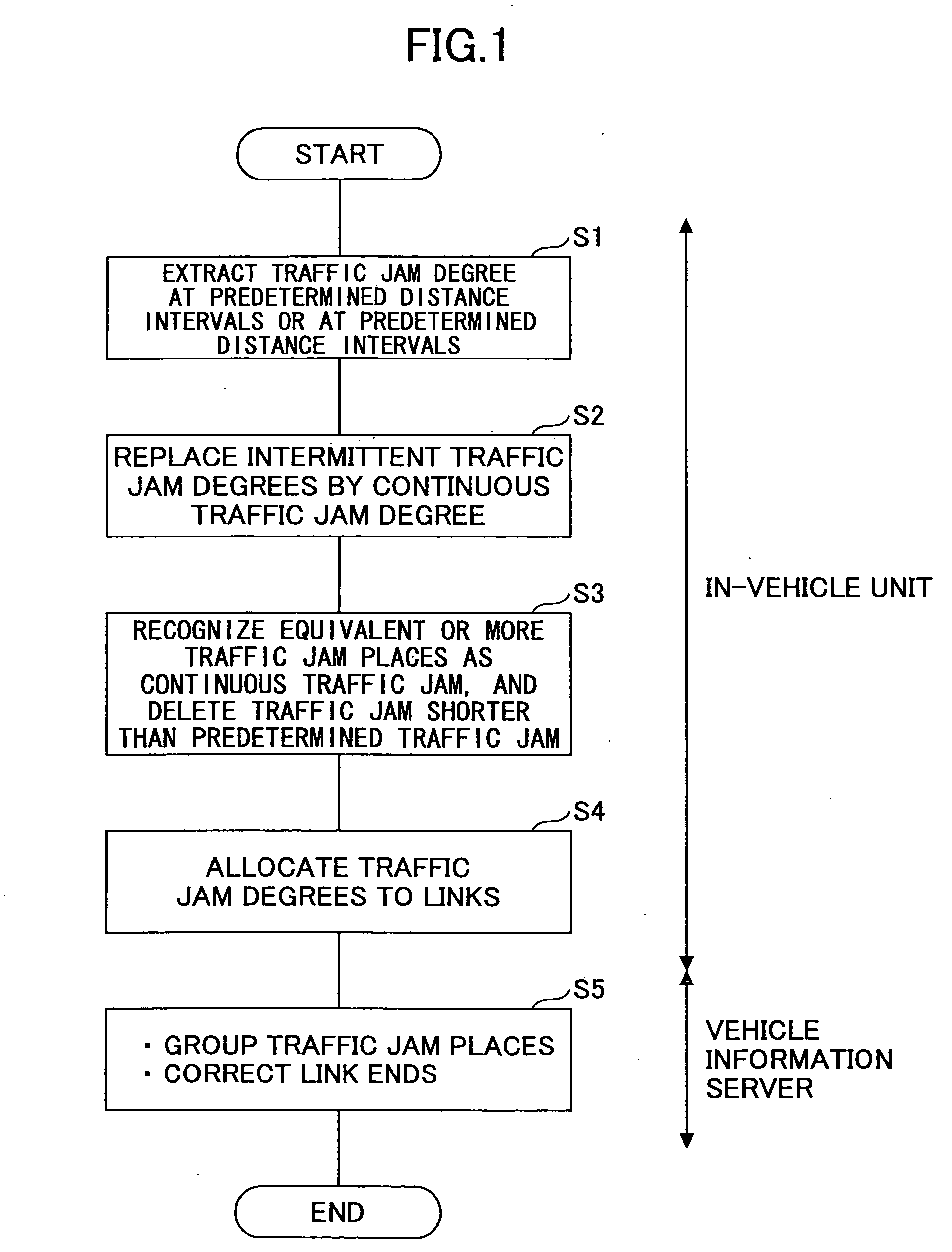

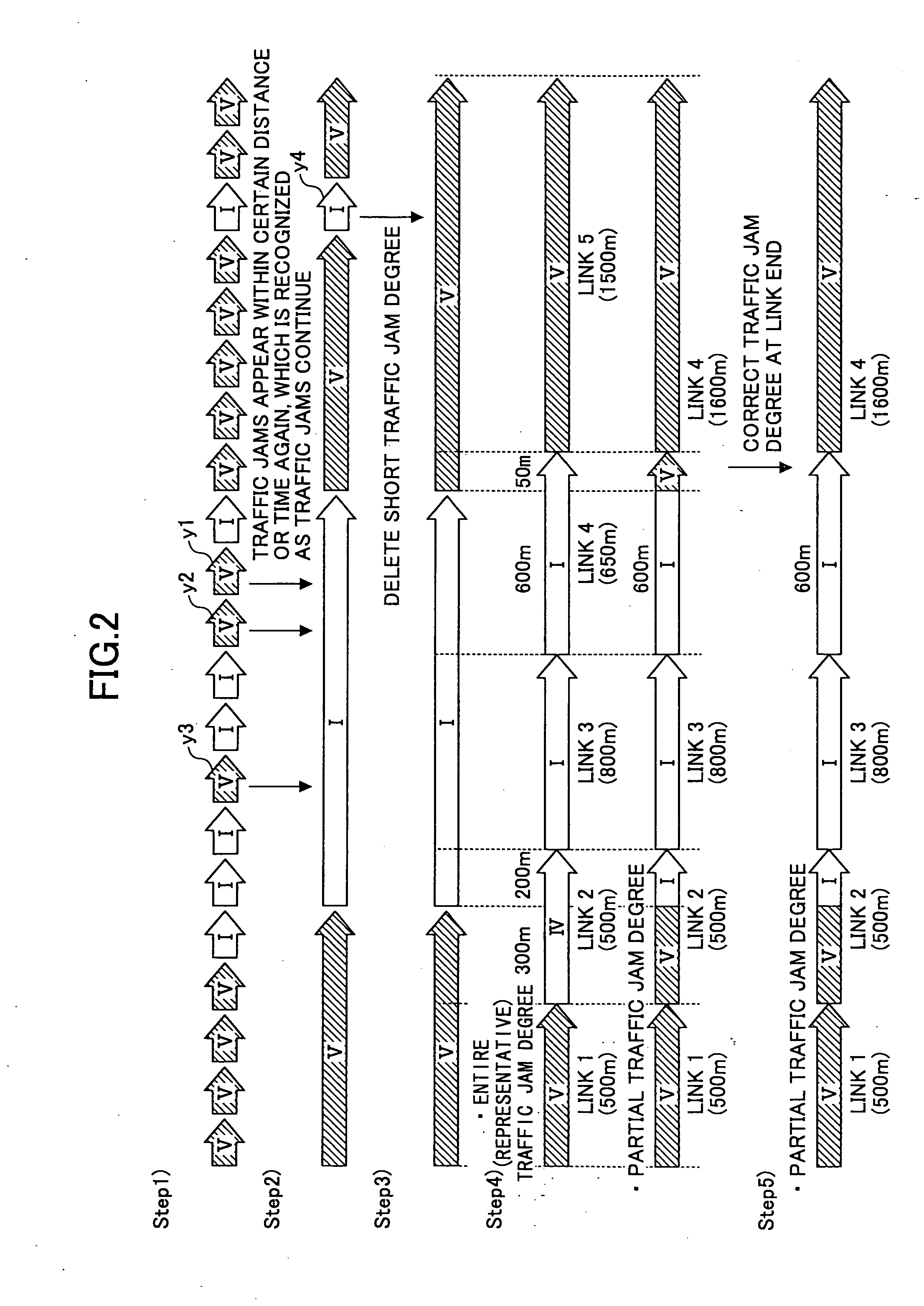

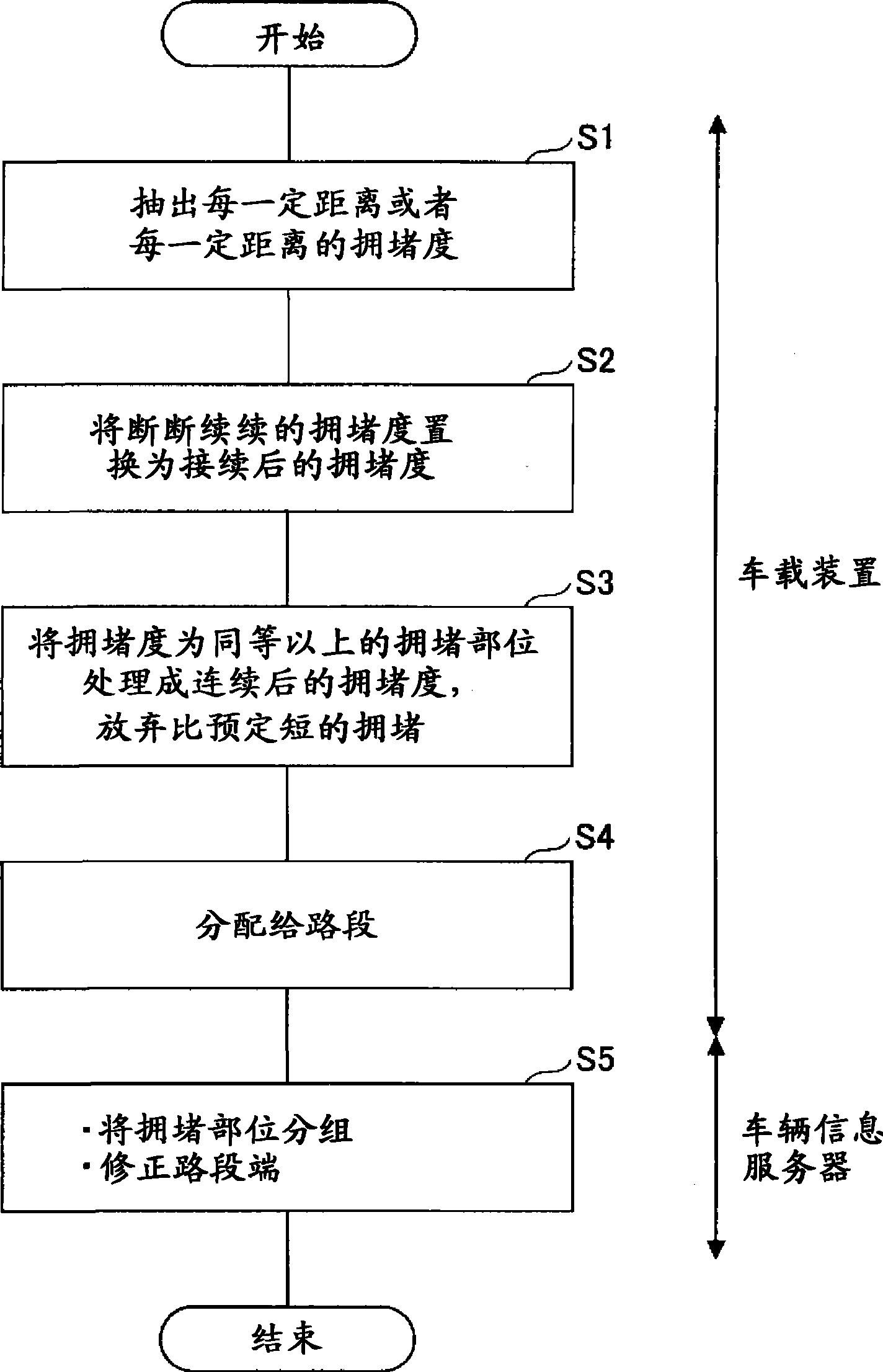

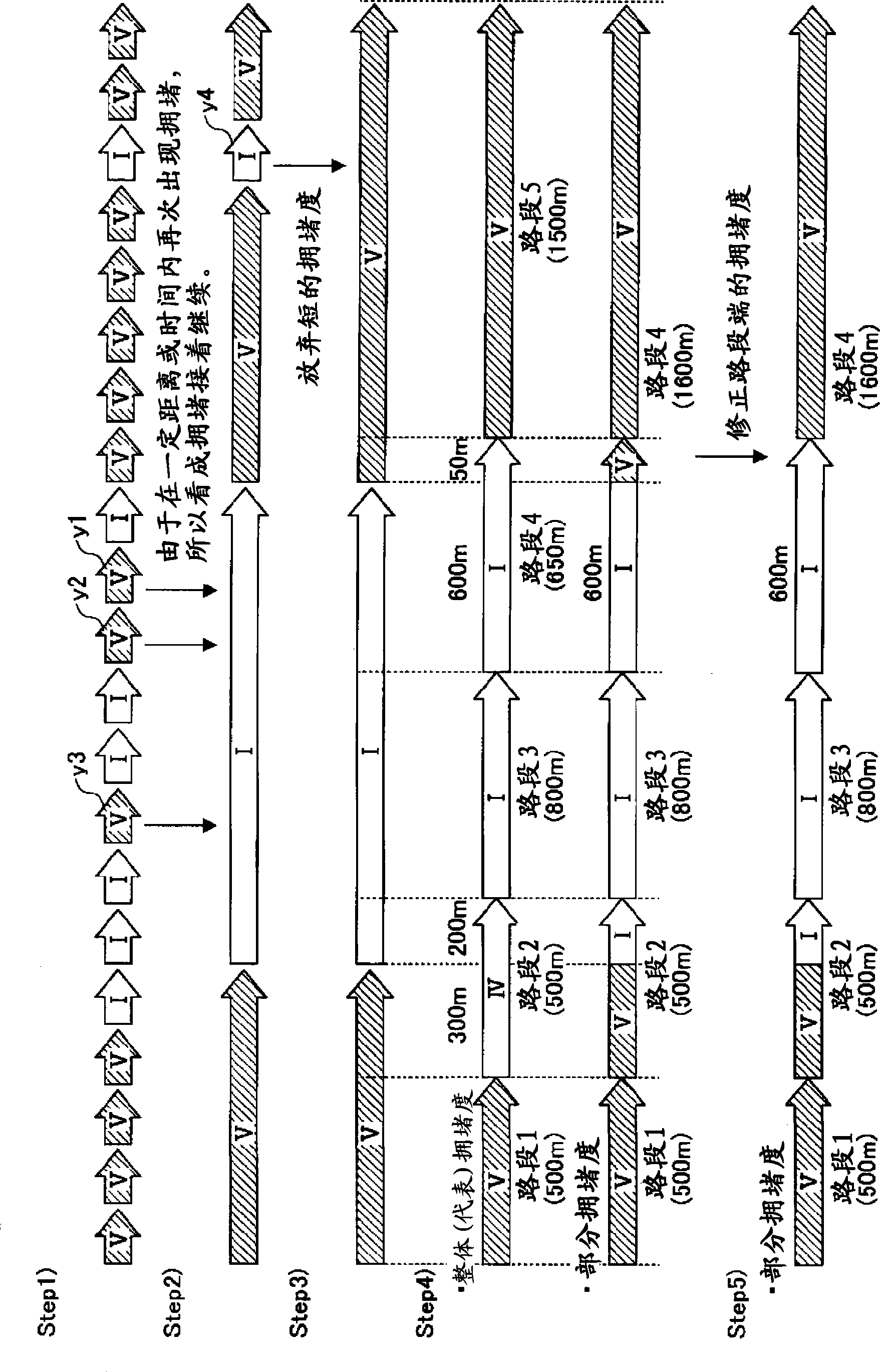

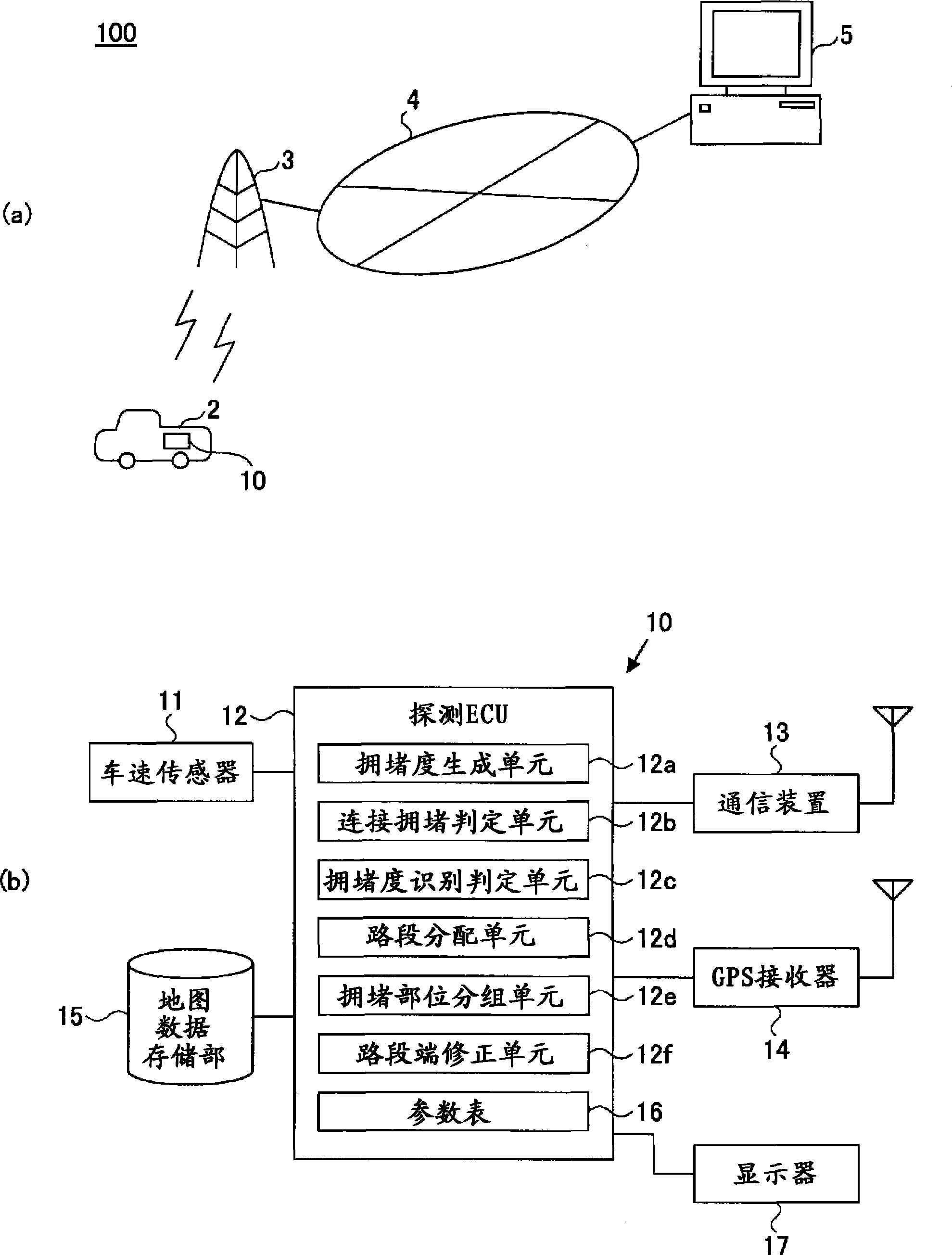

Traffic information generation method, traffic information generation device, and navigation system

ActiveUS20100138141A1Eliminate reductionControlling traffic signalsAnalogue computers for vehiclesTraffic congestionEngineering

Owner:AISIN AW CO LTD +1

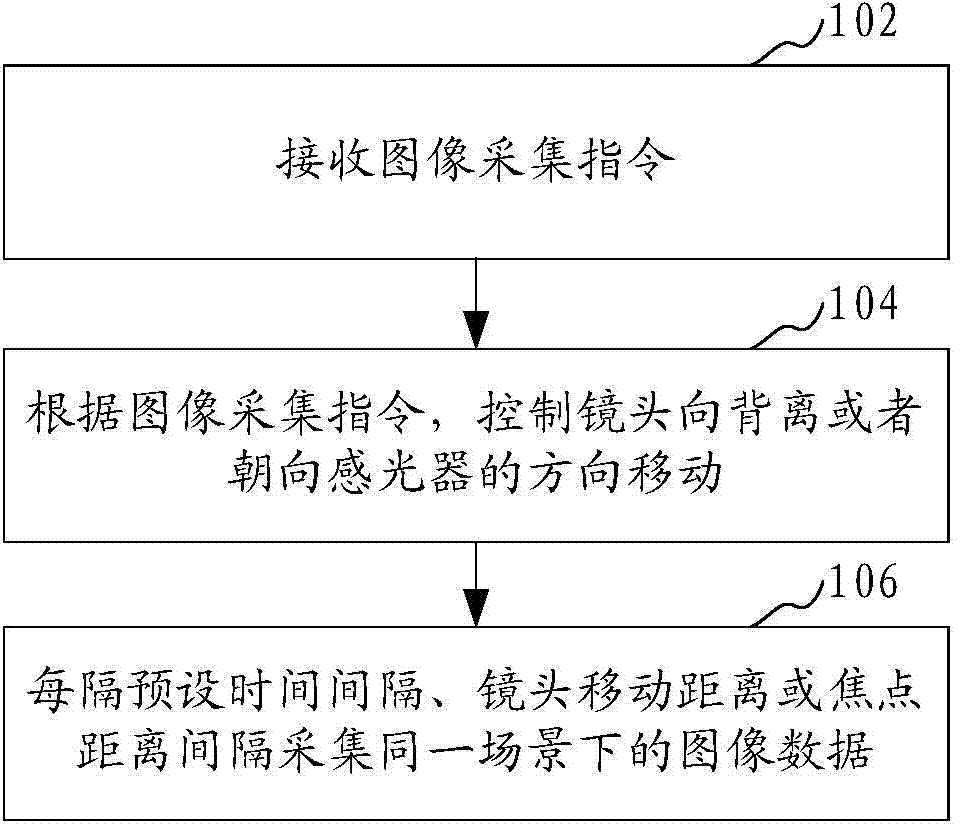

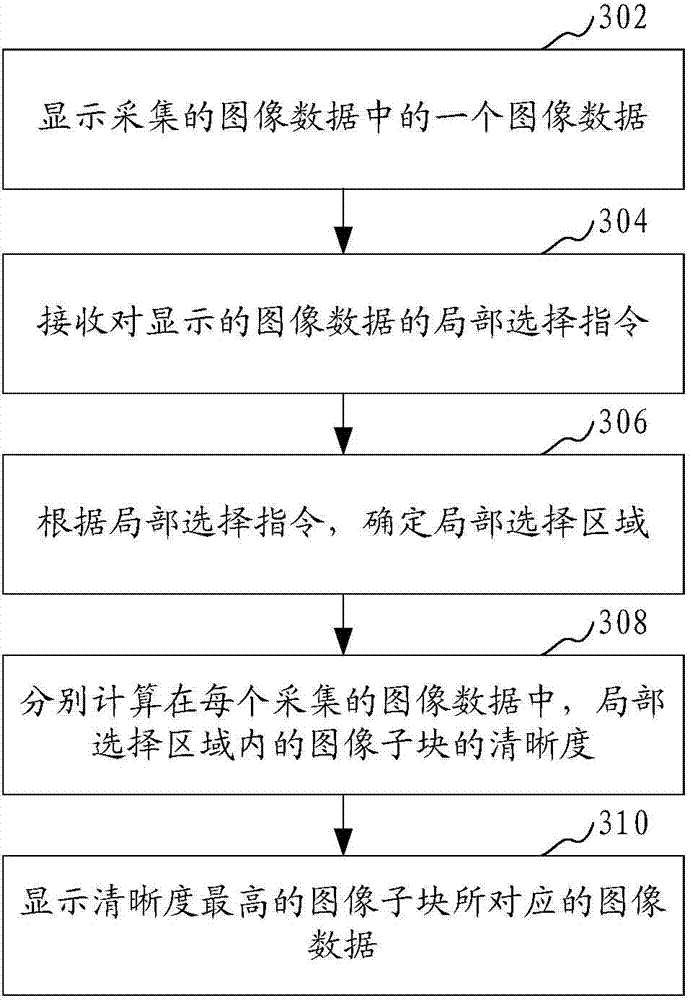

Method and terminal for acquiring image data

The invention provides a method and terminal for acquiring image data. The method comprises the steps of receiving an image acquisition instruction; controlling a lens to move in the direction facing to a photosensitive device or away from the photosensitive device according to the image acquisition instruction; acquiring the image data at the same scene at preset time intervals and at lens moving distance or focus distance intervals. According to the acquisition method and terminal for image data, due to the fact that the image data acquired when an object is located in the field depth range of a focus are clear, multiple image data corresponding to different focuses at the same scene are acquired, and the possibility that the object at the scene is located in the field depth range of one of the focuses can be greatly increased, so that the clear image data can be obtained.

Owner:MEIZU TECH CO LTD

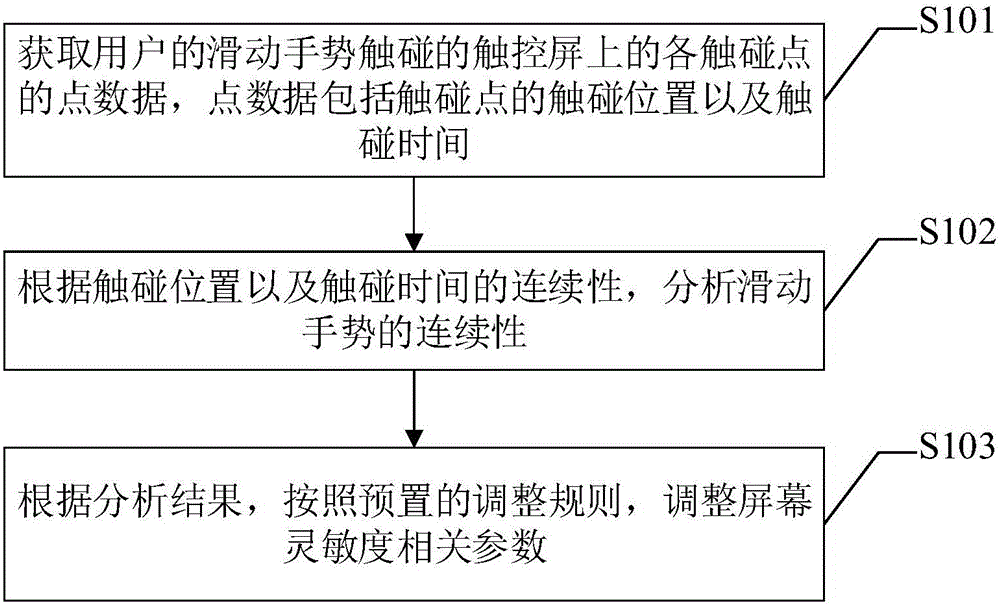

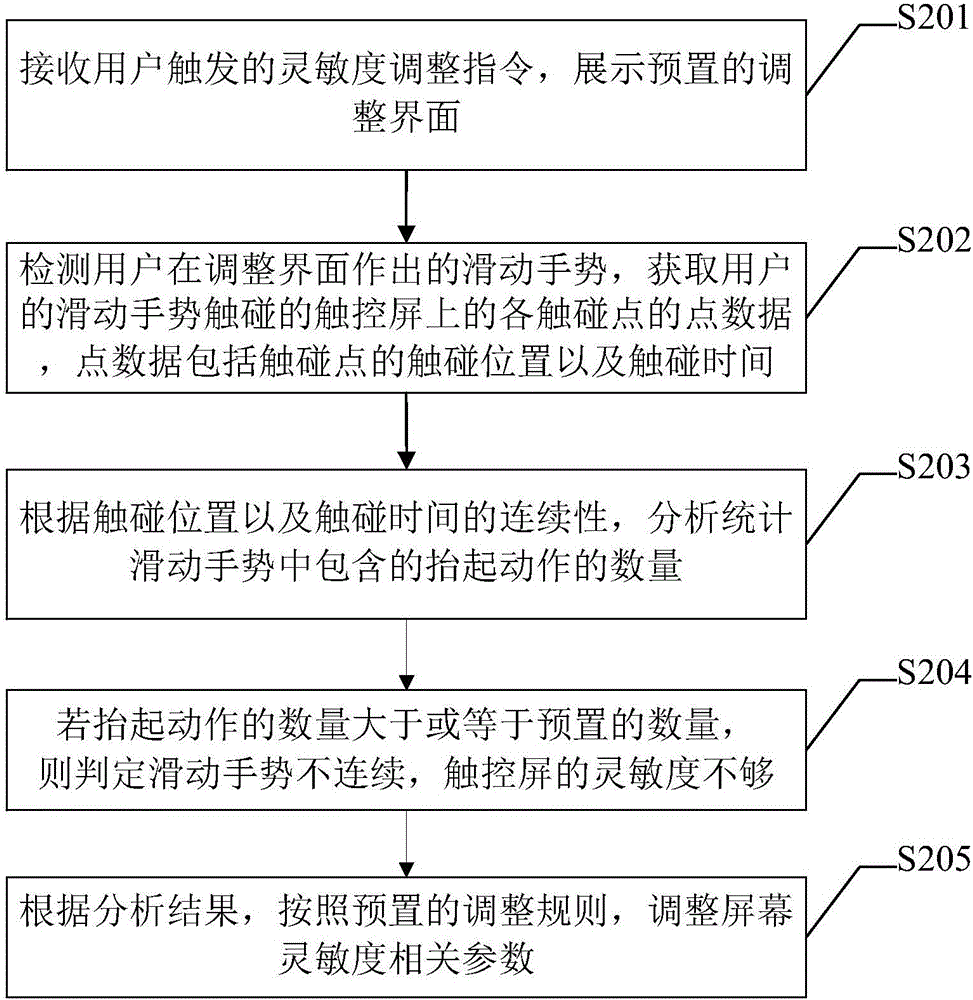

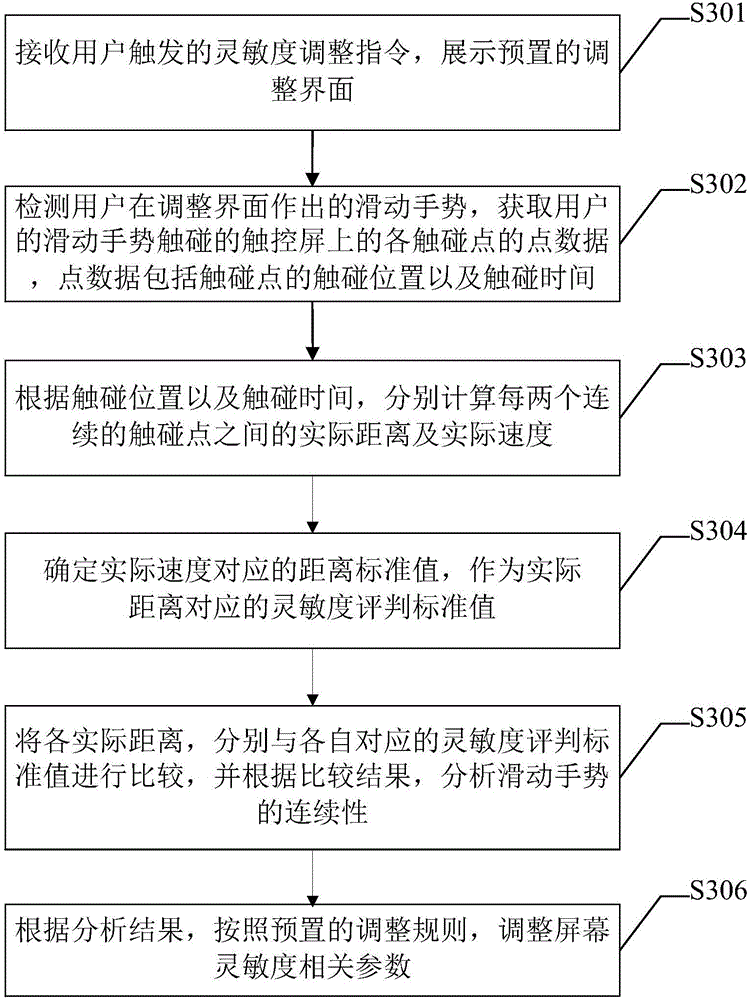

Touch screen sensitivity adjustment method and device

ActiveCN105807997AMeet needsImprove experienceInput/output processes for data processingCapacitanceTouchscreen

The invention discloses a touch screen sensitivity adjustment method and device. The method comprises following steps of obtaining point data of each touch point on a touch screen touched by the slide gesture of a user, wherein the point data comprises touch positions and touch time of the touch points; analyzing the continuity of the slide gesture according to the continuity of the touch positions and the touch time; and adjusting screen sensitivity related parameters according to analyzing results and preset adjusting rules, wherein the screen sensitivity related parameters comprise a shortest touch time interval, a shortest touch distance interval and a touch capacitance change threshold. According to the method and the device, the touch screen sensitivity can be automatically adjusted according to the features of the slide gesture of the user, and the touch screen sensitivity adaptive flexibility can be improved.

Owner:BEIJING ZHUMU LANGMA MOBILE COMM CO LTD

Traffic information creating method, traffic information creating device, display, navigation system, and electronic control unit

InactiveCN101490730ADetection of traffic movementVehicle position indicationDisplay deviceNavigation system

The invention provides a traffic information creating method creating traffic information on a road where a vehicle (2) is travelling. The method includes: a vehicle speed detection step (S1) for detecting a vehicle speed at a predetermined distance interval or a predetermined time interval by a vehicle speed sensor (11); and a congestion degree detection step (S1-3) for referencing a predetermined speed, a predetermined distance number, and a connection judgment distance number correlated to a congestion degree indicating the degree of congestion so as to detect the congestion degree based on the vehicle speed.

Owner:TOYOTA JIDOSHA KK +1

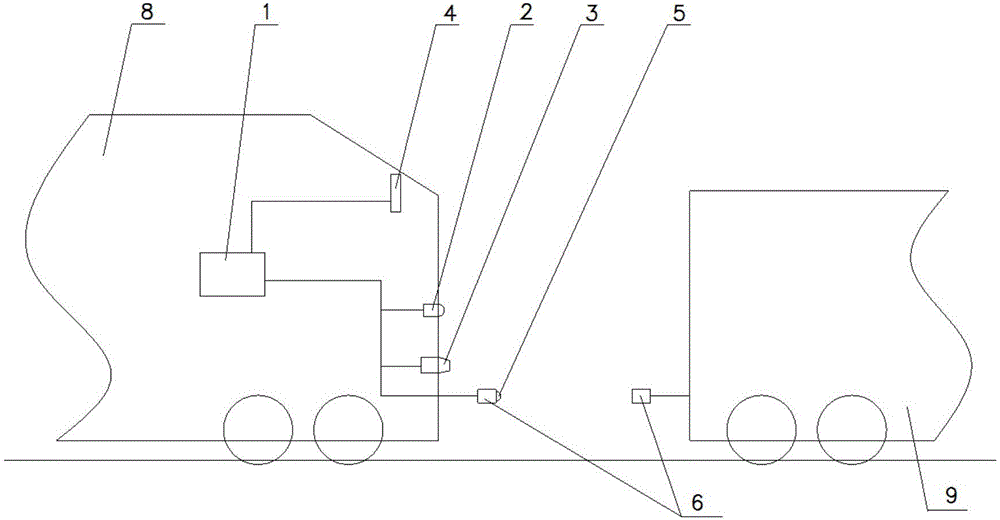

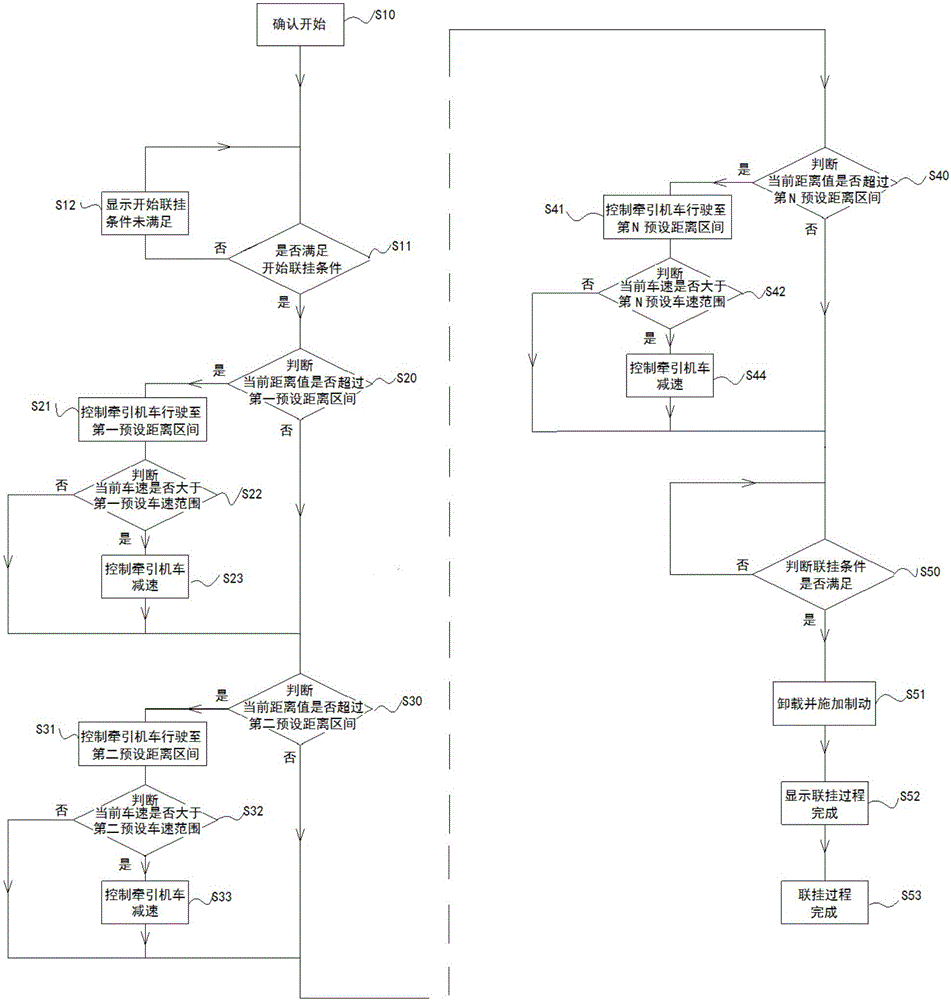

Locomotive as well as automatic linkage hooking control method and device

ActiveCN106379366AStable connectionImprove ride comfortSignalling indicators on vehicleClosed circuit television systemsSimulationHooking

The invention discloses an automatic linkage hooking control method used for a locomotive. The method comprises the following steps of obtaining the initial state of a traction locomotive; when the initial state meets a linkage hooking starting condition, detecting a distance between the traction locomotive and a back trailer; comparing a current distance value with at least two preset distance intervals corresponding to different speed ranges respectively, determining a preset distance interval to which the current distance value belongs, and controlling the traction locomotive to run in the car speed range corresponding to the preset distance interval; when the traction locomotive meets a linkage hooking condition, applying braking to and carrying out linkage hooking operation on the traction locomotive. The invention also discloses an automatic linkage hooking control device used for the locomotive. The invention also discloses the locomotive comprising the automatic linkage hooking control device. By using the automatic linkage hooking control method, linkage hooking operation steps can be simplified; the linkage hooking impact is reduced; the riding comfort of a driver is improved; the operation time wasted due to the failure of linkage hooking is saved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

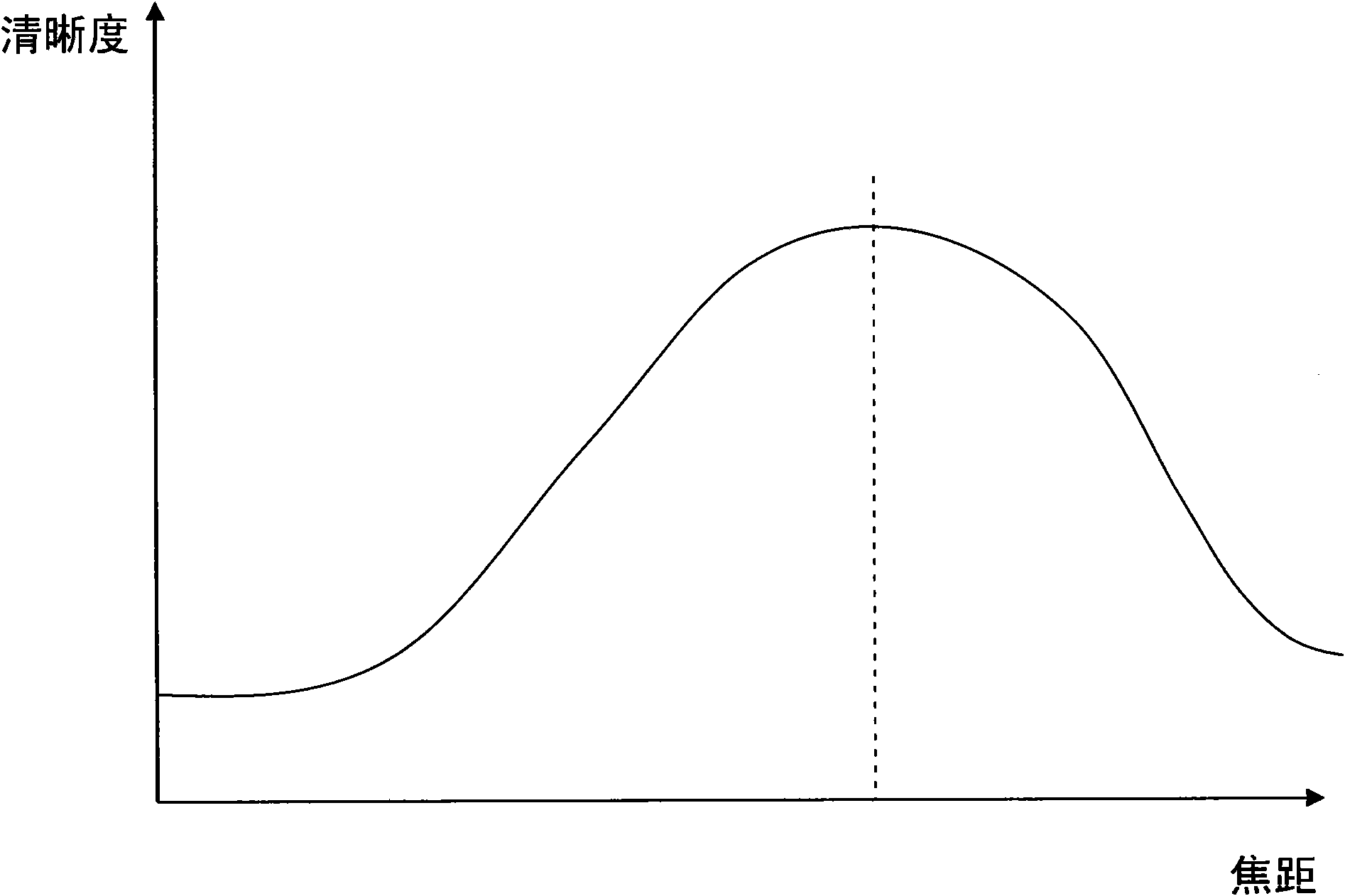

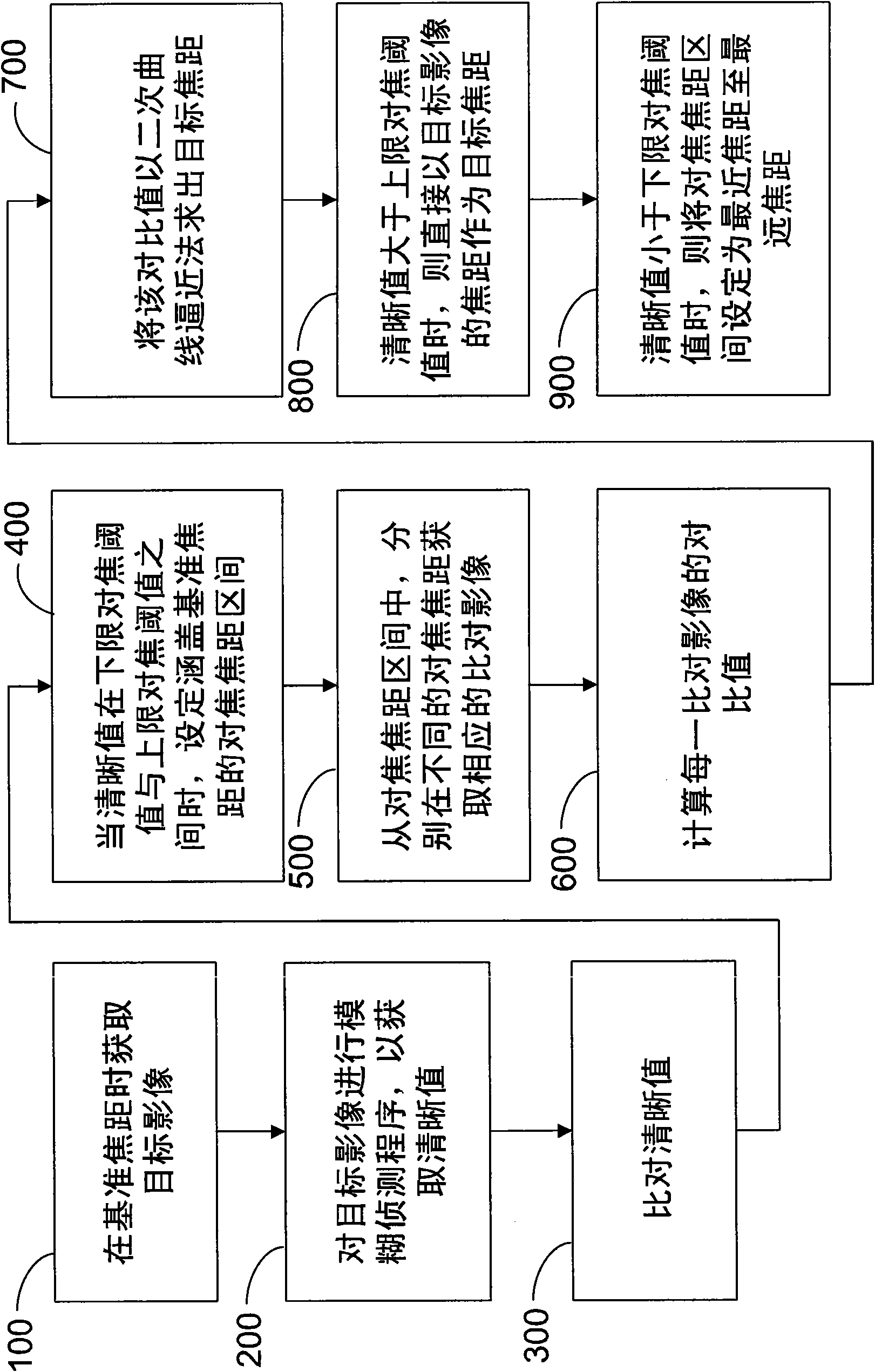

Quick focusing method of digital camera

The invention discloses a quick focusing method of a digital camera, used for judging whether focusing focal distance of the digital camera is necessary to be adjusted when the digital camera is in an auto focusing stage. The quick focusing method comprises the following steps: obtaining a target image when the digital camera is at reference focal distance; performing a fuzzy detection program on the target image to obtain a clearness valve; setting a focusing focal distance interval containing the reference focal distance when the clearness value is between a lower limit focusing threshold and an upper limit focusing threshold; respectively obtaining corresponding comparison images at different focusing focal distances in the focusing focal distance interval; calculating a comparison value of each comparison image; and solving the comparison value and a target focal distance by a quadratic curve approximation method, and performing photographing actions after adjusting a lens of the digital camera to the set target focal distance.

Owner:ALTEK CORP

Method for the exchange of data

ActiveUS7664464B2Less actionEffective distributionChecking apparatusDigital data authenticationTelecommunicationsCommunication unit

Owner:INVENTIO AG

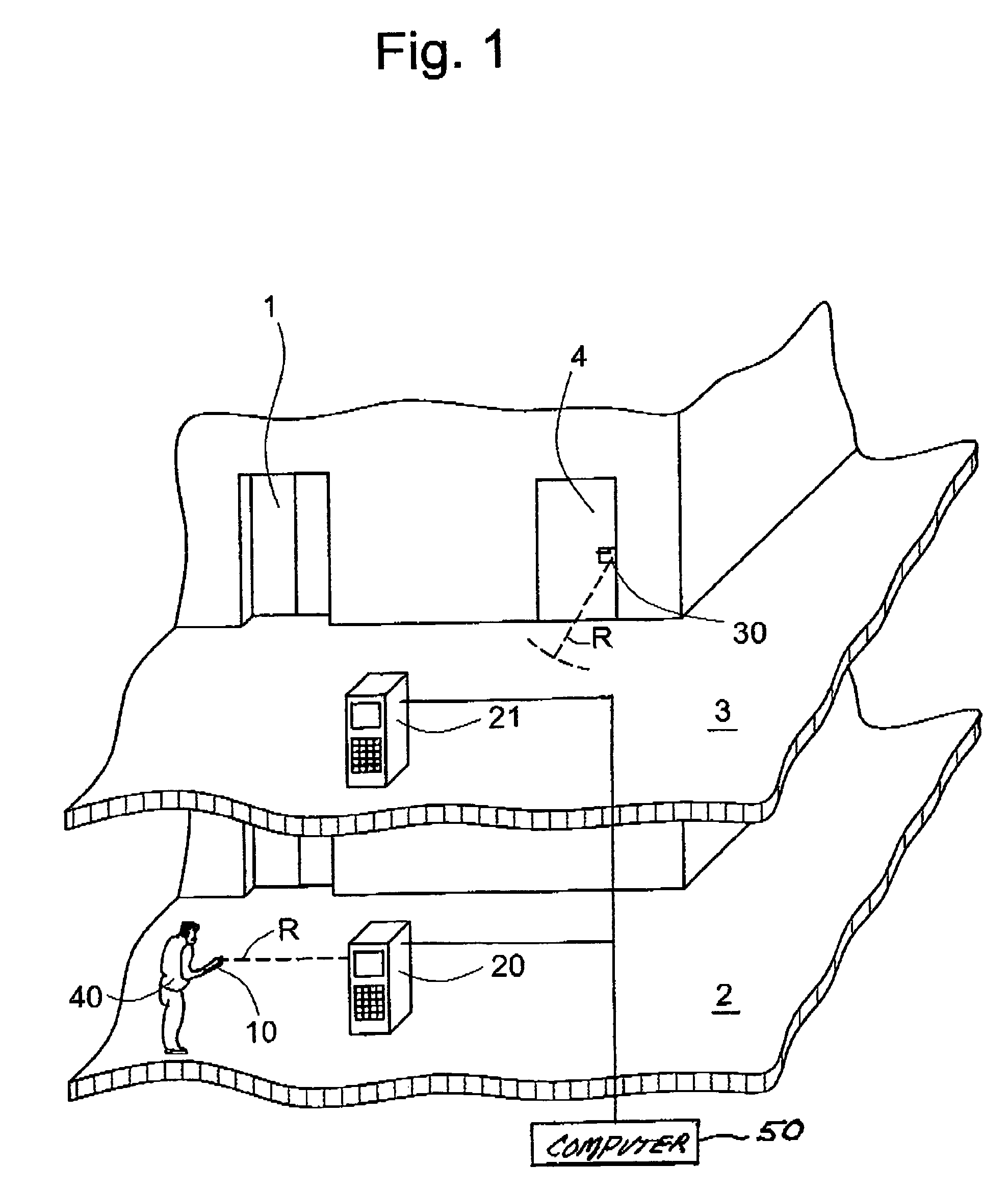

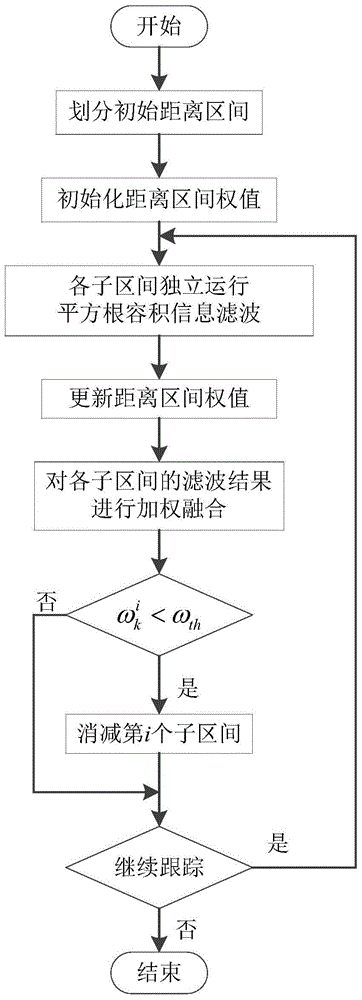

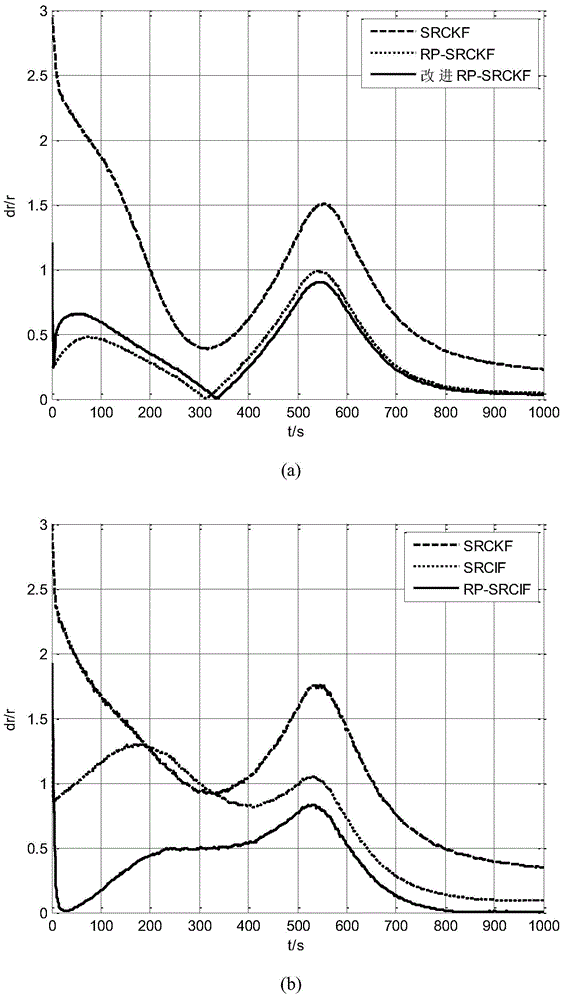

Multiple-unmanned aerial vehicle cooperative passive location method based on improved distance parameterization

InactiveCN104833949AEliminate indeterminate problemsImprove robustnessPosition fixationUncrewed vehicleErrors and residuals

The invention provides a multiple-unmanned aerial vehicle cooperative passive location method based on improved distance parameterization. First, an initial distance interval is divided, and the weight of the distance interval is initialized; then, squared root cubature information filtering is performed separately on the sub intervals, and the weight of the distance interval is updated; and weighted fusion is performed on filtering results of all the sub intervals to obtain a final location result. The problem that the covariance matrix is not positive definite due to round-off error of a computer is eliminated, and the robustness of the filtering method is improved. Compared with a traditional distance parameterization method, the amount of calculation of the adopted improved distance parameterization method is greatly reduced. The influence of the initial filtering value to the location performance is avoided effectively, and the real-time performance of the filtering method is improved. Information filtering under a fully distributed fusion estimation structure makes fusion estimation calculation easier and improves the location accuracy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

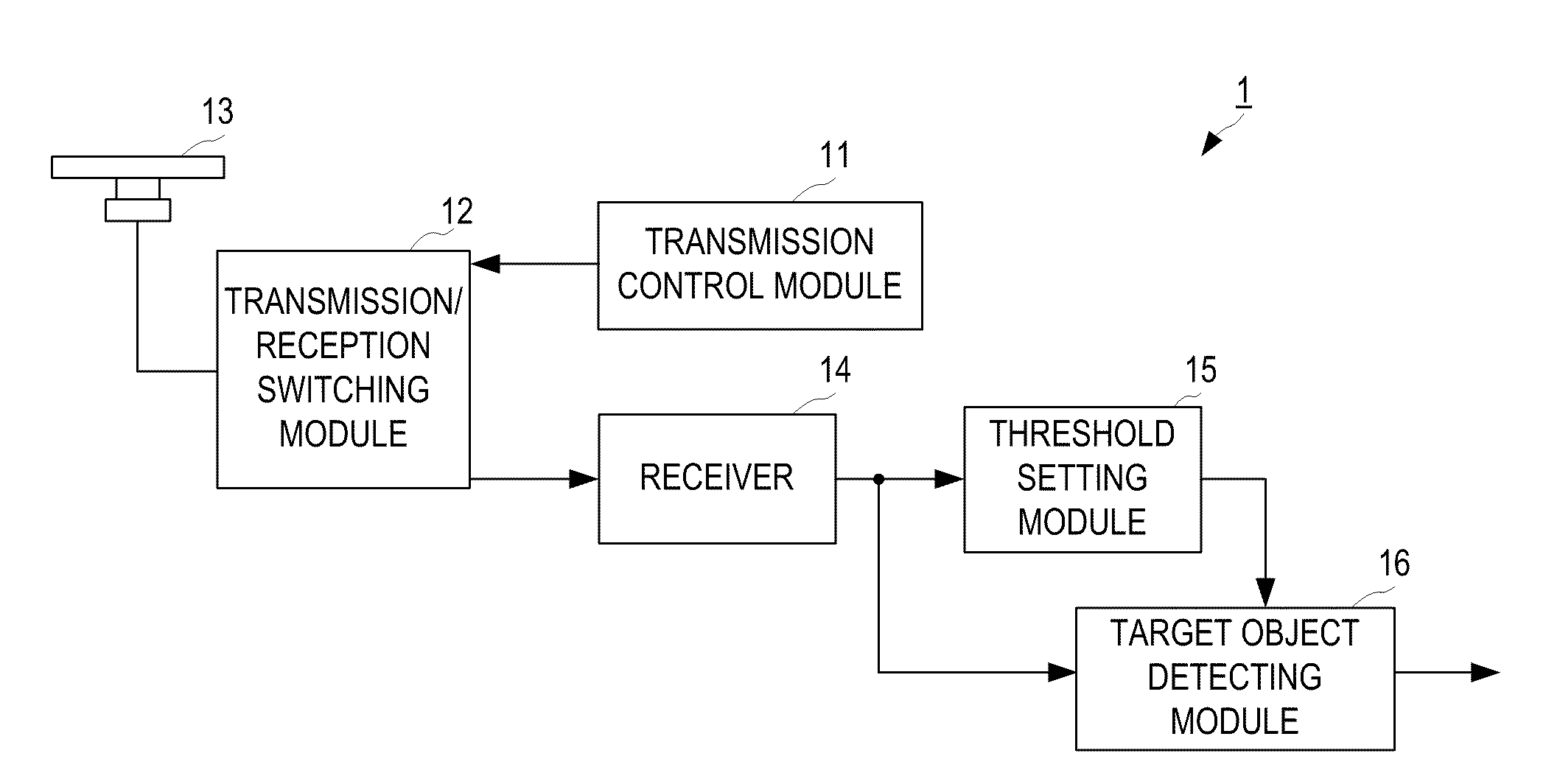

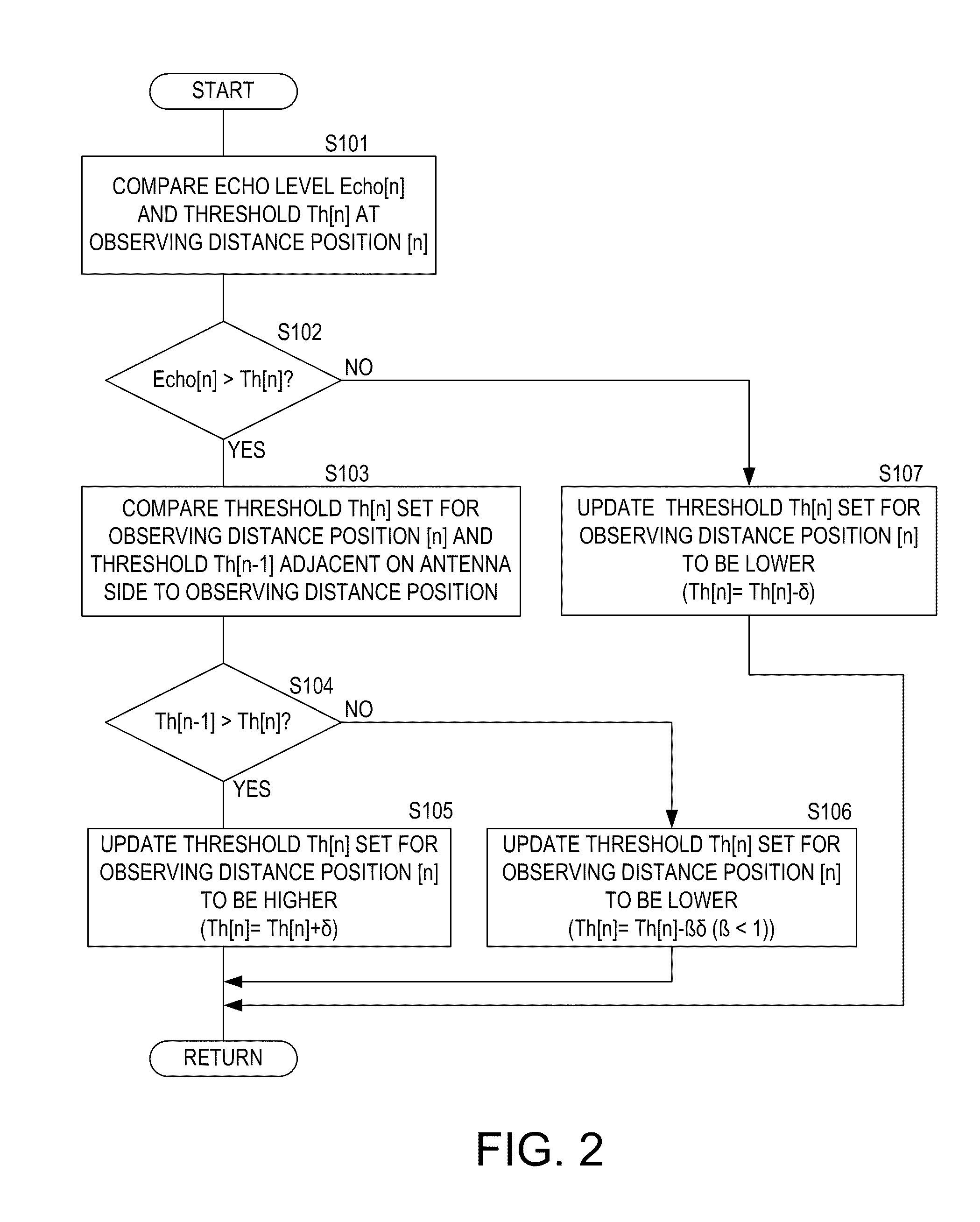

Method, device and program for setting threshold, and method, device and program for detecting target object

InactiveUS20120007767A1Accurate settingSolve the complicated settingRadio wave reradiation/reflectionComputer scienceEcho signal

This disclosure provides a method of setting a threshold according to a level of an echo signal containing an unused component. The echo signal is generated by transmitting and receiving a radio wave with an antenna while the antenna revolves. The method includes acquiring levels of the echo signals at every predetermined distance interval and updating a threshold set for an observing position based on the level of the echo signal at the observing position, the threshold set for the observing position, and a threshold set for a position closer to the antenna than the observing position by the predetermined distance on the same sweep.

Owner:FURUNO ELECTRIC CO LTD

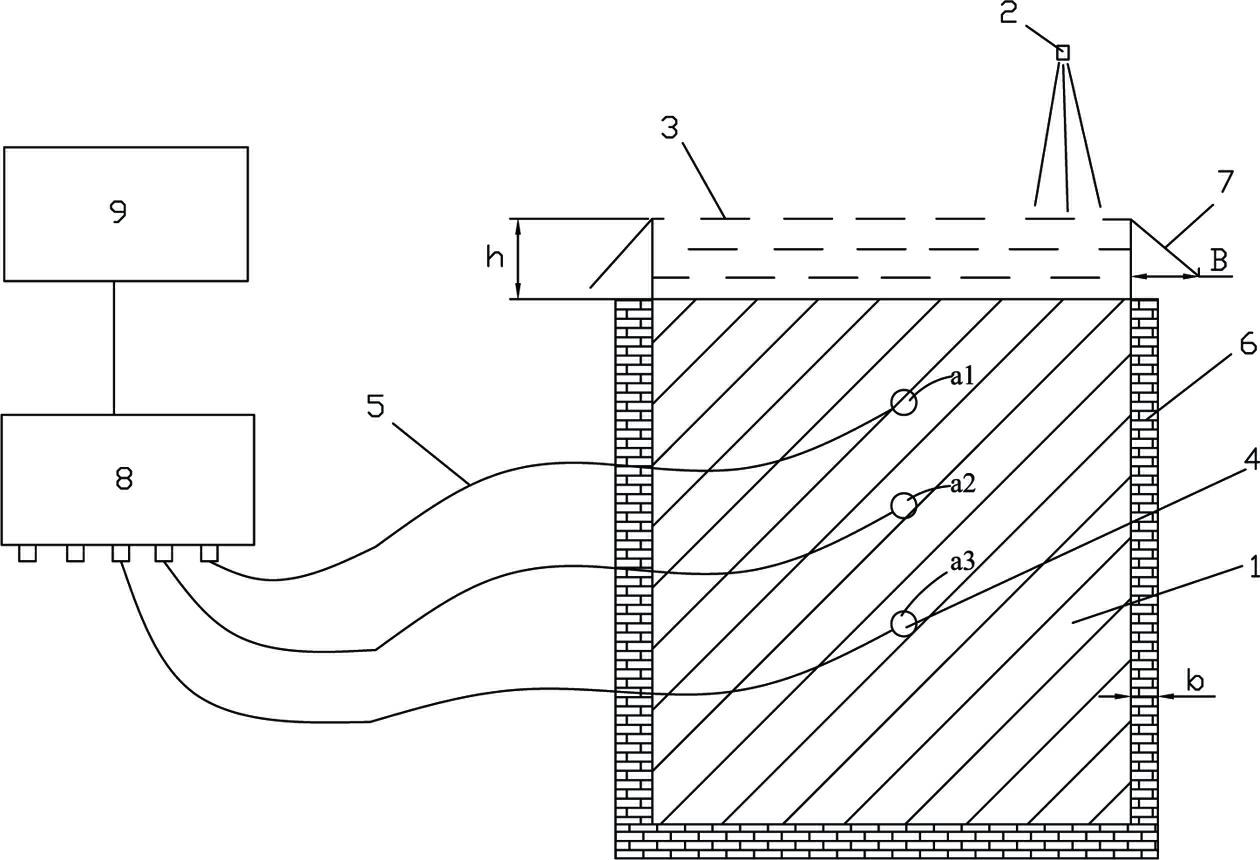

Method and device for testing heat exchange coefficients of steel plate with different water film thickness

InactiveCN102661969AAccurate Cooling ControlAvoid errorsMaterial heat developmentCooling curveData acquisition

The invention provides a method and a device for testing heat exchange coefficients of steel plates with different water film thicknesses. A cylindrical water film cofferdam is welded on the surface of a cylindrical steel plate, the height h of a cofferdam is equal to the tested thickness of the water film; three temperature measuring points are set in a direction perpendicular to cylindrical steel plate at a distance interval x, holes are drilled on the side face of the cylindrical steel plate at positions which are x / 2, x3 / 2 and x5 / away from the upper end face of the cylindrical steel plate, thermocouples are then placed in the holes, and the cold ends of the thermocouples are connected to a multi-channel data acquisition device; during experiment, a steel sample is placed in a heating furnace, then the data acquisition device is started to acquire the temperature; when the steel plate reaches an initial cooling temperature, the steel sample is taken out and placed in a heat-insulation tank which is placed under a spray nozzle, later the spray nozzle is opened to spray water onto the water film cofferdam and thus, and a water film is covered on the surface of the steel plate; and when the steel plate reaches a final cooling temperature, the temperature acquisition is stopped, and thus, the steel plate cooling curve T (t) based on different positions at the upper end face of the cylindrical steel plate is obtained. Therefore, the method and the device can test the heat exchange coefficient of the surface of the steel plates under a condition of different thicknesses of water films.

Owner:BAOSHAN IRON & STEEL CO LTD

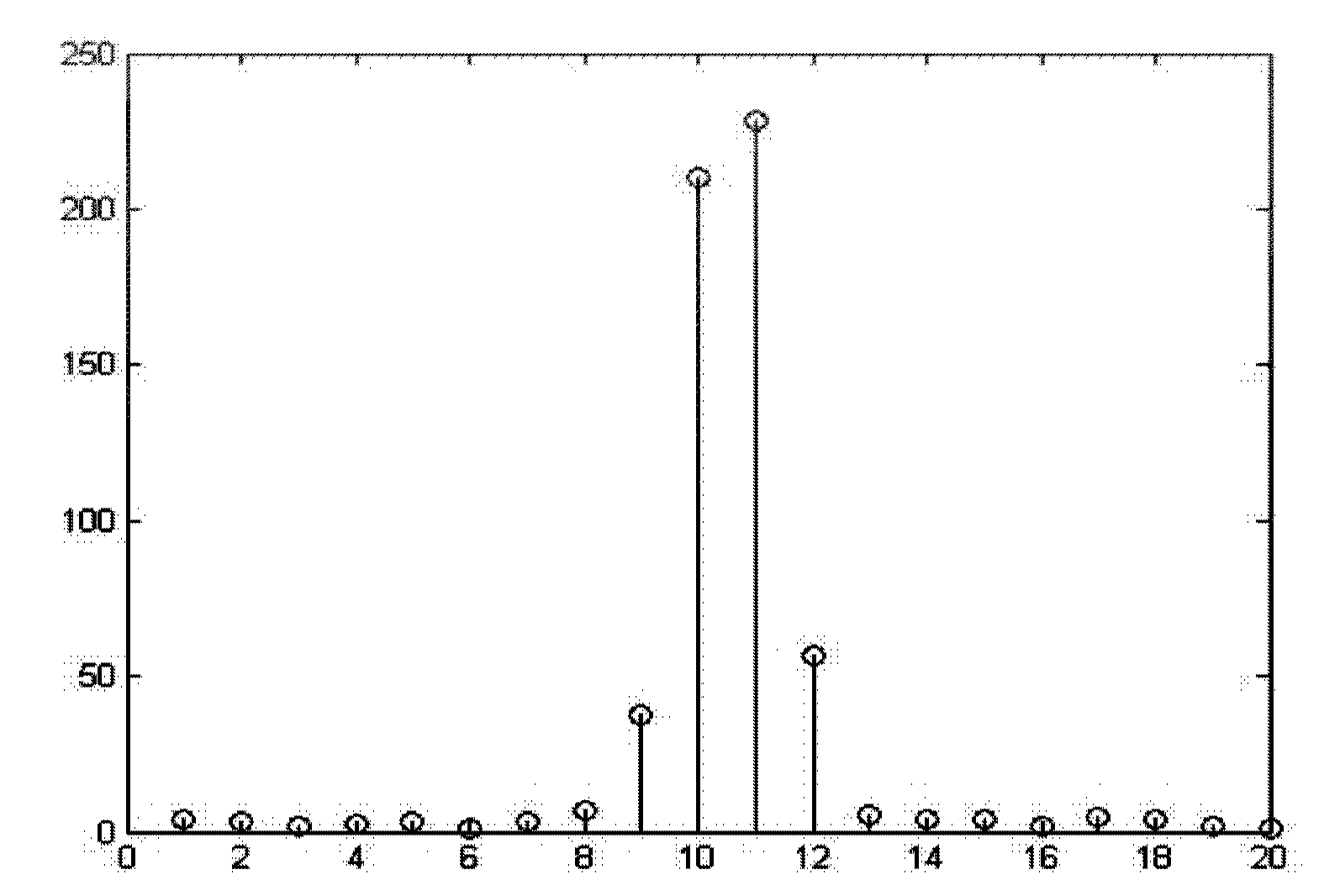

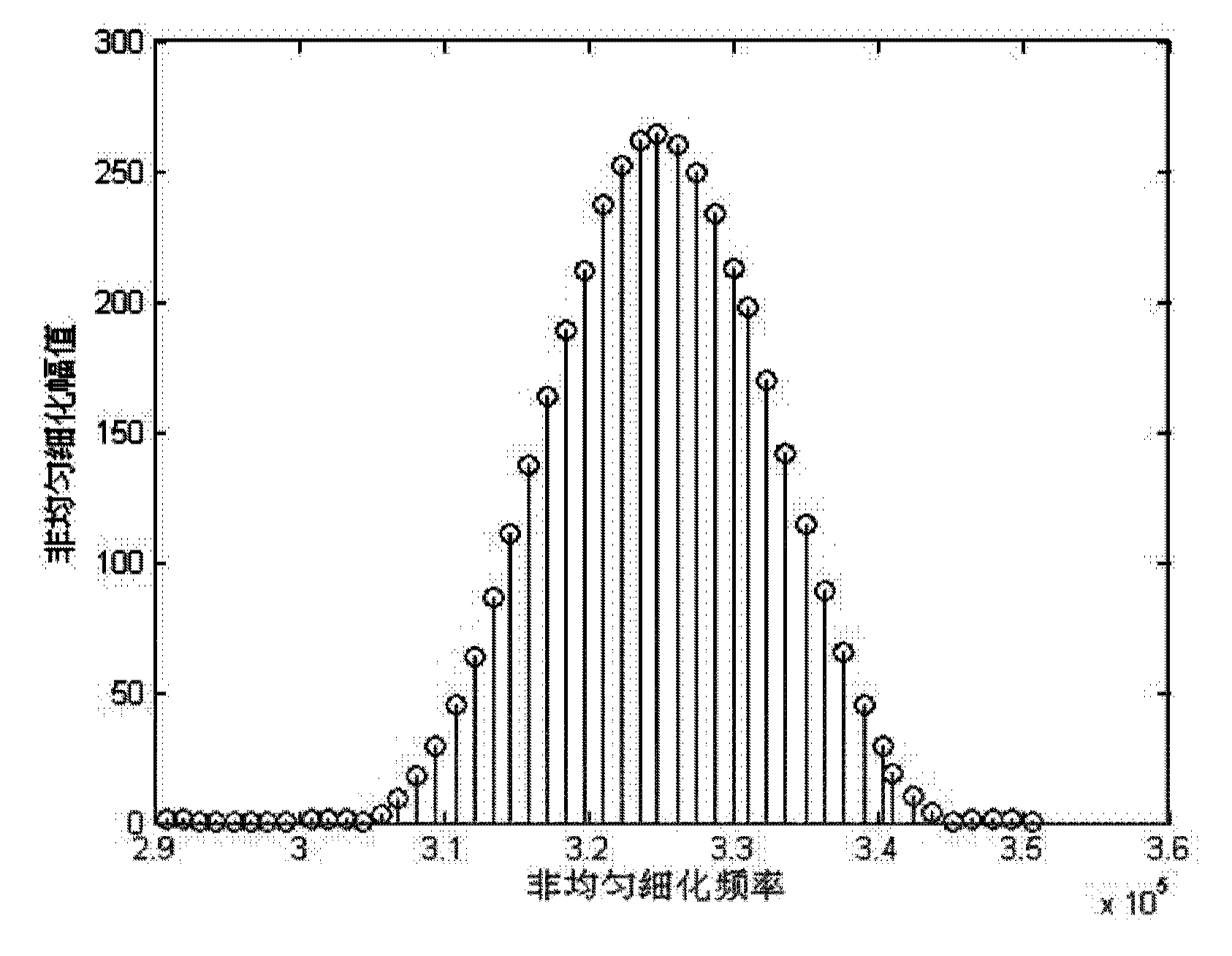

Distance measurement method for frequency modulation continuous wave radar system

ActiveCN103823216AHigh precisionGuaranteed reliabilityRadio wave reradiation/reflectionFrequency spectrumIntermediate frequency

The invention provides a distance measurement method for a frequency modulation continuous wave radar system. The method comprises the following steps: Step S1. discrete intermediate frequency signals collected by the frequency modulation continuous wave radar system are subjected to discrete Fourier transformation to find out the spectral line number km of the discrete spectrum maximum and the spectral line number kc of the discrete spectrum second-maximum; Step S2. the procedure goes to Step S4 if the number kc=km-1, and goes to Step S3 if kc is not equal to km-1; Step S3. the frequency domain in the discrete intermediate frequency signals is shifted to the right based on delta f / 2 to make the spectral line numbers km and kc after shifting meet kc=km-1, wherein delta f is the frequency resolution of the discrete Fourier transformation of the N point; Step S4. the discrete intermediate frequency signals are subjected to discrete Fourier transformation by reducing one sampling point to find out the spectral line number k'm of the discrete spectrum maximum; Step S5. the spectral line number k'm of the discrete spectrum maximum is judged, Step S4 is repeated if k'm=km, and the procedure goes to Step S6 if k'm is not equal to km and k'm=km-1; and Step 6. the distance interval (R1, R2) between the radar and the target is worked out according to the sampling point number of the discrete Fourier transformation and distance relational expression, and the distance value between the radar and the target is R'=(R1+R2) / 2.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

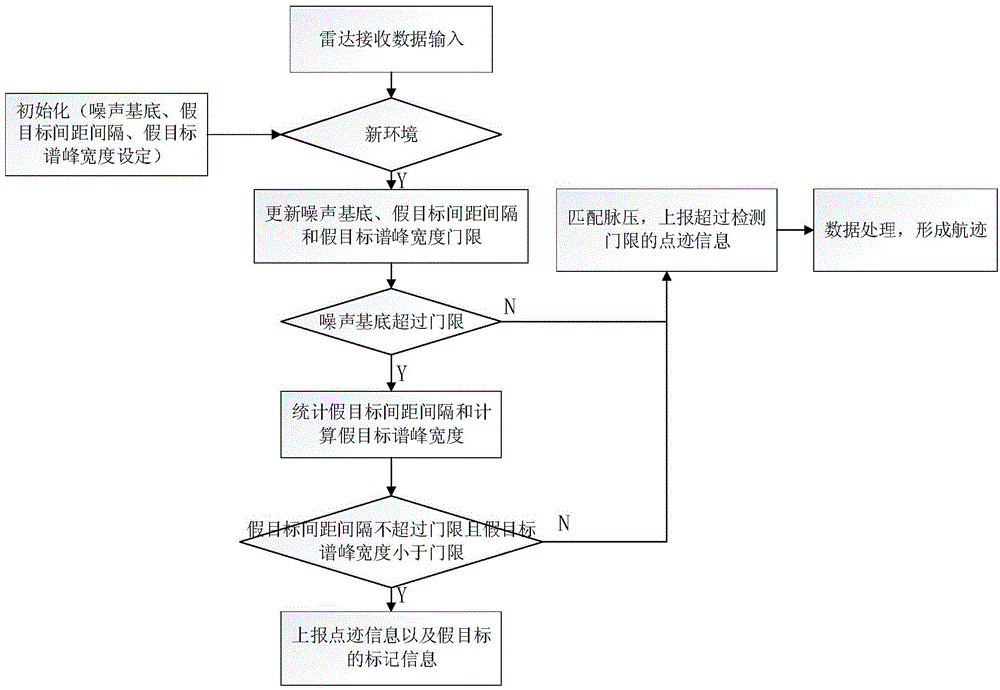

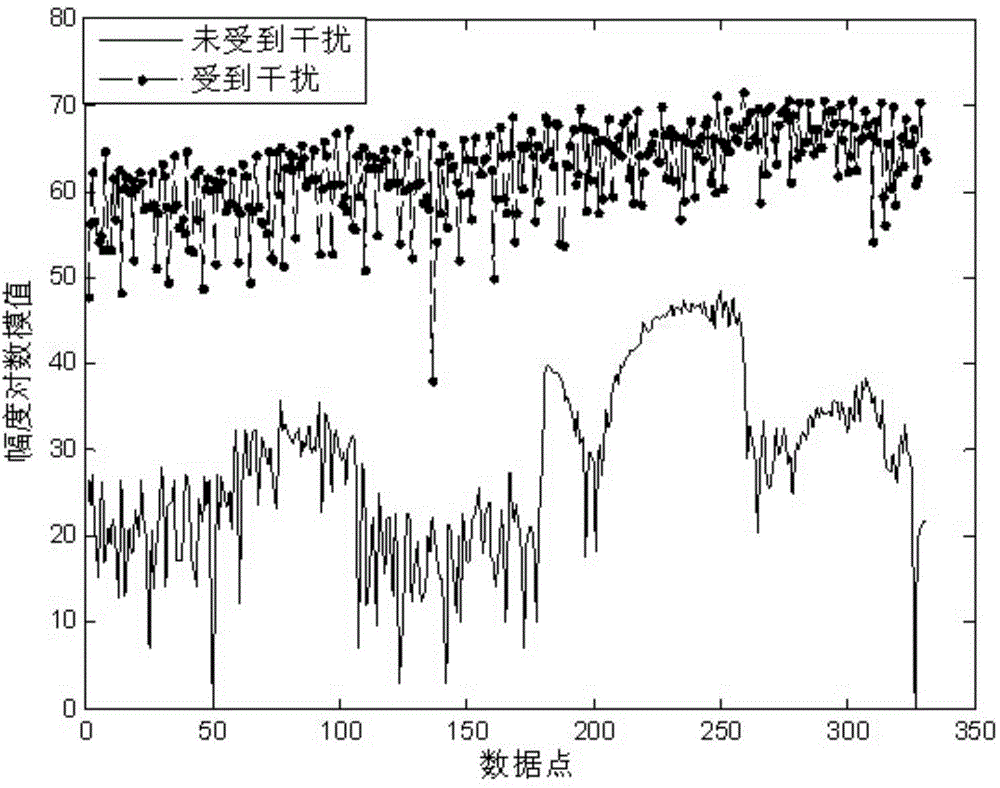

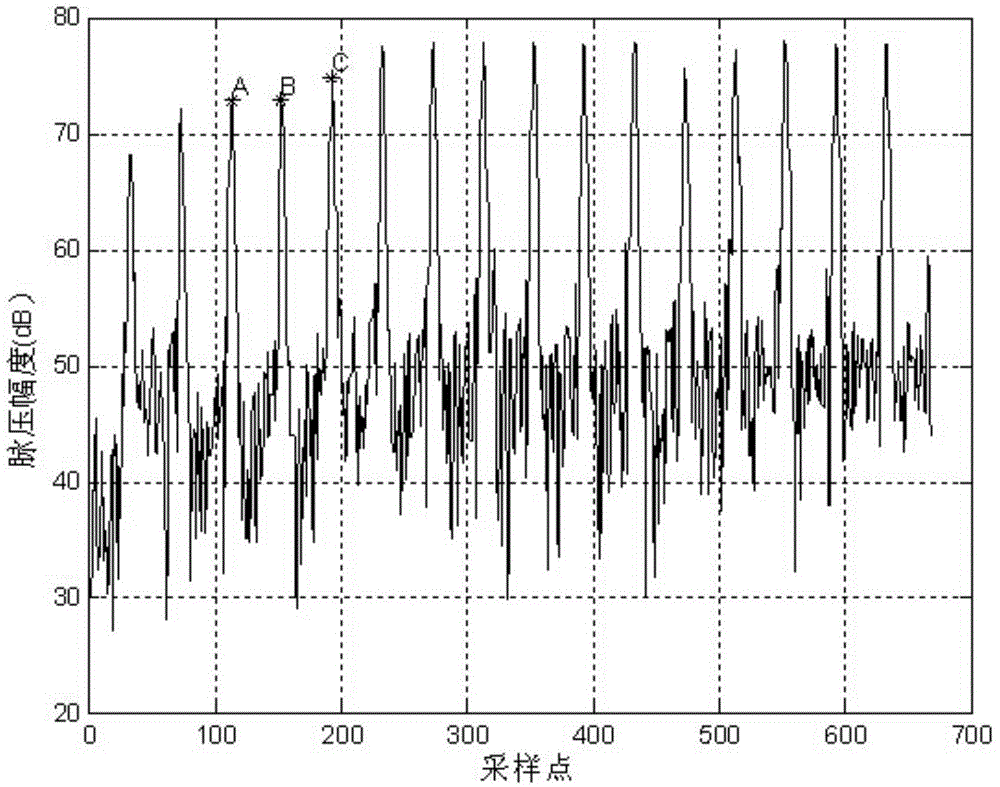

Missile-borne forwarding type interference inhibition method based on false target characteristics

InactiveCN104931939AImprove accuracyWave based measurement systemsPattern recognitionSignal-to-noise ratio (imaging)

The invention discloses a missile-borne forwarding type interference inhibition method based on false target characteristics. The method comprises the following steps: step one, arranging a noise basal threshold, a distance threshold scope between false targets and a false target spectrum peak width threshold in advance; step two, when an environment where a radar is disposed is not changed, executing step three, and otherwise, returning to step one; step three, periodically counting a noise background where the radar works, performing pulse pressure matching on echo data received by the radar, processing the echo data whose signal-to-noise ratio exceeds a preset detection threshold, and making true and false target marks on point track data; and step four, for the point track data with already marked true and false targets, according to target associations before and after current time, rejecting the false targets, and forming a true target track. According to the invention, through control of adjustable parameters among three characteristic parameter thresholds including the noise background, the distance interval of the false targets and a false target spectrum peak broadening width, the probability of correctly rejecting the false targets can be greatly improved.

Owner:HOHAI UNIV

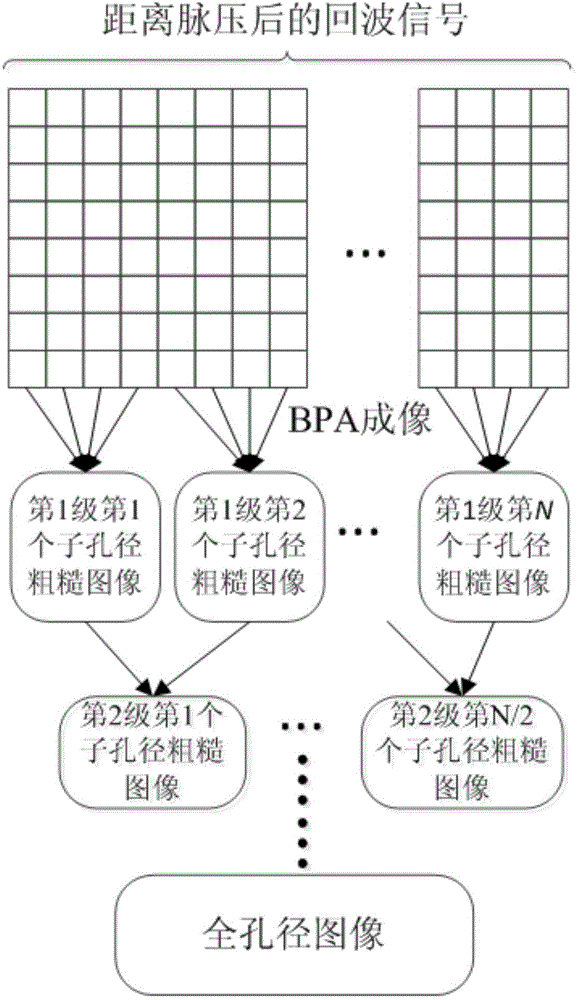

SAR imaging quick backward projection method based on image spectrum compression

ActiveCN104833974AAvoid error accumulationHighlight substantive featuresRadio wave reradiation/reflectionSynthetic aperture sonarFrequency spectrum

The invention discloses an SAR imaging quick backward projection method based on image spectrum compression, which comprises the following steps: firstly, performing direction blocking operation on full aperture of a synthetic aperture radar for dividing into N sub-apertures, wherein N is a positive integer; determining a first-stage sub-aperture imaging grid in a rectangular coordinate system, and performing coherent accumulation on an echo signal s(x,r) after a distance pulse pressure by means of a projection algorithm BPA, thereby obtaining N sub-aperture rough images of first-grade sub-apertures; in the rectangular coordinate system, performing directional frequency spectrum compression on the N sub-aperture rough images of the first-grade sub-apertures; then setting direction interval and distance interval of a next-grade sub-aperture imaging grid, performing coherent accumulation to the N sub-aperture coarse images of the first-grade sub-apertures after directional frequency spectrum compression successively in a paired manner, obtaining the sub-aperture coarse image of a next-grade sub-apertures; and finally, performing directional frequency spectrum compression and coherent accumulation for finally obtaining a full-aperture image.

Owner:XIDIAN UNIV

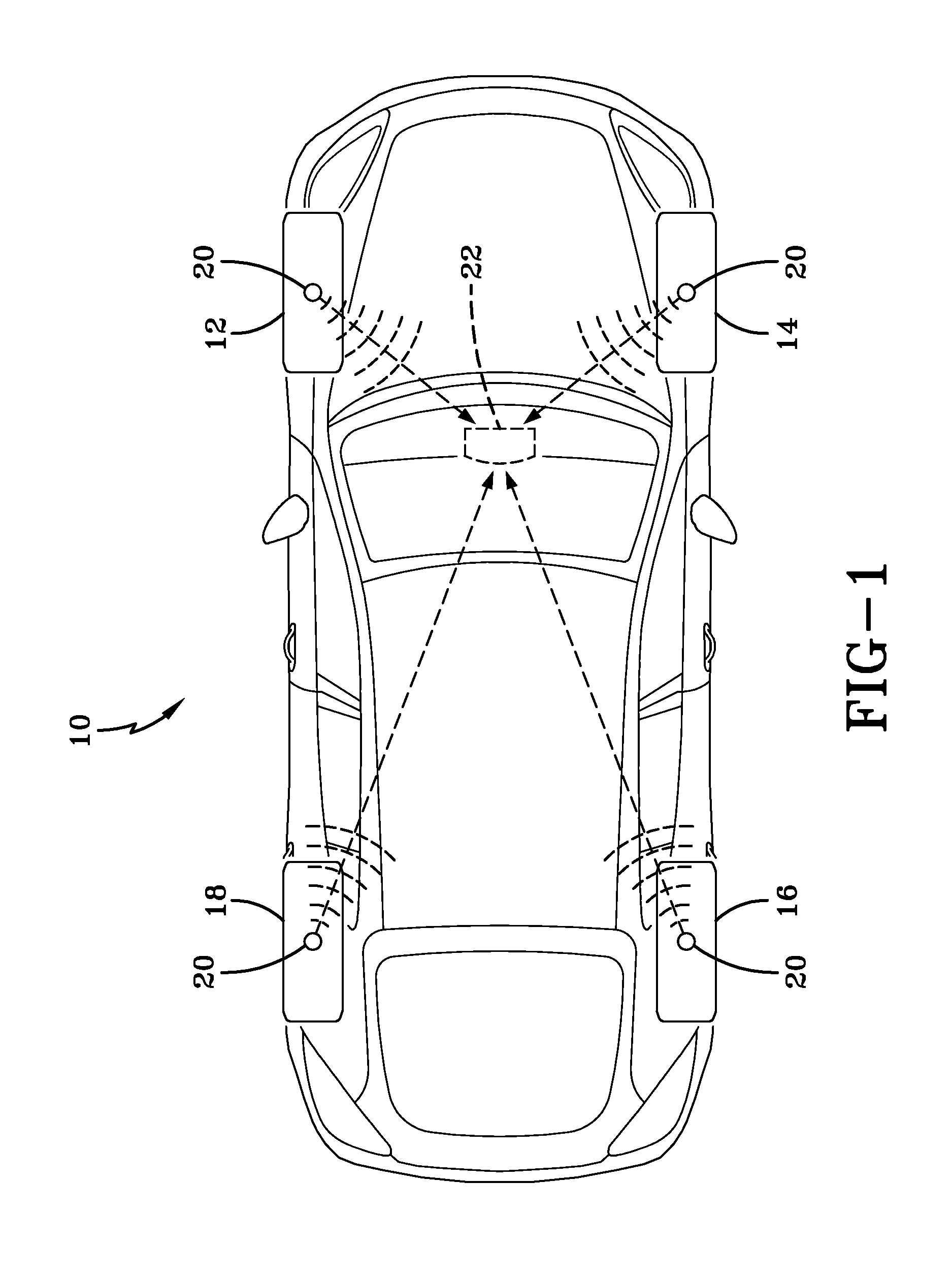

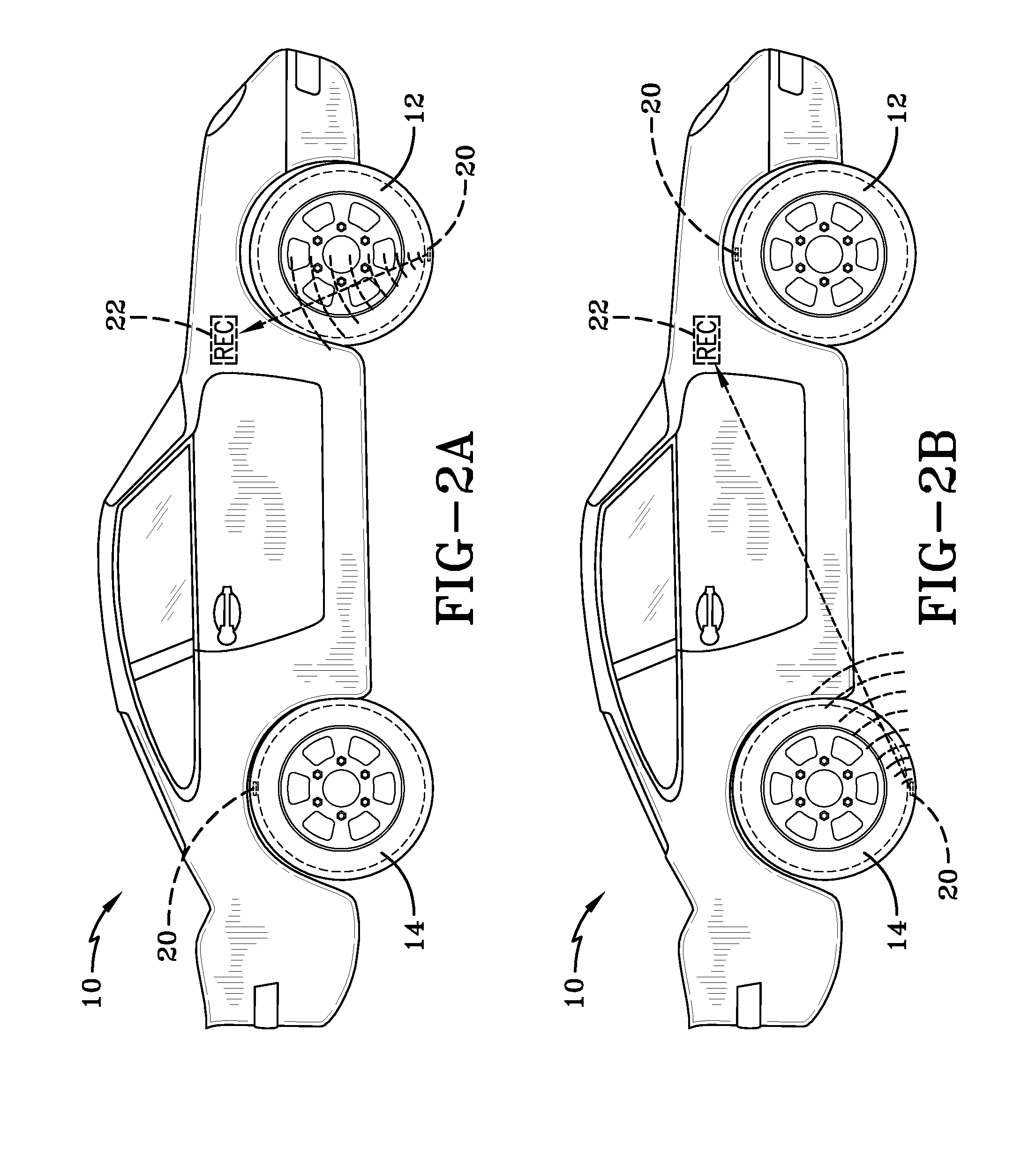

Microphone support for in-vehicle acoustic mode measurement and testing

InactiveCN103511802AEasy to installEasy to adjustStands/trestlesDiagnostic Radiology ModalityIn vehicle

The invention relates to a microphone support, in particular to a microphone support for an in-vehicle acoustic mode measurement and testing. The problems that an existing microphone support is difficult to install, accuracy of the position of a microphone is difficult to guarantee, and the microphone support has limitations when being applied to vehicle models. The microphone support comprises a main support, an auxiliary support, a microphone location clamp, a main-auxiliary support connecting rod, a connecting rod clamp, a bolt and a foot support assembly. The main support and the auxiliary support are respectively composed of a cylinder structure and a guiding rod, circular holes are formed in a cylinder on the outer side at a certain distance interval, the cylinders and the guiding rods are respectively provided with scales in a marked mode, and a spring pin is arranged on the guiding rod in each cylinder and used for being matched with the circular holes in each cylinder to enable the height and the width of the microphone support to be conveniently changed. Threads are arranged on the main-auxiliary support connecting rod, and the threads are matched with internal threads of the connecting rod clamp to achieve the effect of being connected with the main support and the auxiliary support. The foot support assembly vertically moves in an up-and-down mode along the main support, and the height can be adjusted in the vertical direction. The microphone support is simple in structure and convenient to machine, carry and install.

Owner:JILIN UNIV

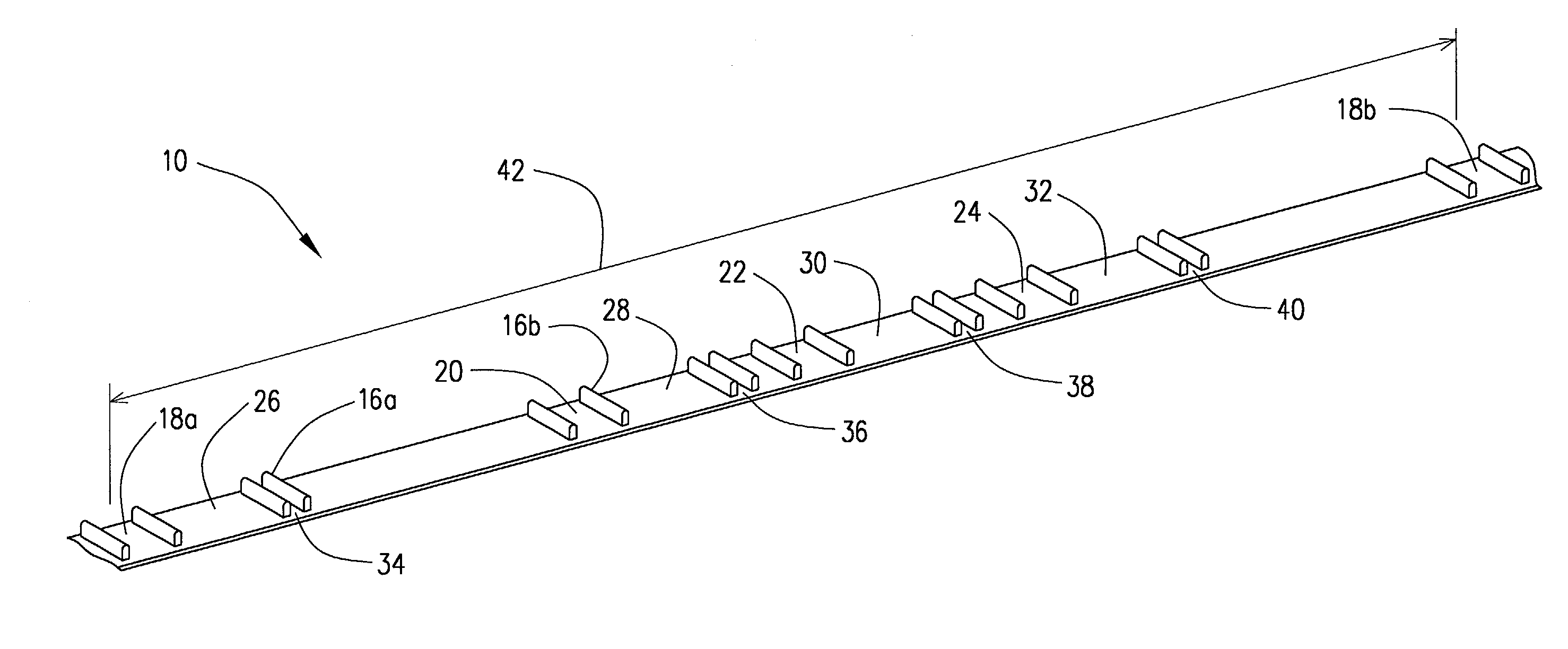

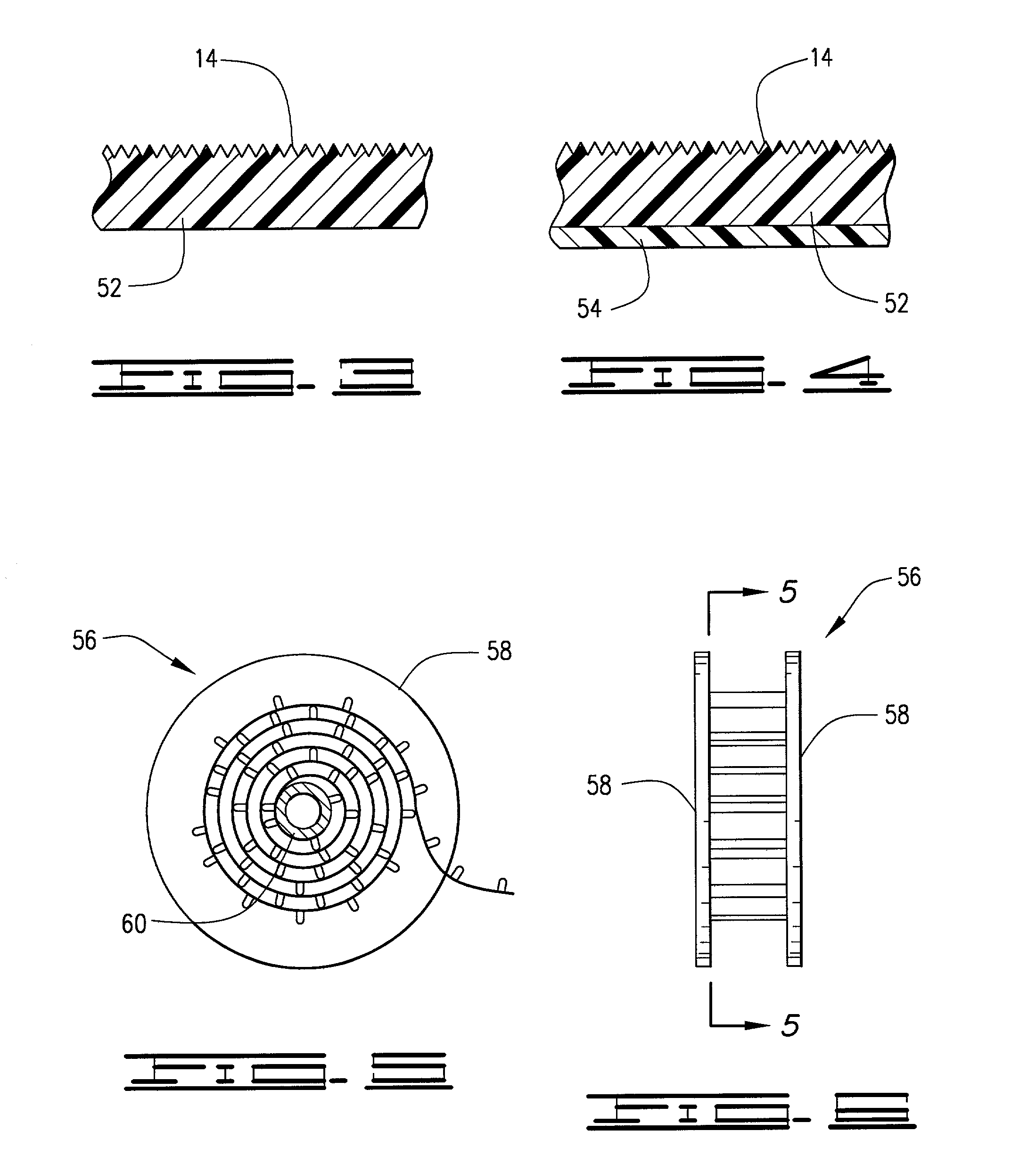

Construction layout stripping having a plurality of pairs of uprights thereon

InactiveUS7028446B2Reduce the time required for installationEasy to adaptBuilding roofsCeilingsDistance intervalRepeat unit

A construction layout stripping and method for laying out construction members or framing members at a fixed distance interval from one another. The construction layout stripping comprises: first, a pliably, non-elastic elongated base; and second, repeating units disposed on the base, the repeating units having a plurality of pairs of uprights at fixed intervals, each pair of uprights defining a partition for receiving a specified size of framing member. In a preferred embodiment, the construction layout stripping has upright defining spaces for receiving 1⅝″, 3⅝″, and ½″ framing members on either 16″ or 24″ centers using the same construction layout stripping. The construction layout stripping may have cutting ribs defined thereon for cutting the stripping at a desired length.

Owner:WINCHESTER RICHARD M

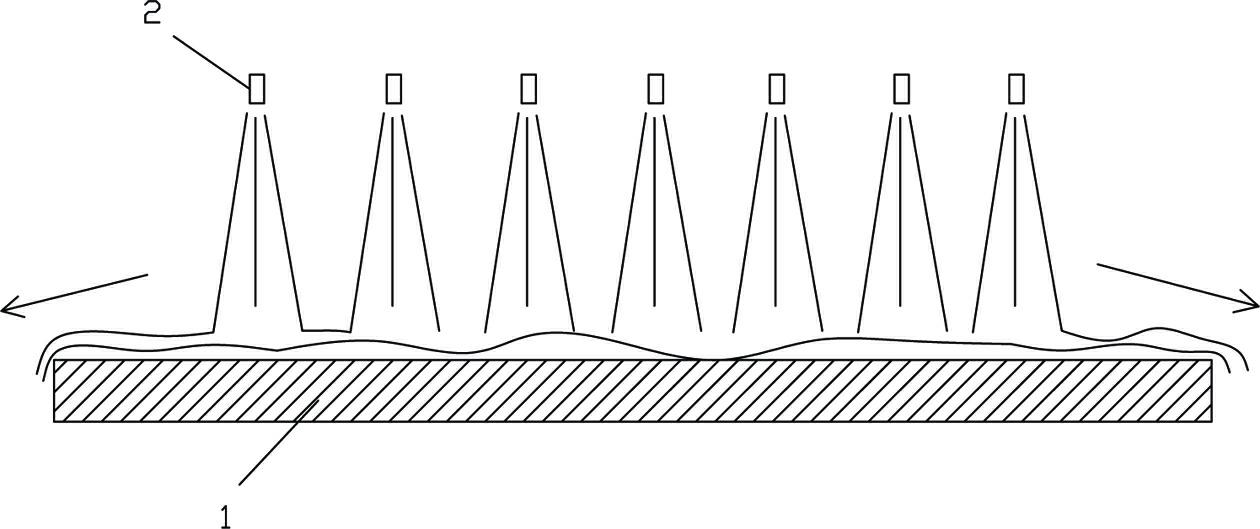

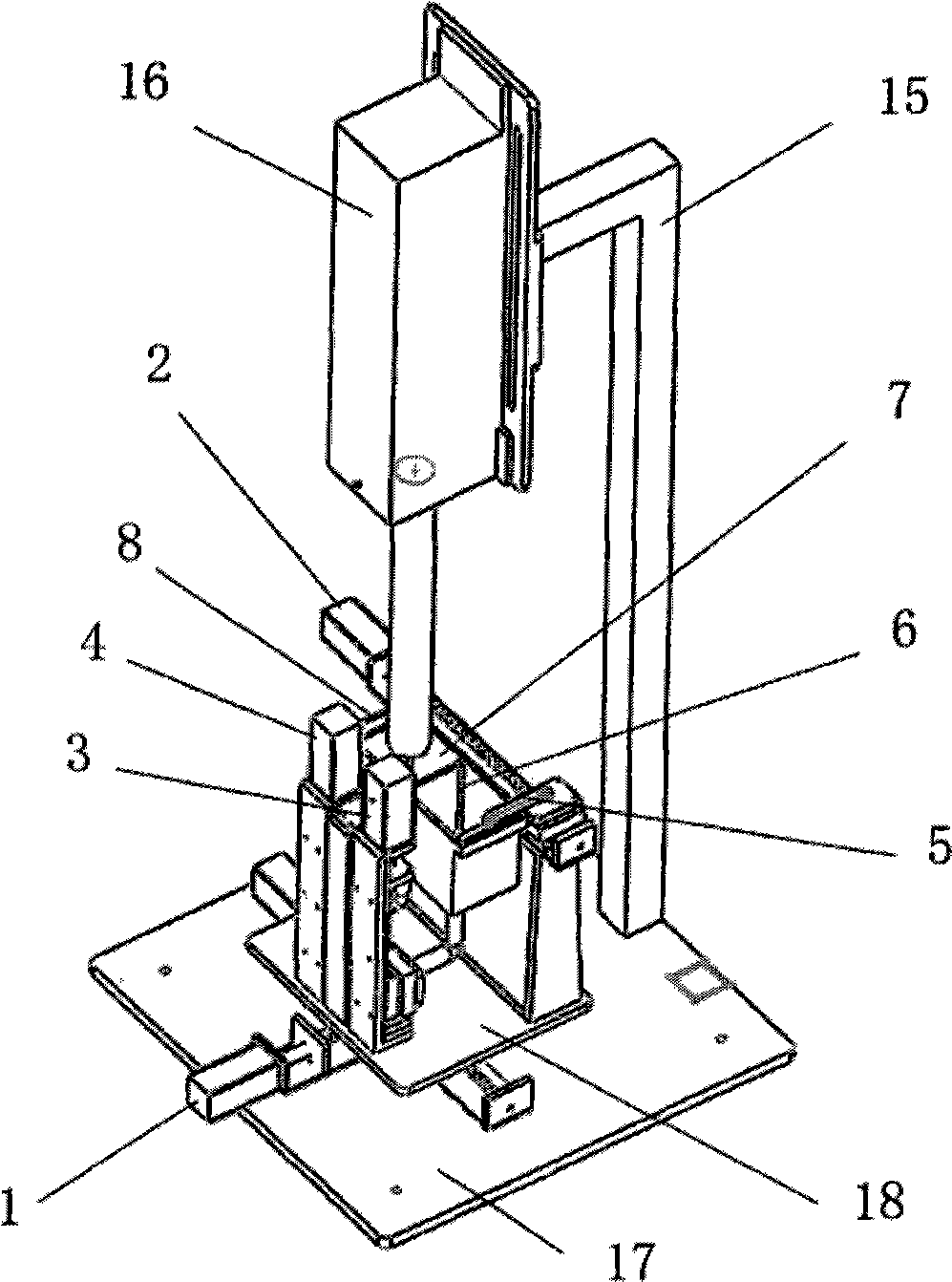

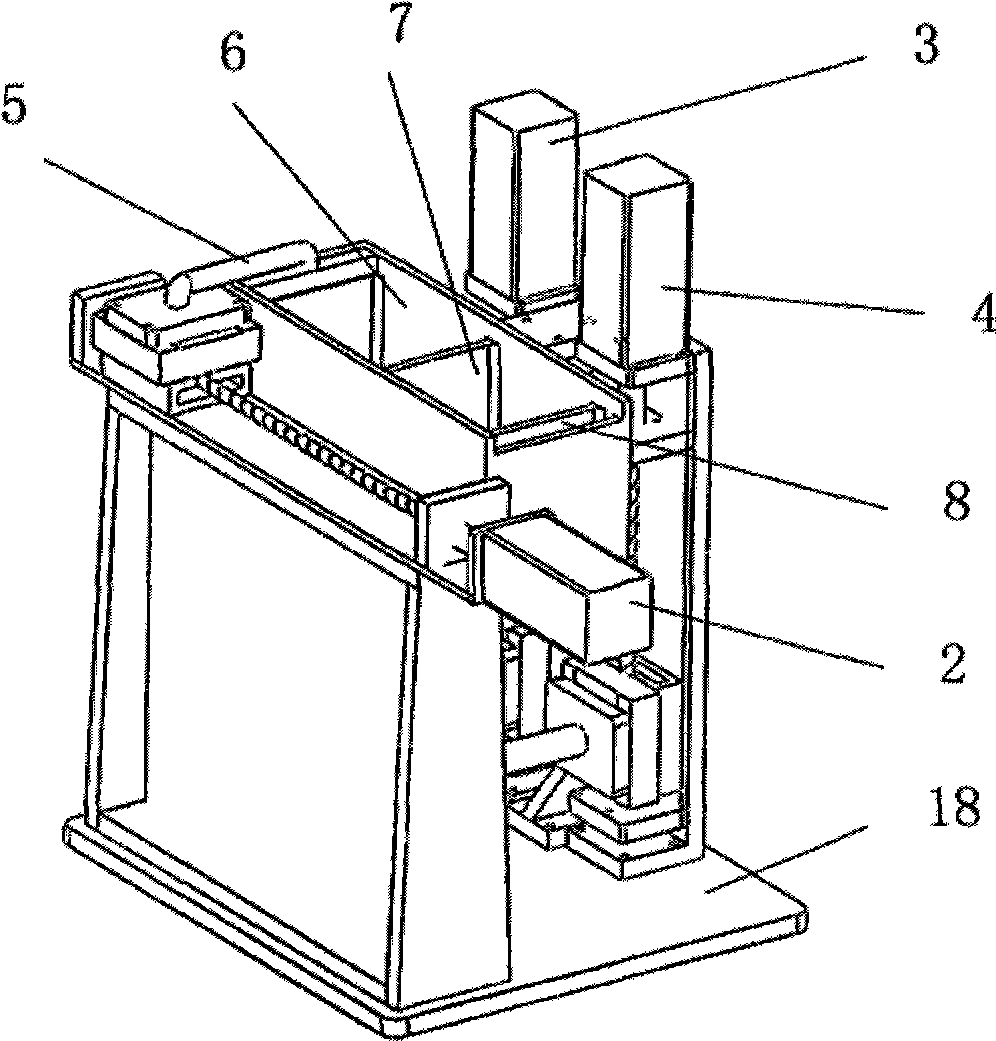

Laser sintering machine based on nano hydroxyapatite and used for manufacturing absorptive artificial bone

InactiveCN101530950AConvenience and precise controlControl degradation rateProsthesisLaser beam welding apparatusLaser scanningNano hydroxyapatite

The invention discloses a laser sintering machine based on nano hydroxyapatite and used for manufacturing an absorptive artificial bone. An X / Y motion mechanism (1) is arranged on a frame (17). A sintering support plate (18) is arranged on the X / Y motion mechanism (1). A raw material box up-down motion machine (3), a raw material box (6), a sintering table up-down motion machine (4) and a sintering table (7) are arranged on the sintering support plate (18). A feeding left-right motion mechanism (2) and a feeding rod (5) are arranged on the sintering support plate (18). A laser and laser focusing system (16) which is corresponding to the sintering table (7) is arranged on a bracket (15) of the frame (17). Nano hydroxyapatite powder (10-100nm) is arranged on the sintering table (7). Laser energy is assembled into a 50-100micron light spot by a focusing system such as a convex lens. A motion table is moved according to the requirement of section profile and certain sintering distance interval (150-500mum), partial powder is subjected to laser scanning, and a three-dimensional artificial bone is formed finally.

Owner:CENT SOUTH UNIV

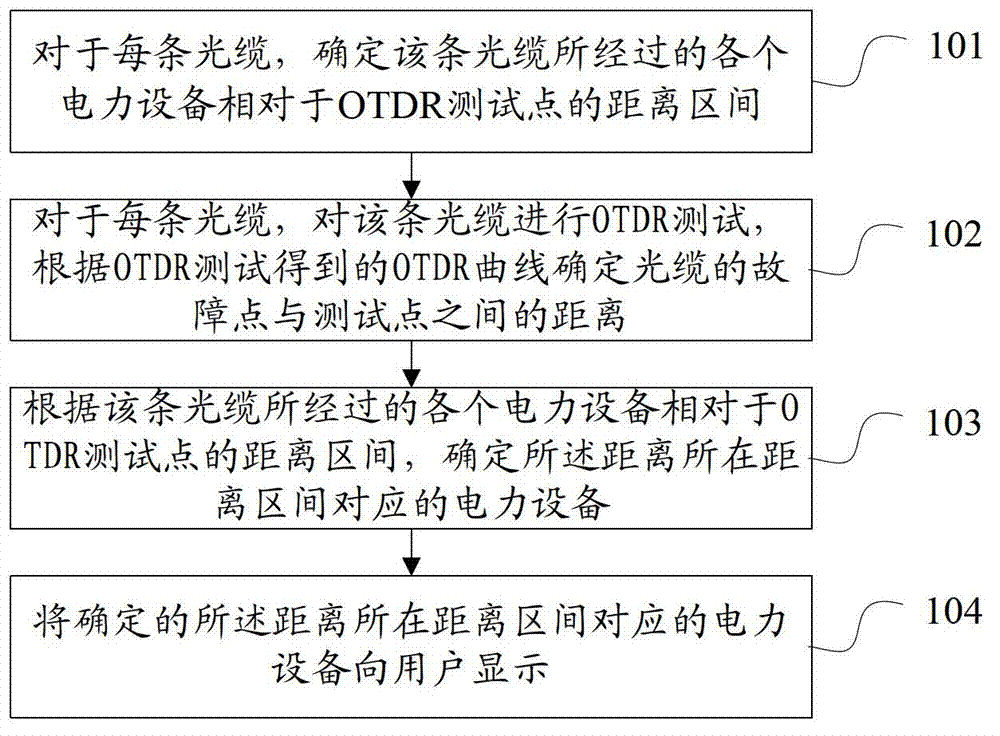

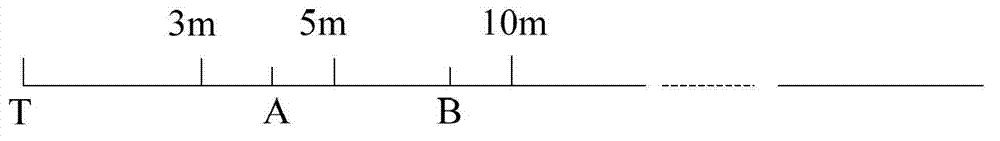

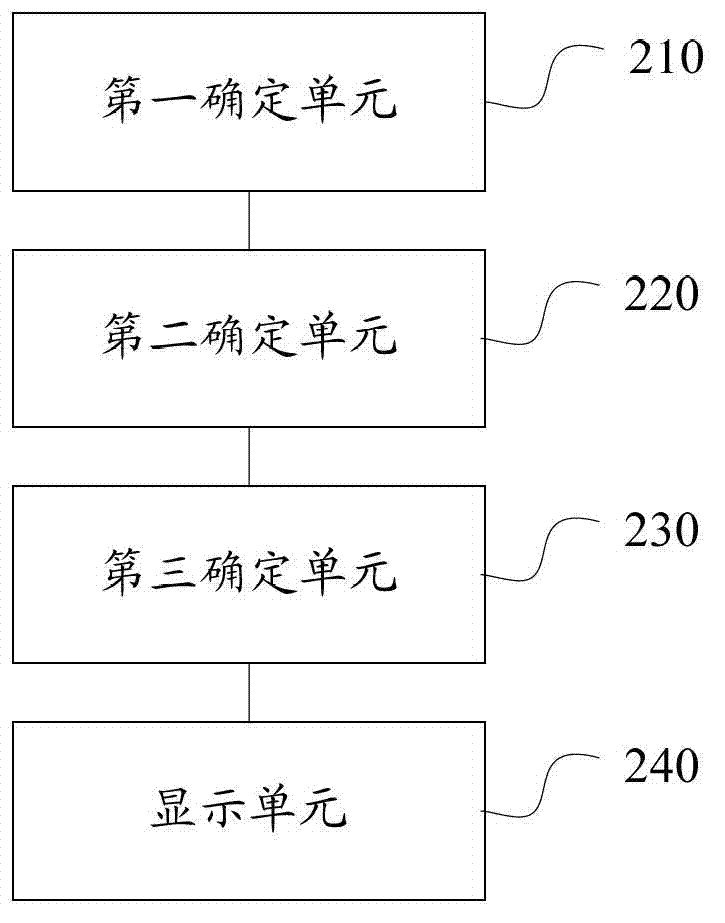

Fault point localizing method and device

InactiveCN102820920AAchieve positioningElectromagnetic transmissionEngineeringOptical time-domain reflectometer

The invention discloses a fault point localizing method and a fault point localizing device. The method comprises the following steps of determining a distance interval of each power device by which each optical cable passes relative to an optical time domain reflectometer (OTDR) test point for each optical cable; conducting the OTDR test on each optical cable, and determining a distance between a fault point of the optical cable and the test point according to an OTDR curve obtained through the OTDR test; and determining a power device corresponding to the distance interval in which the distance stays according to the distance interval of each power device by which the optical cable passes relative to the OTDR test point. The method and the device can realize the localization of the fault point of the optical cable in a communication transmission network.

Owner:STATE GRID ZHEJIANG CIXI POWER SUPPLY +1

Camera control method and device, storage medium and electronic equipment

ActiveCN110505389AAvoid CatonReduce waiting timeImage enhancementTelevision system detailsCamera controlComputer graphics (images)

The embodiment of the invention discloses a camera control method and device, a storage medium and electronic equipment. The electronic equipment comprises a plurality of cameras with different focallengths, when the electronic equipment is in a shooting preview mode, the focusing distance change trend of a first camera running in a foreground is detected, and an image collected by the first camera is set as a preview image; then, according to a preset corresponding relationship between a focusing distance change trend and a camera, a second camera corresponding to the change trend of the focusing distance is determined, the determined second camera is started at the background, the second camera is switched to the foreground for operation when the real-time focusing distance of the firstcamera is located in a focusing distance interval corresponding to the second camera, and an image acquired by the second camera is set as a preview image. Therefore, the camera needing to be switched is started in advance, so that the camera needing to be switched does not need to be started in real time during switching, the waiting time during switching can be saved, and the blockage of the preview image is avoided.

Owner:REALME CHONGQING MOBILE TELECOMM CORP LTD

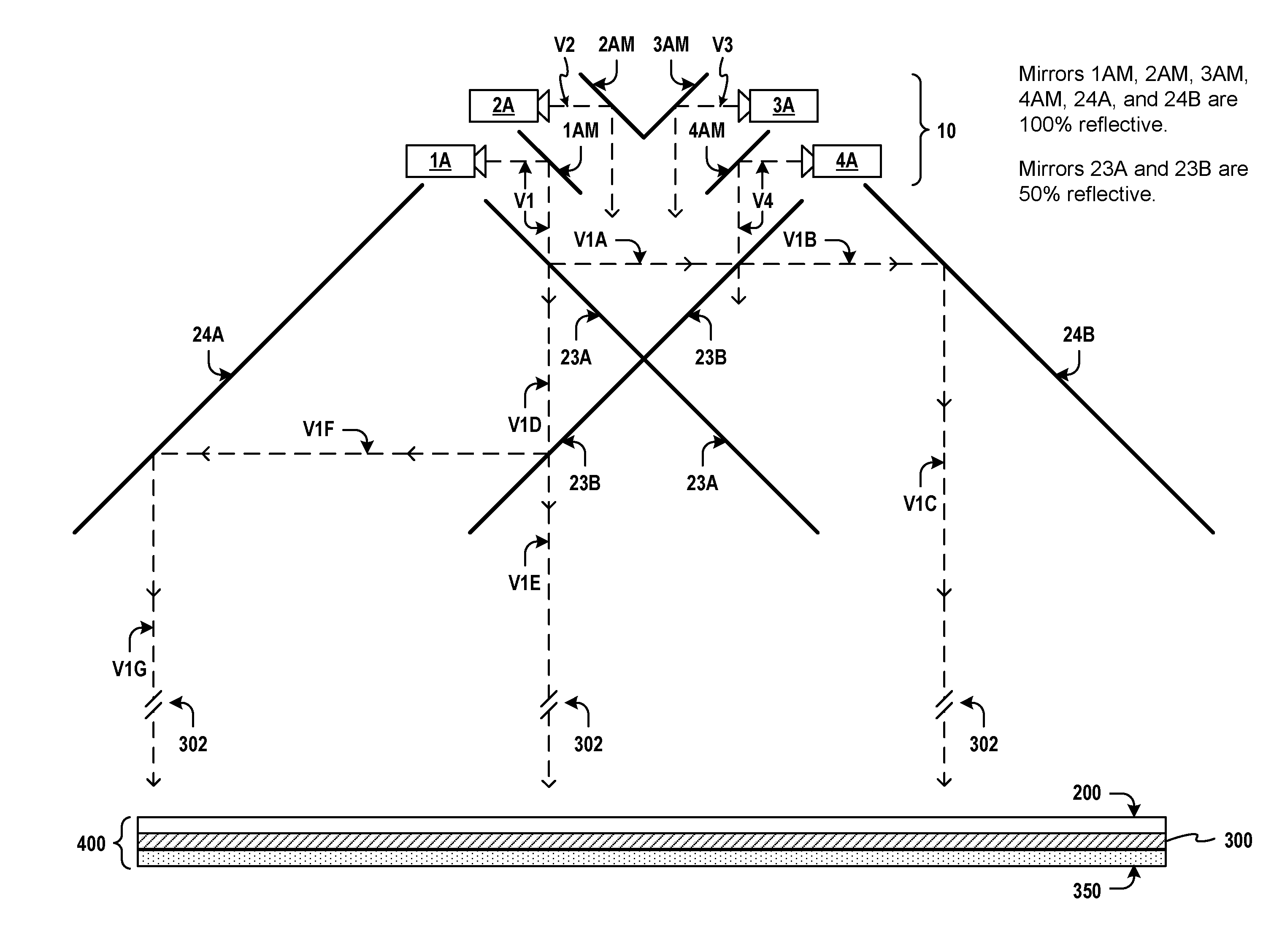

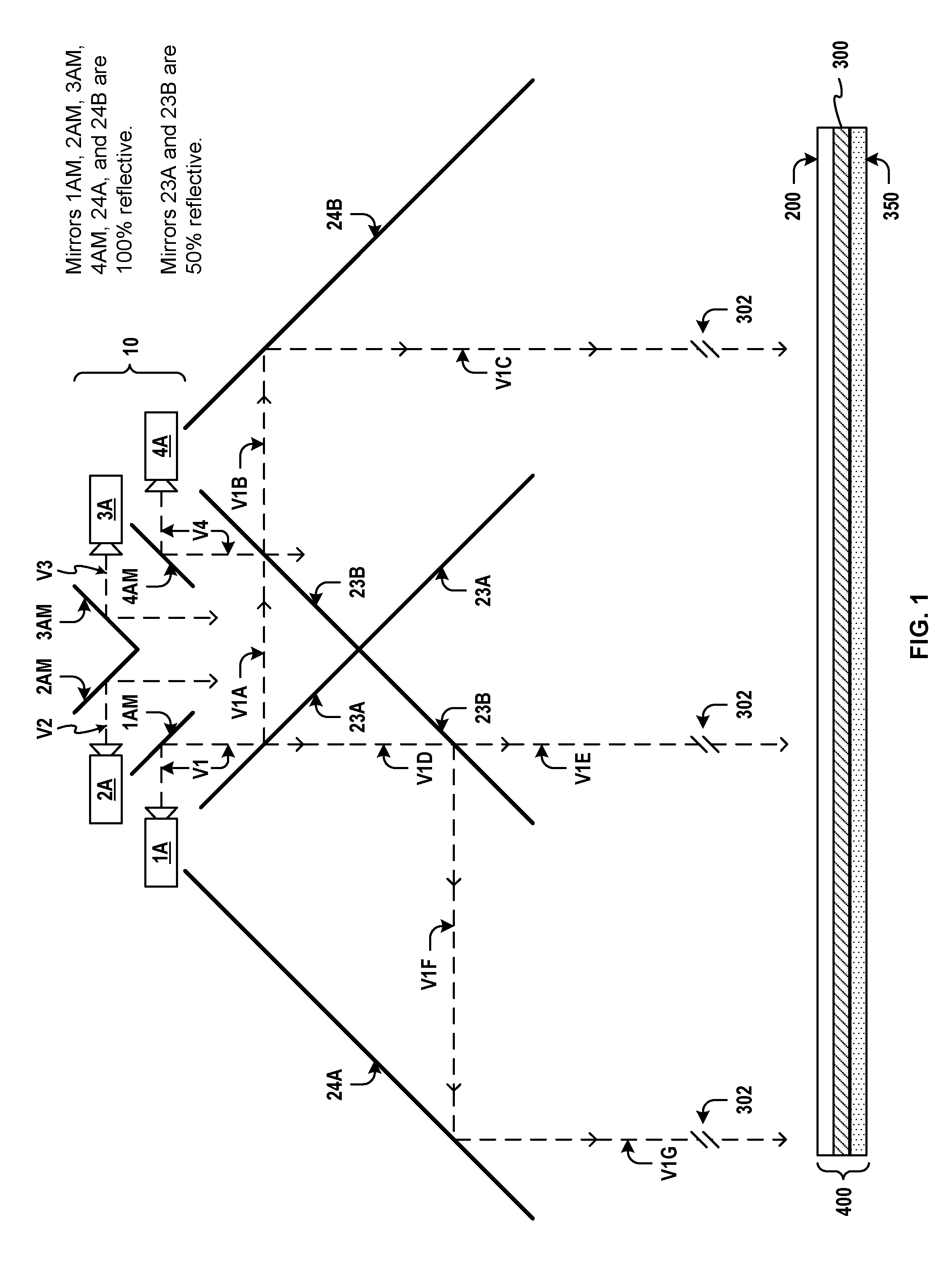

3D Autostereoscopic Display System With Multiple Sets Of Stereoscopic Views

Multiple sets of view channels originate from multiple projected views modulated through an optic assembly comprising a Fresnel lens, a vertical dispersion lenticular lens, and a diffuser. Compact projection enclosures are formed using image-repeating mirrors to create a three-dimensional autostereoscopic viewing experience in free space without the use of special eyeglasses and without the use of view screens. Multiple sets of images are repeated within a viewing zone that may extend well beyond the confines of the enclosure and may be projected through and beyond a glass window. An observer walking past the window will see one view channel per eye, due in part to the repeated images, and due in part to the vertical dispersion of each projected view. Separate images for each view channel may be created by using two or more cameras spaced apart at a distance interval to match the average horizontal distance between the eyes of a human observer. Multiple views or multiple sets of view channels may be generated and projected.

Owner:NELSON BRADLEY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com