Degradable open porous magnesium and magnesium alloy biomaterial and preparation method thereof

A biomaterial and magnesium alloy technology, applied in the field of degradable open-pore porous magnesium and magnesium alloy biomaterials and its preparation, can solve the problems of inability to establish fusion contact points, inability to ensure pore shape uniformity, pore connectivity, etc., to achieve protection Integrity, excellent biocompatibility, and size-controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

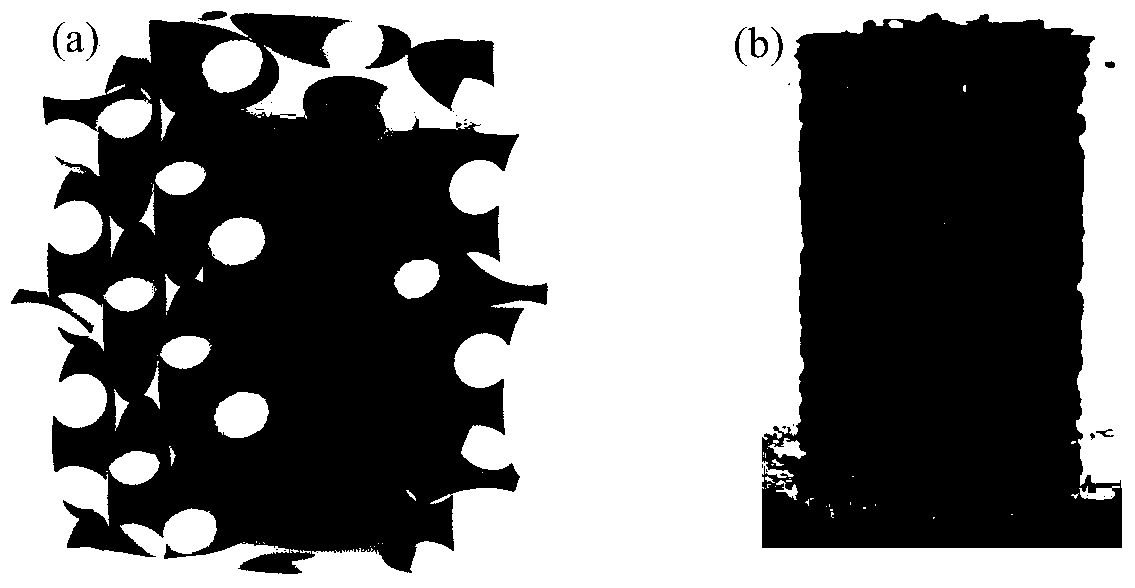

[0029] This embodiment relates to a degradable open-pore porous magnesium alloy used in the field of bone tissue engineering scaffolds, with a diameter of 55 mm, a height of 50 mm, a spherical pore shape, and a pore diameter of 500-600 μm. The number of interconnected pores contained in the inner wall of a single cavity There are 5 to 10 connected pores, the diameter of the connected pores is 150 μm, and the porosity is 90%. Its structure is as figure 1 As shown, (a) is a three-dimensional schematic diagram of the degradable porous magnesium and magnesium alloy bone tissue engineering scaffold, which accurately reflects the pore characteristics described in the present invention, for example, spherical pore type and interconnected pores The hole type and their distribution characteristics; (b) The picture is the corresponding physical map, from which we can see the spherical hole type and the hole type of the connected holes distributed on the hole wall and their distribution ...

Embodiment 2

[0035]This embodiment relates to a degradable open-pore porous magnesium alloy used for bone tissue engineering scaffolds, with a diameter of 100 mm, a height of 100 mm, a cubic hole shape, and a hole diameter of 900-1000 μm. The number of connected holes contained in the inner wall of a single hole There are 3 to 5 connected pores, the diameter of the connected pores is 400 μm, and the porosity is 85%.

[0036] This embodiment relates to the aforementioned degradable open-pore porous magnesium and magnesium alloy preparation method for bone tissue engineering scaffold, the method includes the following steps:

[0037] Step 1, putting cubic sodium chloride crystal particles with a size of 900-1000 μm into a mold with an inner diameter of 100 mm and a height of 100 mm, sintering at a constant temperature of 790 ° C for 24 hours, and cooling with the furnace to obtain an open-pore porous sodium chloride prefabricated body;

[0038] Step 2, the Mg-3wt.%Nd-0.2wt.%Zn-0.5wt.%Zr-0.5w...

Embodiment 3

[0041] This example relates to a degradable open-pore porous magnesium alloy used for bone tissue engineering scaffolds, with a diameter of 200 mm, a height of 200 mm, a spherical pore shape, and a pore diameter of 700-750 μm. The number of interconnected pores contained in the inner wall of a single cavity is 6. ~10 pieces, the diameter of the connected pores is 250 μm, and the porosity is 75%.

[0042] This embodiment relates to the aforementioned degradable open-pore porous magnesium and magnesium alloy preparation method for bone tissue engineering scaffold, the method includes the following steps:

[0043] Step 1, putting spherical sodium chloride crystal particles with a size of 700-750 μm into a mold with an inner diameter of 200 mm and a height of 200 mm, sintering at a constant temperature of 700 ° C for 10 hours, and cooling with the furnace to obtain an open-pore porous sodium chloride preform;

[0044] Step 2, pouring Mg-1wt.%Y-0.5wt.%Ca alloy melt into the mold ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com