Method for preparing bioactive calcium phosphate coating on magnesium alloy surface for endosseous implant

A bioactive calcium and magnesium alloy technology, applied in metal material coating technology, coating, medical science, etc., can solve problems such as uneven distribution of Ca-P coating and uneven distribution of white deposits on the surface of magnesium alloys , to achieve the effect of low cost, easy operation and improved biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

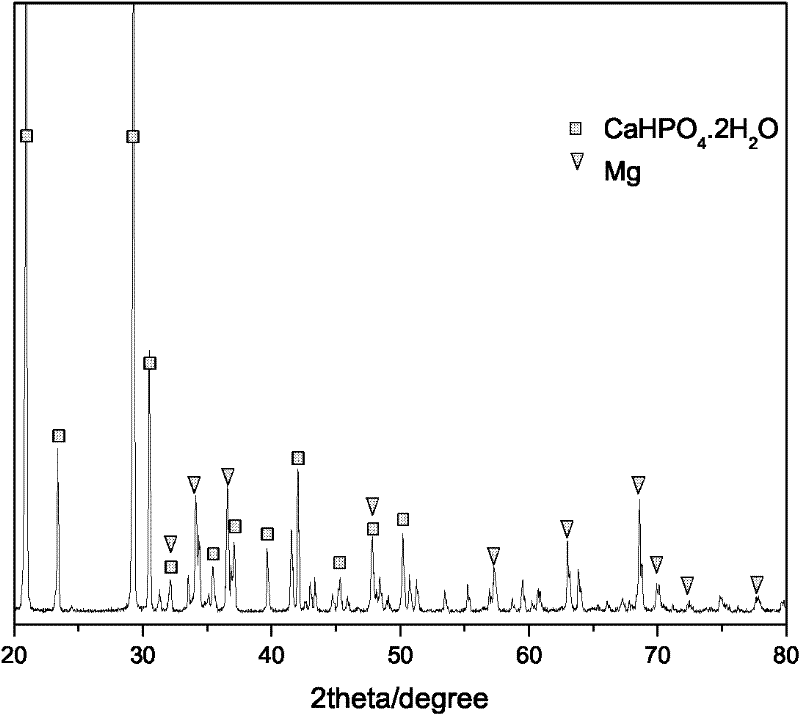

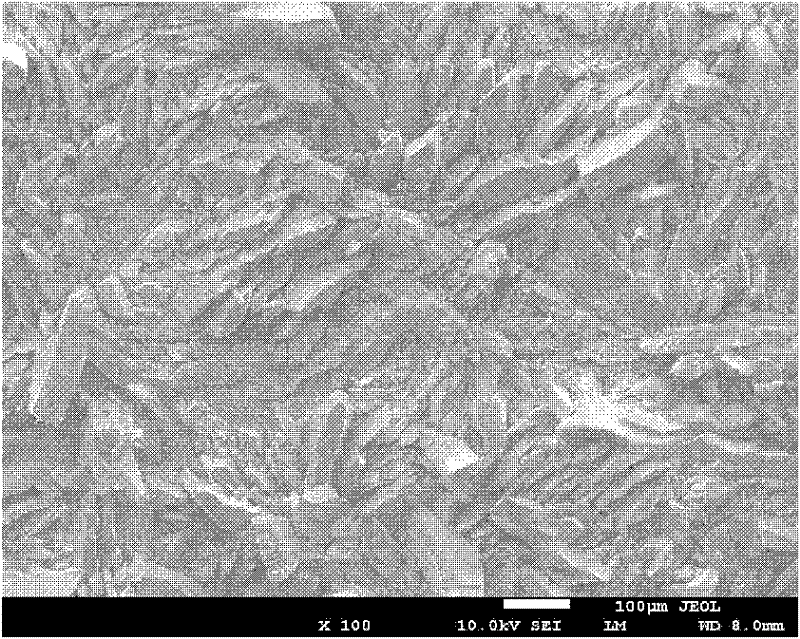

[0028] A bioactive Ca-P coating was prepared on the surface of AZ31 (Mg-Al series) alloy. Firstly, the AZ31 magnesium alloy is made into The samples were polished with 320-mesh water sandpaper and No. 3 metallographic sandpaper in turn. Ultrasonic cleaning with absolute ethanol for 10 min, and air-dried. The sample was soaked in a 20% HF solution in a water bath at a constant temperature (20°C) for 4 hours, washed with deionized water and absolute ethanol successively, and dried. Then put the sample into NaNO 3 : Ca 3 (PO 4 ) 2 :H 2 o 2 = 7:4:2 (wt%) solution soaked in a water bath at a constant temperature (20°C) for 8h. The scanning electron microscope observed that the thickness of the chemical conversion film was 150nm, and the composition analysis showed that the chemical conversion film was MgF 2 , it was observed that the thickness of the Ca-P coating was 10 μm, and the atomic ratio of Ca / P was 1:1. It shows that the prepared Ca-P surface coating has good bio...

Embodiment 2

[0030] A bioactive Ca-P coating was prepared on the surface of NZ30K (Mg-RE series) alloy. Firstly, the NZ30K magnesium alloy is made into The samples were polished with 320-mesh water sandpaper and No. 3 metallographic sandpaper in turn. Ultrasonic cleaning with absolute ethanol for 10 min, and air-dried. The sample was soaked in a 60% HF solution in a water bath at a constant temperature (20°C) for 16 hours, washed with deionized water and absolute ethanol successively, and dried. Then put the sample into NaNO 3 :Na 3 PO 4 : Ca(H 2 PO 4 ) 2 :H 2 o 2 = 2: 2: 5: 1 (wt%) soaking in a water bath at a constant temperature (20° C.) for 48 hours. The thickness of the chemical conversion film was 2 μm observed by the scanning electron microscope, and the composition analysis showed that the chemical conversion film was MgF2. It was observed that the thickness of the Ca-P coating was 20 μm, and the atomic ratio of Ca / P was 1.05:1, indicating that the surface has good biolog...

Embodiment 3

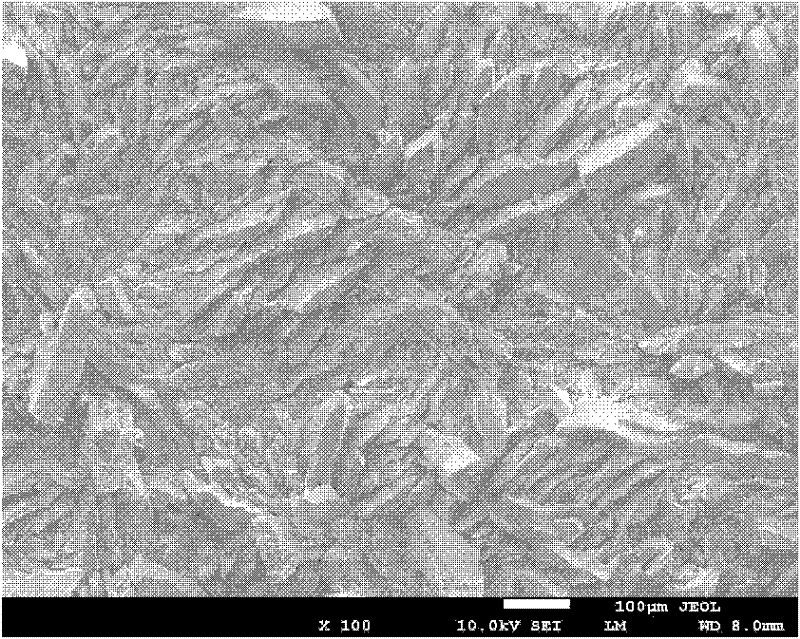

[0034] A bioactive Ca-P coating was prepared on the surface of WE43 (Mg-RE series) alloy. Firstly, the WE43 magnesium alloy is made into The samples were polished with 320-mesh water sandpaper and No. 3 metallographic sandpaper in turn. Ultrasonic cleaning with absolute ethanol for 10 min, and air-dried. The sample was soaked in a 40% HF solution in a water bath at a constant temperature (20°C) for 8 hours, washed with deionized water and absolute ethanol successively, and dried. Then put the sample into NaNO 3 : Ca 3 (PO 4 ) 2 : Ca(H 2 PO 4 ) 2 ·H 2 O:H 2 o 2 =5:1:2:1 (wt%) soaking in a water bath at a constant temperature (20° C.) for 24 hours. The scanning electron microscope observed that the thickness of the chemical conversion film was 600nm, and the composition analysis showed that the chemical conversion film was MgF 2 , it was observed that the thickness of the Ca-P coating was 30 μm, and the atomic ratio of Ca / P was 1.1:1. It shows that the obtained Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com