Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Avoid stress shielding effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

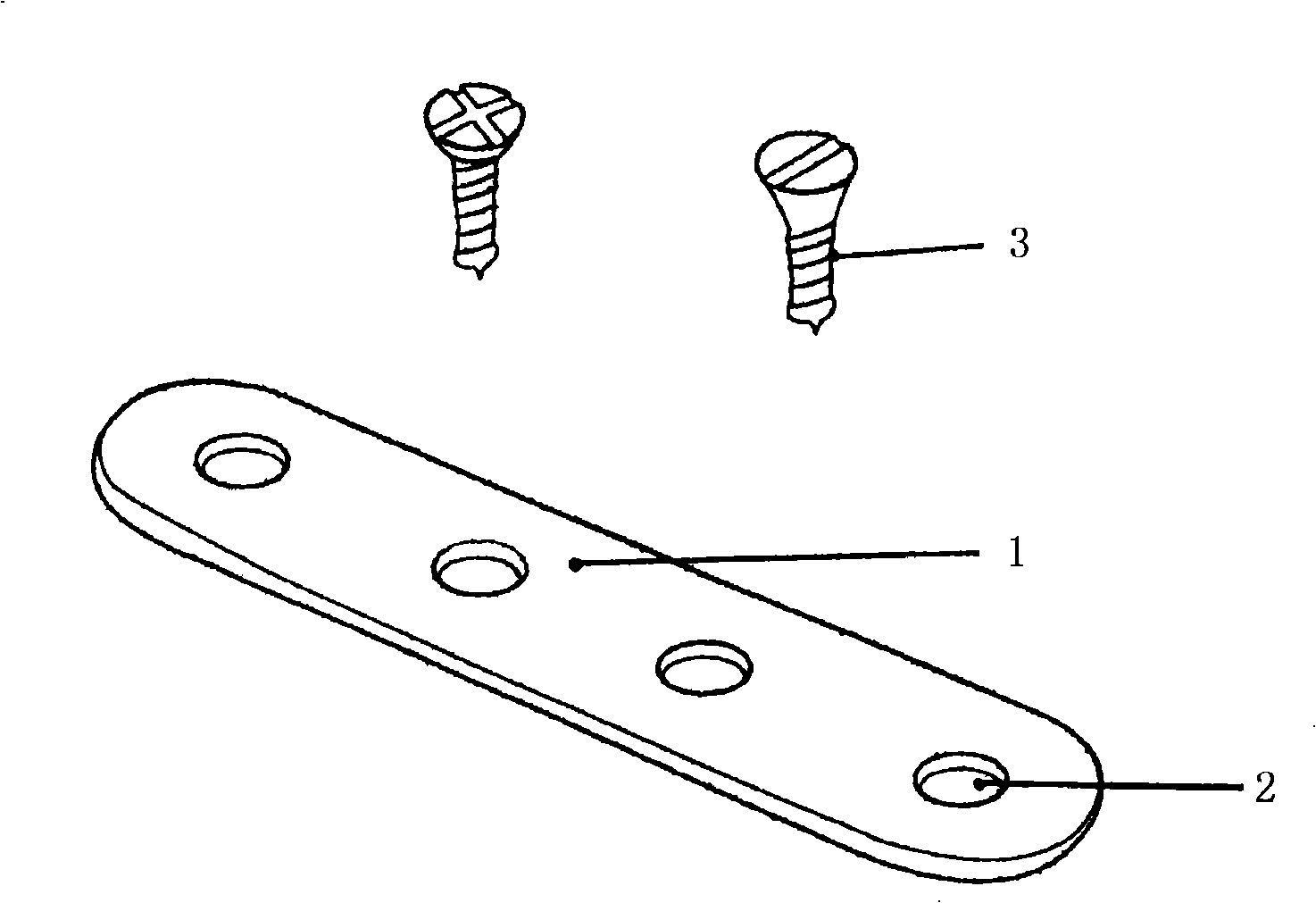

Biological and adsorbable bone internal fixation implantation instrument

InactiveCN101283922APromote healingUniform corrosion degradationInternal osteosythesisProsthesisInternal bone fixationReconstructive surgery

The invention relates to a bone implanting and internal fixation appliance with bioactivity and absorbability, which belongs to the field of bio-medical appliances, particularly to the field of medical appliances used for bone wound surgery, reparative and reconstructive surgery and plastic and cosmetic surgery. The appliance includes bone nails and a bone plate made of magnesium and the alloy thereof with bioactivity and absorbability. The bone implanting and internal fixation appliance is a bone internal fixation device, which comprises a blade plate and matched screws, intramedullary nails, a fracture and dislocation fixing device of vertebral column, bone nails or screws having individual fixation effect, wherein the bone internal fixation device is made of magnesium and the alloy thereof with bioactivity and absorbability. The bone internal fixation device can solve the problem in bioactivity of prior bone internal fixation device and promote healing the tissue where the device in implanted. The device also includes a protection layer prepared on the surface of the internal fixation device for controlling the degradation rate of magnesium alloy and the dissolution rate of magnesium ions, thus controlling the bioactivity and the absorption speed of the magnesium alloy device in an organism.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Metal implant material with controllable corrosion and degradation and its application

InactiveCN1857744AHigh strengthIncrease stiffnessSurgeryPharmaceutical containersCardiovascular stentImplanted device

The present invention relates to biomedicine metal implant material, and is especially metal implant material with controllable erosion and degrading rate and its application. The metal implant material with controllable erosion and degrading rate is magnesium or magnesium alloy with poor anticorrosive property. The metal implant material with controllable erosion and degrading rate of magnesium or magnesium alloy may be used in preparing temporary or short term implanted device, such as degradable blood rack and peripheral rack, bone fracture plate and bone nail for inner fixing, tissue engineering rack, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Photothermal bone repair material for treating osteosarcoma and application of photothermal bone repair material

ActiveCN110302421AFacilitate depositionPromote proliferationEnergy modified materialsTissue regenerationMetal particleAluminum metal

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

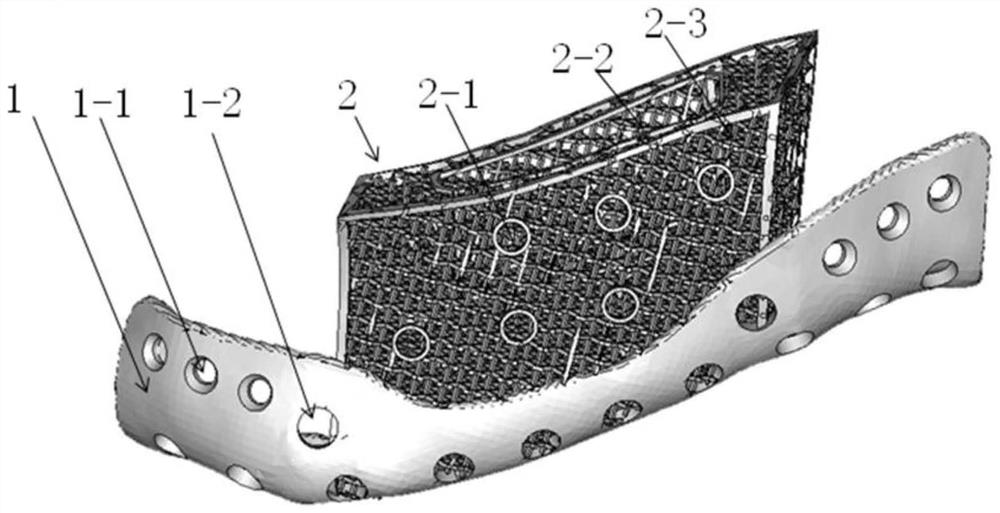

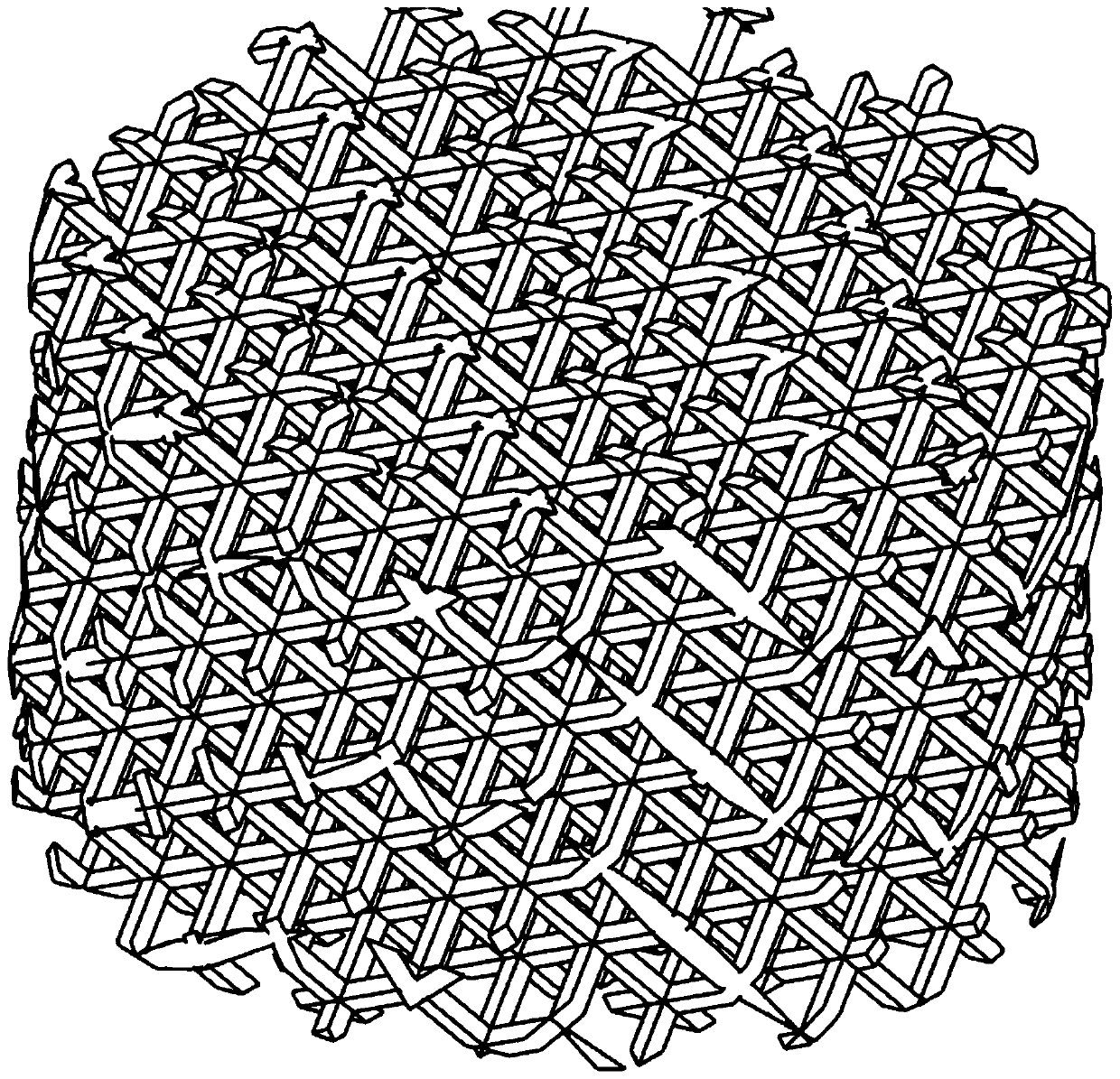

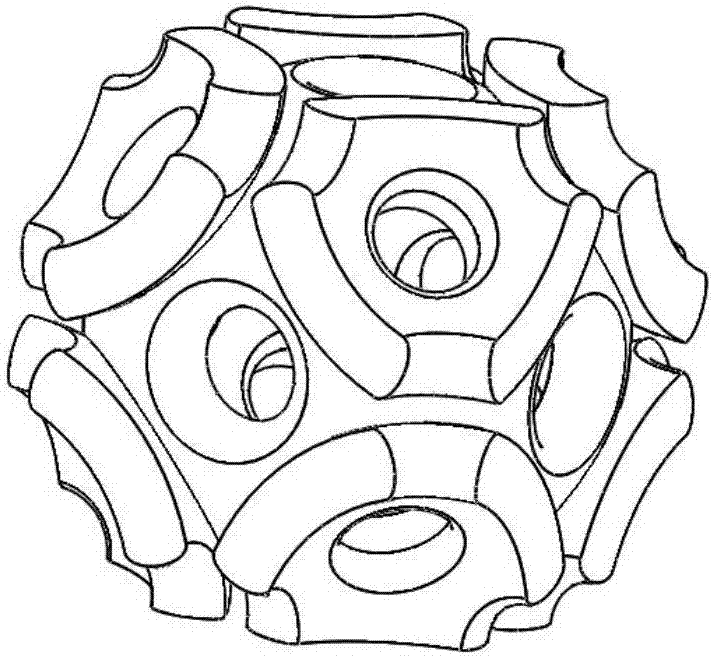

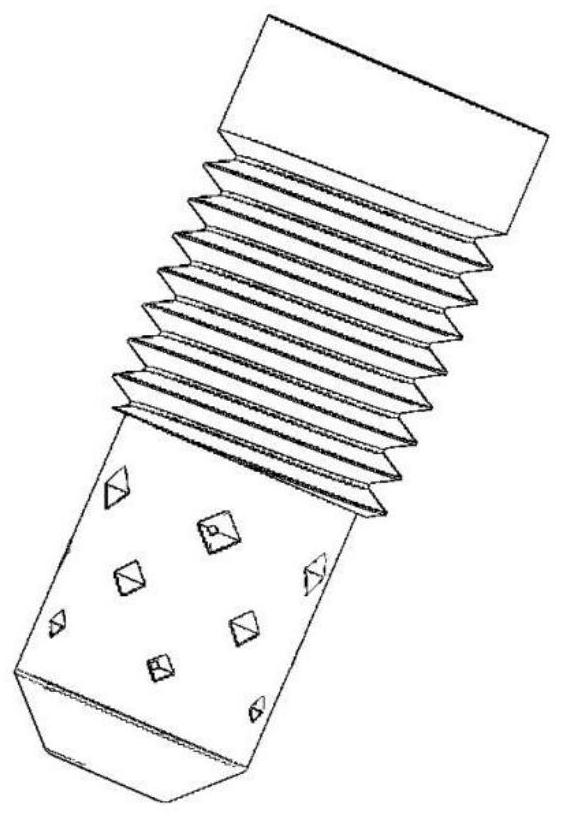

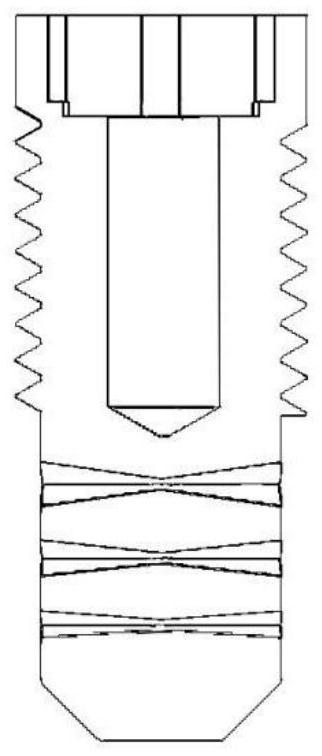

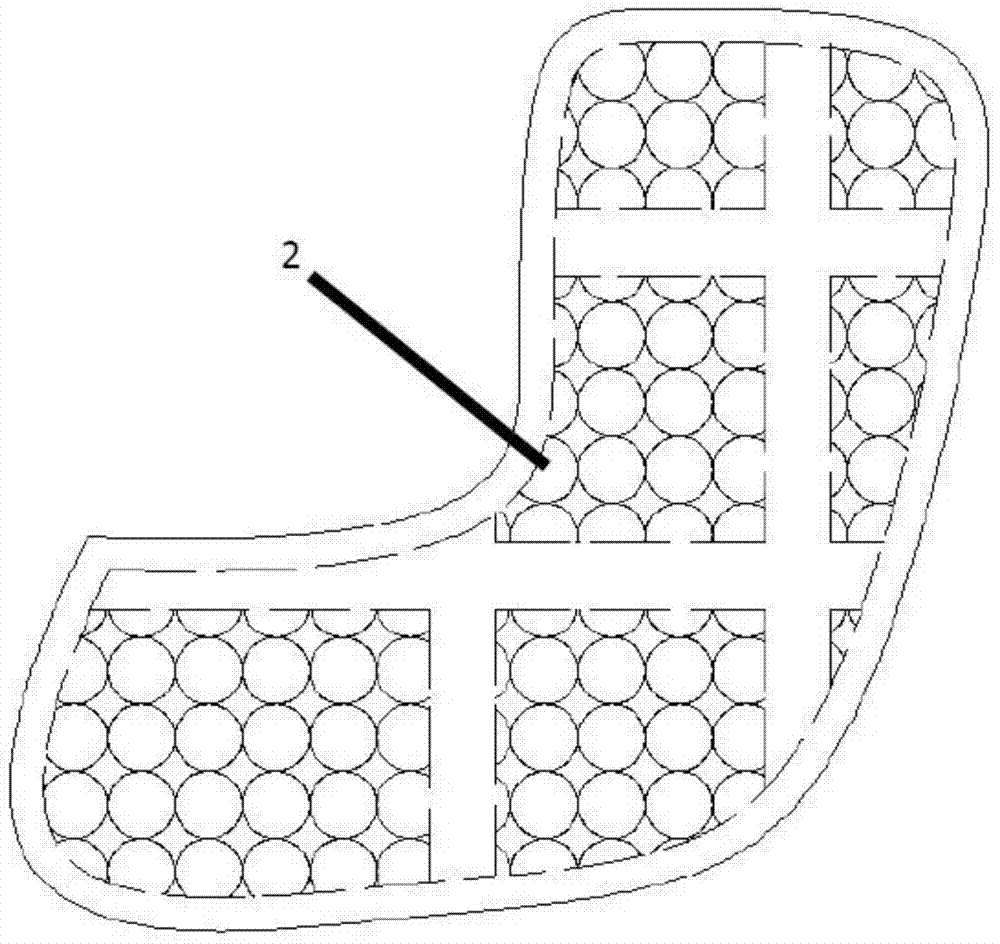

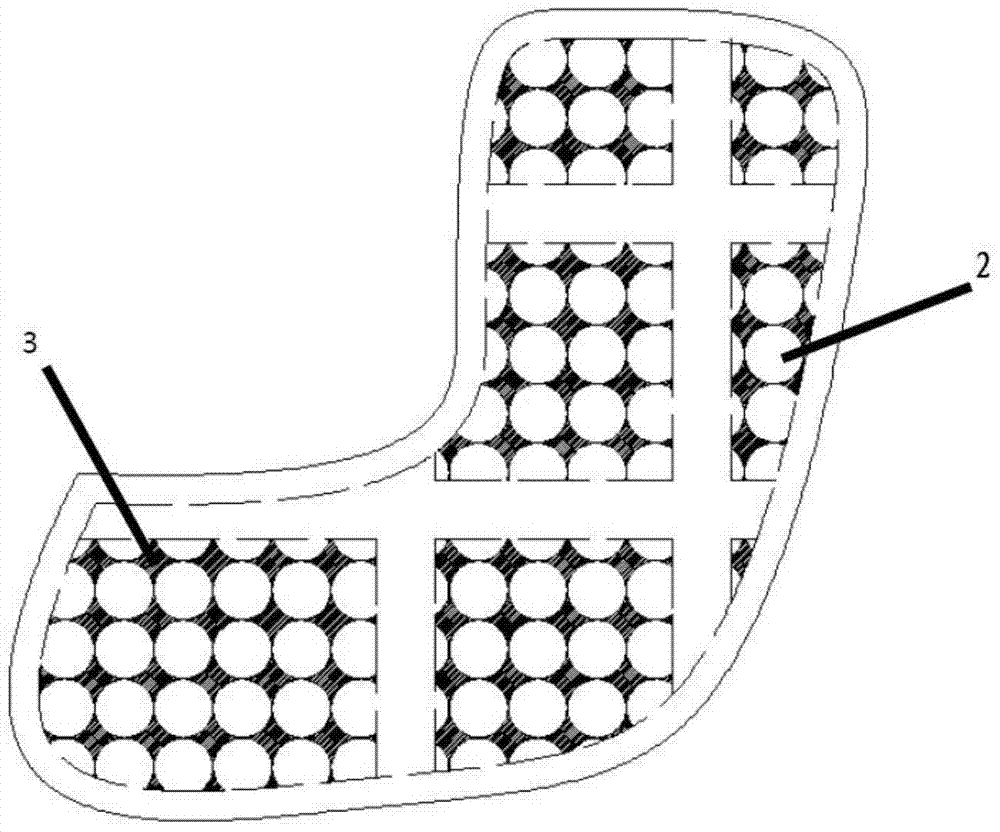

Bonelike porous biomechanical bionic designed spinal fusion device and preparation method and use thereof

InactiveCN106344221AAvoid stress shielding effectsGood treatment effectAdditive manufacturing apparatusSpinal implantsPorosityBiomechanics

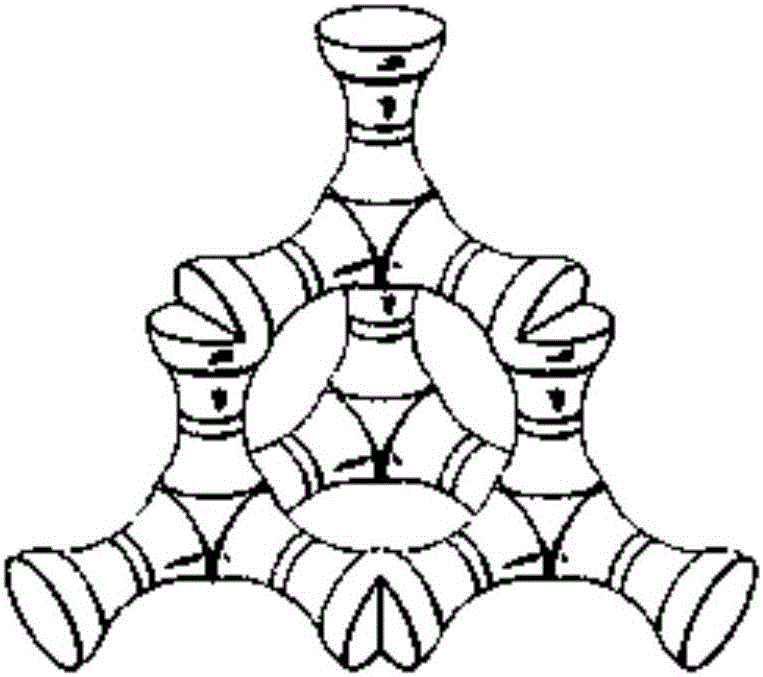

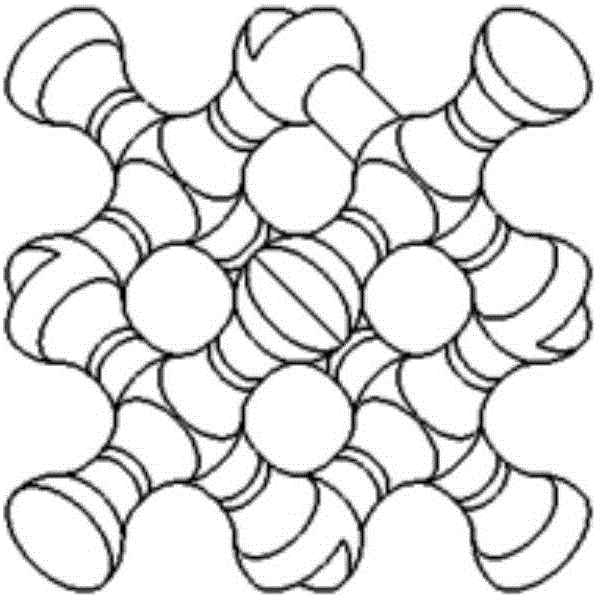

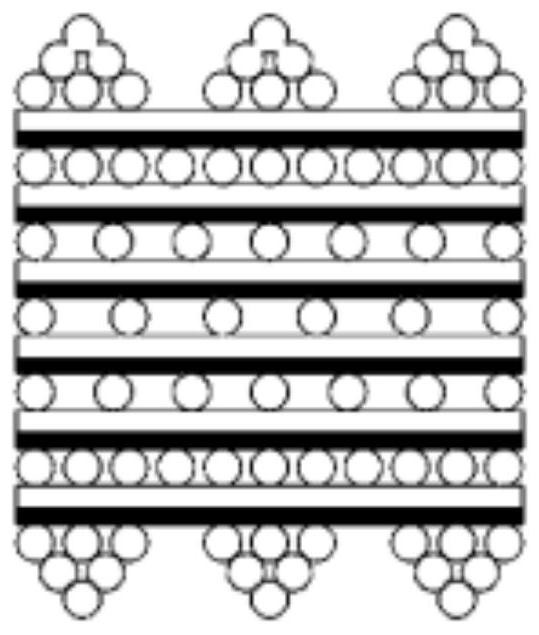

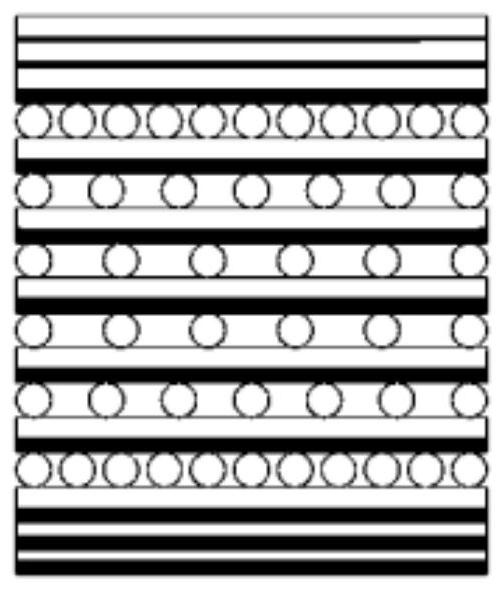

The invention relates to a bone-like porous biomechanical bionic design spine fusion device and its preparation method and application, which belong to the field of biomedical materials and are composed of a plurality of microporous spatial structural units, the microporous spatial structural unit is a regular tetrahedral structure, and the microporous The spatial structure unit body includes a base point and a filling geometry; the base point is located at the apex of the front tetrahedron; the filling geometry is arranged at the position of the base point, and the filling geometry intersects with the adjacent filling geometry to form a regular tetrahedral edge, and multiple microporous spatial structure units The shape, size and porosity of the pores of the material can be precisely adjusted to achieve the mechanical properties of natural bone matching. performance, and can be customized according to the needs of patients, with good biocompatibility, bioactivity, and biomechanical suitability, and has broad application prospects in orthopedic clinics.

Owner:SICHUAN UNIV

Personalized dental implant and manufacturing method thereof

InactiveCN106510873AExtended service lifeAvoid damageDental implantsAdditive manufacturing apparatusPorosityAdhesive

The invention relates to a dental implant and belongs to the field of medicine. The personalized dental implant is characterized by comprising a tooth root and an abutment. The shape and size of the tooth root are matched with alveolar bone, and the porosity in the axial and circumferential directions of the tooth root changes in a gradient way, so that the elastic modulus of the tooth root is matched with the elastic modulus of the alveolar bone to eliminate a stress shielding effect, and the force transfer effect between the dental implant and the alveolar bone is relatively good; the surface of the tooth root is mineralized to promote the integration of the dental implant and bone; the abutment and a tooth root connection section are inwardly sunken to form a gingival recess filled with an adhesive to improve the stability of the dental implant. The invention also relates to a method for manufacturing the dental implant. The method is characterized in that the alveolar bone space configuration and the bone elastic modulus are obtained by a medical imaging technique; and then the three-dimensional shape and elastic modulus of the matched dental implant are derived reversely; after 3D printing integral molding, the dental implant of which the shape, size and elastic modulus are matched with those of the alveolar bone is prepared.

Owner:SHANGHAI RUIBO MEDICAL TECH CO LTD

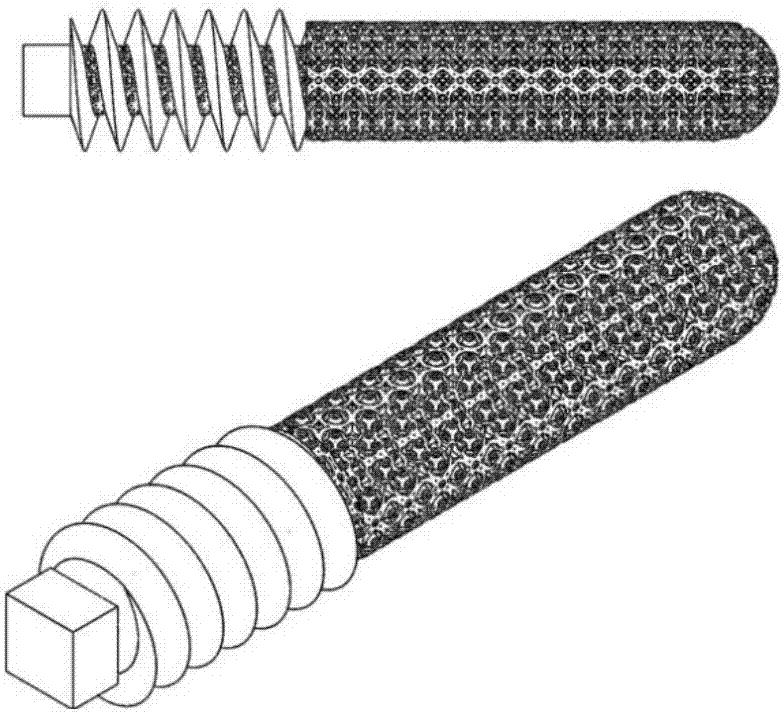

Multistage through-hole porous tooth implantation body

ActiveCN106859792AEasy accessPromote growth and proliferationDental implantsSolid structurePore diameter

The invention discloses a multistage through-hole porous tooth implantation body. The multistage through-hole porous tooth implantation body comprises a gingiva passing through segment and a screw thread segment; the gingiva passing through segment is of a smooth solid structure, and is arranged on the upper part of the screw thread segment; the multistage through-hole porous tooth implantation body also comprises a porous structure segment; the porous structure segment is arranged on the lower part of the screw thread segment; the hole diameter of transverse through holes on the porous structure segment from the lower part to the upper part is increased successively; the transverse through holes with the same hole diameter are arranged in a radiation manner along the periphery of the porous structure segment. The multistage through-hole porous tooth implantation body is capable of increasing combination strength, increasing combination speed, and is provided with the porous structure conveniently.

Owner:ZHEJIANG UNIV OF TECH

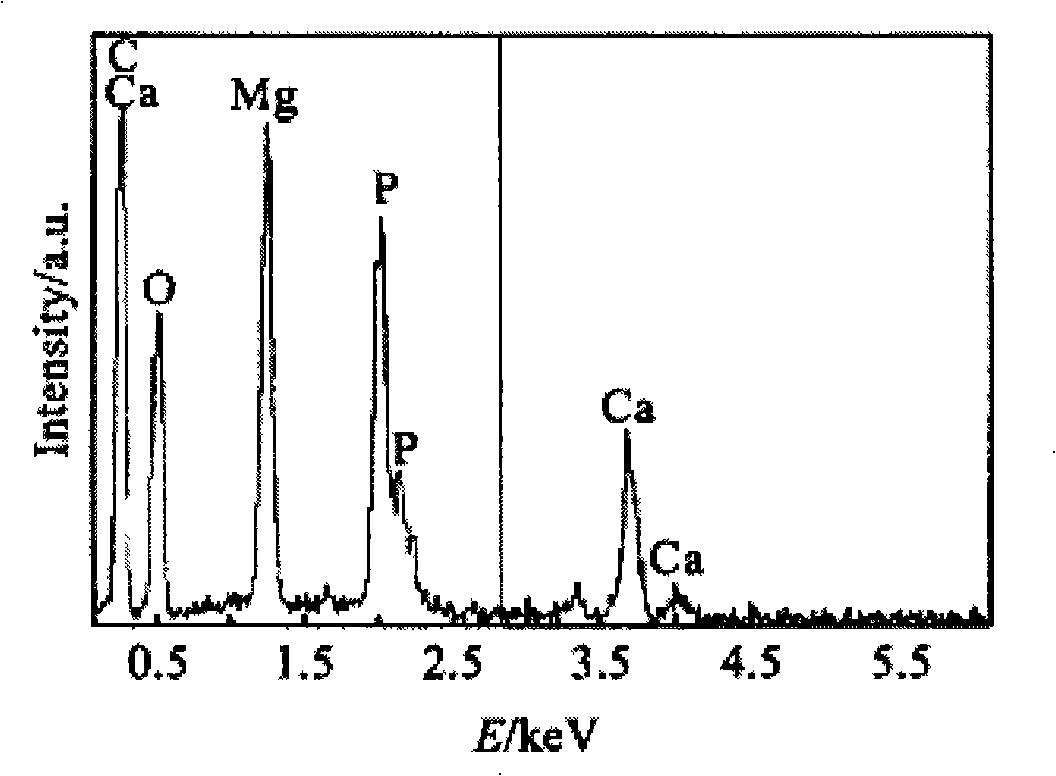

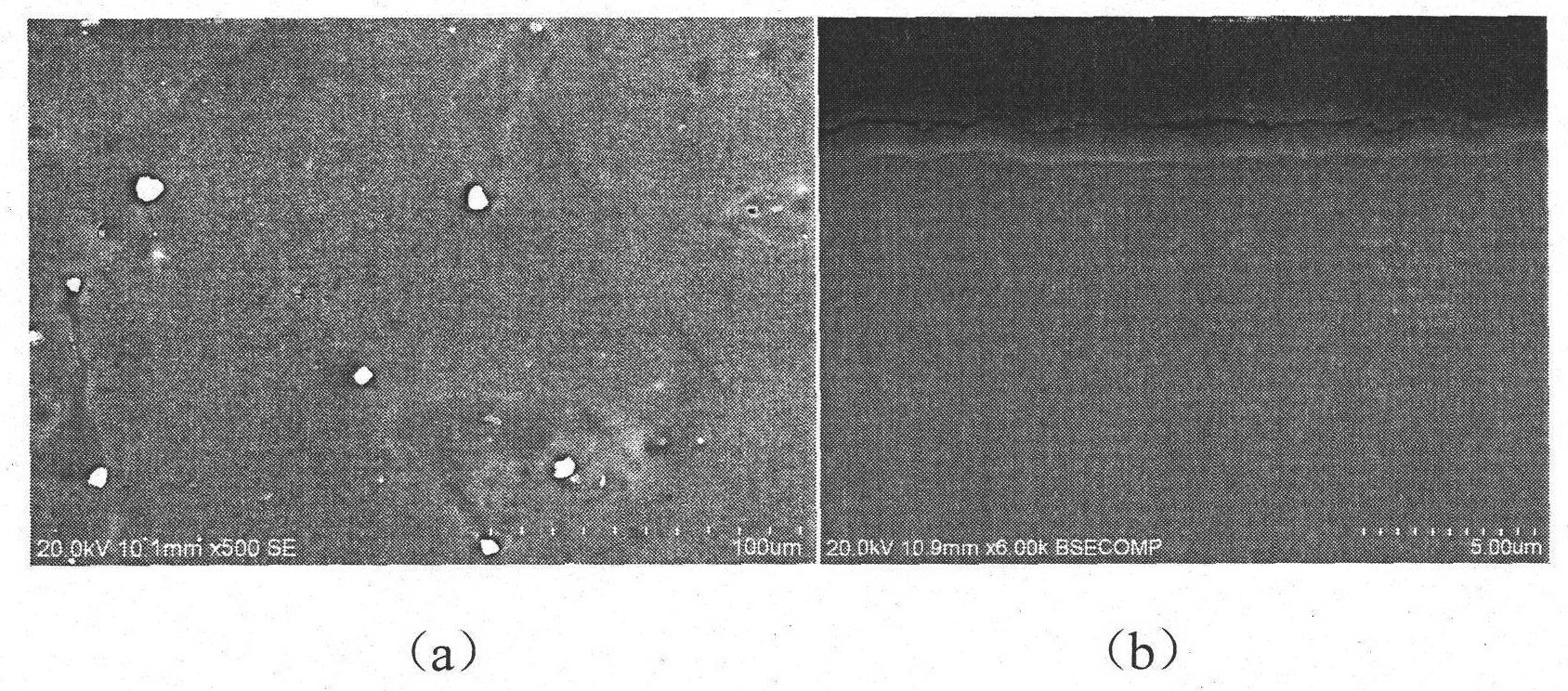

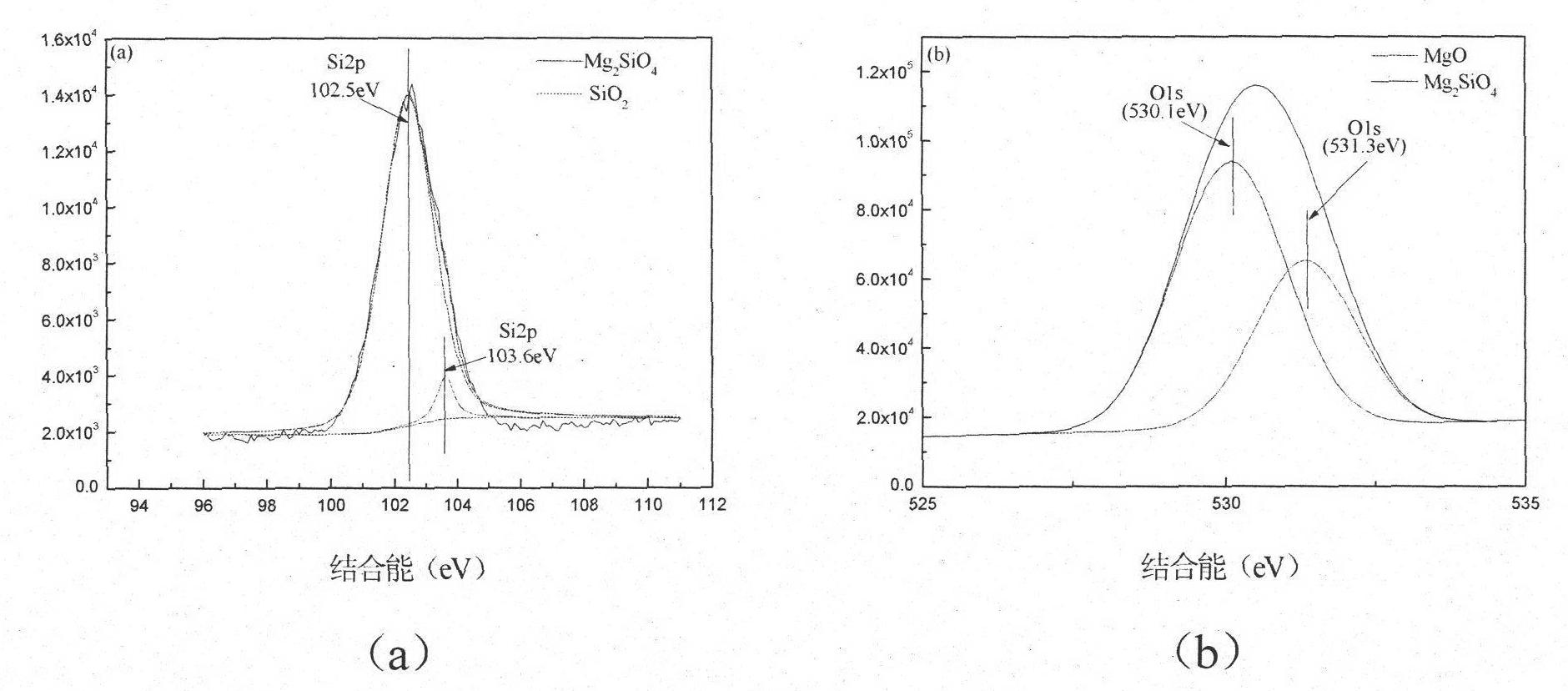

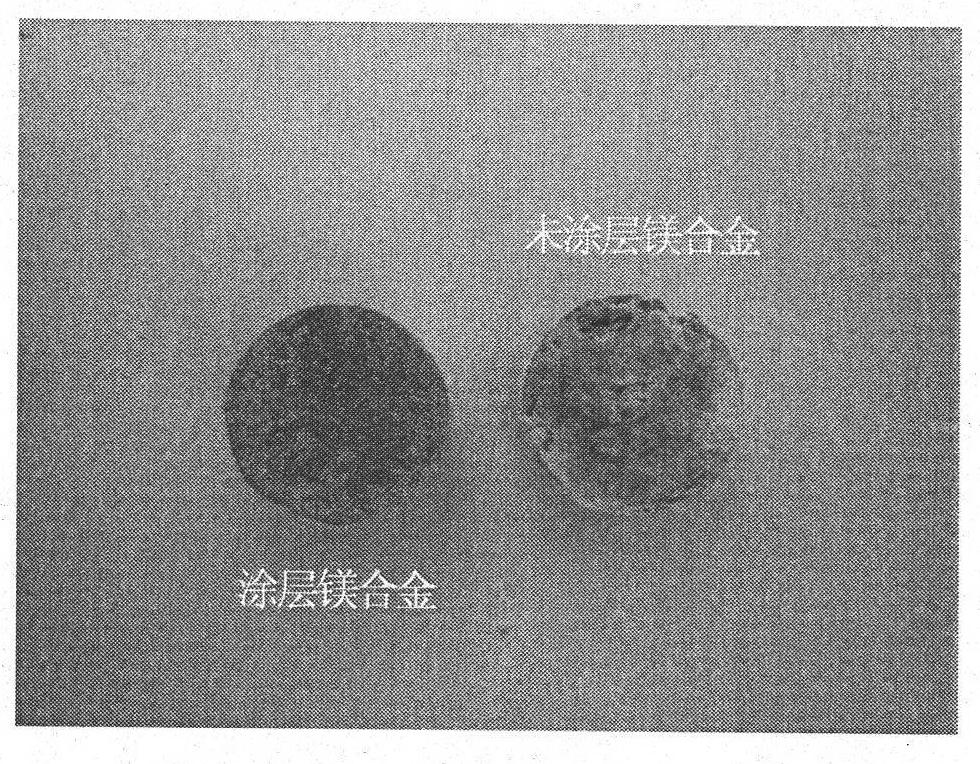

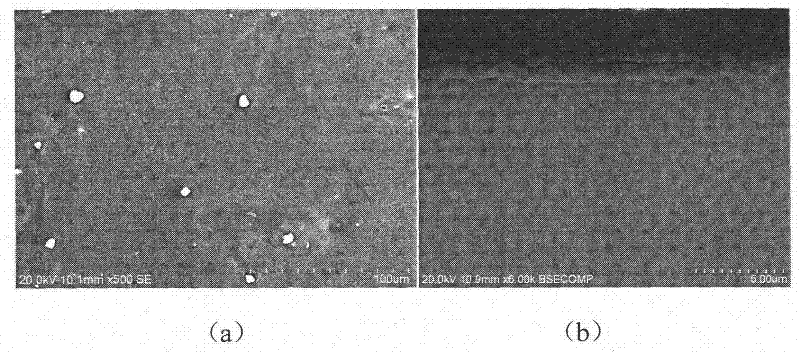

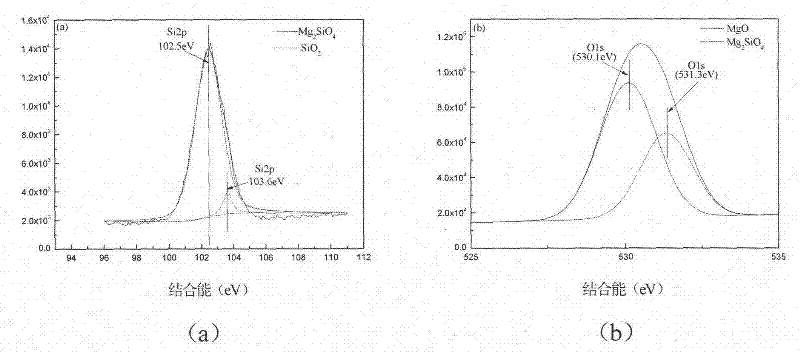

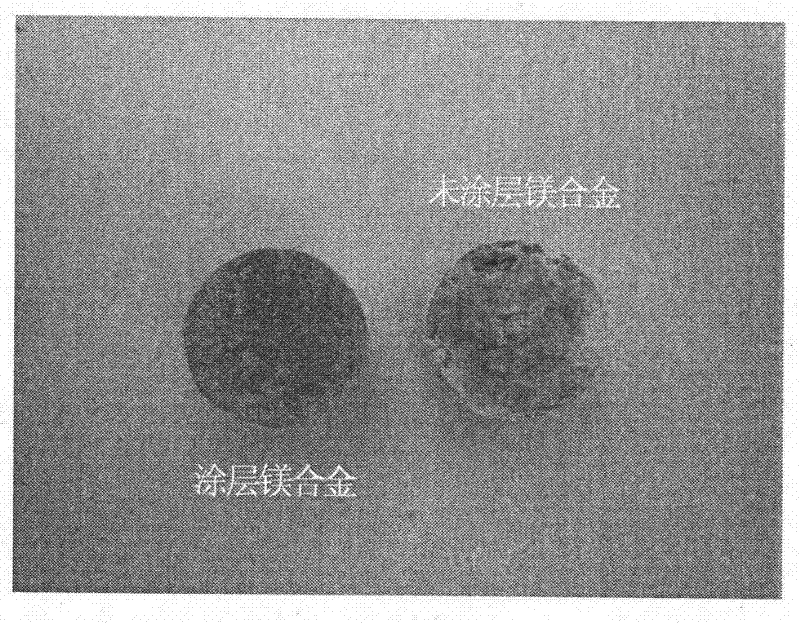

Silicate coating-containing absorbable medical magnesium-based metal and preparation method and application thereof

InactiveCN102146562APromote healingSlow degradationMetallic material coating processesProsthesisCorrosionMagnesium silicate

The invention relates to a silicate coating-containing absorbable medical magnesium-based metal, a preparation method and application thereof. The magnesium-based metal belongs to the field of biomedical appliances and is particularly suitable for the field of medical appliances used for bone trauma surgery, reparative and reconstructive surgery, and coining and cosmetology. The magnesium-based metal consists of a magnesium-based metal substrate and a silicate coating formed on the surface of the substrate, wherein the silicate coating consists of magnesium silicate and magnesium oxide. In an alkaline environment, a protective coating is prepared on the surface of the magnesium-based metal by a low temperature chemical deposition method. The method is simple and feasible and has low requirement on equipment; and the thickness of the coating can be controlled to be between several hundred nanometers and 5 mu m. The protective coating is uniform and dense, has high corrosion resistance, simultaneously has high biological activity and metal appearance, and can control the degradation rate of the magnesium-based metal and the dissolution rate of magnesium ions so as to control the biological activity and the absorption rate of magnesium-based metal implanted devices in organisms. The magnesium-based metal can be used for preparing intra-osteal fixing devices.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

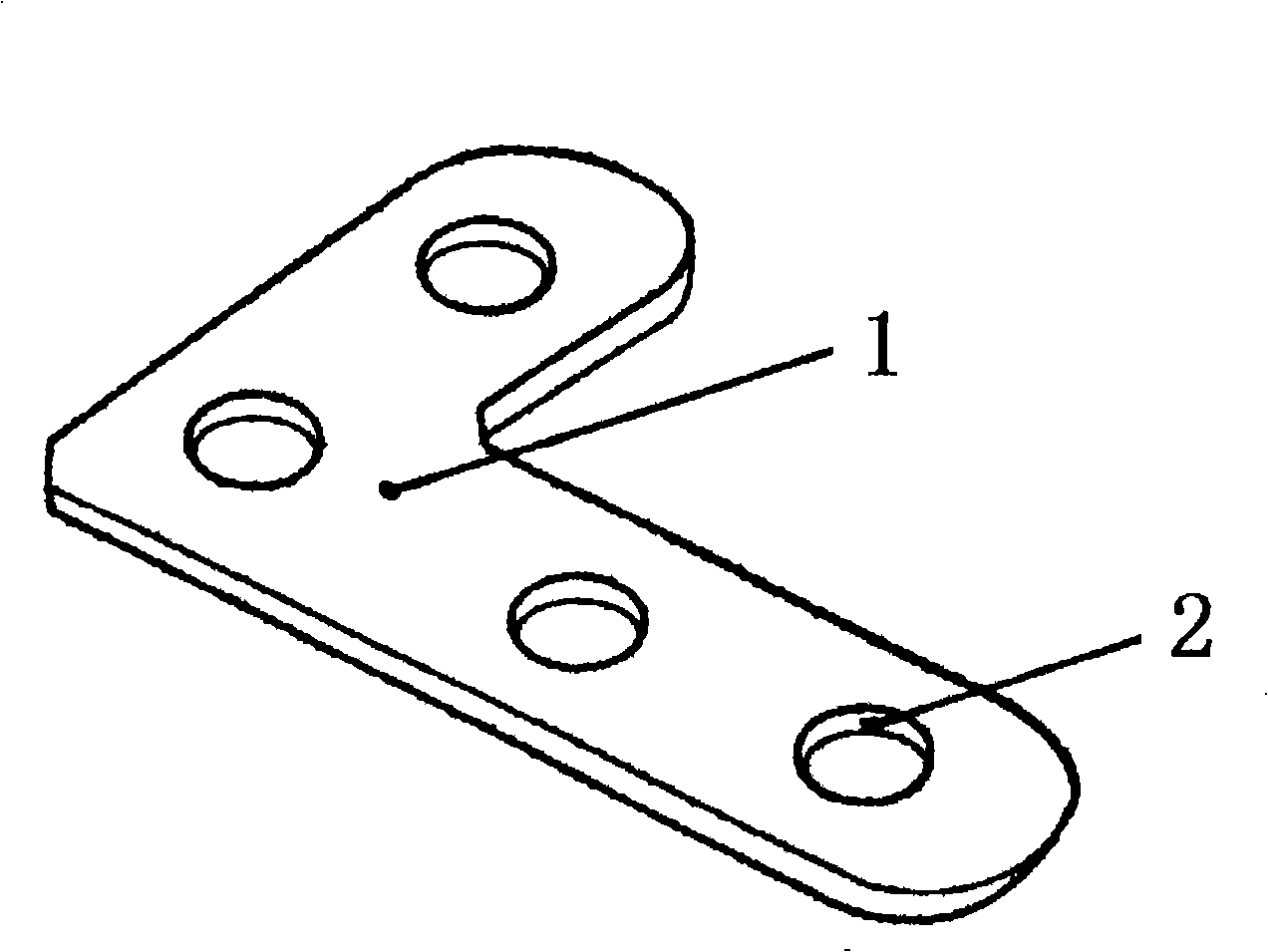

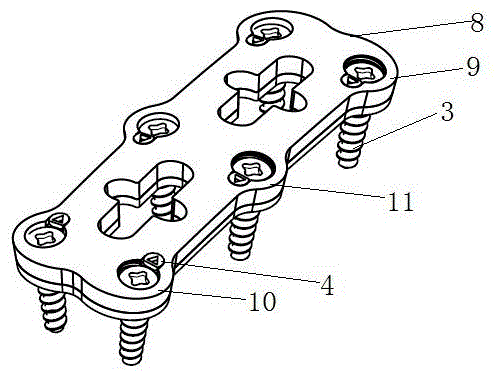

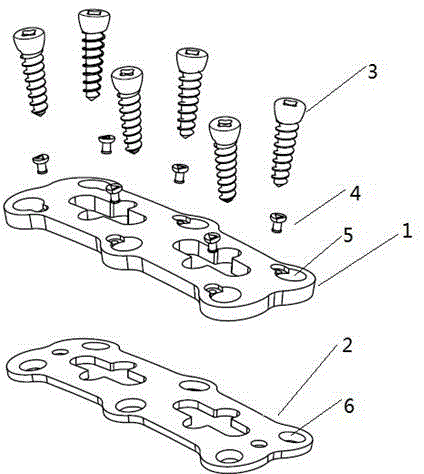

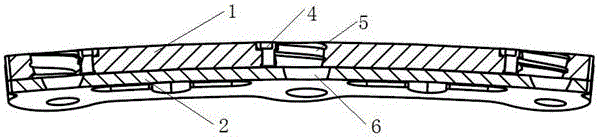

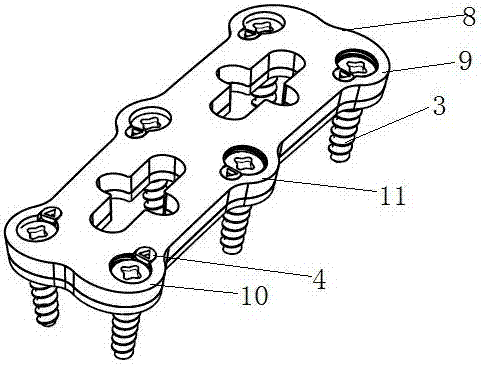

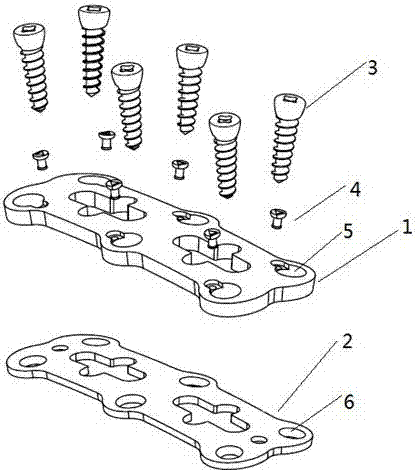

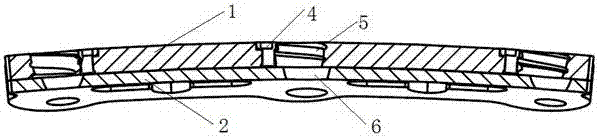

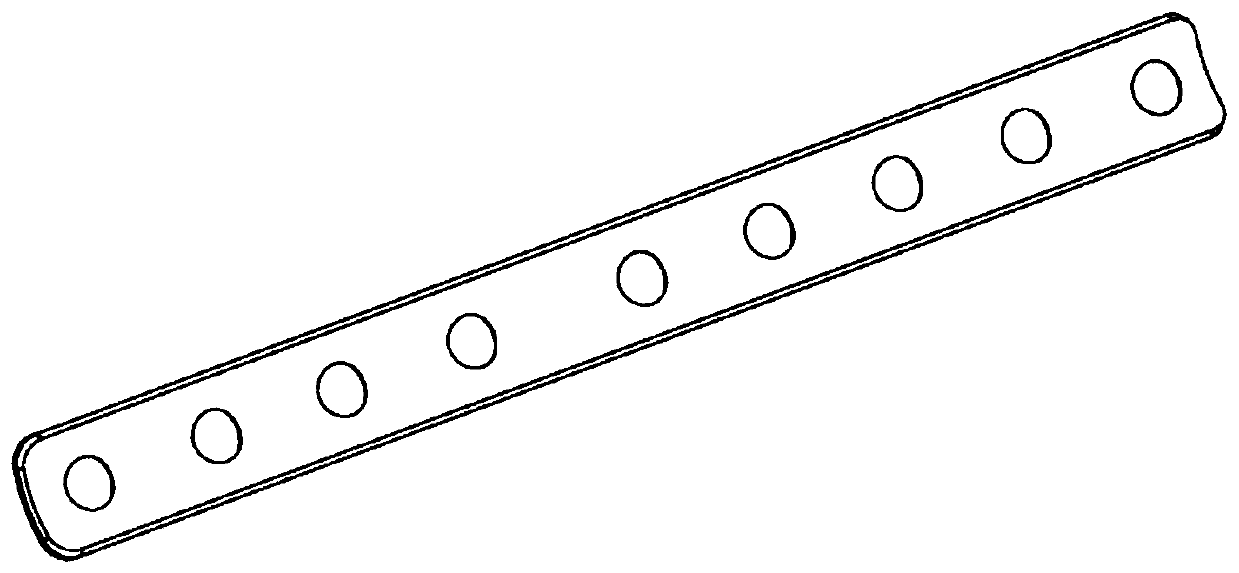

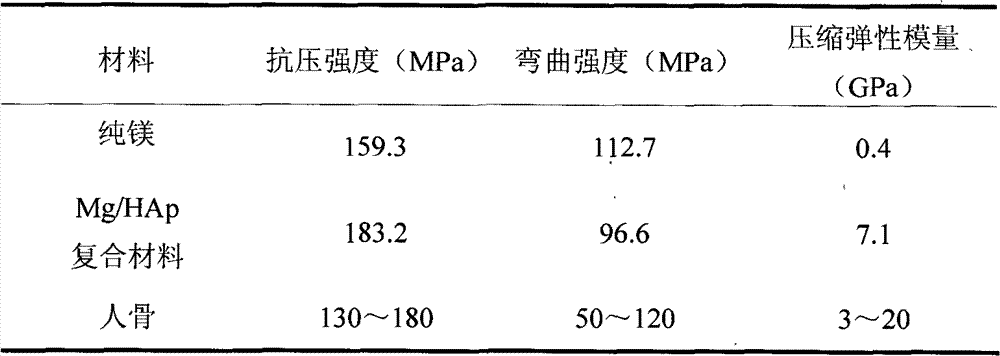

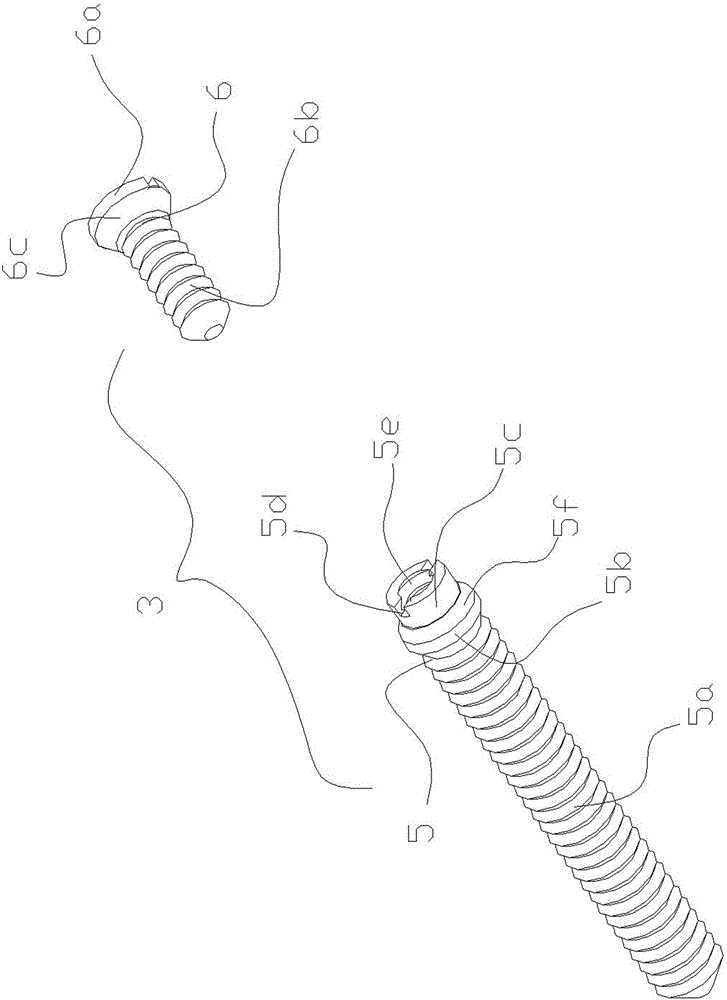

Spinal fixation device

ActiveCN104856748AGuaranteed compressive strengthGood dispersionInternal osteosythesisBone platesSpinal columnBone healing

The invention provides a spinal fixation device, and belongs to orthopaedic implants. The spinal fixation device comprises a bone lamella and screws, lamella holes are formed in the upper surface and the lower surface of the bone lamella in a penetrating mode, and the screws can be matched with the lamella holes. When the spinal fixation device is used, the screws penetrate through the lamella holes to fix the bone lamella on the bone, operation is easy, fixing is firm, and bone healing is facilitated.

Owner:BEIJING NATON TECH GRP CO LTD +2

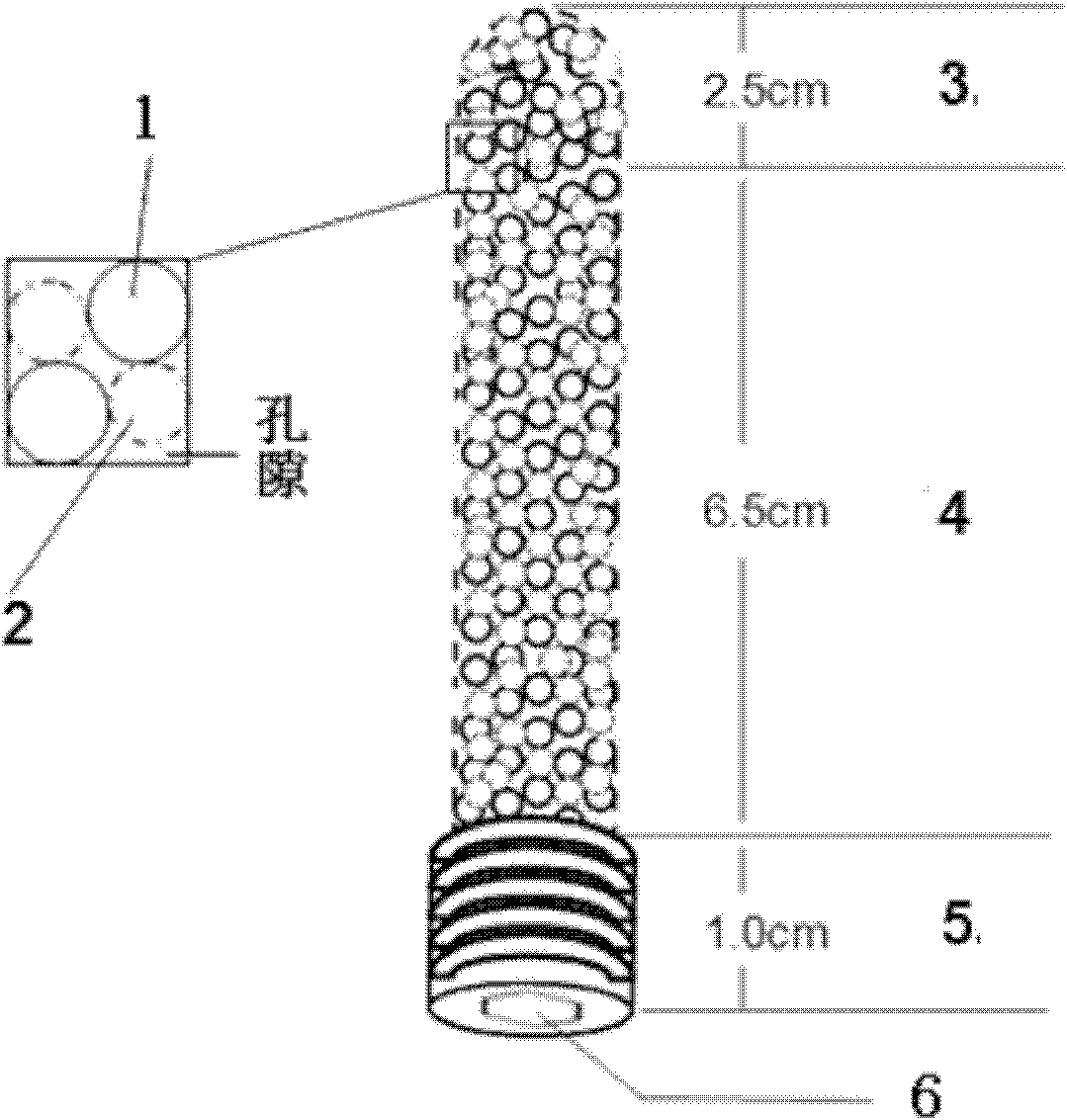

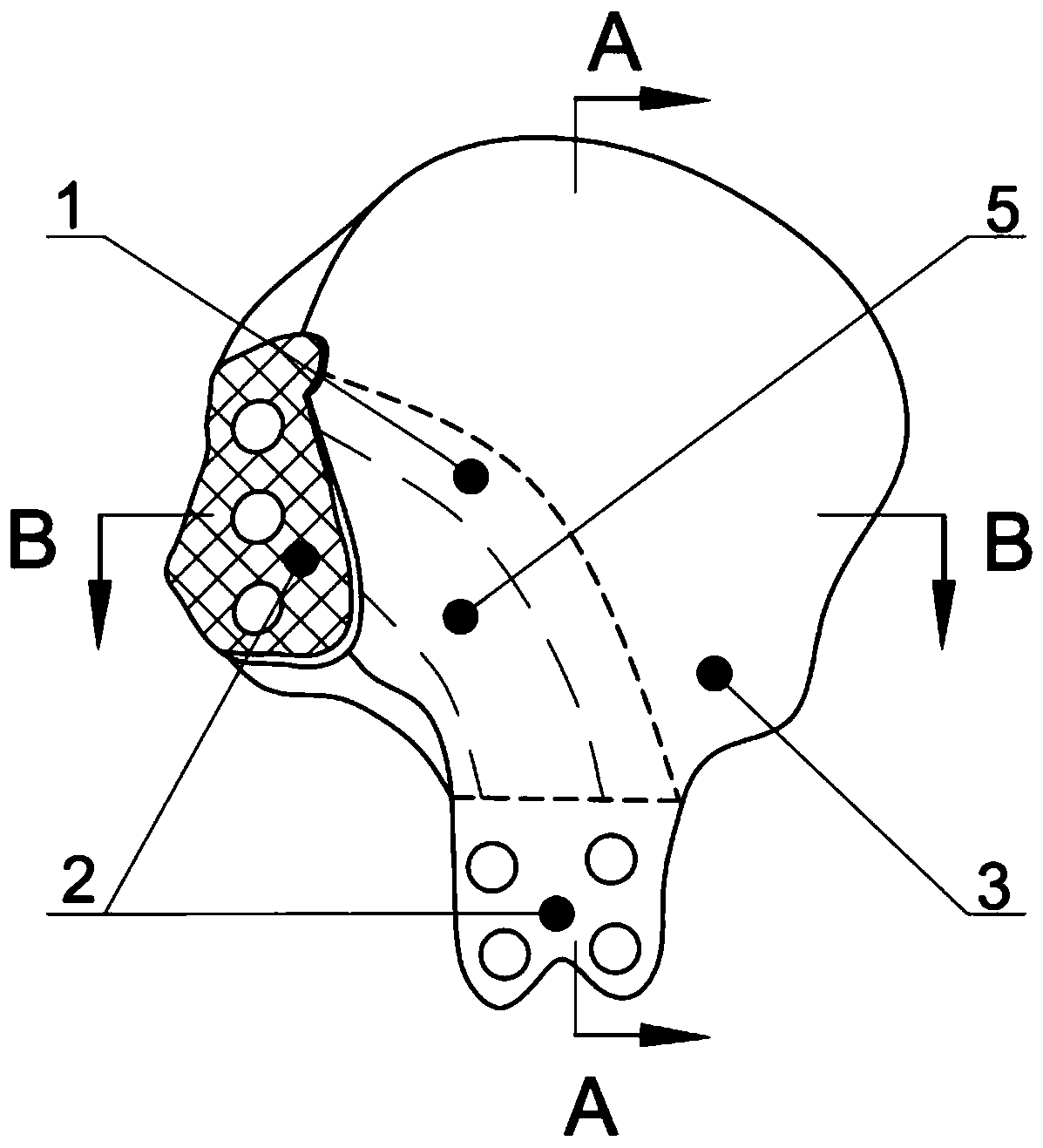

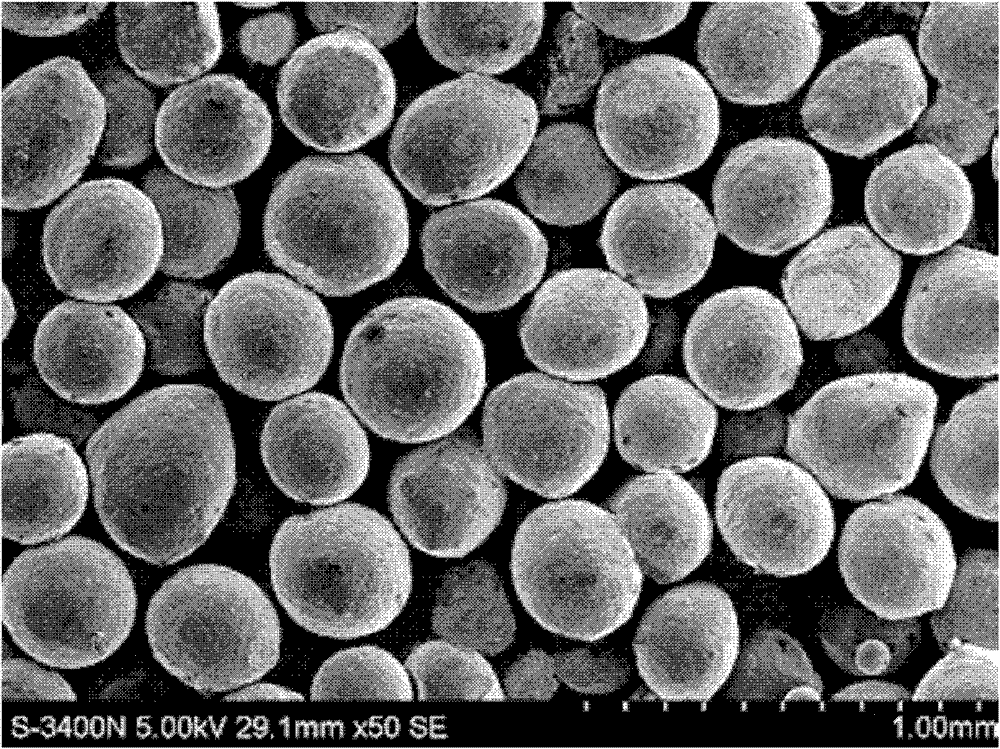

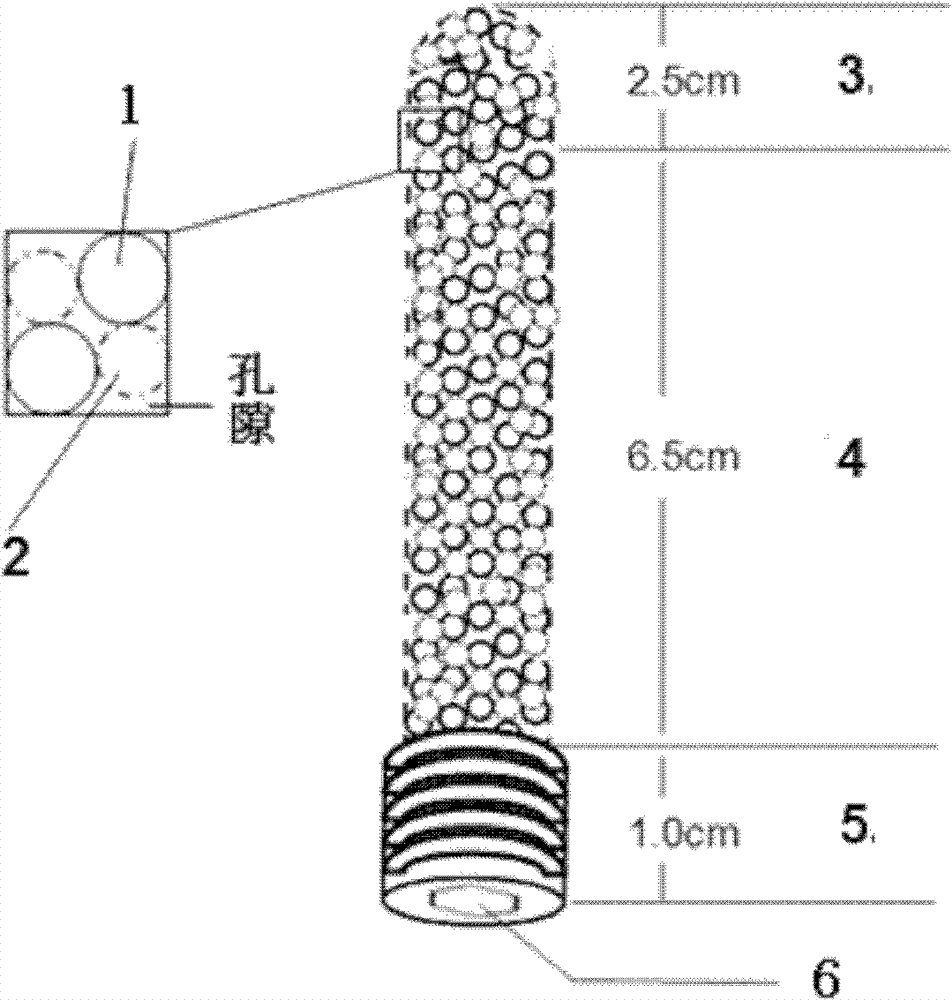

Method for forming composite rhBMP-2 elasticity modulus graded porous titanium alloy support rod for femoral head and neck

The invention relates to a method for forming a composite rhBMP-2 elasticity modulus graded porous titanium alloy support rod for the femoral head and the neck. Titanium alloy powder is prepared with an electrode induction melting gas atomization method, and the integrated elasticity modulus graded porous titanium alloy support rod consisting of a head part, a body part and a tail part is prepared according to actually measured biomechanical parameters of the femoral head, the neck and a rotor, wherein the head part and the body part are prepared by sintering the titanium alloy powder and pore-forming agents through the adoption of a cold rolling method, the tail part is prepared by directly sintering the titanium alloy powder, and the porous titanium alloy support rod is immersed in a rhBMP-2 / gelatin controlled release microsphere solution. The product prepared by the method can simulate the biomechanical properties of the femoral head and the neck of a human body to the utmost extent, thereby being beneficial to the stress transfer between materials and bone tissue interfaces, avoiding poor bone restoration caused by the stress shielding effect; and simultaneously, sustained-release microspheres on which bone induced growth factors (rhBMP-2) are loaded endue the materials per se with good bone conductivity.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

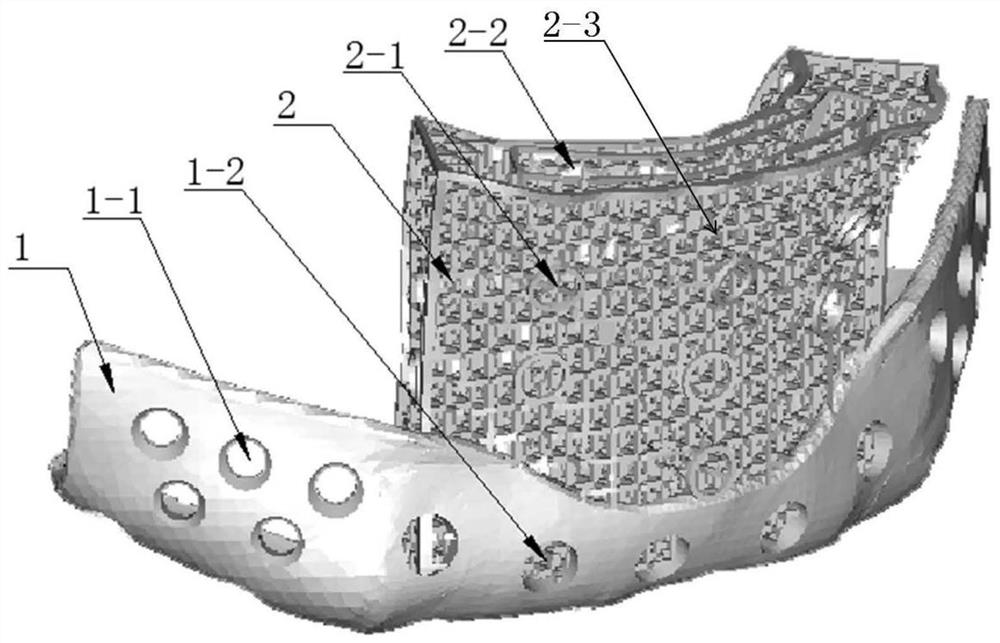

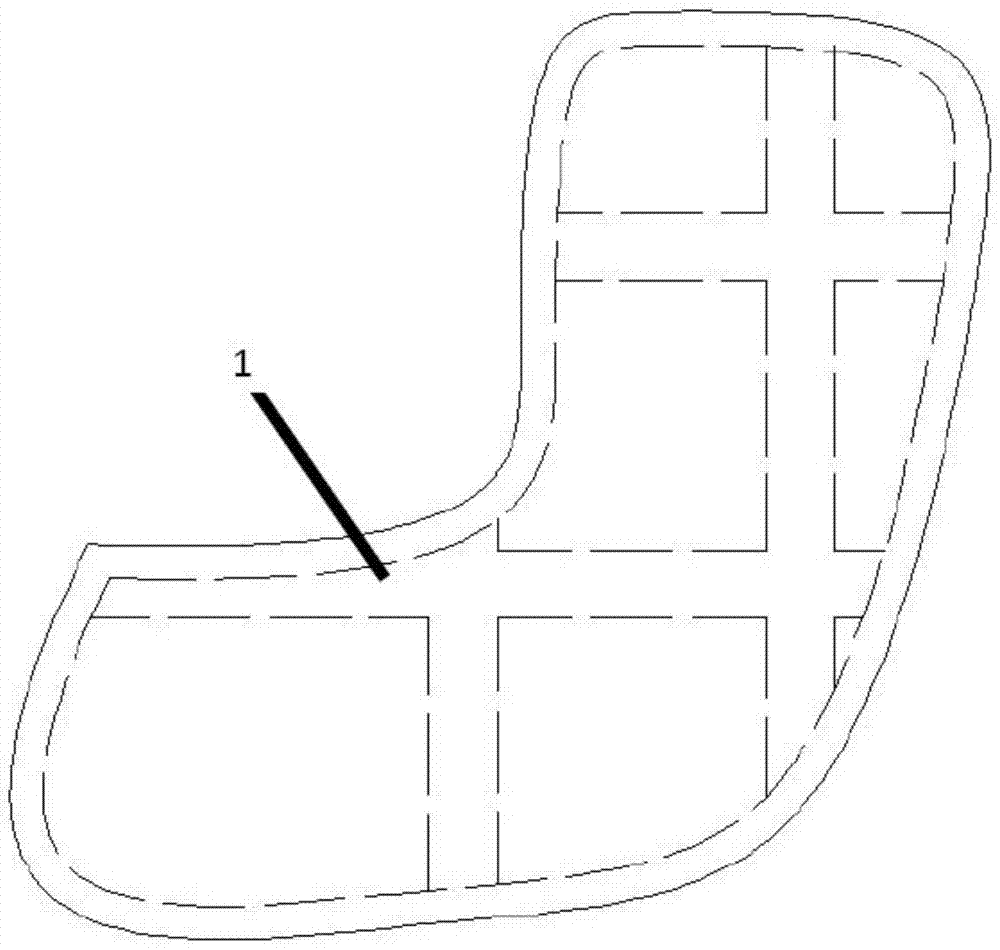

Implant for maxillofacial bone defect repair, and preparation method of implant

PendingCN112107394AWeight reduction stress maskingReduce stress shieldingBone implantTomographyTOOTH IMPLANTATIONSBone grafting

The invention discloses an implant for maxillofacial bone defect repair, and a preparation method of the implant. The implant structurally comprises a fixing unit and a porous structure part; the porous structure part is integrally connected with the fixing unit; the fixing unit comprises a screw hole and a first through hole; the fixing unit is matched with a healthy residual bone in shape; the porous structure part is located in the middle of the fixing unit and comprises a second through hole and an implant reserved socket; the porous structure part is filled in a maxillofacial disease bonearea or defect area; and the shape and size of the porous structure part are matched with the jaw anatomical structure of the maxillofacial disease bone area or defect area. According to the invention, personalized customization can be realized according to individual needs of patients; the implant is light in weight and low in material cost; meanwhile, the modulus of the implant is also reduced;therefore, the stress shielding effect caused by mismatching of the implant and the bone tissue modulus is avoided; the porous structure has the biological functions of promoting bone tissue ingrowth, vascularization and the like; and meanwhile, intraoperative bone grafting is carried out by reserving an implant alveolar socket, so that postoperative tooth implantation is facilitated.

Owner:FUJIAN CTRUE MATERIALS TECH

Biomedicine implant material with controllable degrading rate and its application

The present invention relates to biomedicine metal implant material, and is especially biomedicine implant material with controllable degrading rate and its application. The biomedicine implant material with controllable degrading rate has a magnesium or magnesium alloy matrix and a coated degradable polymer layer with thickness controlled within 0.01-5 mm. The biodegradation is completed step by step so as to ensure the mechanical performance of the material during degradation and match the degradation rate with the service period of the implanted device. The biomedicine metal implant material of magnesium or magnesium alloy may be used in preparing temporary or short term implanted device, such as degradable blood rack and peripheral rack, bone fracture plate and bone nail for inner fixing, tissue engineering rack, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A spinal fixation device

ActiveCN104856748BGuaranteed compressive strengthGood dispersionInternal osteosythesisBone platesIliac screwBone healing

Owner:BEIJING NATON TECH GRP CO LTD +2

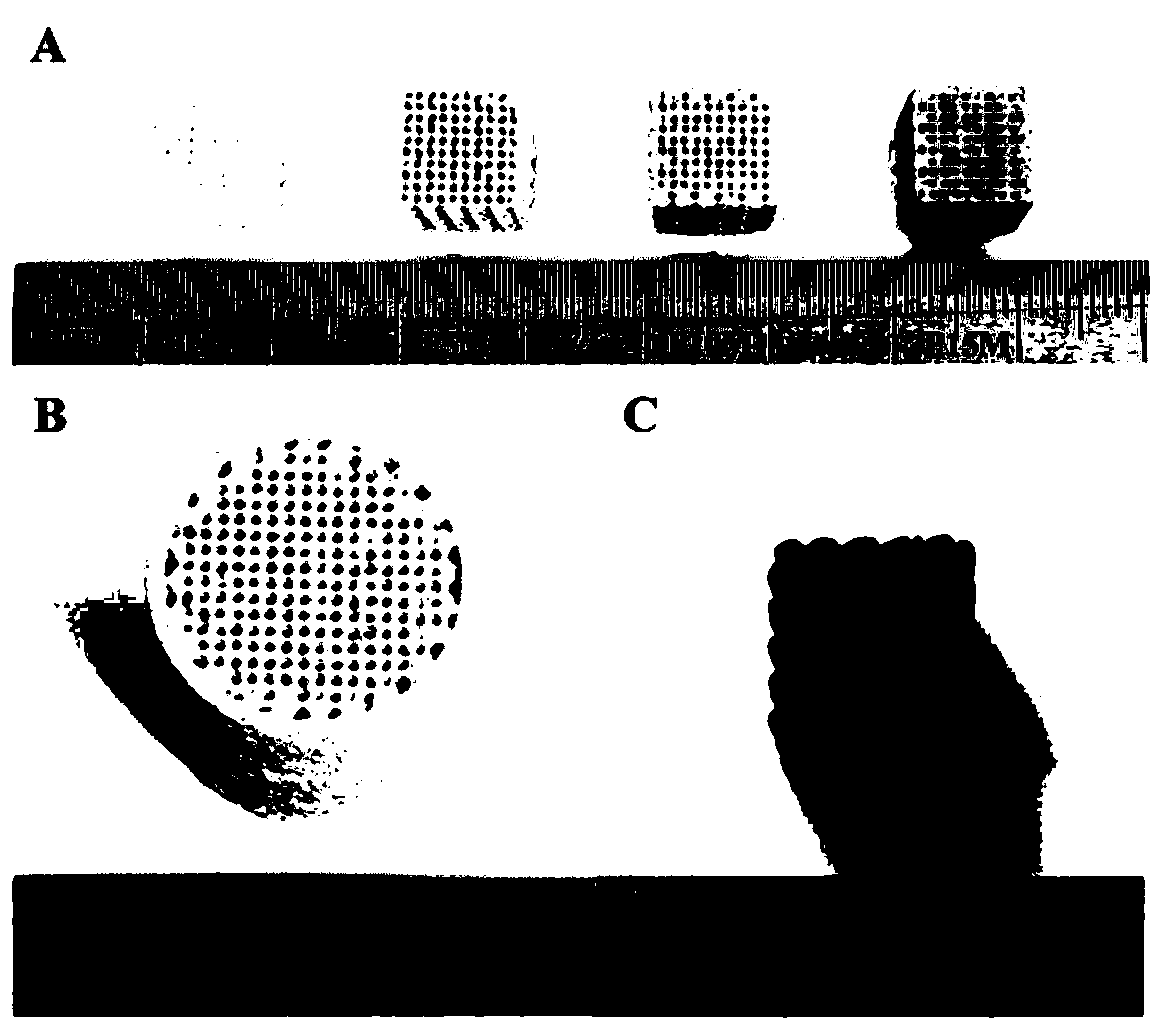

Medical enhanced biodegradable GTR/GBR integrated film and preparation method thereof

The invention discloses a medical enhanced biodegradable GTR / GBR integrated film and a preparation method thereof. The integrated film contains polylactic acid and a magnesium alloy hole plate packedin the polylactic acid, which are integrally shaped. In accordance with the situation that at current market, a biodegradable film is low in intensity and cannot maintain integrity for a long time, anon-biodegradable film needs to be operated for the second time, infection is easy to cause, and the pain of patients can be increased, the invention researches and develops the GTR / GBR integrated film having high intensity and biodegradable properties. The integrated film combines the advantages of the relevant biodegradable film and the non-biodegradable film materials as far as possible, so that the medical enhanced biodegradable GTR / GBR integrated film is high in intensity and appropriate in price.

Owner:TAISHAN MEDICAL UNIV

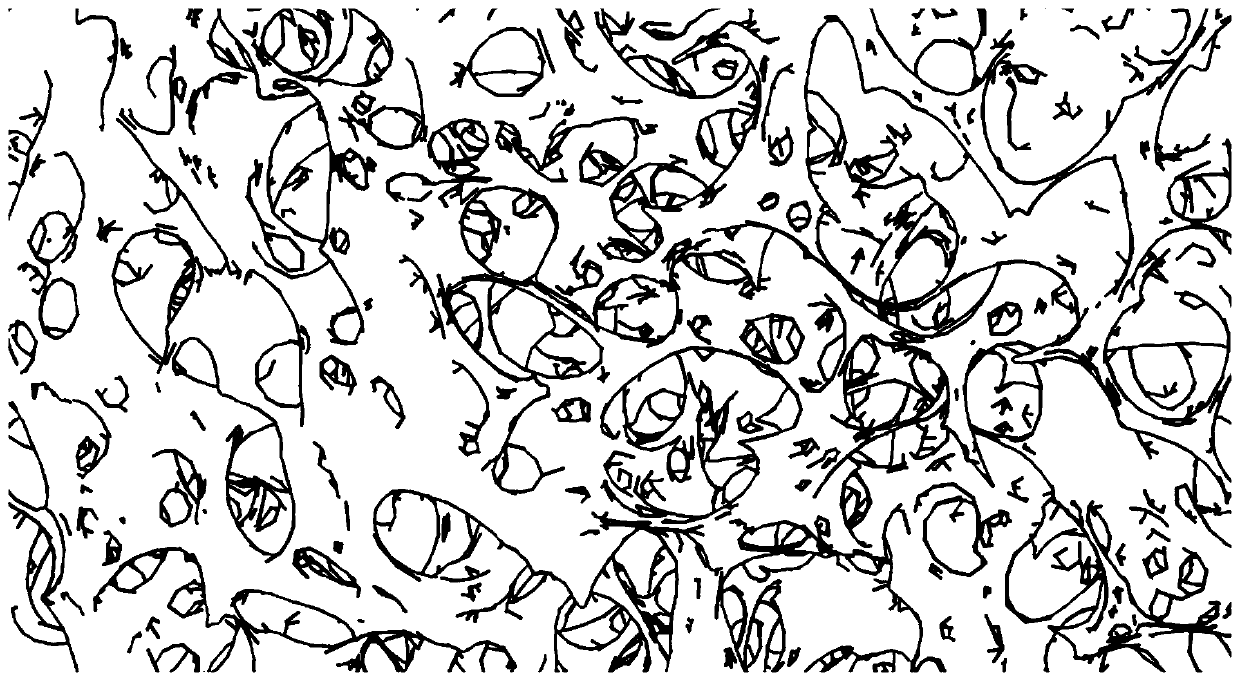

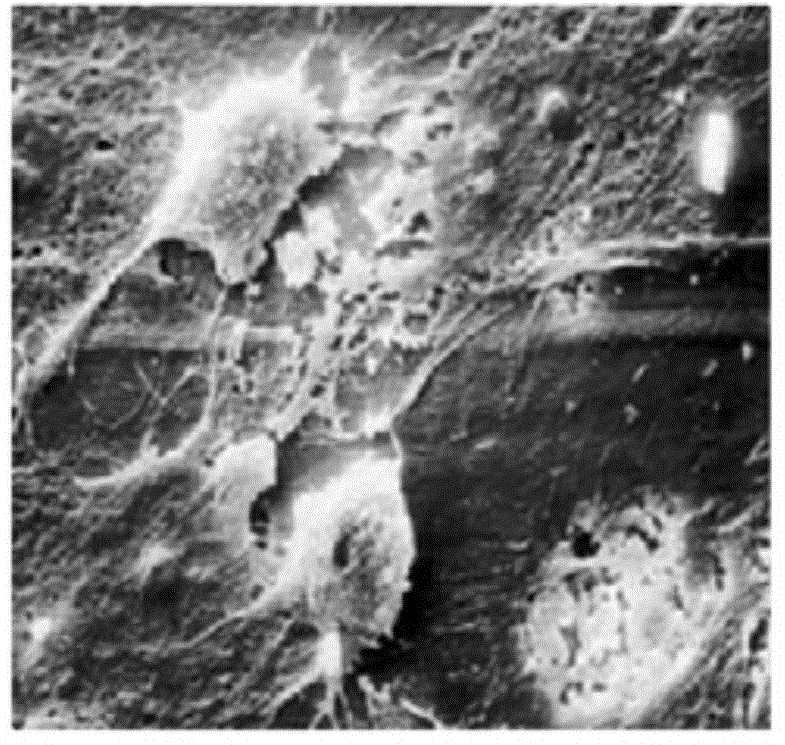

Metal bionic bone trabecula for repairing cancellous bone defect and preparing method thereof

InactiveCN109771101AImprove restoration qualityImprove repair speedBone implantNiobiumMetallic materials

The invention discloses a metal bionic bone trabecula for repairing a cancellous bone defect and a preparation method thereof. The method includes the steps that with a fast fuse fabrication (FFF) method, metal powder is melted and subjected to electrostatic filament drawing, deposition molding is conducted according to a preset bone trabecula model, and the metal bionic bone trabecula is obtained. According to the preparing method, metal materials are printed into a porous structure similar to the bone trabecula through the FFF technology, the printing precision meets the condition that the filament diameter is 10 microns or below, and true bionics is achieved. Moreover, the adopted metal materials of tantalum, titanium tantalum alloy or titanium tantalum niobium zirconium alloy and the like has biological activities for promoting tissue regeneration, and fully meets clinical use requirements. The bionic bone trabecula prepared with the method can perfectly replace an autologous or allogeneic bone.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

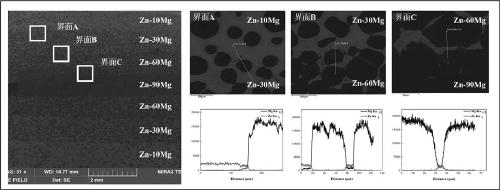

Preparation method for controllable degradation type zinc-magnesium gradient material

ActiveCN110449579AMeet performance requirementsImprove corrosion resistanceTissue regenerationProsthesisGradient materialVolumetric Mass Density

The invention relates to a preparation method for a controllable degradation type zinc-magnesium gradient material, belongs to the technical field of preparation and application of medical biomaterials. According to the preparation method, the problem that a single homogeneous material can hardly meet the application requirement of the diversity of a degradable implant material can be solved, magnesium powder and zinc powder serve as raw materials, and the controllable degradation type zinc-magnesium gradient material is developed through a preparation technology of powder preparation, ball-milling and powder mixing, powder laying, pre-pressing forming and spark plasma sintering; the density of the material is 3.58 g / cm<3>, the compactness reaches 98.2%, the compressive strength is about 261 MPa, the bending strength is 114 MPa, the bending modulus is 7.1 GPa, the material is matched with bone tissue of a human body in performance, the stress shielding effect can be effectively avoided, and the performance requirement of a hard tissue implant of the human body can be met; and meanwhile, the gradient material is soaked and corroded, has good corrosion resistance at the early stage and has the characteristic of obviously increased corrosion rate in the later stage, and the unique functional requirements that the outer layer material is corrosion-resistant at the initial stage ofimplantation, can ensure the mechanical property and is rapidly degraded in the later stage of implantation can be met.

Owner:TAIYUAN UNIV OF TECH

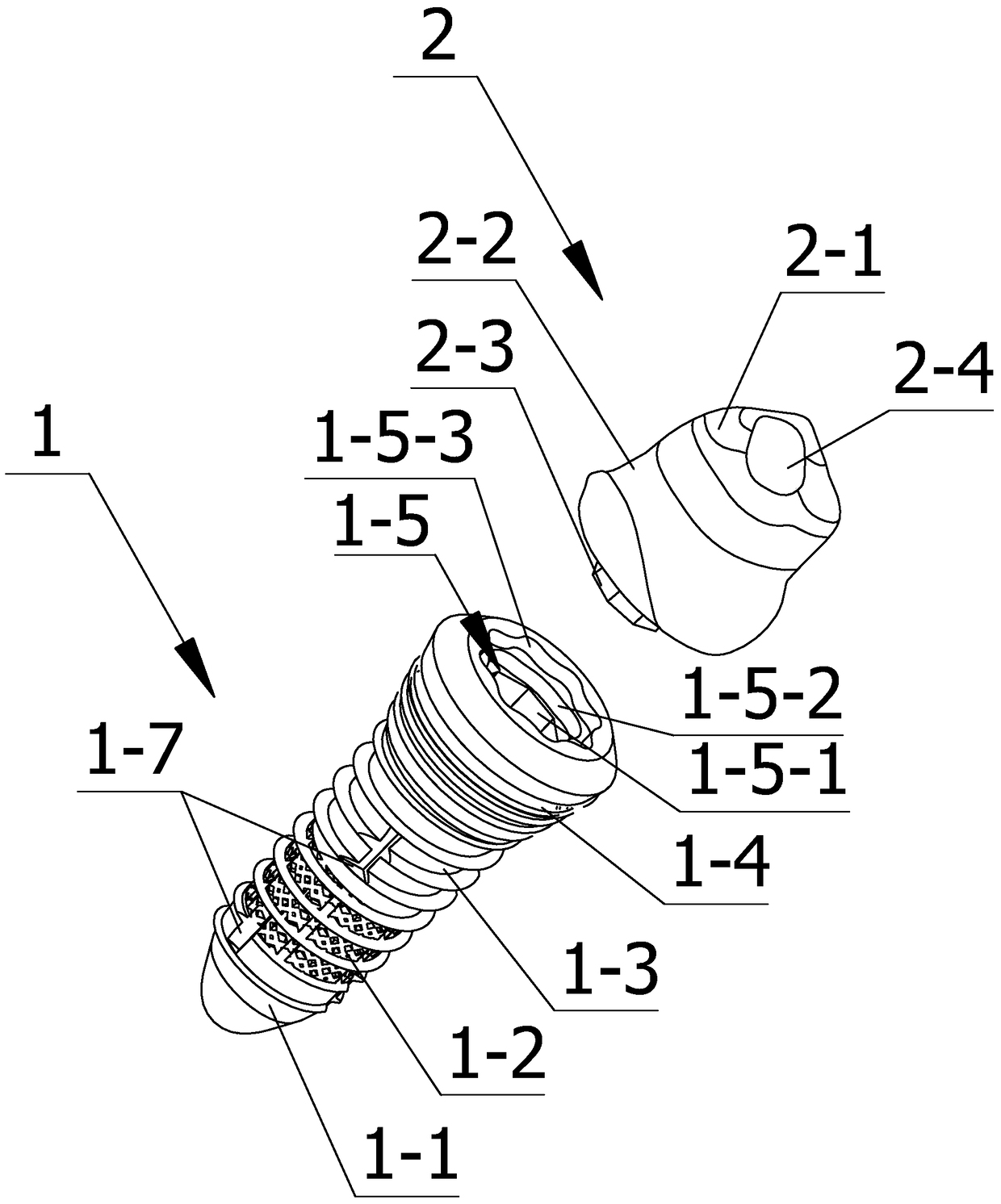

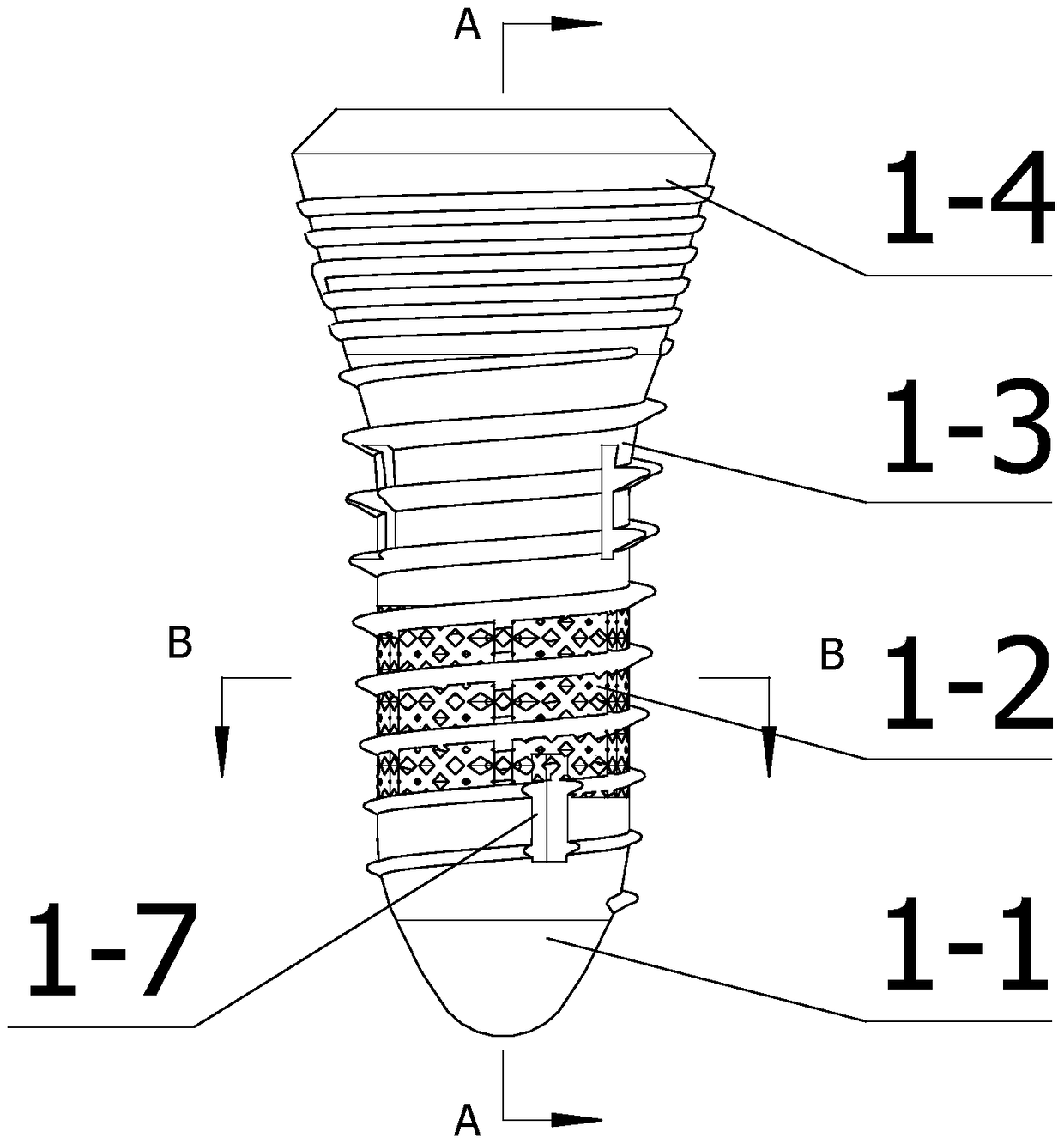

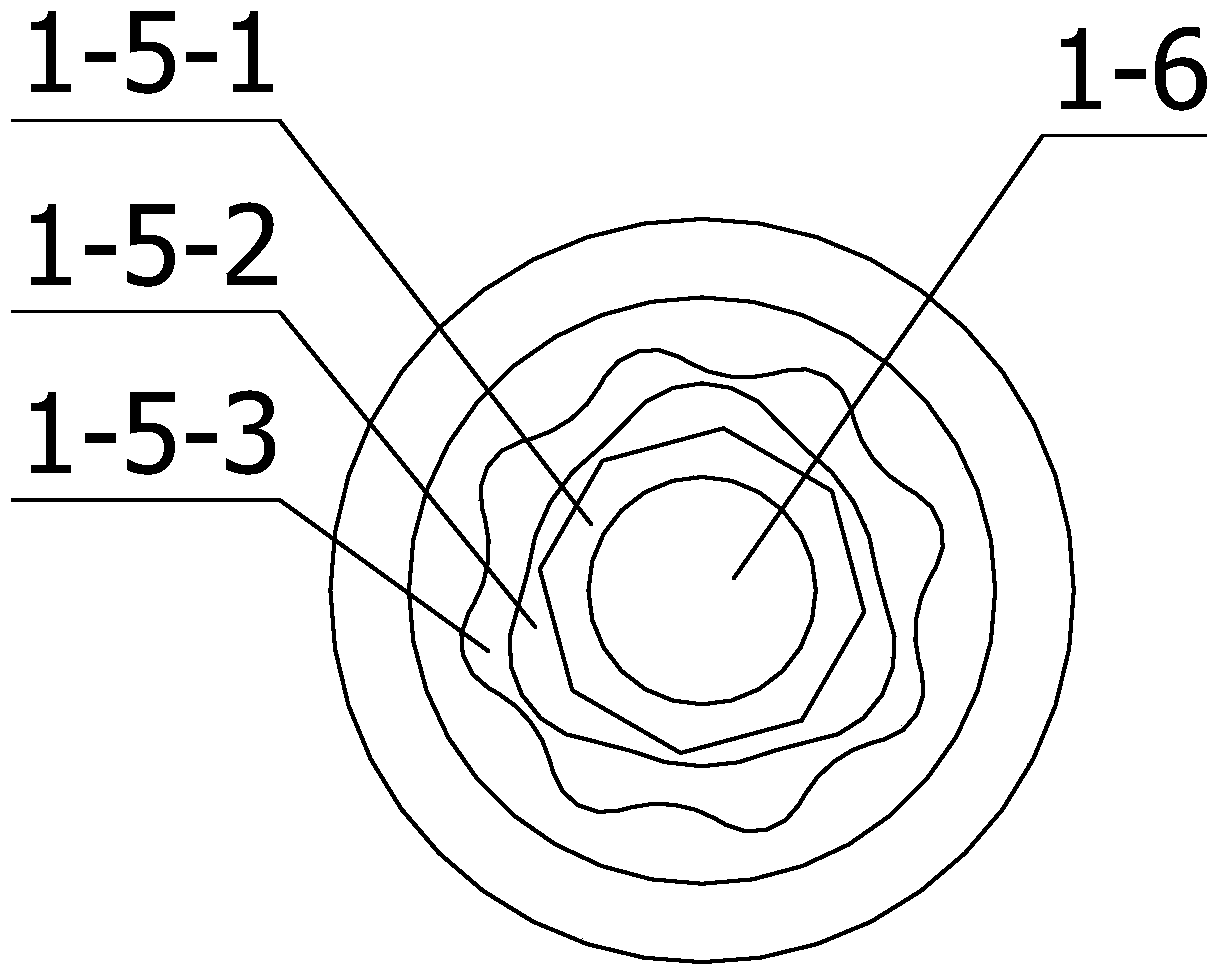

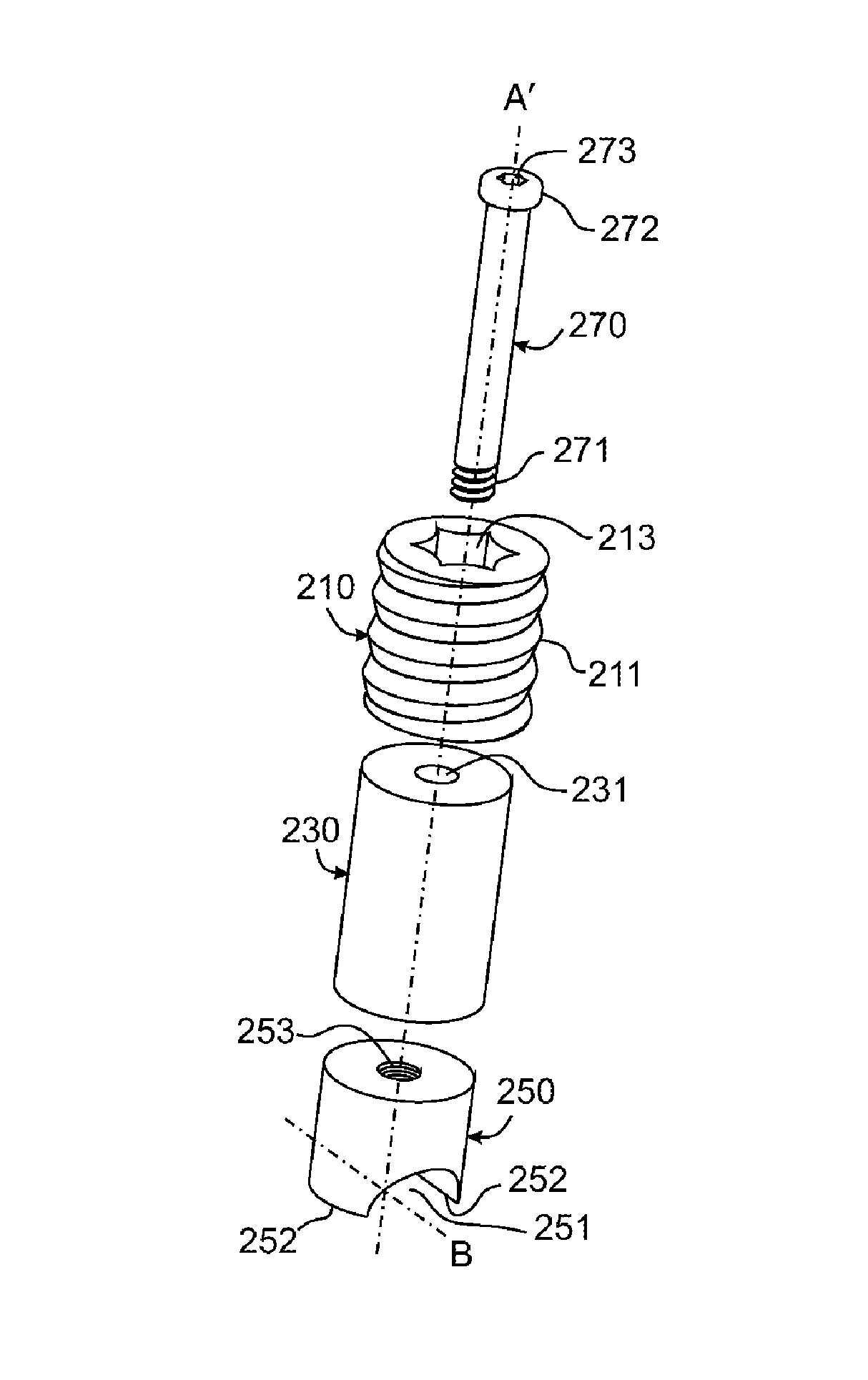

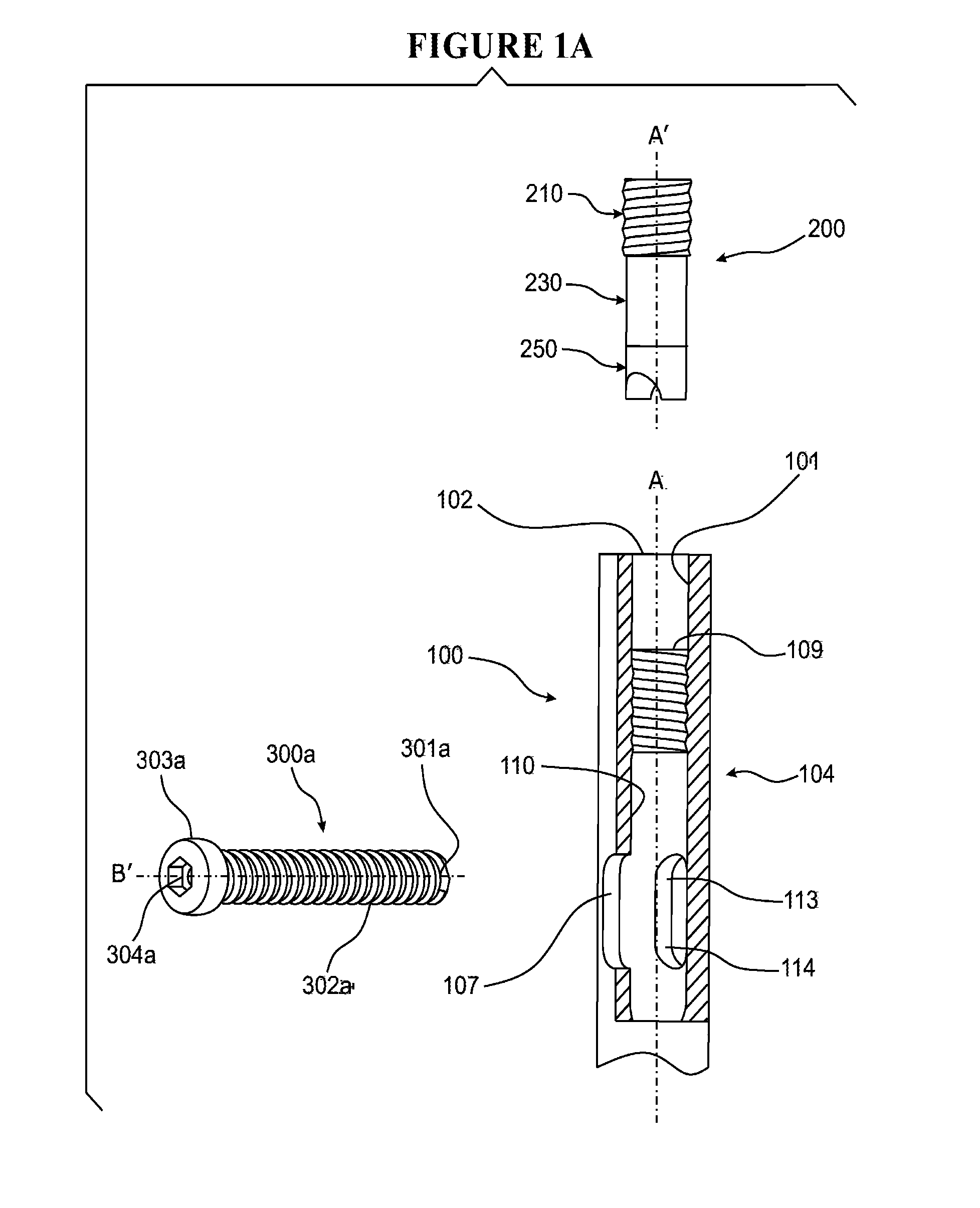

Multi-segment implant components and methods of making the same

The invention relates to a multi-segment implant assembly and a preparation method thereof, including an implant, a personalized abutment and fixing bolts, and the implant includes the first implant segment, the second implant segment, the third implant segment and the implant transgingival segment , the second implant section is a porous section, the implant body is provided with a threaded counterbore, and the upper end of the implant is provided with an abutment interface; the personalized abutment includes the crown connection section, the abutment transgingival section and the implant connection section, personalized The middle part of the abutment is also provided with a stepped hole, and the threaded end of the fixing bolt is threadedly connected with the threaded counterbore. The implant component can be customized according to the actual modulus of the patient's alveolar bone. The porous segment structure can effectively increase the contact area between the dense bone and the implant, improve the fit with the dense bone, and continuously stimulate the dense bone. The problem of looseness after installing the firmware is solved, the bonding force with the alveolar bone after implantation is improved, and the bone fusion effect is good; the preparation method has fast molding speed and short manufacturing cycle, and can meet the actual needs of different patients.

Owner:FUJIAN CTRUE MATERIALS TECH

Biomimetic design osteoid porous bone product and preparation method thereof

ActiveCN105877874BImprove adhesionPromote growthAdditive manufacturing apparatusBone implantDefect repairStructural unit

Owner:成都百年贝雅医疗科技有限公司

Bioactive absorbable medical strapping tape and forming method

InactiveCN104623742ADegradation safetyImprove mechanical propertiesSurgeryBiocompatibilityPolycaprolactone

The invention relates to the field of bio-medical instruments, and in particular relates to a bioactive absorbable medical strapping tape and a forming method. The bioactive absorbable medical strapping tape is prepared by combining a biological absorbable high polymer material and bioactive ceramic or bioactive glass, wherein in percentages by weight, the biological absorbable high polymer material accounts for 70-95% of the total weight of the composite material and the bioactive ceramic or bioactive glass accounts for 5-30% of the total weight of the composite material; the biological absorbable high polymer material is selected from any one or more of polylactic acid, polycaprolactone, a polylactic acid-glycolic acid copolymer, polyglycolic acid, polyhydroxyalkanoate and polyhydroxybutyrate, and the molecular weight is 100,000-2,000,000. The medical strapping tape not only can achieve expected physical properties, mechanical properties, degradation rate, biocompatibility and osteogenesis effect, but also can relieve stress shielding, accelerate fracture healing and avoid second operation.

Owner:深圳市博立生物材料有限公司

Compression device for interlocking compression nailing systems and method of use

InactiveUS9480506B2Simple designReduce manufacturing costInternal osteosythesisStress concentrationSet screw

Owner:ZEHTAB MOHAMMAD JAVAD +2

Multi-segment through-hole porous dental implant

A multi-segment through-hole porous dental implant, comprising a gingival section and a threaded section, the gingival section is a smooth solid structure, the gingival section is located on the upper part of the threaded section, and the dental implant also includes a porous structure section , the porous structure section is located at the bottom of the threaded section, and in the porous structure section, a porous structure with an increasing pore diameter is adopted sequentially from bottom to top; The holes are radial, and the individual transverse through-holes are distributed along the circumference. The invention provides a multi-segment through-hole porous dental implant that can effectively improve the bonding strength, increase the bonding speed, and easily realize the porous structure.

Owner:ZHEJIANG UNIV OF TECH

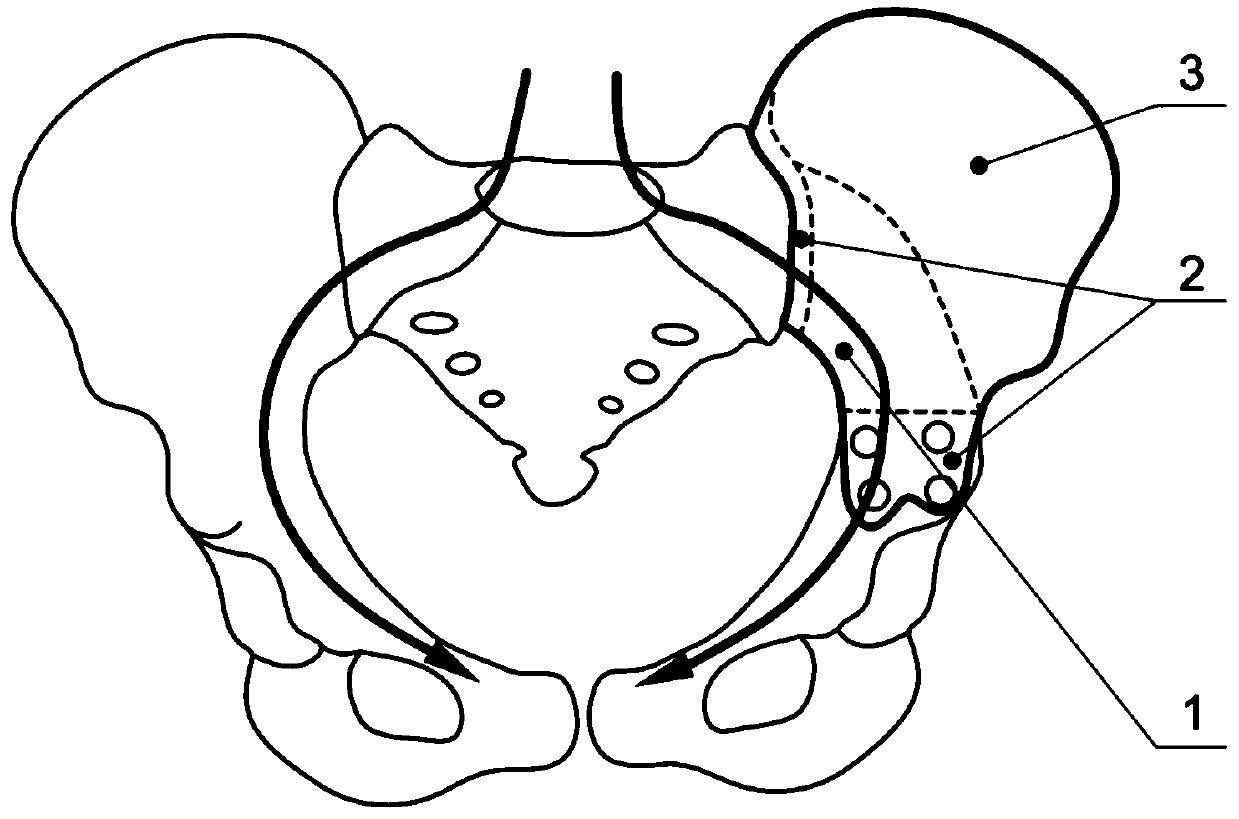

Fiber-reinforced 3D printed polymer pelvis substitute

ActiveCN111265344AImprove reconstruction effectImprove long-term stabilityJoint implantsTissue regenerationFiberHuman body

A fiber-reinforced 3D printed polymer pelvis substituteis divided into an acetabulum-free pelvis substitute and an acetabulum-containing pelvis substitute, wherein the acetabulum-free pelvis substitute comprises a reinforced bearing part, a boundary part and a non-bearing part, and the acetabulum-containing pelvis substitute comprises a reinforced bearing part, a boundary part, a non-bearing partand an acetabular cup part; the boundary part is connected with the bone; the non-bearing part plays a role in maintaining the original anatomical morphology of the pelvis; reinforced fibers are arranged in the reinforced bearing part and play a role in enhancing tensile strength and bending strength of the substitute. The trend of the reinforced fibers is determined according to the force line direction of the defect substitute part in the pelvis integral force line, and the fineness and the volume of the reinforced fibers are determined according to the stress distribution of the pelvis in aservice state, so that the pelvis substitute has an enough safety coefficient under the physiological load of a human body; the reinforced bearing part meets the mechanical environment requirements of the pelvis part of the human body under various gait conditions by designing the shape and the trend, fineness and volume of the internal reinforced fibers.

Owner:XI AN JIAOTONG UNIV

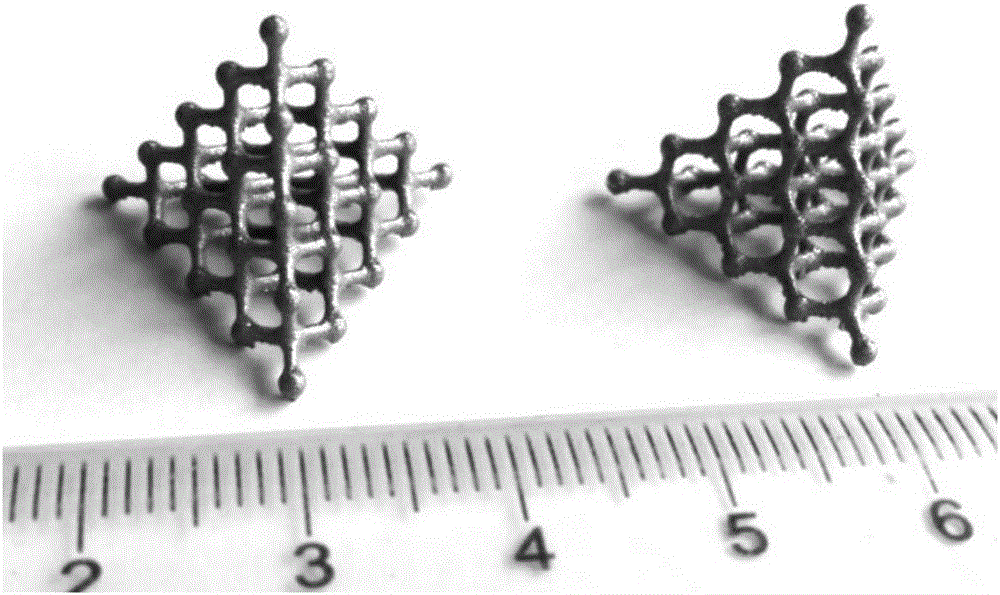

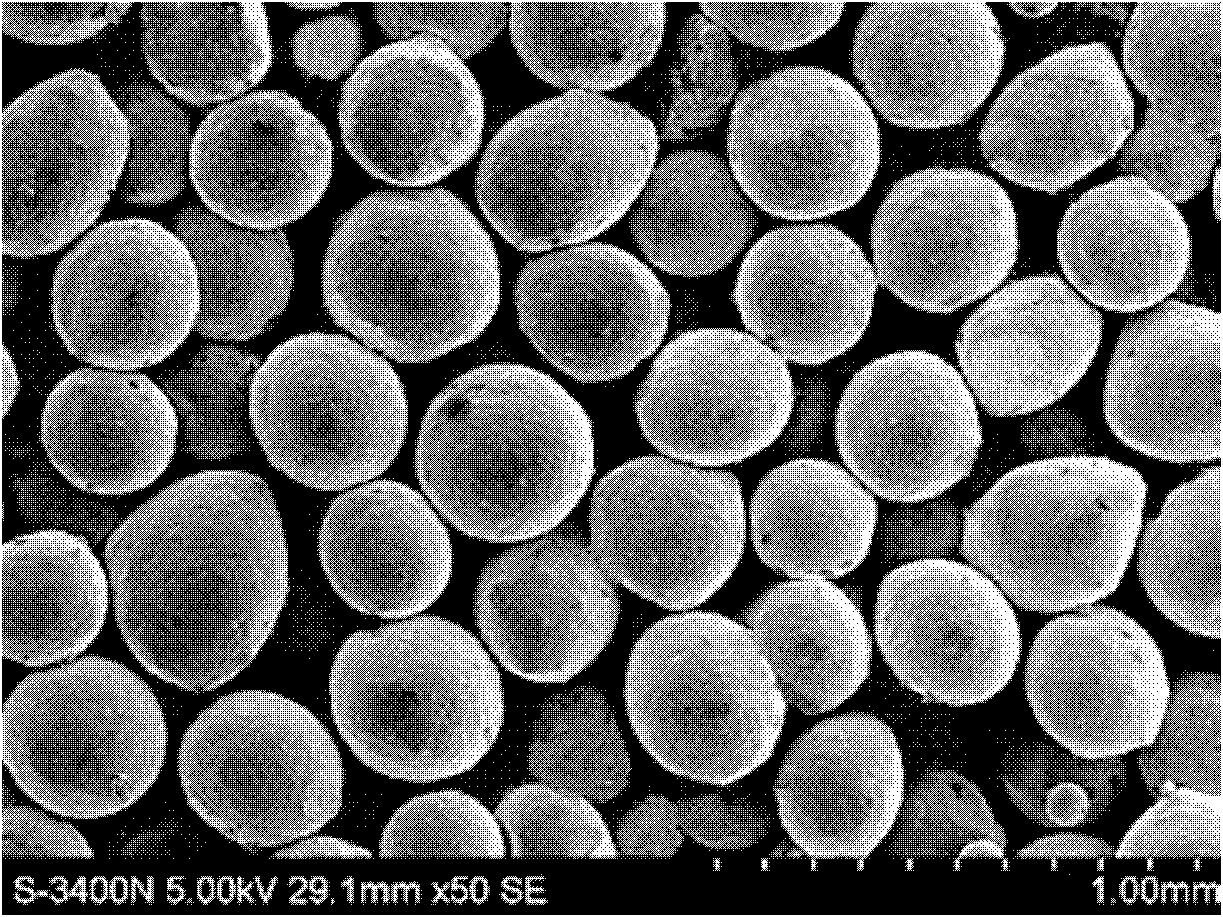

A kind of manufacturing method of personalized customized tantalum implant

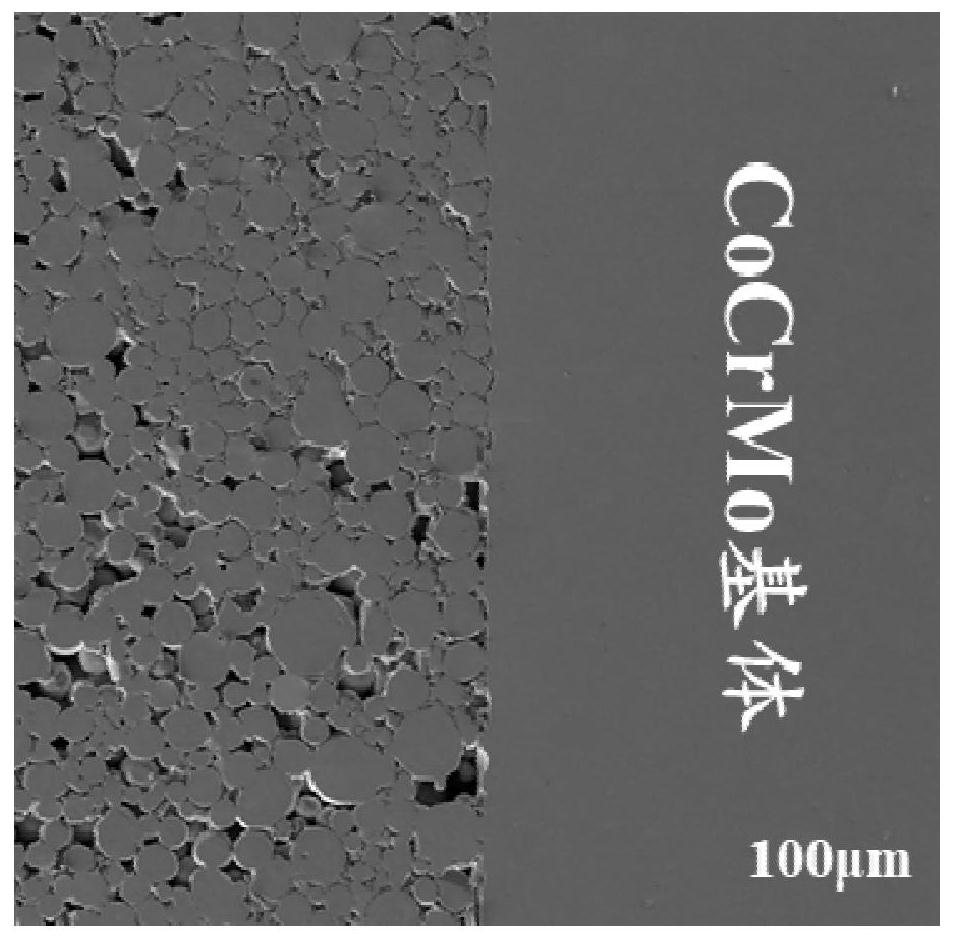

InactiveCN104783929BAvoid stress shielding effectsIncrease success rateBone implantNegative typeGas phase

The invention discloses a personally-customized tantalum implantation material manufacturing method. The method comprises the following steps of adopting CT, MRI and other scanning images for rebuilding the appearance of a prosthesis of an implantation material, designing a three-dimensional negative type model of the implantation material according to the appearance of the prosthesis of the implantation material, and then utilizing additive manufacturing for obtaining a negative type mold of a support, wherein the amount of residual carbon of the negative type model is quite low; filling the mold with spherical beads capable of being burnt off and a high residual-carbon resin and curing agent mixture or a graphite powder, resin and curing agent mixture. Pyrolysis is performed in the vacuum environment or a special atmosphere oven; due to the fact that the amount of residual carbon is quite low, the carbon support of the implantation material with spherical holes can be obtained, finally, a tantalum layer is deposited on the surface of the carbon support by means of the chemical vapor deposition method, and personally-customized tantalum implantation material manufacturing is completed. The final tantalum implantation material is the mixture, wherein metal tantalum is deposited on the surface of the mixture, the carbon support is arranged inside the mixture, and the carbon support accounts for 1%-10% of the mixture by mass.

Owner:XI AN JIAOTONG UNIV +1

A carbon fiber composite material bone plate and its preparation method

ActiveCN106580417BHigh mechanical strengthOvercoming fit problemsBone platesFiberStress concentration

The invention discloses a carbon fiber composite material bone plate and a preparation method thereof. The preparation method specifically comprises the following steps of: coiling, stacking and laying up carbon fiber prepreg cloth according to the design, preheating, pre-forming, preheating and molding; cooling, feeding into a demolding table, opening the mold, taking out the product, cleaning and drying; performing CNC machining on a bulk material according to a bone plate design drawing so as to form a bone plate blank; and performing biosafety coating treatment on the surface of the obtained bone plate blank. The bone plate is high in biocompatibility; by virtue of biological coating, the biosafety of medical implants is improved; the bone plate is close to real bone strength; the various mechanical parameters are equivalent to those of bones, the adaptation problem is solved, and a stress-shielding effect caused by stress concentration is avoided; the carbon fiber composite material bone plate has excellent X-ray penetrability, can meet the nuclear magnetic resonance testing requirements and is suitable for batch production and low in cost.

Owner:XIAMEN HOWER MATERIAL

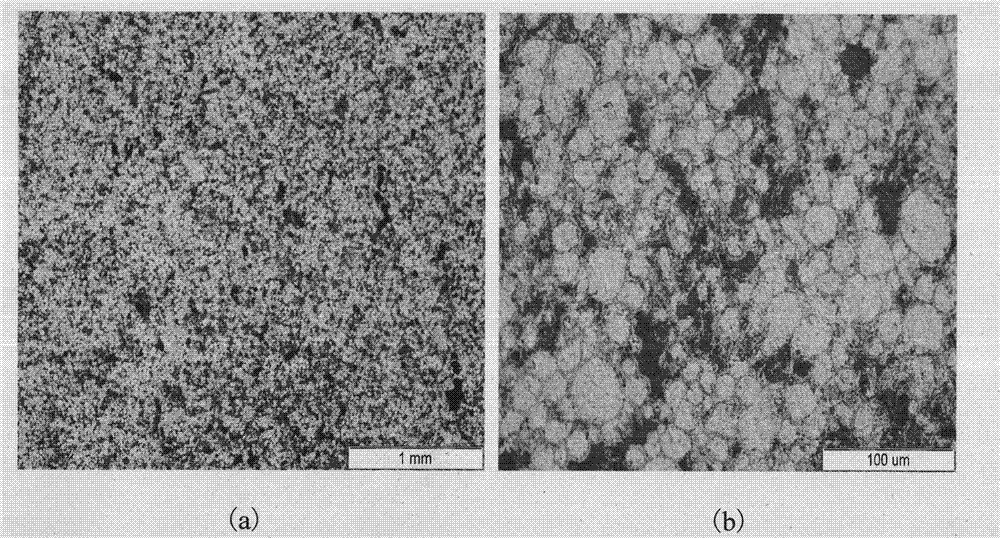

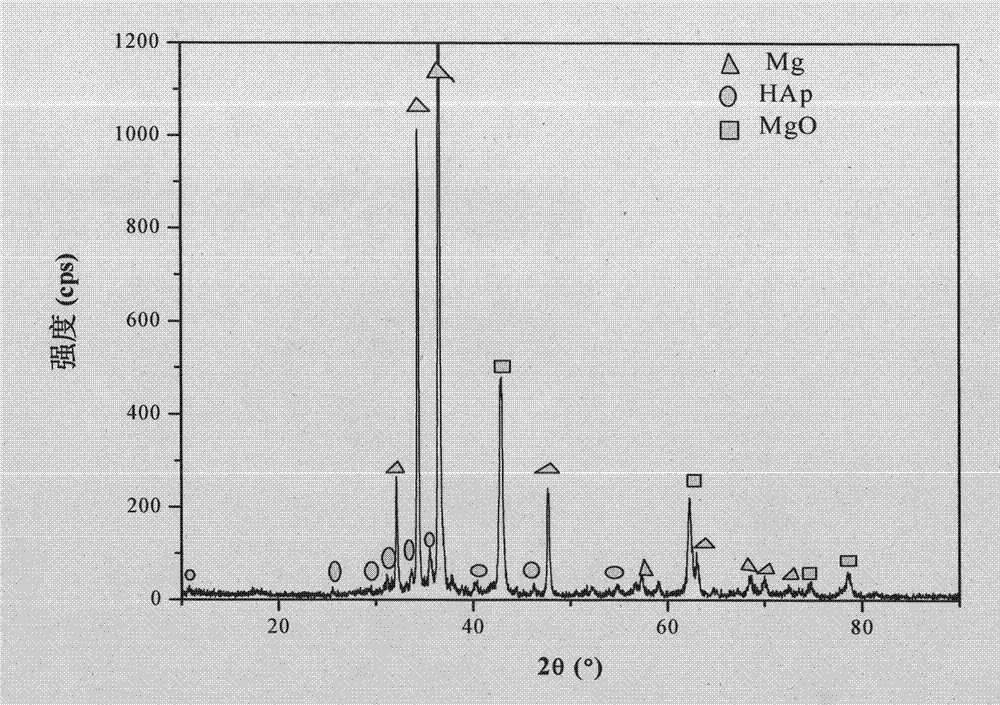

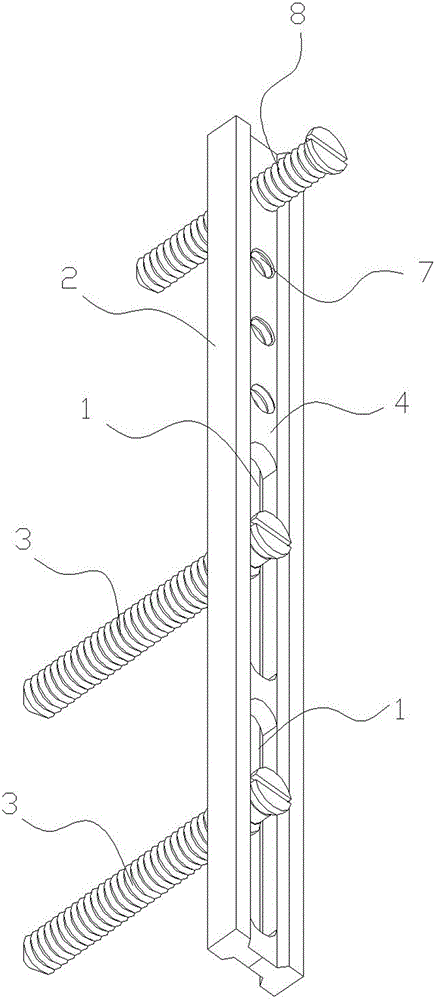

Magnesium/hydroxyapatite composite material and preparation method thereof

The invention relates to a magnesium / hydroxyapatite composite material and a preparation method thereof. The magnesium / hydroxyapatite composite material is prepared by mixing magnesium and hydroxyapatite serving as raw materials in a mass ratio of 80.5-99.9 percent: 0.1-19.5 percent for molding and sintering the mixture in a vacuum microwave sintering furnace. The composite material provided by the invention has proper mechanical property and can meet the requirements on human body bone tissue materials. A microwave sintering method is adopted, so the method has the advantages of high temperature rise speed, short sintering time, short preparation period, low energy consumption and no pollution.

Owner:TIANJIN UNIV

sliding steel plate

InactiveCN103190947BStrong and fixedAvoid stress shielding effectsInternal osteosythesisFastenersSlide plateEngineering

Owner:方玉树

Biomedical degradation-absorption-controllable macromolecule metal composite implantation material and use thereof

InactiveCN100381182CHigh strengthImprove mechanical propertiesSurgeryProsthesisPolymer metalWhiskers

The invention discloses a biological medical planting material and composite material and application of controllable decomposable macromolecular metal, which is characterized by the following: adopting decomposable macromolecular material as base and pure magnenium and alloy with bulk percentage at 5-50% from board, rod, pipe, filament, whisker and porous material as reinforcer, improving dynamical property in the composite material, controlling decomposing period effectively.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for forming composite rhBMP-2 elasticity modulus graded porous titanium alloy support rod for femoral head and neck

The invention relates to a method for forming a composite rhBMP-2 elasticity modulus graded porous titanium alloy support rod for the femoral head and the neck. Titanium alloy powder is prepared with an electrode induction melting gas atomization method, and the integrated elasticity modulus graded porous titanium alloy support rod consisting of a head part, a body part and a tail part is prepared according to actually measured biomechanical parameters of the femoral head, the neck and a rotor, wherein the head part and the body part are prepared by sintering the titanium alloy powder and pore-forming agents through the adoption of a cold rolling method, the tail part is prepared by directly sintering the titanium alloy powder, and the porous titanium alloy support rod is immersed in a rhBMP-2 / gelatin controlled release microsphere solution. The product prepared by the method can simulate the biomechanical properties of the femoral head and the neck of a human body to the utmost extent, thereby being beneficial to the stress transfer between materials and bone tissue interfaces, avoiding poor bone restoration caused by the stress shielding effect; and simultaneously, sustained-release microspheres on which bone induced growth factors (rhBMP-2) are loaded endue the materials per se with good bone conductivity.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

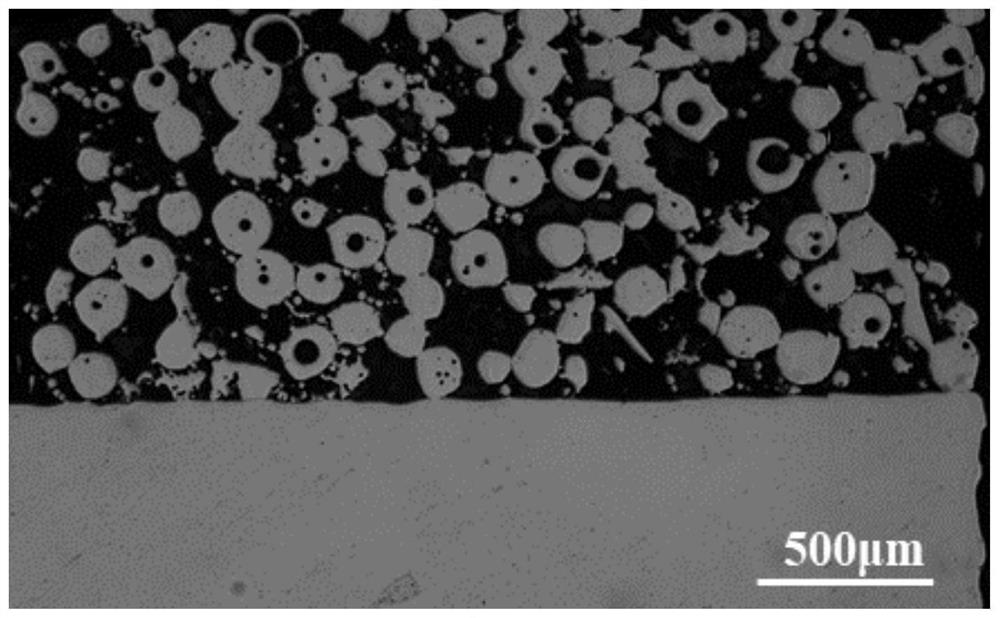

Biomedical metal porous coating capable of replacing bone cement and preparation method of biomedical metal porous coating

The invention discloses a biomedical metal porous coating capable of replacing bone cement and a preparation method of the biomedical metal porous coating. Metal powder is laid on the surface of a metal-based implant, and the metal porous coating is formed on the surface of the metal-based implant through spark plasma vacuum sintering. The metal porous coating meets specific pore characteristics and performance indexes required by bone tissue ingrowth, is well combined with the metal-based implant, and can be used instead of the bone cement, so that bone tissue can enter the metal porous coating along with bone growth, effective combination with the metal-based implant is facilitated, and a series of negative influences caused by using the existing bone cement are avoided. The preparation temperature of the metal porous coating is relatively low, a pore forming agent is not used, the preparation period is short, and operation is easy.

Owner:HUNAN UNIV

A kind of elastic intervertebral fusion device with magnesium powder function-enhanced polymer material porous structure and preparation method thereof

ActiveCN110025409BPromote ingrowthRegulated release rateAdditive manufacturing apparatusSpinal implantsStructural engineeringIntervertebral fusion

The invention discloses an elastic interbody fusion cage having a biodegradable magnesium powder function reinforced high molecular material porous structure and a preparation method of the elastic interbody fusion cage. The elastic interbody fusion cage mainly consists of a main body part and a bone grafting part, wherein the main body part is a porous magnesium reinforced composite material hexahedron having gradient bore diameter distribution, and the bone grafting part consists of a plurality of bar-shaped sawteeth. A medical coating having a bone induction effect and an inflammation resisting effect covers the inner part and the surface of the fusion cage. The preparation method comprises the steps of performing high-temperature melting on PCL granules, mixing the melted PCL granuleswith magnesium powder to obtain composite material granules, and then performing integral shaping by a melting and deposition method. The elastic gradient bore diameter structure of the elastic interbody fusion cage disclosed by the invention is well matched with the elasticity modulus of human bones, and the fusion rate is increased. By the integral shaping method, the mechanical intensity of thefusion cage is increased, release of magnesium ions in the degradation process achieves the effect of acid and base neutralization, and the degradation rate is adjusted and controlled to be in a reasonable range.

Owner:SOUTHEAST UNIV

Silicate coating-containing absorbable medical magnesium-based metal and preparation method and application thereof

InactiveCN102146562BPromote healingReduce the initial degradation rateMetallic material coating processesProsthesisAbsorption rateReconstructive surgery

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com