Metal bionic bone trabecula for repairing cancellous bone defect and preparing method thereof

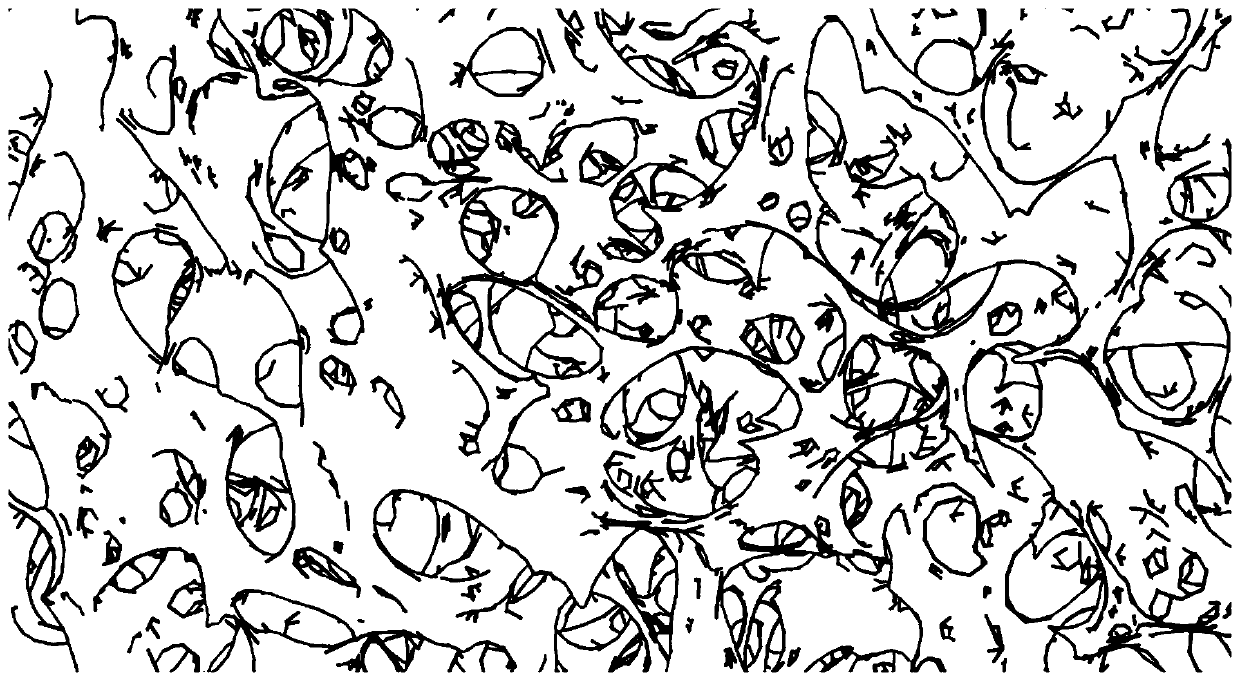

A technology of bionic bone and cancellous bone, which is applied in the direction of bone implants, can solve the problems of limited printing accuracy, interference with bone healing, and difficulty in meeting requirements, so as to improve the quality and speed of repair, reduce the risk of secondary fractures, The effect of avoiding the stress shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of metal tantalum powder

[0024] The tantalum powder that meets the requirements of 3D printing is prepared by the method of hydrogenation powder, in order to prepare a trabecular bone substitute that meets the requirements of clinical operations through 3D printing technology.

[0025] The metal material is hydrogenated, and successively undergoes crushing and ball milling, screening (to ensure fluidity), shaping and post-dehydrogenation to obtain metal powder. The purpose of the sieving treatment is to ensure that the fluidity is 20-50g / 12Sec. The purpose of the shaping treatment is to control the particle size range between 200mu and 400mu.

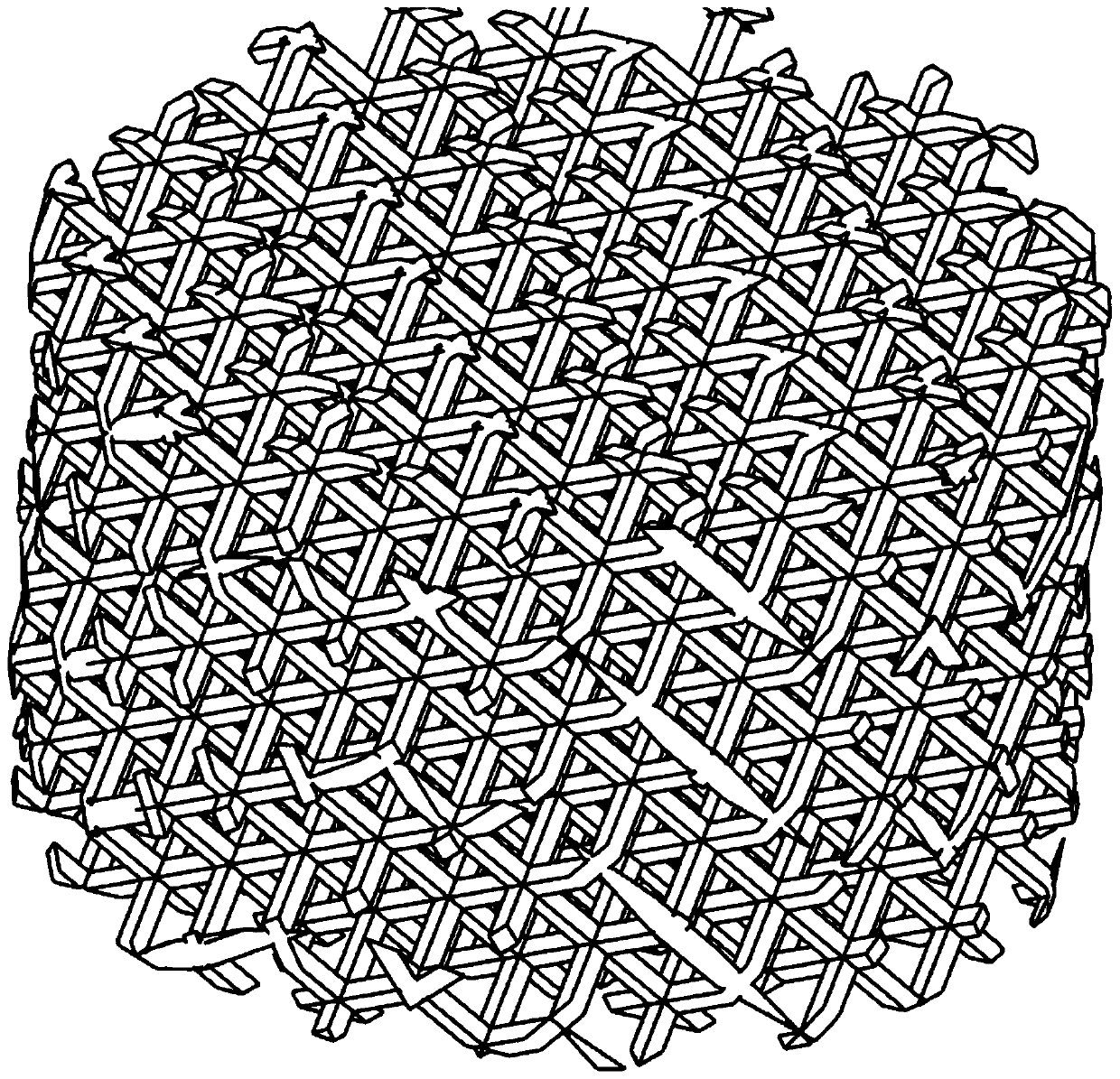

[0026] 2. Preparation of metal bionic bone trabecular

[0027] The prepared tantalum metal powder is melted at a high temperature at 2700-3000°C, and then the molten metal liquid passes through the high-voltage electrostatic force of the FFF technology printing platform (the diameter of the metal wire coming ou...

Embodiment 2

[0029] 1. Preparation of titanium-tantalum-niobium-zirconium alloy powder

[0030] Titanium, tantalum, niobium, and zirconium alloy powders that meet the requirements of 3D printing are prepared by hydrogenation powder making, in order to prepare trabecular bone substitutes that meet clinical operations through 3D printing technology.

[0031] First, the titanium-tantalum-niobium-zirconium alloy material (titanium 60%, tantalum 2%, niobium 34%, zirconium 4%, the following mass percentages) is hydrogenated, and it is successively subjected to crushing and ball milling treatment, screening treatment, shaping treatment and dehydrogenation After post-processing, titanium-tantalum-niobium-zirconium alloy powder is obtained.

[0032] 2. Preparation of titanium-tantalum-niobium-zirconium alloy bionic trabecular bone

[0033] The prepared titanium, tantalum, niobium, and zirconium alloy powders are melted at a high temperature at a melting temperature of 2200-2600°C. Then, the molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com