Electric preheating and constant temperature membrane separation device for producing high-purity hydrogen

An electric preheating, high-purity technology, used in hydrogen separation, separation methods, dispersed particle separation, etc., can solve problems such as processing technical difficulties, and achieve the effect of easy temperature control and fast heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific examples. It should be noted that the examples cited are only used to further illustrate the technical features of the present invention, rather than to limit the present invention.

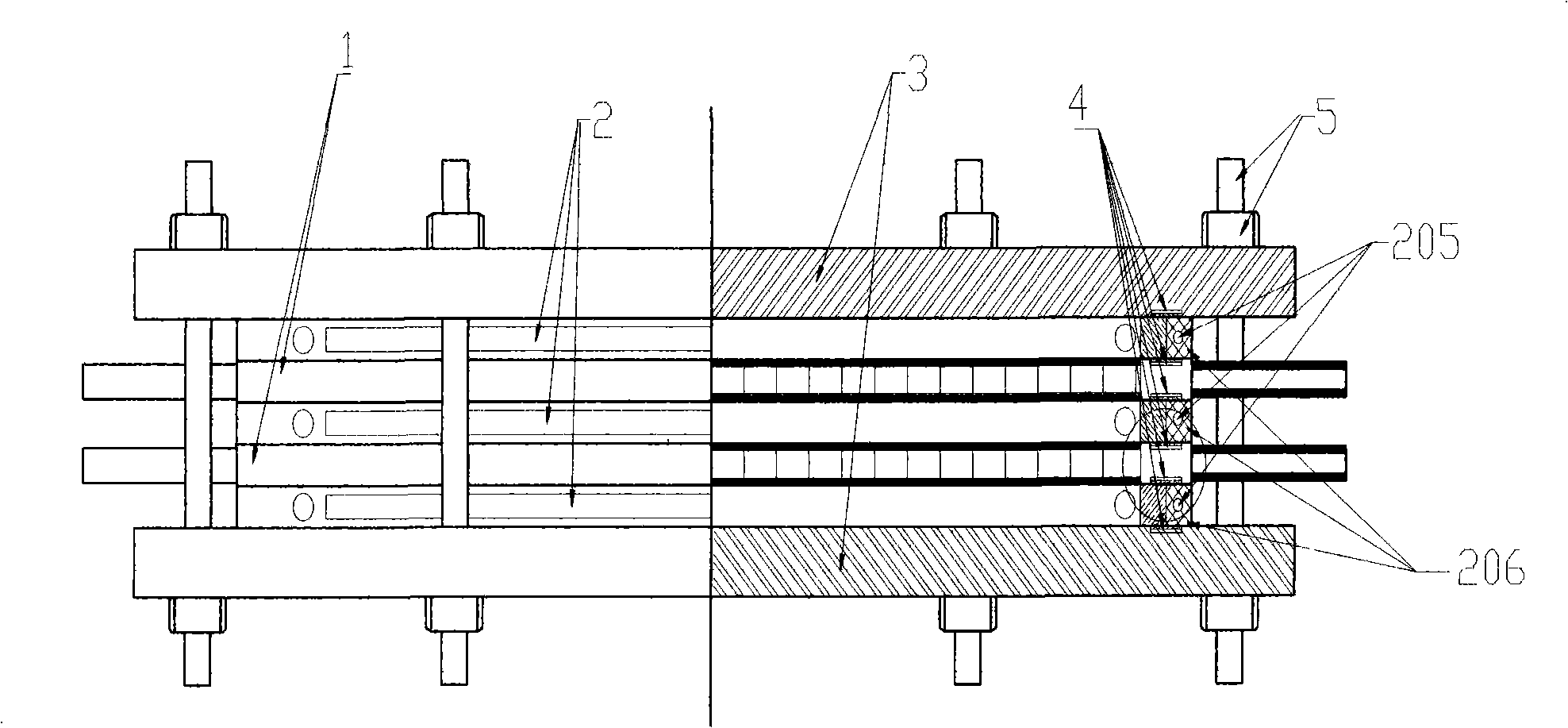

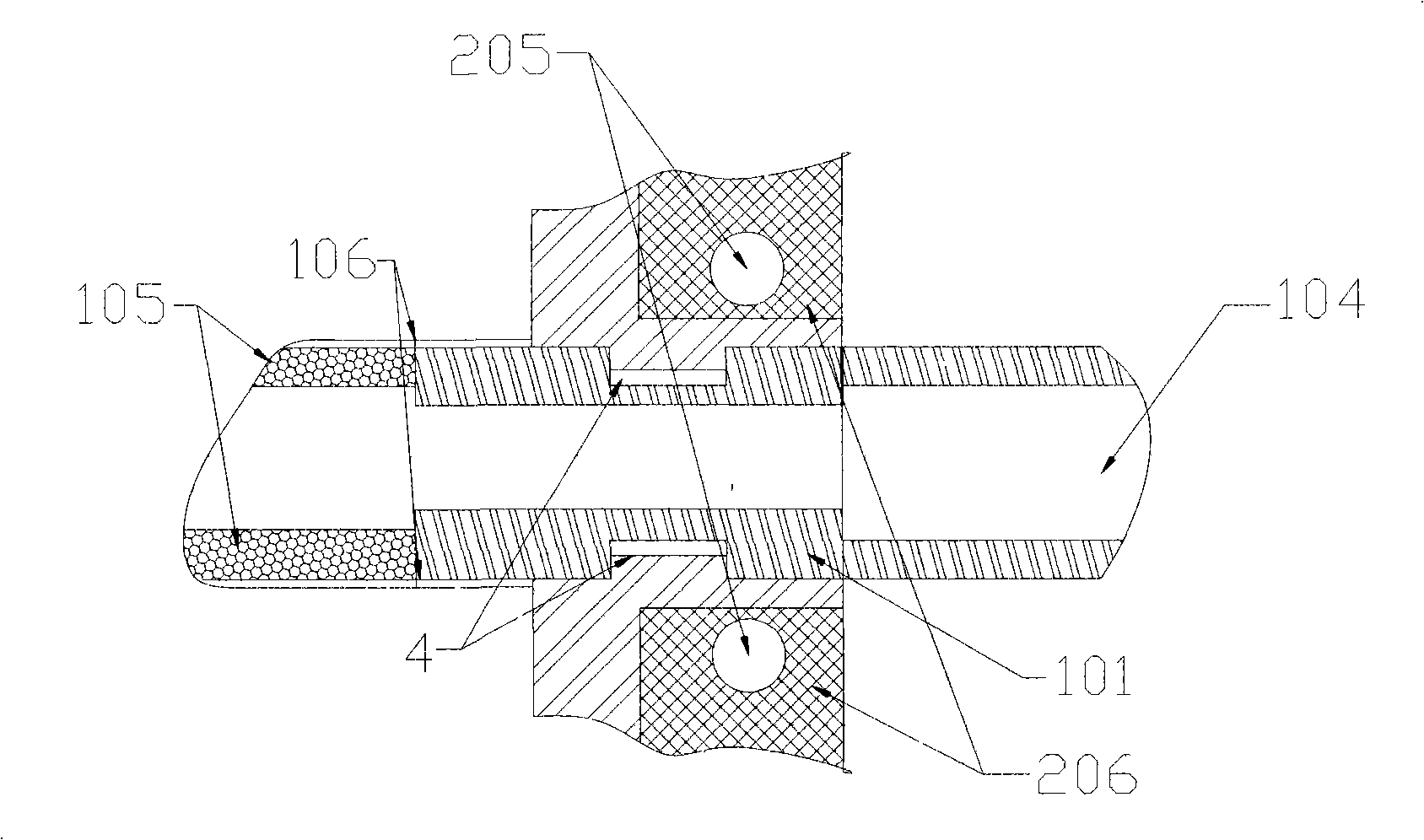

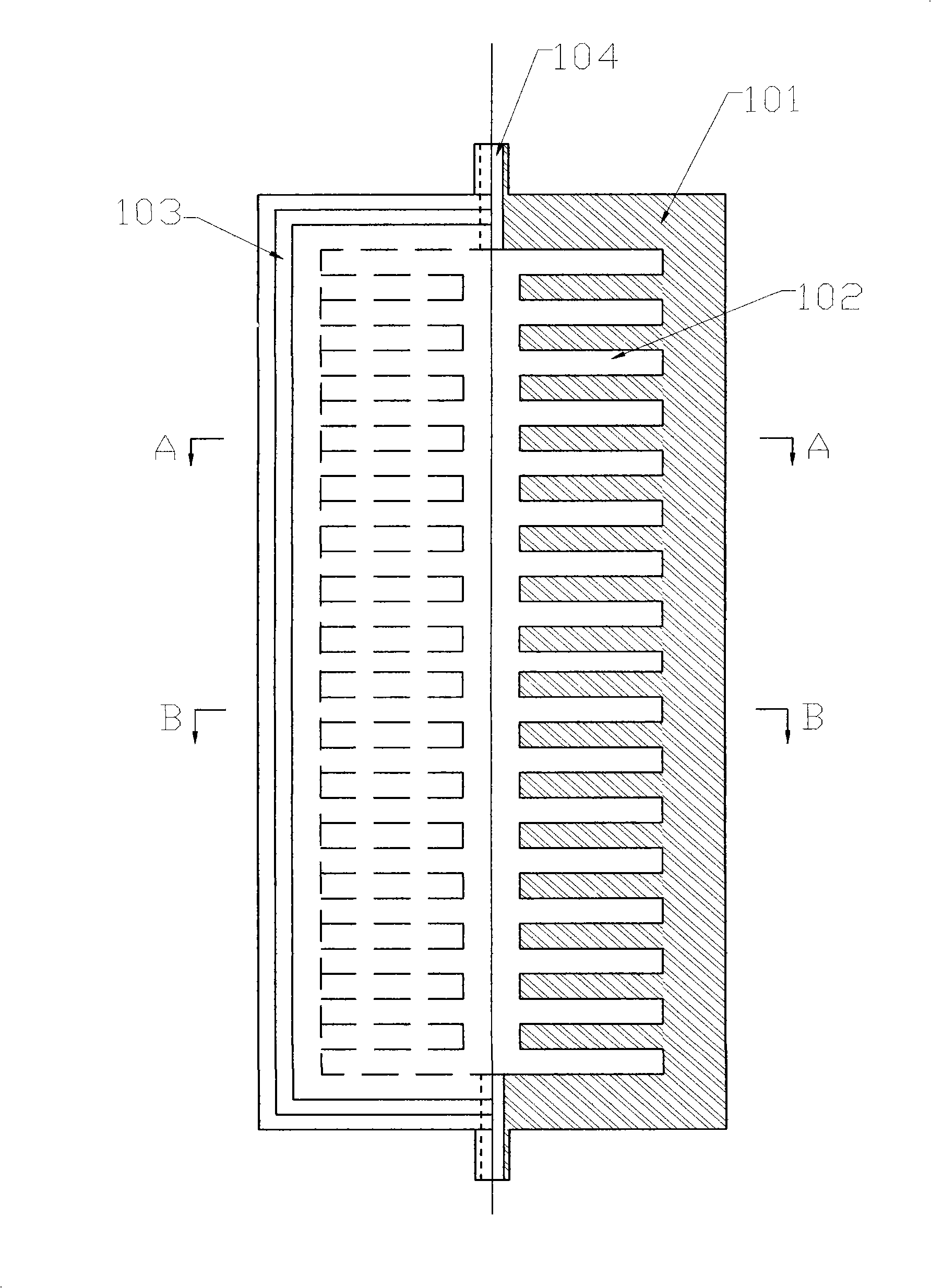

[0037] Such as figure 1 , 2As shown, a membrane separation device for producing high-purity hydrogen with electric preheating and constant temperature, including a palladium membrane module 1, a synthesis gas circulation frame 2, a blind flange 3, a graphite gasket 4, bolts and nuts 5, and an electric heating wire 205. A plurality of palladium membrane modules 1 are arranged between two blind flanges 3, and a synthetic gas circulation frame 2 is arranged between the blind flanges 3 and the palladium membrane modules 1 and between the palladium membrane module and the palladium membrane module. The gas circulation frame 2 separates the two, and to maintain sealing, graphite ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com