Magnesium/hydroxyapatite composite material and preparation method thereof

A technology of hydroxyapatite and composite materials, applied in the field of preparation of magnesium/hydroxyapatite composite materials by microwave sintering method, can solve the problems of slow heating rate, long sintering time, large energy consumption, etc., and achieve fast heating rate , short sintering time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

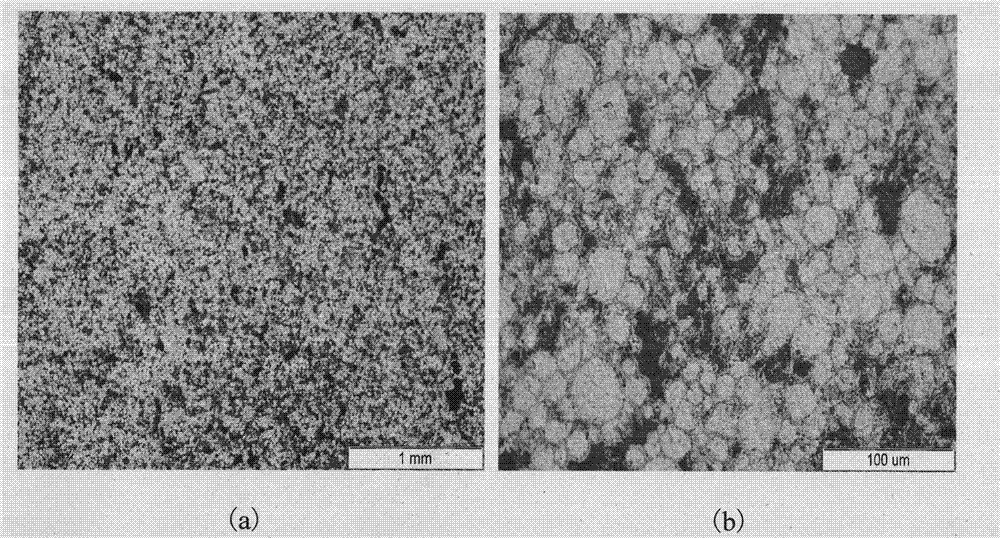

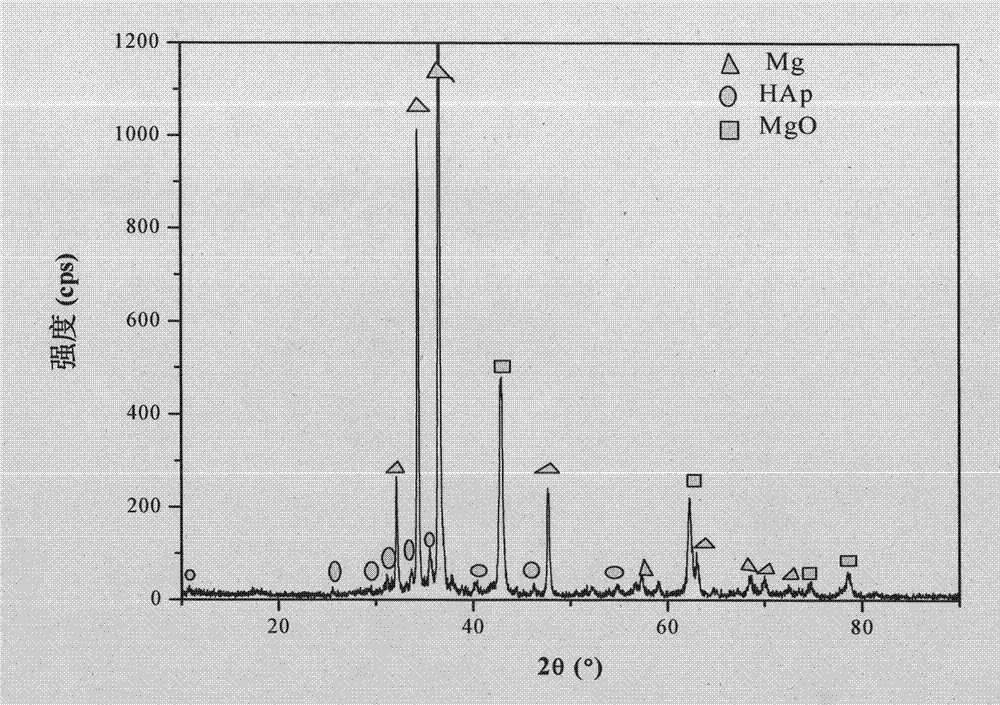

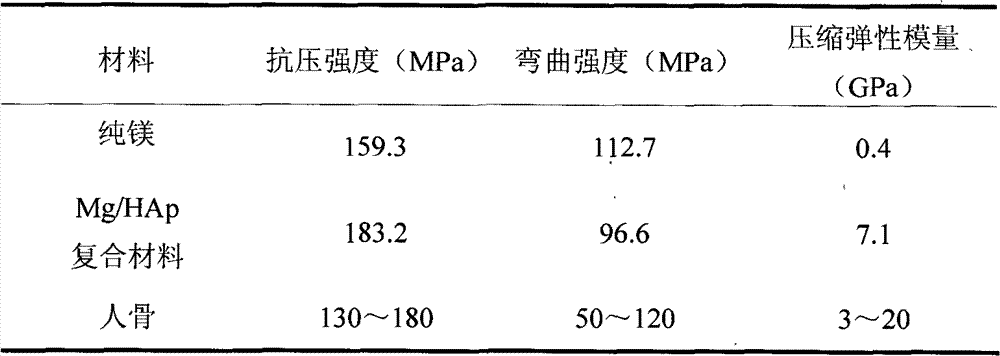

Embodiment 1

[0018] (1) The method of magnetic stirring is used to mix powder, the total mass of powder is 20g, the mass percentage of magnesium powder (purity 99.8%, particle size ≤ 80 μm), hydroxyapatite powder (purity 97.5%, particle size ≤ 80 μm) was 19.5%, the stirring speed was 1200 rpm, and magnetic stirring was performed for 4 hours.

[0019] (2) Dry the mixed powder in step (1) in a vacuum oven for 2 hours at a drying temperature of 60 degrees Celsius.

[0020] (3) The mixed powder in step (2) is cold-pressed into a mold, the size of the compressed sample is Φ11×12 mm, the size of the bent sample is 30×5×4 mm, and the pressure is 500 MPa.

[0021] (4) A ceramic tube is placed in the glass tube, silicon carbide is used as an auxiliary heating substance, and 5 grams of silicon carbide is placed between the ceramic tube and the glass tube. The sample is placed in a ceramic tube with an electrical insulating sheet at the bottom.

[0022] (5) Sinter the green body in step (3) in a va...

Embodiment 2

[0025] (1) The method of magnetic stirring is used to mix powder, the total mass of powder is 20g, the mass percentage of magnesium powder (purity 99.8%, particle size ≤ 80 μm), hydroxyapatite powder (purity 97.5%, particle size ≤ 80 μm) 5%, the stirring speed was 1200 rpm, and magnetic stirring was performed for 2 hours.

[0026] (2) Dry the mixed powder in step (1) in a vacuum oven for 2 hours at a drying temperature of 100 degrees Celsius.

[0027] (3) The mixed powder in step (2) is cold-pressed into a mold, the size of the compressed sample is Φ11×12 mm, the size of the bent sample is 30×5×4 mm, and the pressure is 450 MPa.

[0028] (4) A ceramic tube is placed in the glass tube, silicon carbide is used as an auxiliary heating substance, and 7 grams of silicon carbide is placed between the ceramic tube and the glass tube. The sample is placed in a ceramic tube with an electrical insulating sheet at the bottom.

[0029] (5) Sinter the green body in step (3) in a vacuum m...

Embodiment 3

[0032] (1) The method of magnetic stirring is used to mix powder, the total mass of powder is 20g, the mass percentage of magnesium powder (purity 99.8%, particle size ≤ 80 μm), hydroxyapatite powder (purity 97.5%, particle size ≤ 80 μm) 10%, the stirring speed was 1200 rpm, and magnetic stirring was performed for 2 hours.

[0033] (2) Dry the mixed powder in step (1) in a vacuum oven for 2 hours at a drying temperature of 100 degrees Celsius.

[0034] (3) The mixed powder in step (2) is cold-pressed into a mold, the size of the compressed sample is Φ11×12 mm, the size of the bent sample is 30×5×4 mm, and the pressure is 600 MPa.

[0035] (4) A ceramic tube is placed in the glass tube, silicon carbide is used as an auxiliary heating substance, and 7 grams of silicon carbide is placed between the ceramic tube and the glass tube. The sample is placed in a ceramic tube with an electrical insulating sheet at the bottom.

[0036] (5) Sinter the green body in step (3) in a vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com