3D-printed gradient-diameter medical porous metal bone tissue scaffold

A 3D printing, porous metal technology, applied in the field of 3D printing medical metal implants, can solve the problems of bone healing, difficult bone tissue implants, unfavorable bone tissue ingrowth, etc., achieving simple and convenient adjustment, and the method is simple and effective. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

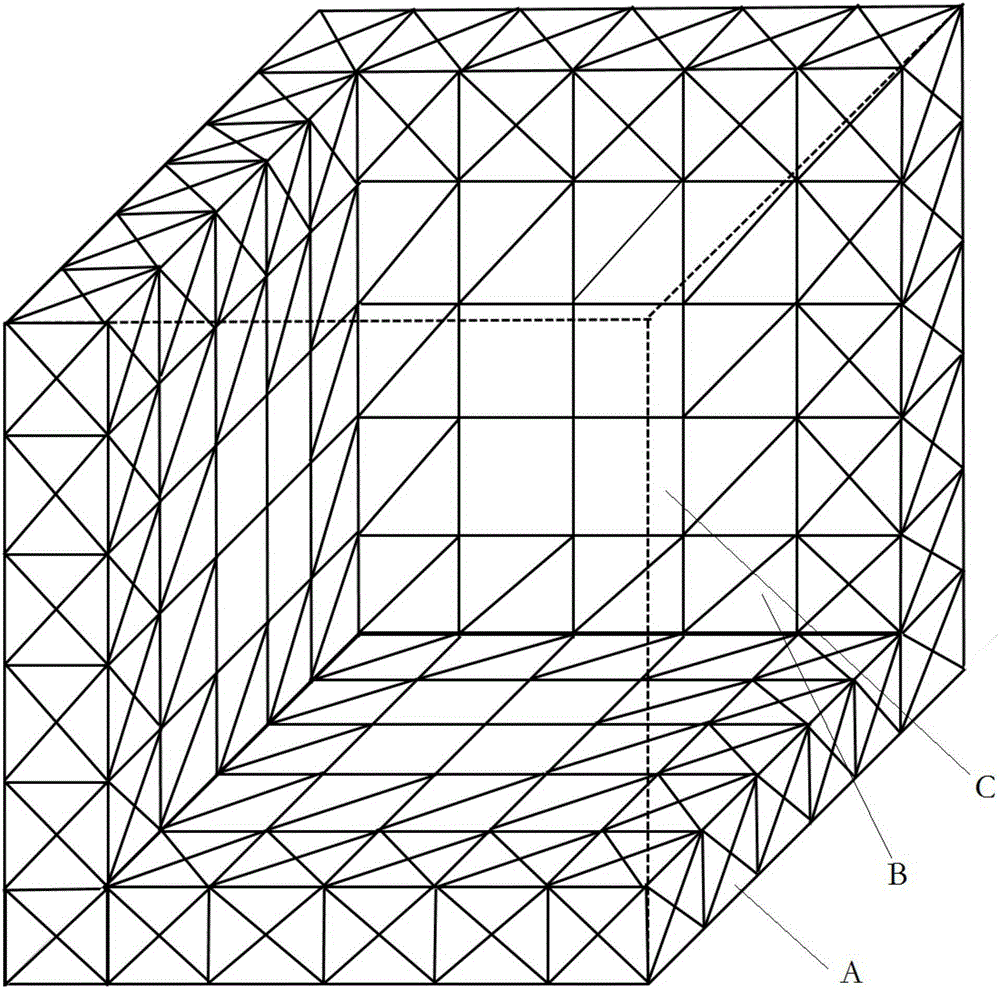

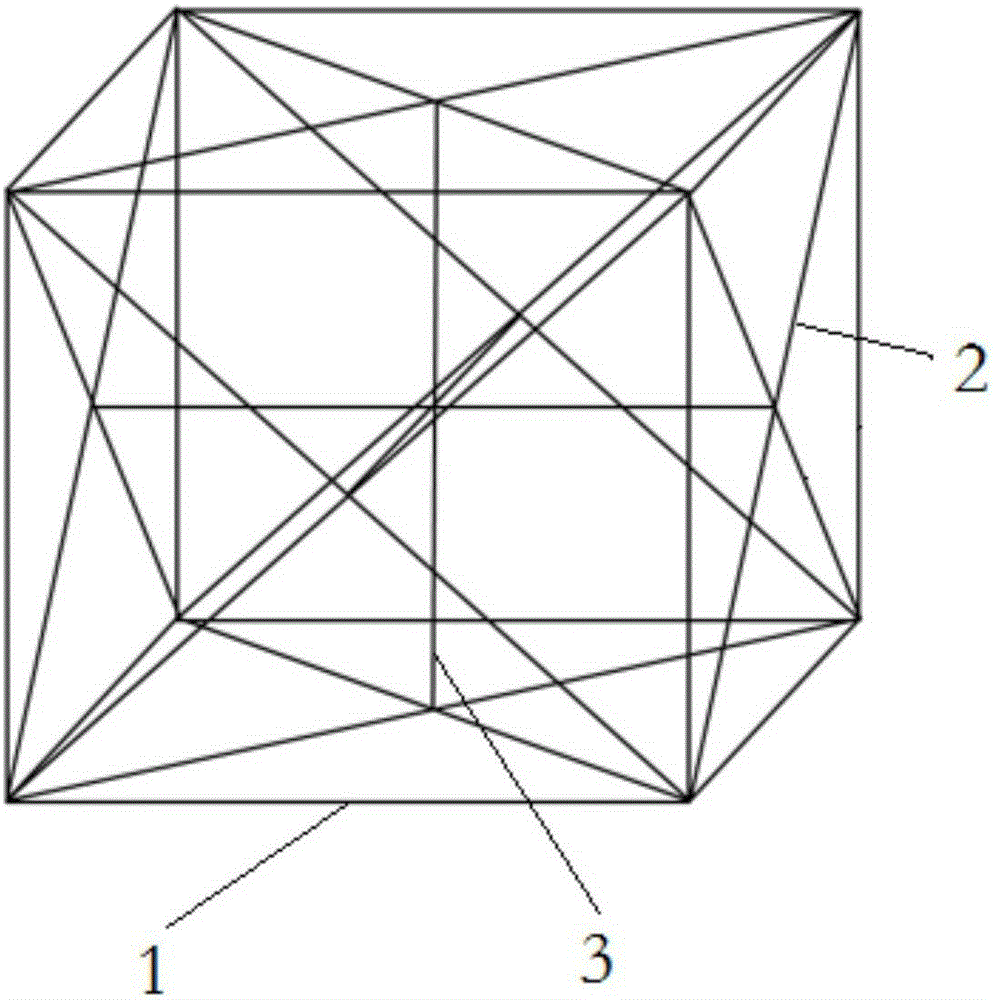

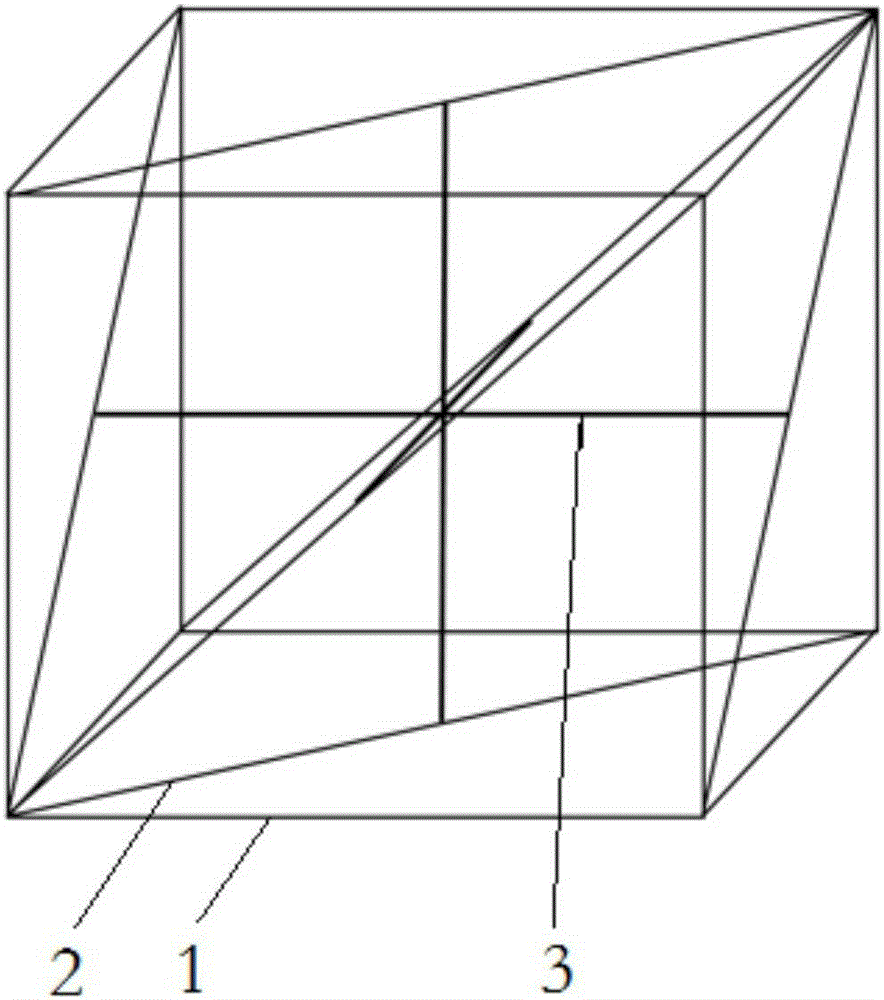

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. The drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] figure 1 Shown is a schematic diagram of the structure of the 3D printed gradient aperture medical porous metal bone tissue scaffold. The complete structure of the scaffold is a hexahedral structure. figure 1 In order to partially omit the view, only three exterior facades that are orthogonal to each other are kept, Figure 2 to Figure 4 are the three components that make up the bracket. The 3D printing gradient aperture medical porous metal bone tissue scaffold is composed of component A, component B and component C, component A, component B and component C are respectively located on the outer, middle and inner layers of the three-dimensional structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com