Method for preparing low melt strength polyester / clay nanocomposites for CO2 foam

A technology of nanocomposites and low melt strength, which is applied in the field of preparation of polyester/clay nanocomposites, can solve the problems of energy and time consumption, and achieve the goals of saving time and energy, excellent gas barrier, and reducing process costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

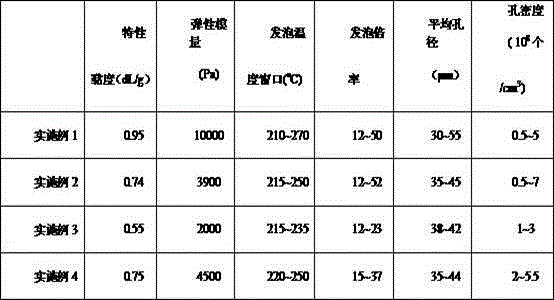

Examples

Embodiment 1

[0037] Bottle-grade polyester chips (polymerization degree 150), chain extender pyromellitic anhydride, and organic clay modified by methyl-tallow-bis(2-hydroxyethyl) quaternary ammonium salt at 110 o Dried under C conditions for 12 hours, and fully premixed in the following parts by mass.

[0038] 100 pieces of polyester chips

[0039] 0.8 parts of chain extender

[0040] 1 part clay

[0041] The polyester / clay nanocomposite was obtained by melting and blending the premix with a twin-screw extruder, the screw speed was 240 rpm, and the screw barrel temperature was 270 o C, the die head temperature is 260 o c. The prepared polyester / clay nanocomposite is water-cooled and granulated for analysis and foaming.

Embodiment 2

[0043] Recycled polyester bottle flakes (polymerization degree 125), chain extender pyromellitic anhydride at 100 o Dried under C conditions for 8 hours, and fully premixed in the following parts by mass.

[0044] 100 copies of recycled polyester bottle flakes

[0045] 0.5 parts of chain extender

[0046] Recycled polyester bottle flakes and chain extender premix are reactively extruded through a single-screw extruder to prepare modified polyester. The residence time of the material in the extruder is 120 seconds, and the extrusion temperature is 285 o c. The extrudate is water-cooled, pelletized, and modified clay with 1-decyl-2-methyl-3-dodecyl imidazolium salt at 120 o C and dried for 14 hours, and fully mixed in the following parts by mass.

[0047] Modified polyester 100 parts

[0048] 3 parts clay

[0049] The premixture of modified polyester and organically modified clay was melt-blended by a twin-screw extruder to obtain a polyester / clay nanocomposite. The spee...

Embodiment 3

[0051] Engineering plastic grade polyester chips (polymerization degree 200) and octadecyl-bis(2-hydroxyethyl) quaternary ammonium salt modified organoclay at 120 o Fully dry under C conditions for 12 hours, and fully premix in the following parts by mass.

[0052] 100 pieces of polyester chips

[0053] 10 parts clay

[0054] The above premixture is melted and blended by a twin-screw extruder to prepare a polyester / clay nanocomposite masterbatch. The rotating speed of the twin-screw extruder is 200 revolutions per minute, and the screw barrel temperature is 270 o C, die head temperature 265 o c. The extruded product is water-cooled and granulated, and is mixed with engineering plastic grade polyester chips (polymerization degree 200), epoxy chain extender 4,4′-diaminodiphenylmethane tetraglycidyl ether at 100 o C under the condition of drying for 15 hours, and fully mixed in the following parts by mass.

[0055] 100 pieces of polyester chips

[0056] Nanocomposite maste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com