Biomimetic design osteoid porous bone product and preparation method thereof

A porous bone and bone-like technology, applied in the field of biomedical materials, can solve the problems of high production cost, long processing cycle and high equipment requirements, and achieve the effects of fast processing, small footprint and shortened cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

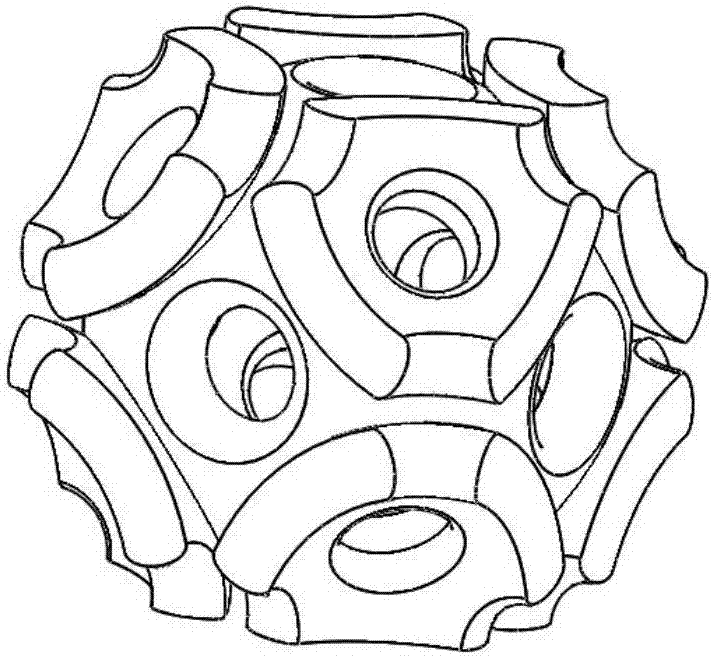

[0029] In the modeling software, place nine hollow spherical shells, such as figure 1 As shown, the position of the center of the sphere is strictly in accordance with the position of the BCC atoms in crystallography. The outer radius of the spherical shell is 0.75mm, the inner radius is 0.55mm, and there will be holes with a diameter of 0.3mm on the spherical shell. The pores of this model The ratio is 59.83%, the pore diameter is 350±20 μm, and the interpenetrating micropore diameter is 90±10 μm.

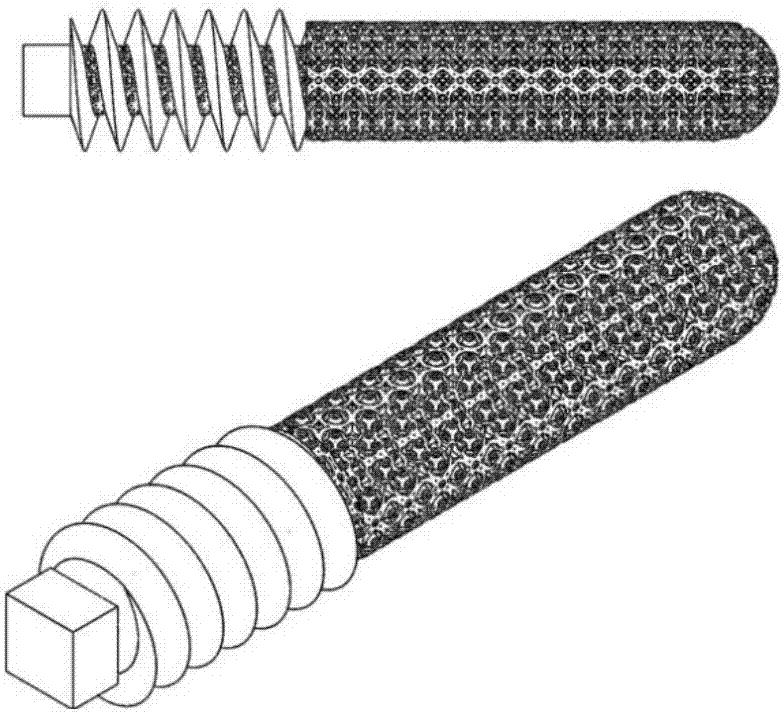

[0030] Using pure titanium spherical powder as raw material, using the above-mentioned unit body as the pore structure unit, array in three-dimensional space and then perform excision / Boolean operation to obtain bone-like porous titanium nail rod products, such as figure 2 shown. Export the design as an STL format file and input it into a 3D printer for printing.

Embodiment 2

[0032] Modeling is carried out in the modeling method of Example 1, wherein the outer radius of the spherical shell is 0.7mm, the inner radius is 0.5mm, the diameter of the spherical shell hole is 400mm, and other parameters remain unchanged. Using pure titanium spherical powder as raw material, convert the 3D model of the designed product into an STL format file, input it into a 3D printer for printing and molding, and obtain a product with a porosity of 74.4%, a pore diameter of 400±20 μm, and an interpenetrating micropore diameter of 200± 10 μm.

Embodiment 3

[0034] Modeling is carried out in the modeling method of Example 1, wherein the outer radius of the spherical shell is 0.7mm, the inner radius is 0.35mm, the diameter of the spherical shell hole is 300mm, and other parameters remain unchanged. Using pure titanium spherical powder as raw material, convert the 3D model of the designed product into an STL format file, and input it into a 3D printer for printing and molding, such as image 3 As shown, the porosity of the obtained product is 85.2%, the pore diameter is 300±20 μm, and the interpenetrating micropore diameter is 200±10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com