Biomedical metal porous coating capable of replacing bone cement and preparation method of biomedical metal porous coating

A metal porous, biomedical technology, applied in coatings, medical science, prostheses, etc., can solve the problems of difficult to achieve controllable adjustment of pore size, low bonding strength without bone cement, poor bone growth, etc., to achieve beneficial Effective binding, avoiding stress shielding effect, good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a biomedical metal porous coating that can replace bone cement of the present invention, comprising the following steps:

[0029] (1) Select CoCrMo metal powder (its specific composition is Co: 66.8wt.%; Cr: 28.61wt.%; Mo: 4.56wt.%; particle size range is 150~300 μm, oxygen content is below 4000ppm) as raw material, The screened metal powder is laid on the surface of the metal block of the cobalt-based implant (the mass ratio of the cobalt-based implant is: Co-27Cr-6Mo).

[0030](2) Place the cobalt-based implant with CoCrMo powder laid in step (1) in a graphite mold, and conduct spark plasma vacuum sintering at a heating rate of 80 °C / min, a sintering temperature of 800 °C, and a holding time of 10 min , the vacuum degree is 10Pa, the pressure is 20MPa, and the pressure is maintained throughout the process to obtain a biomedical metal porous coating.

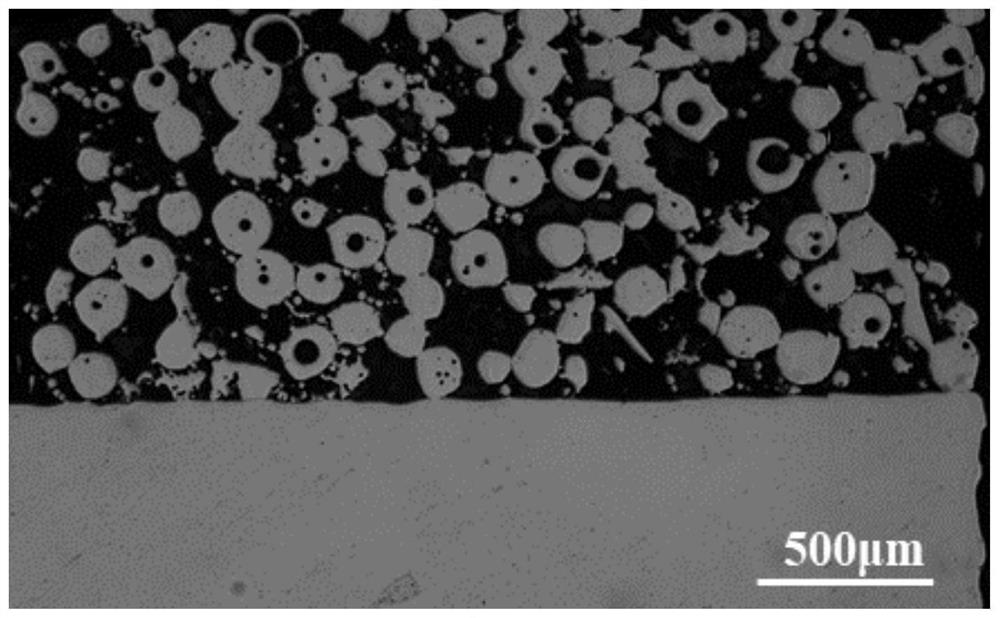

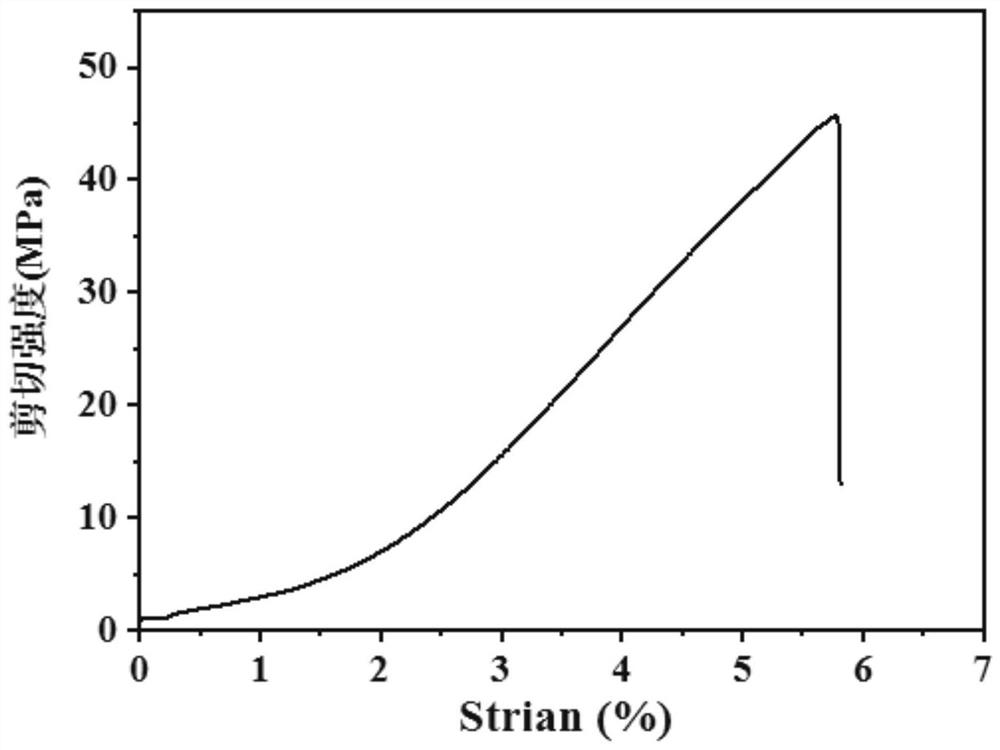

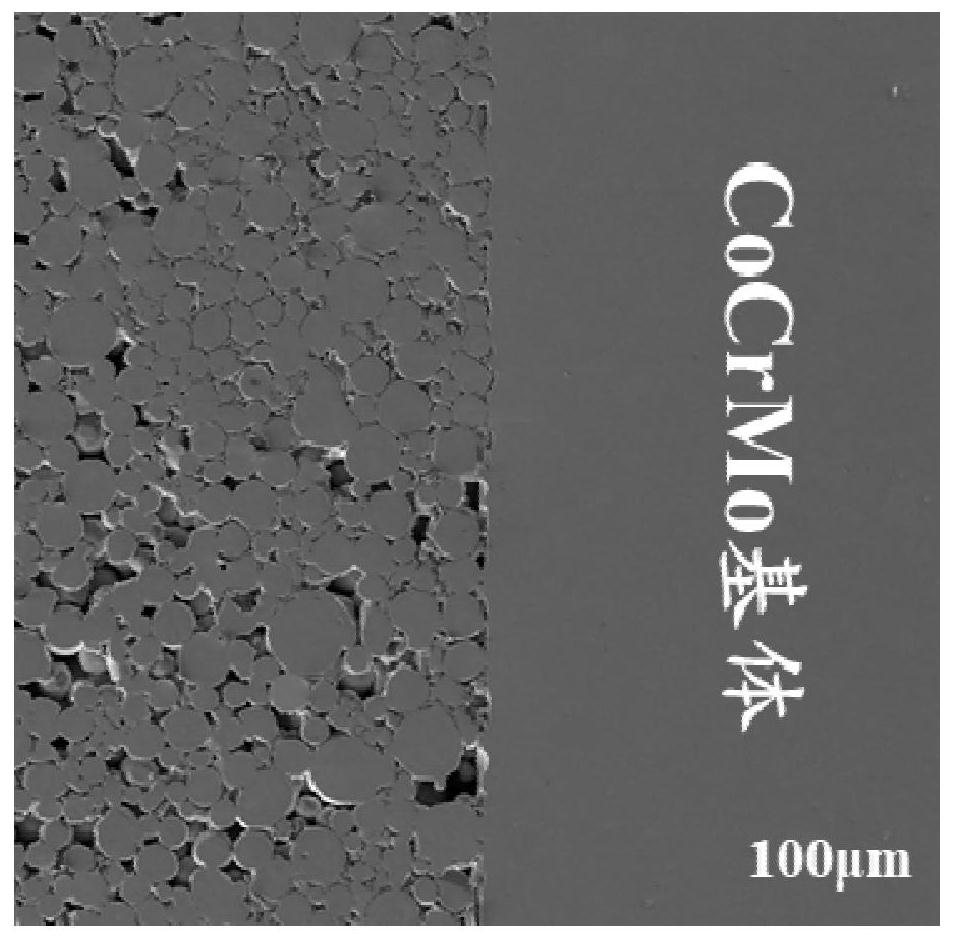

[0031] (3) Through tissue observation and mechanical performance testing of the product of thi...

Embodiment 2

[0033] A method for preparing a biomedical metal porous coating that can replace bone cement of the present invention, comprising the following steps:

[0034] (1) Select CoCrMo metal powder (its specific composition is Co: 66.8wt.%; Cr: 28.61wt.%; Mo: 4.56wt.%; particle size range is 100~200 μm, oxygen content is below 4000ppm) as raw material, The screened metal powder is laid on the surface of the metal block of the cobalt-based implant (the composition of the cobalt-based implant is: Co-27Cr-6Mo).

[0035] (2) Place the cobalt-based implant with CoCrMo powder laid in step (1) in a graphite mold, and perform spark plasma sintering at a heating rate of 100 °C / min, a sintering temperature of 850 °C, and a holding time of 15 min. The vacuum degree is 10Pa, the pressure is 20MPa, and the pressure is maintained throughout the process to obtain a biomedical metal porous coating.

[0036] (3) Through tissue observation and mechanical performance testing of the product of this exa...

Embodiment 3

[0038] A method for preparing a biomedical metal porous coating that can replace bone cement of the present invention, comprising the following steps:

[0039] (1) Select CoCrMo metal powder (its specific composition is Co: 66.8wt.%; Cr: 28.61wt.%; Mo: 4.56wt.%; particle size range is 100~200 μm, oxygen content is below 4000ppm) as raw material, The screened metal powder is laid on the surface of the metal block of the cobalt-based implant (the composition of the cobalt-based implant is: Co-27Cr-6Mo).

[0040] (2) Place the cobalt-based implant with CoCrMo powder laid in step (1) in a graphite mold for spark plasma sintering at a heating rate of 60°C / min, a sintering temperature of 780°C, and a holding time of 5 minutes. The vacuum degree is 10Pa, the pressure is 15MPa, and the pressure is maintained throughout the process to obtain a biomedical metal porous coating.

[0041] Through tissue observation and mechanical performance testing of the product in this example, the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com