Fiber-reinforced 3D printed polymer pelvis substitute

A 3D printing, fiber-reinforced technology, used in joint implants, joint implants, medical science, etc., can solve the problems of limited application, low static strength and fatigue strength of polymer materials, and improve early stability. , the effect of enhancing mechanical properties and meeting the requirements of mechanical environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

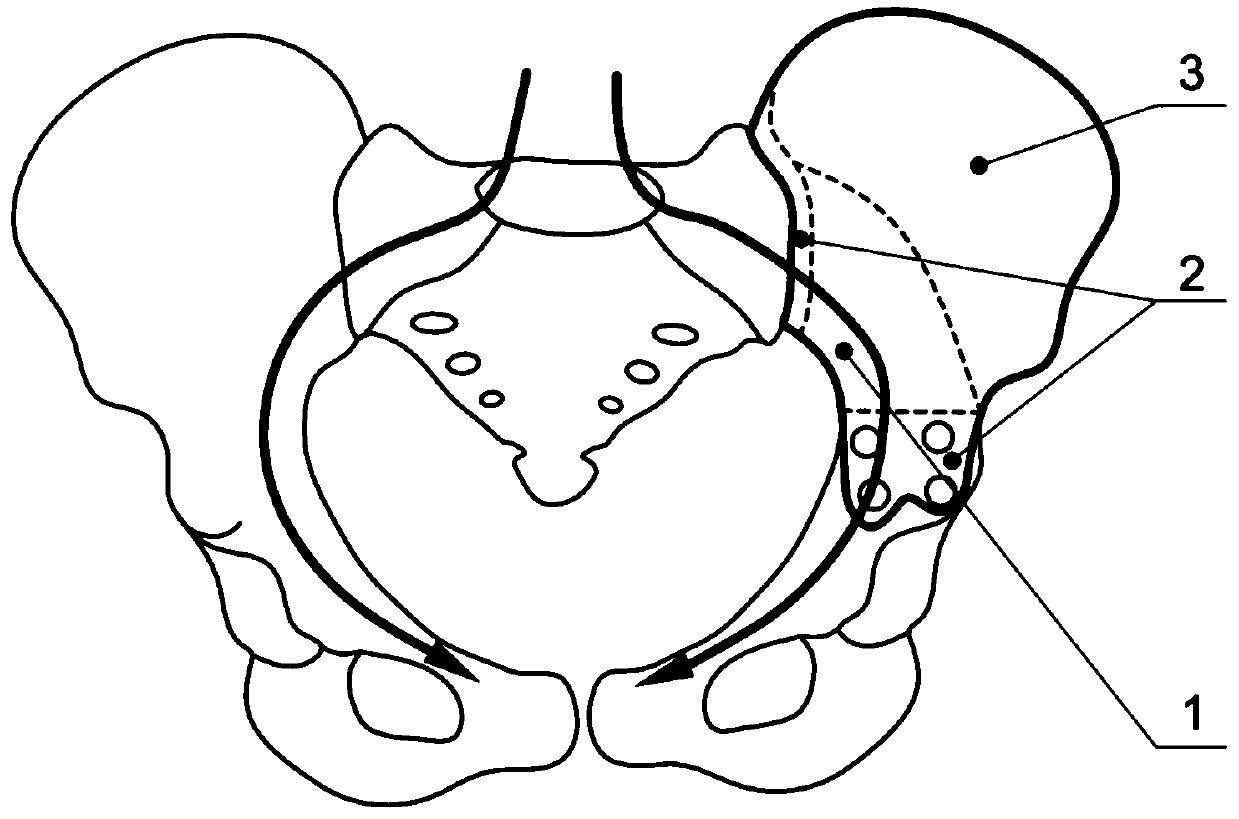

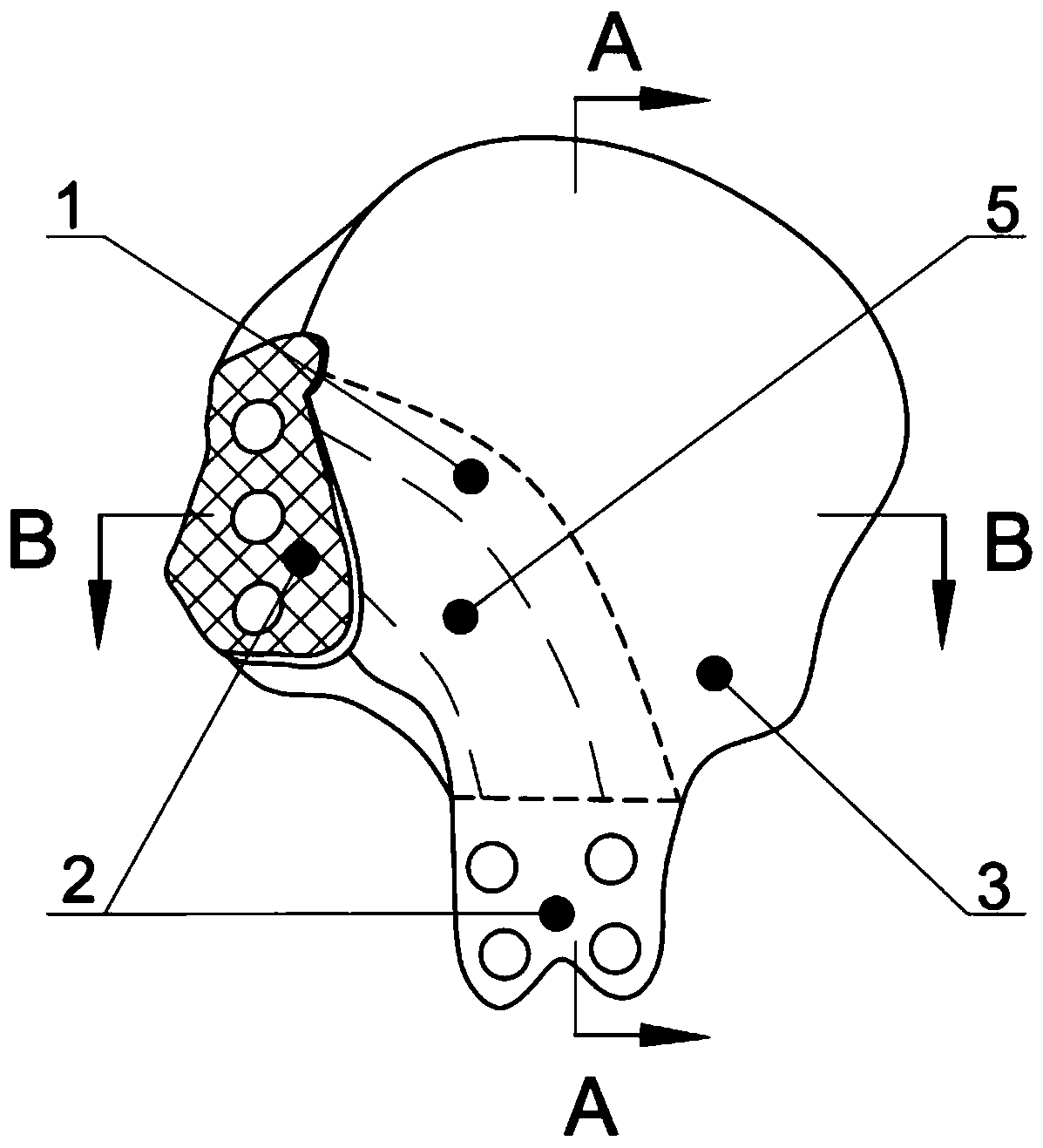

[0026] Embodiment 1, take I type prosthesis (iliac resection) as example, as figure 1 , figure 2 , image 3 and Figure 4 As shown, a fiber-reinforced 3D printed polymer pelvic substitute, the pelvic bone substitute is a non-acetabular pelvic bone substitute, and the non-acetabular pelvic bone substitute includes reinforced load-bearing part 1, boundary part 2 and non-weight-bearing Part 3: There are reinforcing fibers 5 inside the reinforced load-bearing part 1 to enhance the tensile and bending strength of the substitute; the boundary part 2 is connected with the remaining bone; the non-load-bearing part 3 is the pelvic bone substitute without the reinforced load-bearing part 1 and The remaining part behind the boundary part 2 plays a role in maintaining the original anatomical shape of the pelvis, and the shape of the non-weight-bearing part 3 can be determined according to the same type of clinical needs.

[0027] The reinforced load-bearing part 1 is designed accordin...

Embodiment 2

[0032] Embodiment 2, take II+III (acetabulum+ischium resection) type prosthesis as example, as Figure 5 , Figure 6 and Figure 7 As shown, a fiber-reinforced 3D printing polymer pelvic substitute, the pelvic substitute is an acetabular pelvic substitute, and the difference from the Type I prosthesis in Example 1 is that the acetabular pelvic substitute The fixing method between the boundary part 2 and the remaining bone is screw fixation; in addition, the acetabular pelvic bone substitute includes an acetabular cup part 4, and the inside of the acetabular cup part 4 contains reinforcing fibers 5; the laying direction of the reinforcing fibers 5 is radial. Except for the connection mode and the acetabular cup part 4, other parts are similar to those described in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com