A kind of manufacturing method of personalized customized tantalum implant

A manufacturing method and implant technology, applied in the direction of bone implants, etc., can solve the problems of difficult and difficult processing of personalized customized tantalum implants, avoid stress shielding effect, increase the success rate, and benefit Osteogenic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Reconstruct the 3D model of bone tissue in 3D modeling software using CT or MRI multi-planar reconstruction images of bone tissue in clinical patients, and then import the 3D model of bone tissue into the reverse software to design a personalized bone repair implant model ;

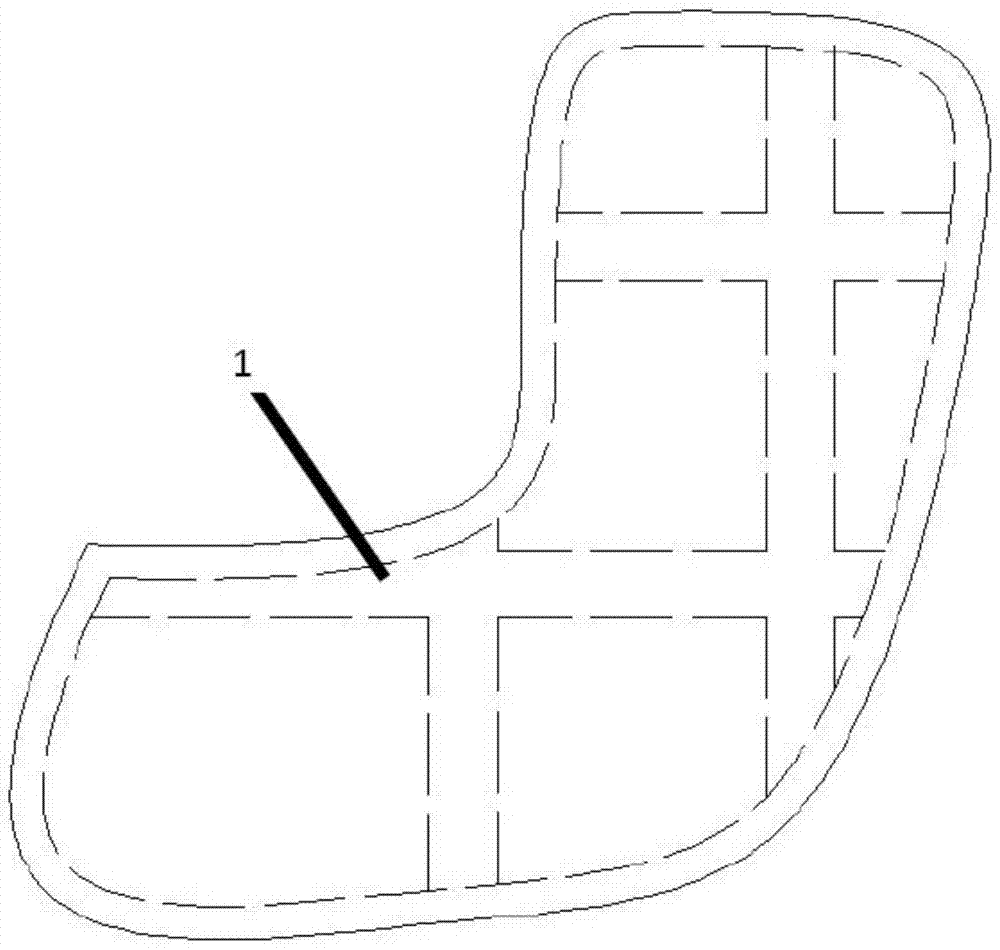

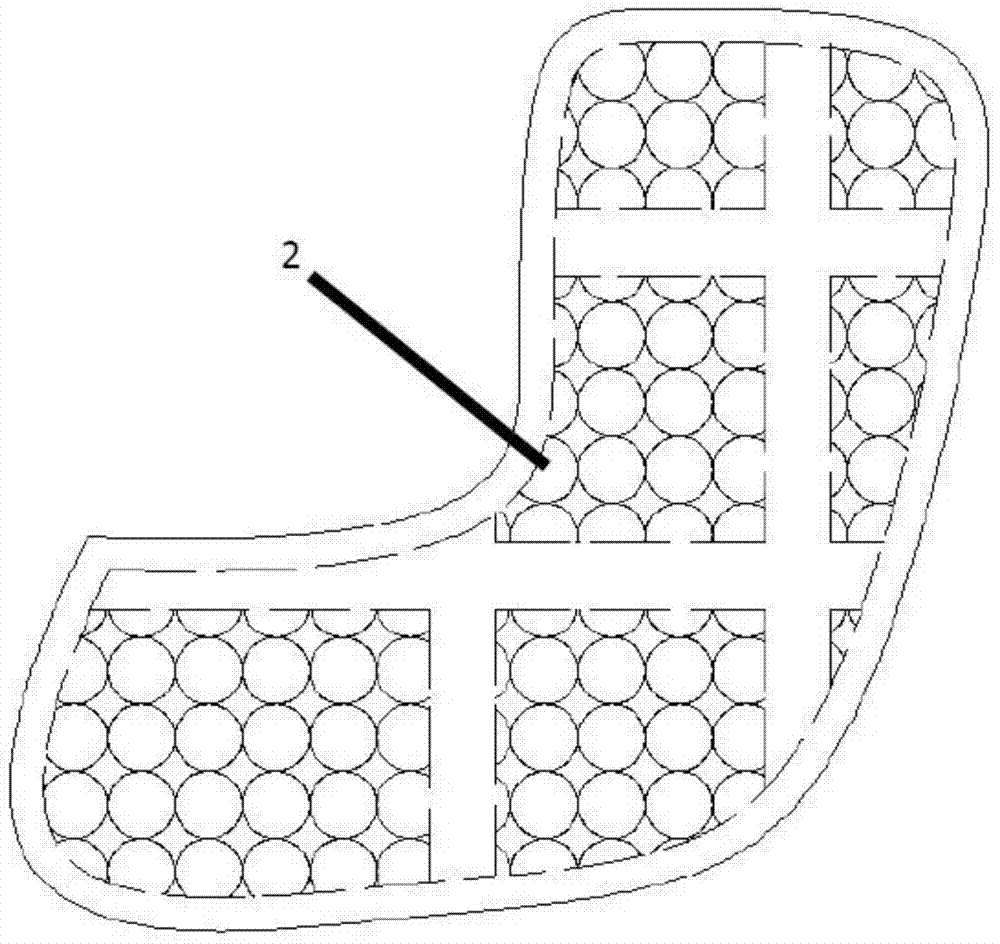

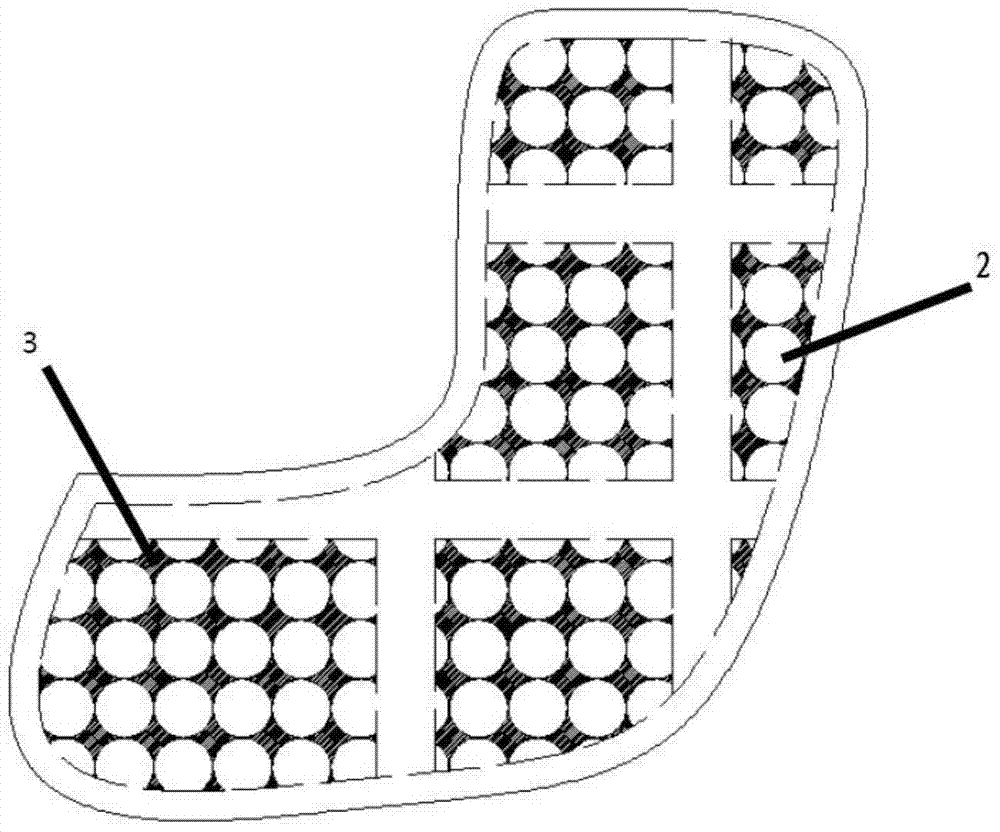

[0041] 2) Carry out shelling processing on the personalized bone repair implant model to obtain the shell of the model after shelling, and then add criss-cross grids 1 inside the shell of the model after shelling to obtain the implant negative body containing the grid 1 inside. type mold, wherein, the thickness h of the implant negative mold is 0.5mm, the diameter d of the network frame 1 is 0.5mm, and the distance between adjacent network frames 1 is 1mm;

[0042] 3) Utilize the 3D printer to prepare the negative mold of the implant containing the grid frame inside in step 2), such as figure 1 shown;

[0043] 4) Fill the implant negative mold with a grid frame 1 inside with expandable methyl ...

Embodiment 2

[0050] 1) Reconstruct the 3D model of bone tissue in 3D modeling software using CT or MRI multi-planar reconstruction images of bone tissue in clinical patients, and then import the 3D model of bone tissue into the reverse software to design a personalized bone repair implant model ;

[0051] 2) Carry out shelling processing on the personalized bone repair implant model to obtain the shell of the model after shelling, and then add criss-cross grids 1 inside the shell of the model after shelling to obtain the implant negative body containing the grid 1 inside. type mold, wherein, the thickness h of the implant negative mold is 0.5mm, the diameter d of the network frame 1 is 0.5mm, and the distance between adjacent network frames 1 is 1mm;

[0052] 3) Utilize the 3D printer to prepare the negative mold of the implant containing the grid frame inside in step 2), such as figure 1 shown;

[0053]4) Fill the implant negative mold with a grid frame 1 inside with expandable methyl m...

Embodiment 3

[0060] 1) Reconstruct the 3D model of bone tissue in 3D modeling software using CT or MRI multi-planar reconstruction images of bone tissue in clinical patients, and then import the 3D model of bone tissue into the reverse software to design a personalized bone repair implant model ;

[0061] 2) Carry out shelling processing on the personalized bone repair implant model to obtain the shell of the model after shelling, and then add criss-cross grids 1 inside the shell of the model after shelling to obtain the implant negative body containing the grid 1 inside. type mold, wherein, the thickness h of the implant negative mold is 0.5mm, the diameter d of the network frame 1 is 0.5mm, and the distance between adjacent network frames 1 is 1mm;

[0062] 3) Utilize the 3D printer to prepare the negative mold of the implant containing the grid frame inside in step 2), such as figure 1 shown;

[0063] 4) Fill the implant negative mold with a grid frame 1 inside with expandable methyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com