High-melt-strength polypropylene material resistant to cyclic processing as well as preparation method and application thereof

A high melt strength, polypropylene material technology, applied in the field of polymer materials, can solve the problems of non-recyclable processing and reduced melt strength, so as to avoid the reduction of melt strength, reduce chain scission, and improve melt strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

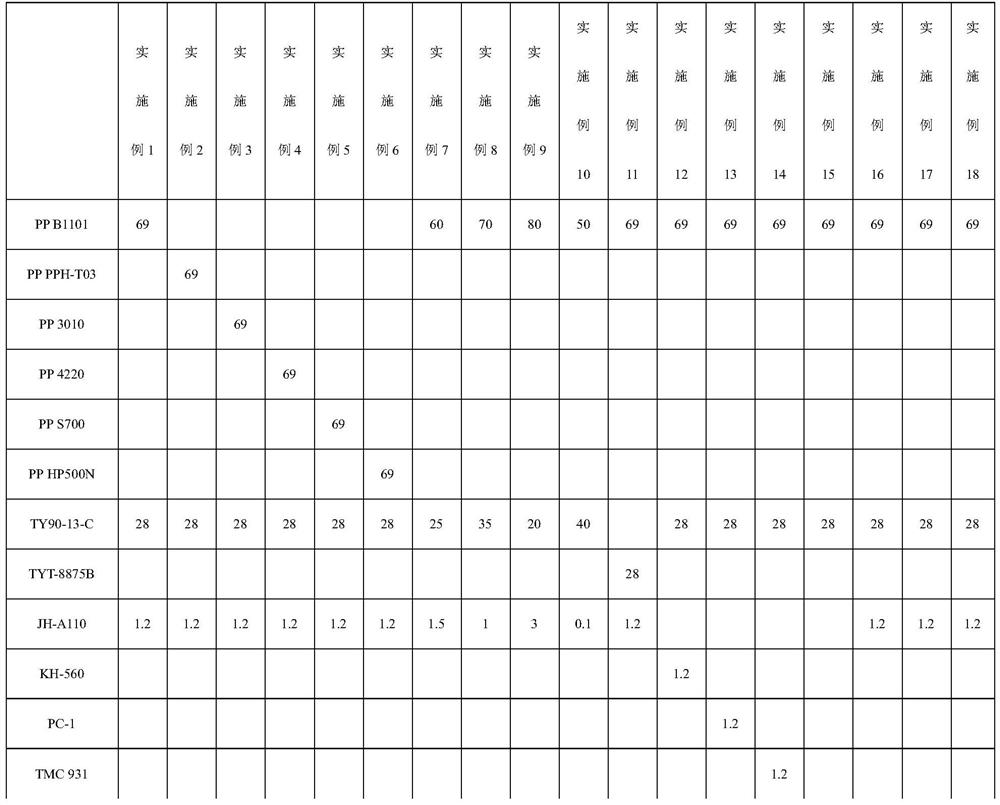

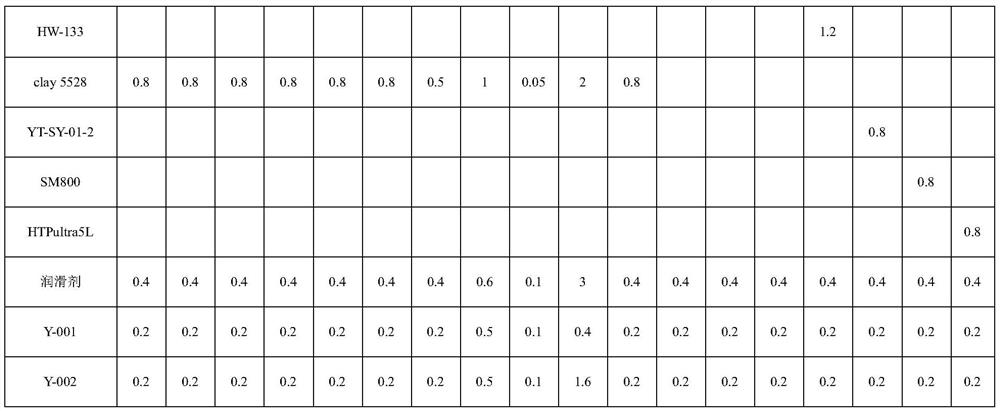

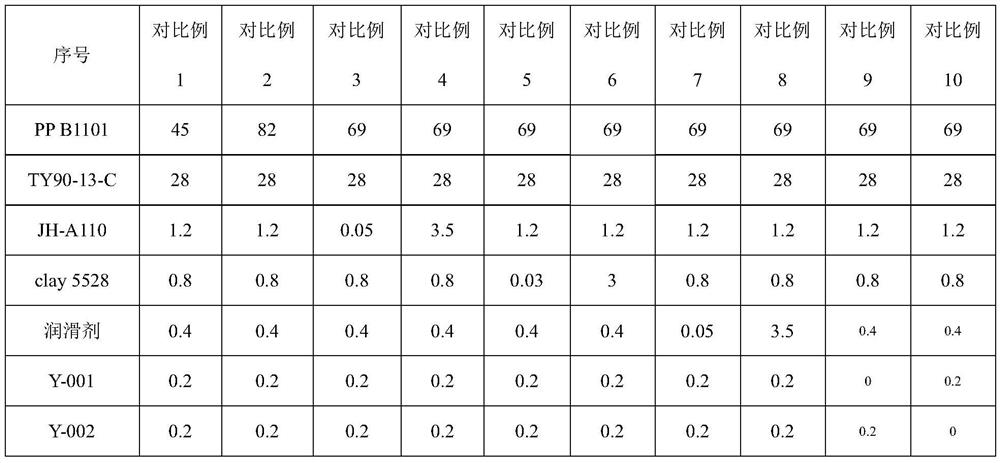

[0090] A high-melt-strength polypropylene material resistant to cyclic processing, in parts by weight, comprising the components shown in Table 1 below:

[0091] Table 1

[0092]

[0093]

[0094] The preparation method of the high-melt-strength polypropylene material resistant to cyclic processing of the above-mentioned embodiments 1-18 is specifically:

[0095] S1. The modifier aminosilane coupling agent, nucleating agent and talc powder were weighed and then mixed in a high-speed mixer at 100°C. The mixing speed was 300r / min and the mixing time was 6min to obtain mixture A;

[0096] S2. Add the resin matrix, lubricant, main antioxidant, and auxiliary antioxidant together with the mixture A into the high-speed mixer after weighing, the mixing speed is 300r / min, and the mixing time is 5min to obtain the mixture B;

[0097] S3. Adding the mixture B to a twin-screw extruder for melt extrusion, pelletizing and cooling to obtain a high-melt-strength polypropylene material ...

Embodiment 19

[0099] A high-melt-strength polypropylene material resistant to cyclic processing, its components and content are basically the same as in Example 2, the difference is that T-01 with a particle size of 1000 mesh is used as talc powder.

[0100] A preparation method of a high melt strength polypropylene material resistant to cyclic processing, specific example 2.

Embodiment 20

[0102] A high-melt-strength polypropylene material resistant to cyclic processing, its components and content are basically the same as in Example 2, the difference is that the talc powder is TYT-777A with a particle size of 3000 mesh.

[0103] A preparation method of a high melt strength polypropylene material resistant to cyclic processing, specific example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com