Bonelike porous biomechanical bionic designed spinal fusion device and preparation method and use thereof

A biomechanical and fusion device technology, applied in the field of biomedical materials, can solve the problems of dense titanium alloy stress shielding, implant stress absorption, and load inability to transmit, and achieve the effects of short manufacturing time, reduced cost, and good therapeutic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

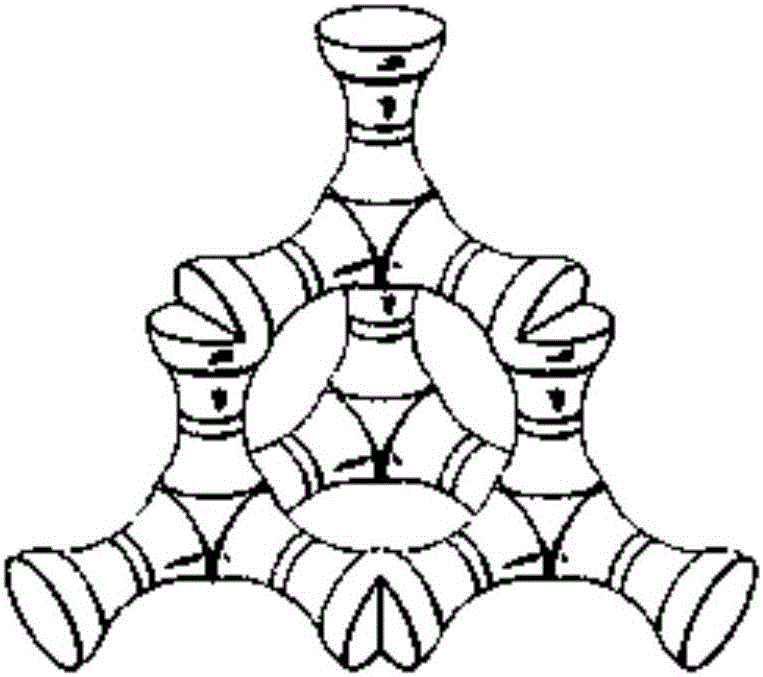

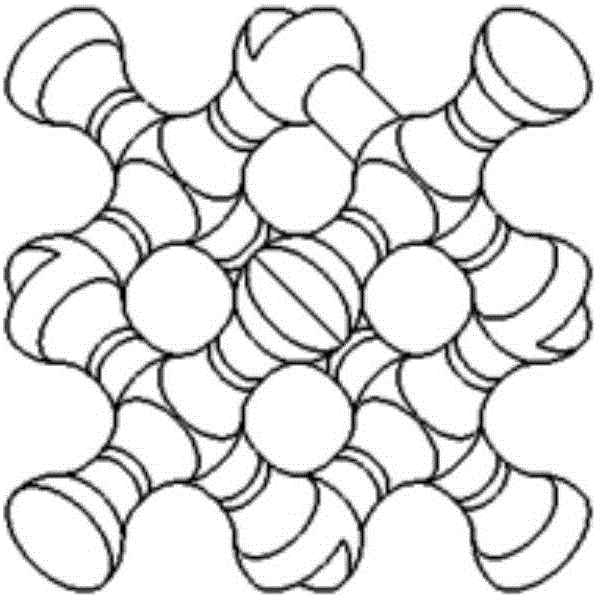

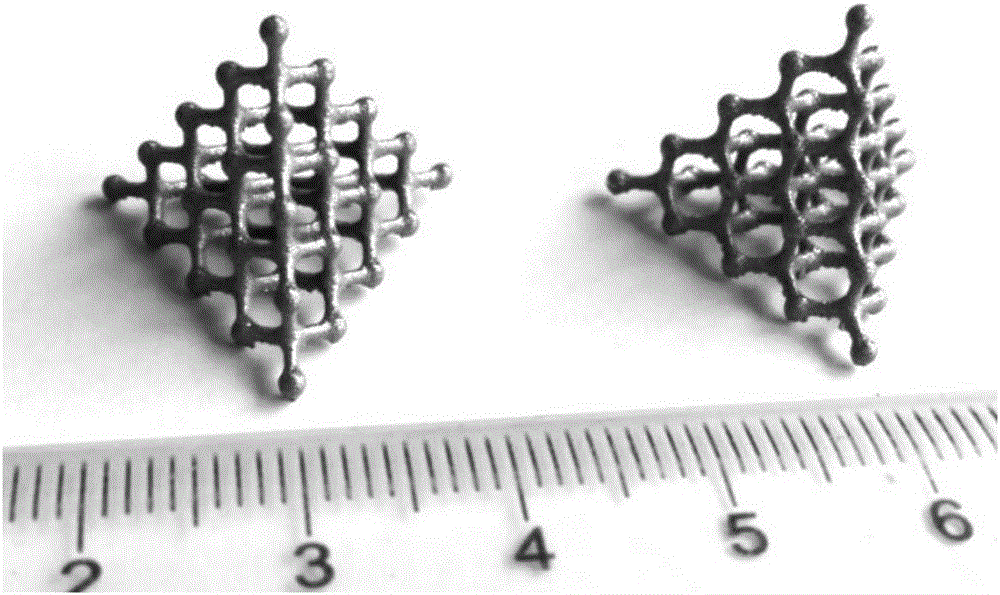

[0031] In the modeling software, place nine spheres so that the positions of the centers of the spheres are strictly in accordance with the positions of atoms in the diamond structure in crystallography, where the radius of the spheres is 0.2mm, and then add dumbbell-shaped cylinders between each sphere with a minimum radius of 0.1mm. unit model see figure 1 , 3D model diagram of diamond cubic crystal structure microporous space structure unit body, figure 2 It is the 3D model figure after the microporous spatial structure unit body array of embodiment 1; image 3 It is an enlarged view of the microporous spatial structural unit body printed by SLM, and the microporous structural unit entity is printed by 5 times magnification.

[0032] Among them, the minimum tangential radius of the dumbbell-shaped cylinder is 50 μm, the length is 500 μm, and the diameter of the hole formed by the six cylinders is 900 μm; the porosity of the model is 84.2%, and the pore diameter is 860±20...

Embodiment 2

[0035] Modeling is carried out in the modeling method of Example 1, wherein the radius of the sphere is 0.25 mm, and other parameters remain unchanged. Using pure titanium spherical powder as raw material, the 3D model of the designed product was converted into an STL format file, and input into a 3D printer for printing. The resulting product had a porosity of 74.4% and a pore diameter of 800±15 μm. The maximum compressive strength of the product is 92.1MPa, equivalent to that of human cortical bone.

Embodiment 3

[0037]Modeling is carried out in the modeling method of Example 1, wherein the radius of the sphere is 0.25mm, the minimum diameter of the dumbbell-shaped cylinder is 0.08mm, and other parameters remain unchanged. Using pure titanium spherical powder as raw material, the 3D model of the designed product was converted into an STL format file, and input into a 3D printer for printing. The resulting product had a porosity of 80.2% and a pore diameter of 860±18 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com