A kind of elastic intervertebral fusion device with magnesium powder function-enhanced polymer material porous structure and preparation method thereof

A technology of polymer material and intervertebral fusion, applied in the field of medical equipment, can solve the problems of vertebral contact edge damage, limited strength, easy to cause inflammation, etc., to achieve the effect of adjusting intervertebral height, avoiding injury, and protecting bone marrow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of an elastic intervertebral fusion device with magnesium powder reinforced polymer porous structure, comprising the following specific steps:

[0039] Step 1: Based on the real model of the finite element human spine, use SOLIDWORKS software to design and improve the adaptability data model of the intervertebral fusion device of this structure, and import the model program into the computer that controls the melt extrusion rapid prototyping machine superior;

[0040] Then, add the PCL particles into the cavity of the twin-screw extruder, the particle size of the PCL particles is 2-3mm, set the working temperature of the extruder at 55°C-65°C, and add the mass Magnesium powder with a fraction percentage of 10% to 20%, the particle size of the magnesium powder is 25±5μm, under the protection of inert gas, set it to the circulation banburying mode, stir for 1 hour, and the speed is 30r / min~50r / min;

[0041] When the PCL / Mg composite material is mixed...

Embodiment 1

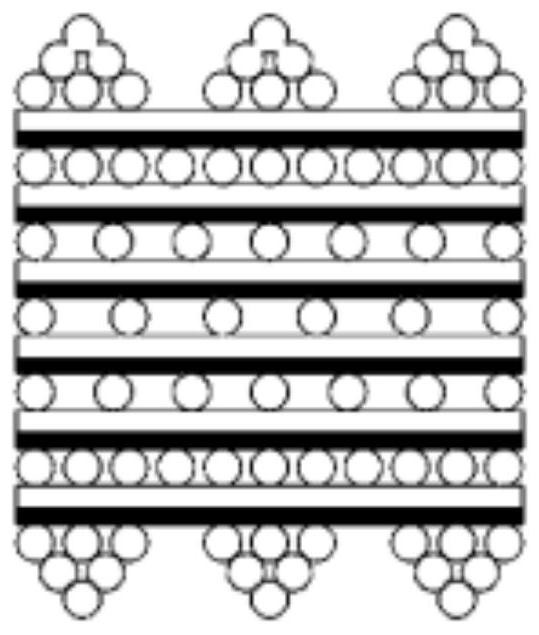

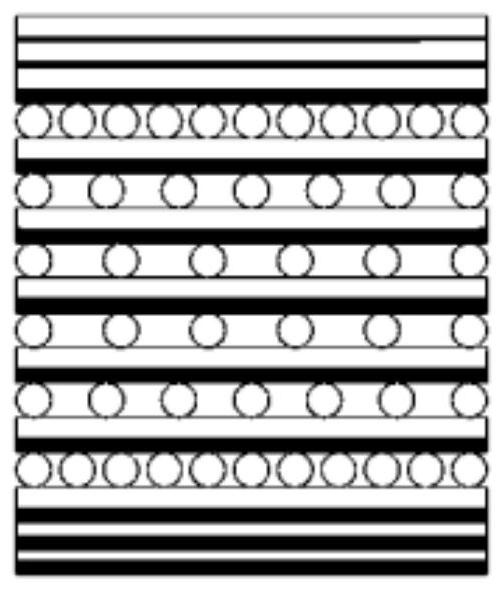

[0048] Such as Figure 1-4 As shown, an elastic intervertebral fusion device with porous structure of magnesium powder reinforced polymer material, the main part 1 has a length of 10 mm, a width of 8 mm, and a height of 6 mm. The side length of the triangular prism of the bone graft part 2 is 0.5 mm, the length is 10 mm, and the distance between the prisms is 0.5 mm. The diameter of the piled wire material by the fused deposition method is 0.3mm, and the number of piled up layers is 20 layers. The gradient distribution of pore size from the first layer to the twentieth layer is 600 μm, 620 μm, 640 μm, 660 μm, 680 μm, 700 μm, 720 μm, 740 μm, 760 μm, 780 μm, 780 μm, 760 μm, 740 μm, 720 μm, 700 μm, 680 μm, 660 μm, 640 μm , 620μm, 600μm, the porosity is 80%.

[0049] The preparation method of the elastic intervertebral fusion device with the porous structure of the above-mentioned magnesium powder reinforced polymer material is as follows:

[0050] Step 1, set up this model in ...

Embodiment 2

[0055] An elastic intervertebral fusion device with magnesium powder reinforced polymer material porous structure, the main part 1 of which has a length of 20 mm, a width of 10 mm and a height of 8 mm. The side length of the triangular prism of the bone graft part 2 is 0.6 mm, the length is 20 mm, and the distance between the prisms is 0.6 mm. The diameter of the piled wire material by the fused deposition method is 0.4mm, and the number of piled up layers is 20 layers. The gradient distribution of pore size from the first layer to the twentieth layer is 700 μm, 720 μm, 740 μm, 760 μm, 780 μm, 800 μm, 820 μm, 840 μm, 860 μm, 880 μm, 880 μm, 860 μm, 840 μm, 820 μm, 800 μm, 780 μm, 760 μm, 740 μm , 720μm, 700μm, the porosity is 82%.

[0056] The preparation method of the elastic intervertebral fusion device with the porous structure of the above-mentioned magnesium powder reinforced polymer material is as follows:

[0057] Step 1, set up this model in SOLIDWORKS software, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com