Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

411results about How to "Improve extrusion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

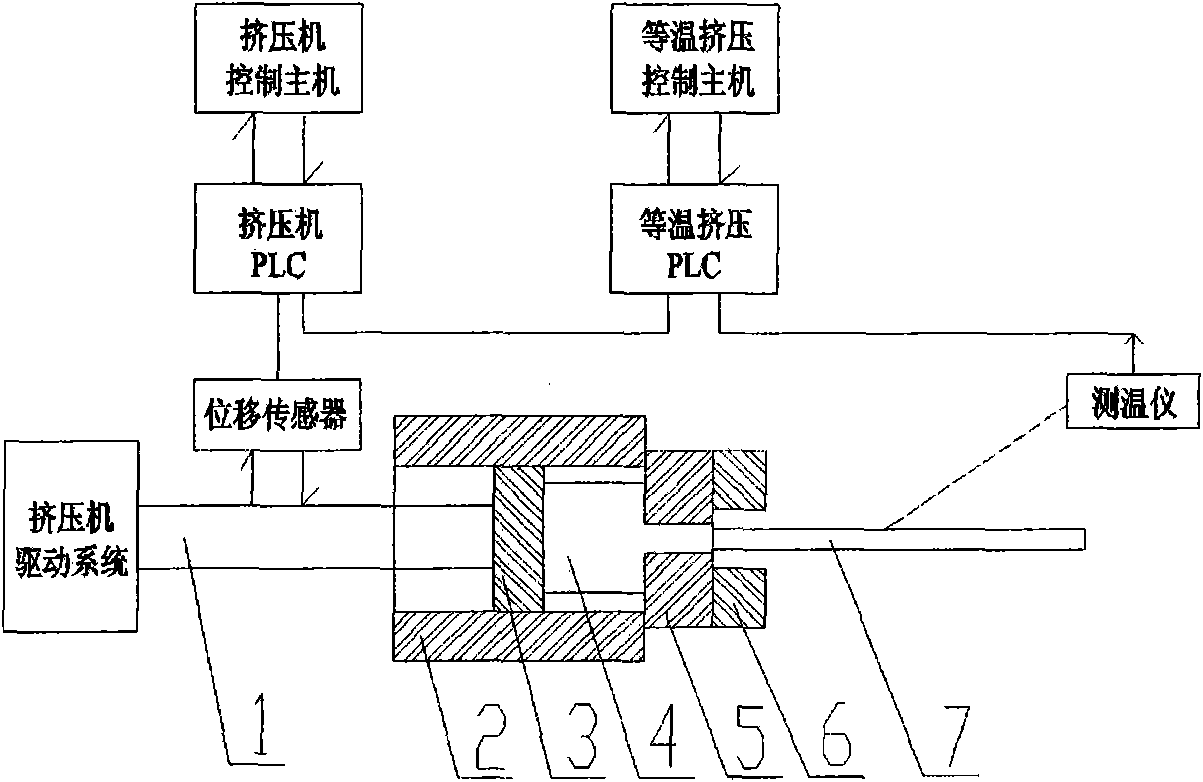

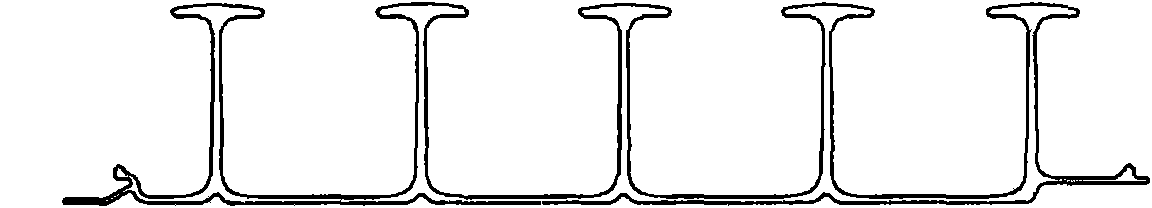

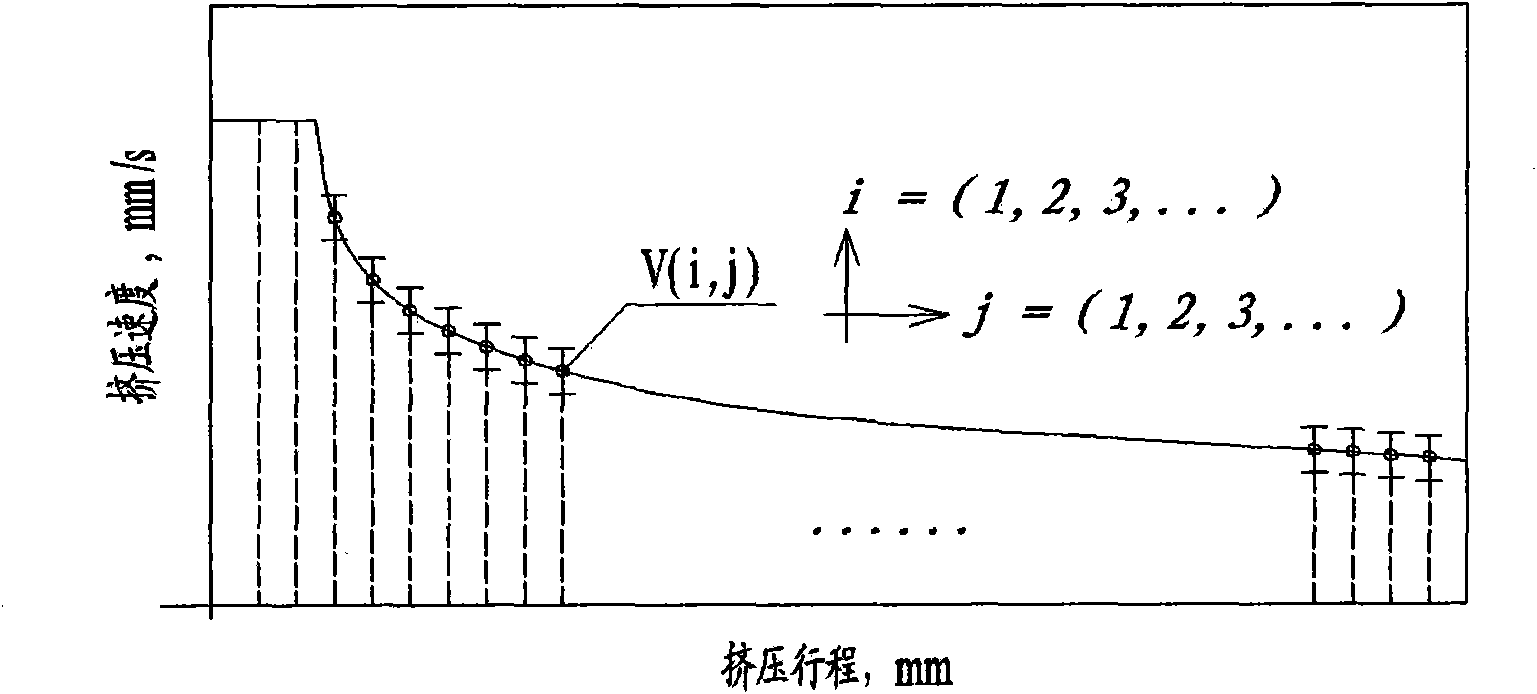

Method for controlling speed regulation of isothermal extrusion of industrial aluminum profiles for transportation

InactiveCN102049426AShort measurement response timeUniform microstructureExtrusion control devicesTemperature controlControl system

The invention discloses a method for controlling the speed regulation of the isothermal extrusion of industrial aluminum profiles for transportation, wherein a control system host machine, an isothermal extrusion PLC (Programmable Logic Controller) and an industrial aluminum profile outlet temperature thermodetector are used. The isothermal extrusion curves of the industrial aluminum profiles and profile outlet temperature control information are saved in the control system host machine. The method comprises the steps of: continuously monitoring and acquiring extruded profile outlet temperature by the thermodetector, importing temperature data into the isothermal extrusion PLC, issuing an extrusion speed regulation instruction by the isothermal extrusion PLC and a control system according to the detected temperature, transmitting the extrusion speed regulation instruction to an extruder PLC through the isothermal extrusion PLC, and regulating the increment / decrement of the extrusion speed of an extruder; and meanwhile, feeding back the real-time extrusion speed of the extruder to the isothermal extrusion PLC by the extruder PLC, and carrying out the processes in cycle. The method disclosed by the invention obviously improves the automation degree and production and manufacture efficiency of the extrusion production procedure of the industrial aluminum profiles and solves the technical problems of huge quality fluctuation and low production efficiency caused by controlling on the basis of manual experience for a long time.

Owner:GUANGDONG XINGFA ALUMINUM

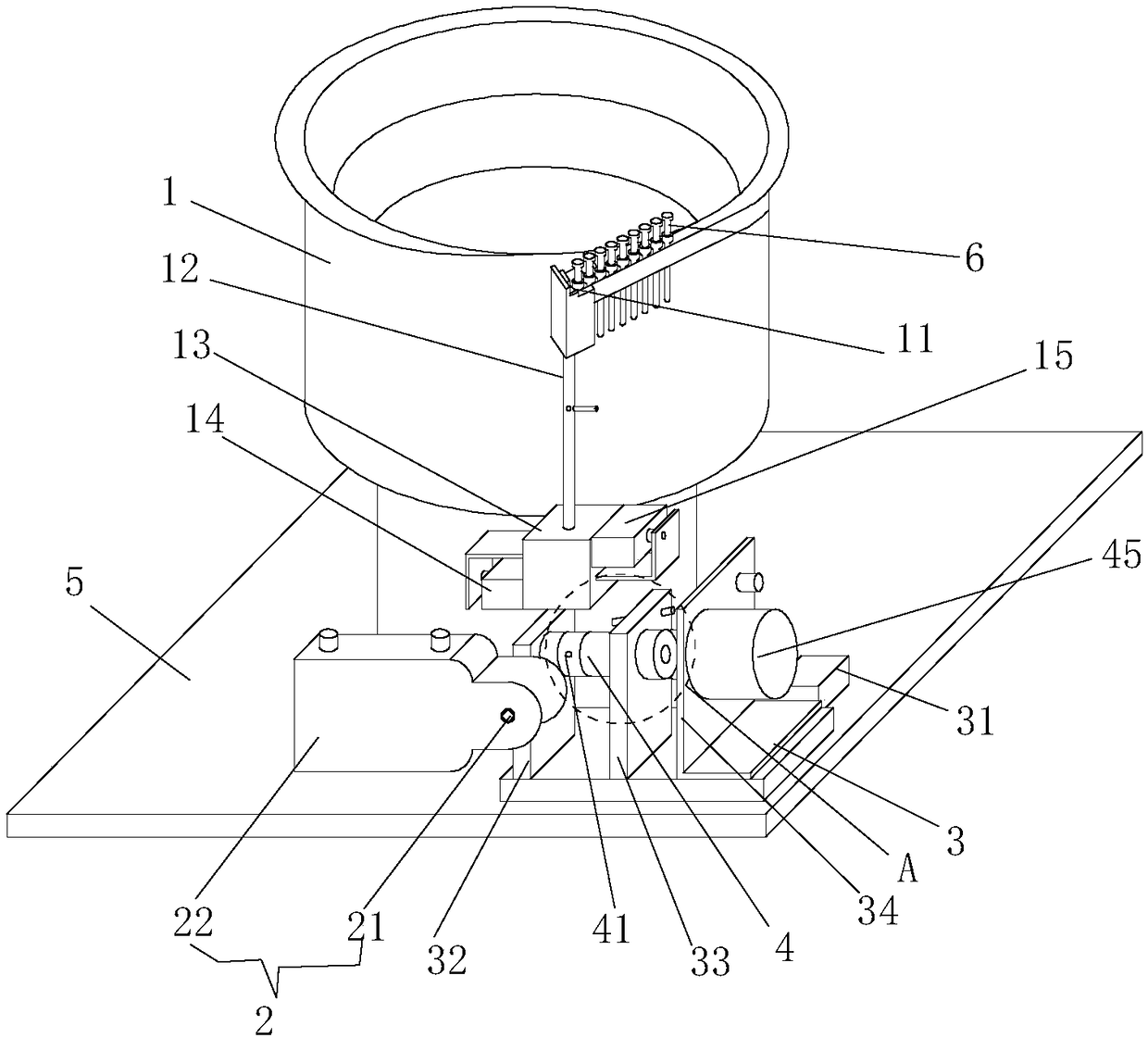

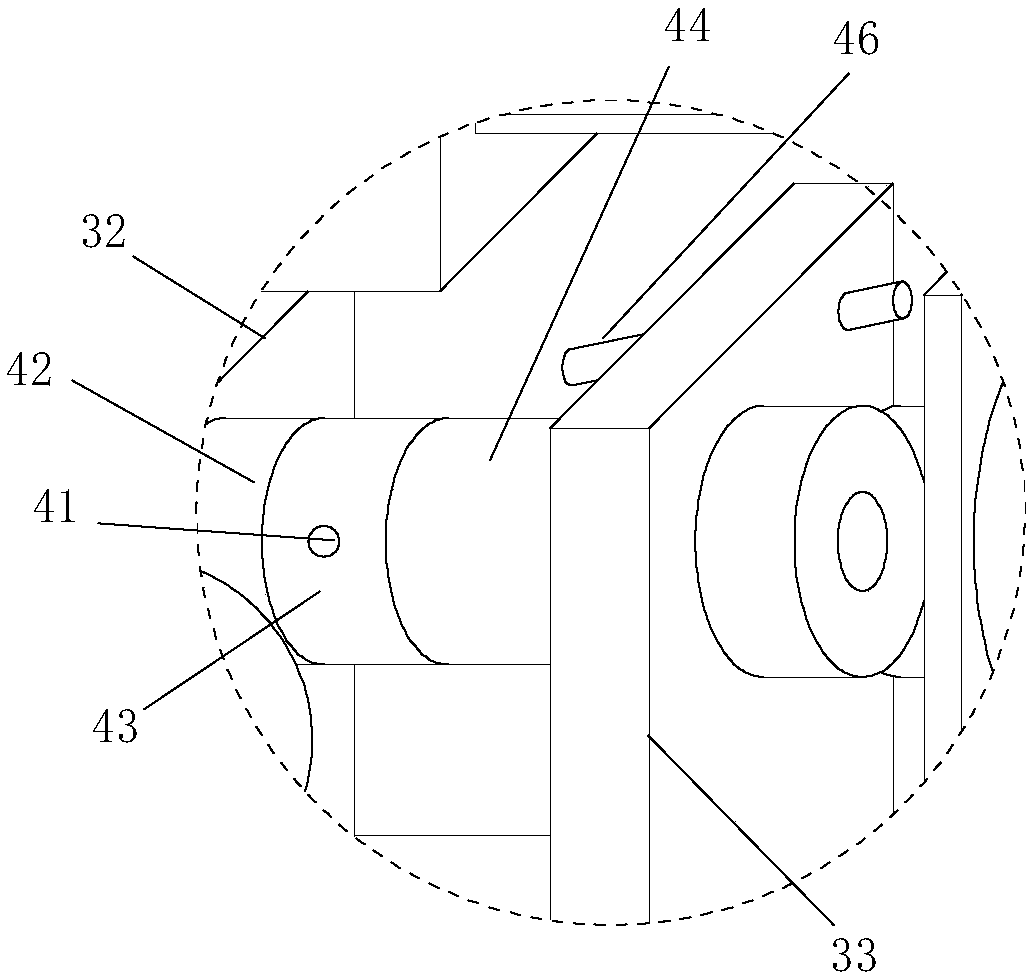

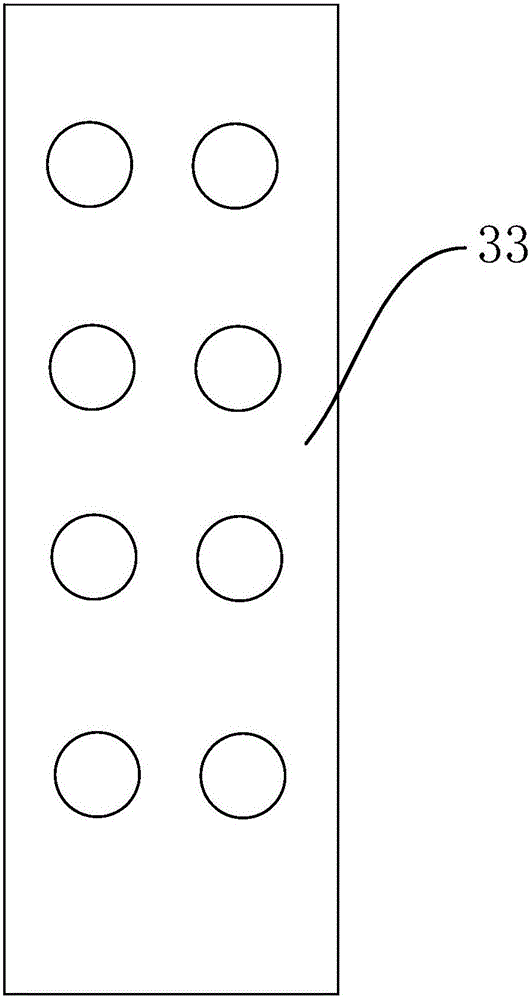

Production method of alumina multichannel ceramic membrane support

InactiveCN106242624AHigh bonding strengthImprove flexural strengthCeramic shaping apparatusClay processing apparatusTunnel kilnMicrowave

A production method of an alumina multichannel ceramic membrane support belongs to the technical field of multichannel ceramic membranes. The production method of the alumina multichannel ceramic membrane support comprises the following steps: carrying out a plastic extrusion molding technology on alumina adopted as a main raw material, drying the molded material in a natural drying and microwave drying combination mode, and sintering the dried material in a shuttle kiln or a tunnel kiln. Rare earth oxide, nanometer alumina sol and a sintering aid are mixed, so the flexural strength and the acid and alkali corrosion resistance of the above obtained product are improved; introduction of an organic binder in the production process of an alumina multichannel ceramic membrane greatly reduces deformation of a green body in the extruding, drying and sintering processes and improves the yield of the product; and the nanometer alumina sol has high intergranular binding strength, so the granule morphology is kept, thereby the channels of the produced product are smooth and have small filtering resistance, and the water flux is improved by 20% or above.

Owner:山东华瓷环保设备科技有限公司

Pop-top can flattening equipment

The invention discloses pop-top can flattening equipment. The pop-top can flattening equipment comprises a fixing seat and is characterized in that an extrusion cylinder penetrating up and down is arranged at the upper end of the fixing seat, a feeding channel for placing a zip-top can is arranged on one side of the upper end of the extrusion cylinder, the front end of the feeding channel is provided with a turnover plate capable of turning the zip-top can into the extrusion cylinder through an inserting shaft, an extrusion device capable of extruding the extrusion cylinder is arranged at theupper end of the extrusion cylinder, a sealing device capable of sealing the lower end of the extrusion cylinder is arranged at the lower end of the extrusion cylinder, the fixing seat is provided with the extrusion device which can drive the turnover plate to rotate to turn the pop-top can into the extrusion cylinder and then drive the extrusion device after the zip-top can in the extrusion cylinder is extruded, and the sealing device is driven to open the driving device enabling a zip-top ring in the extrusion cylinder to fall out. The pop-top can flattening equipment is simple in structureand convenient to use.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

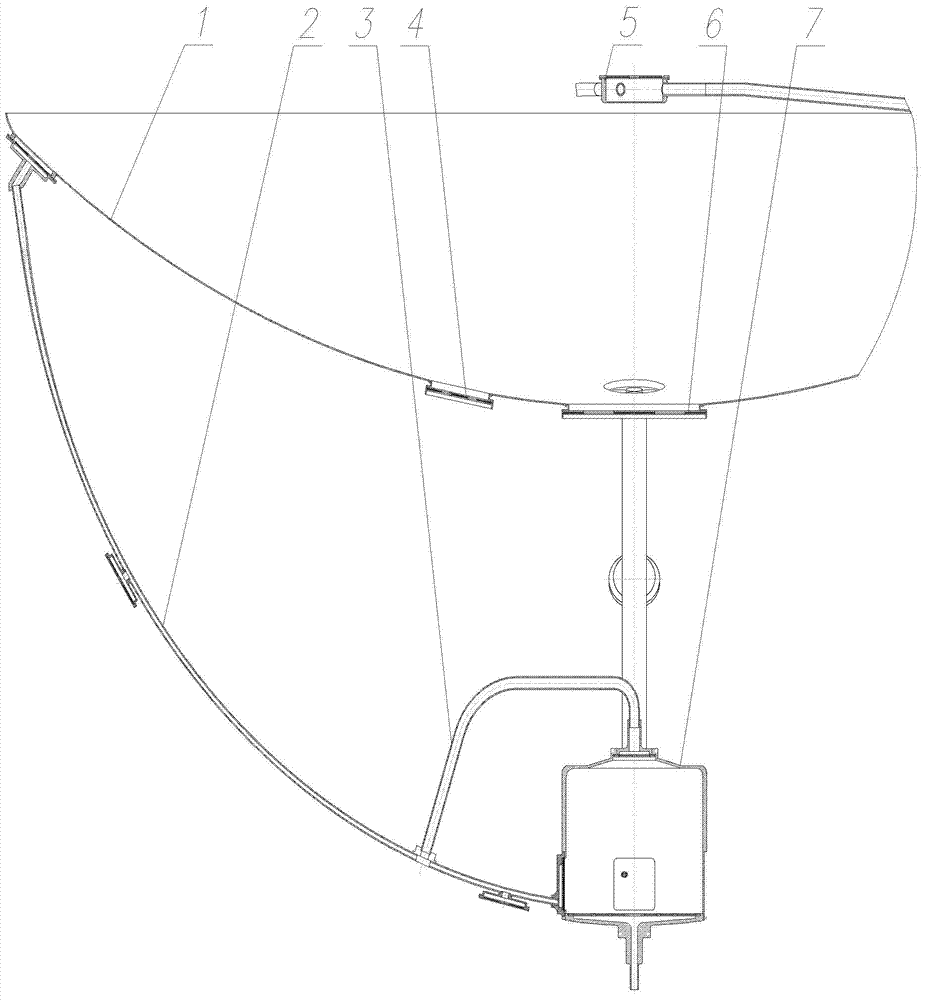

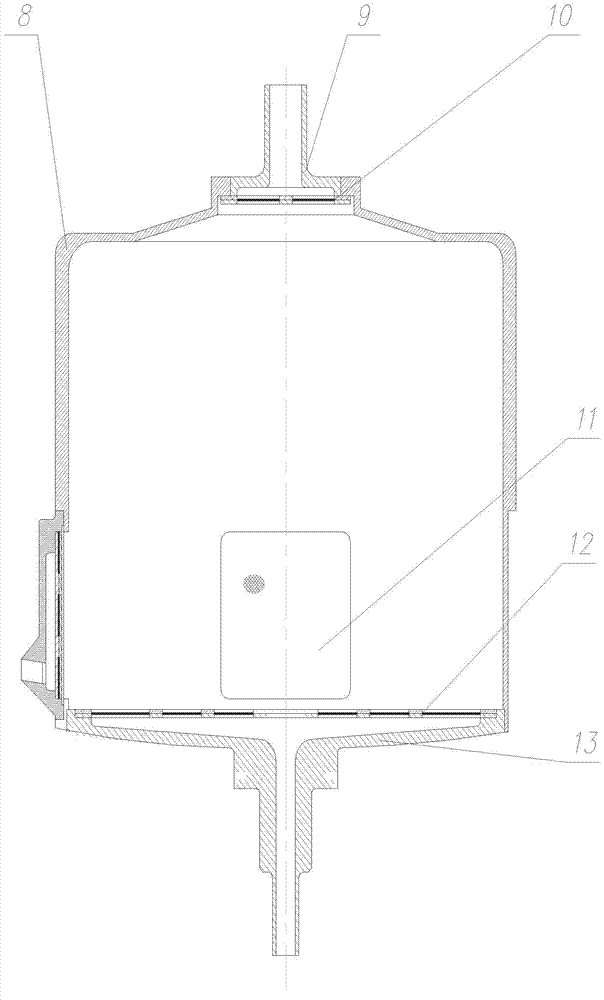

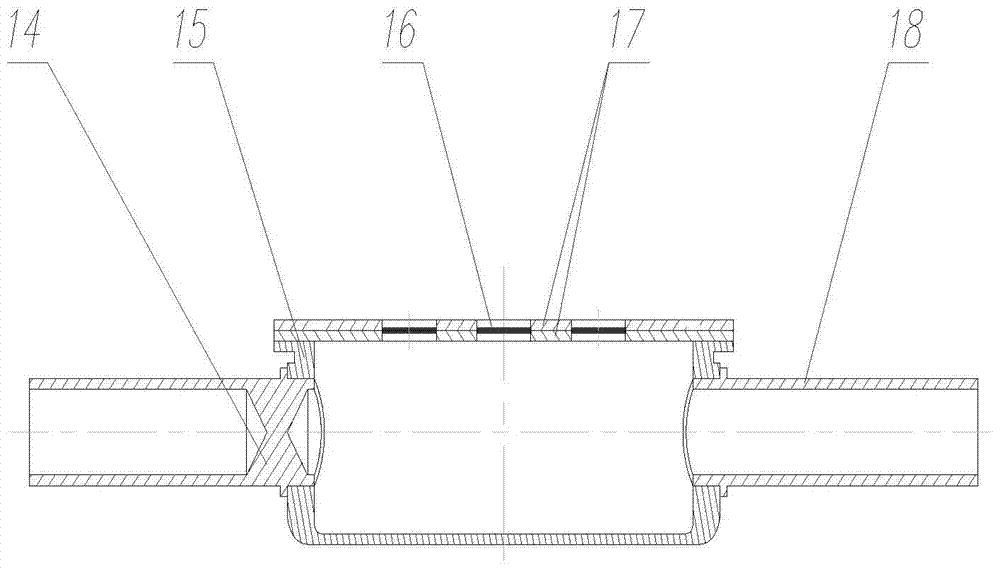

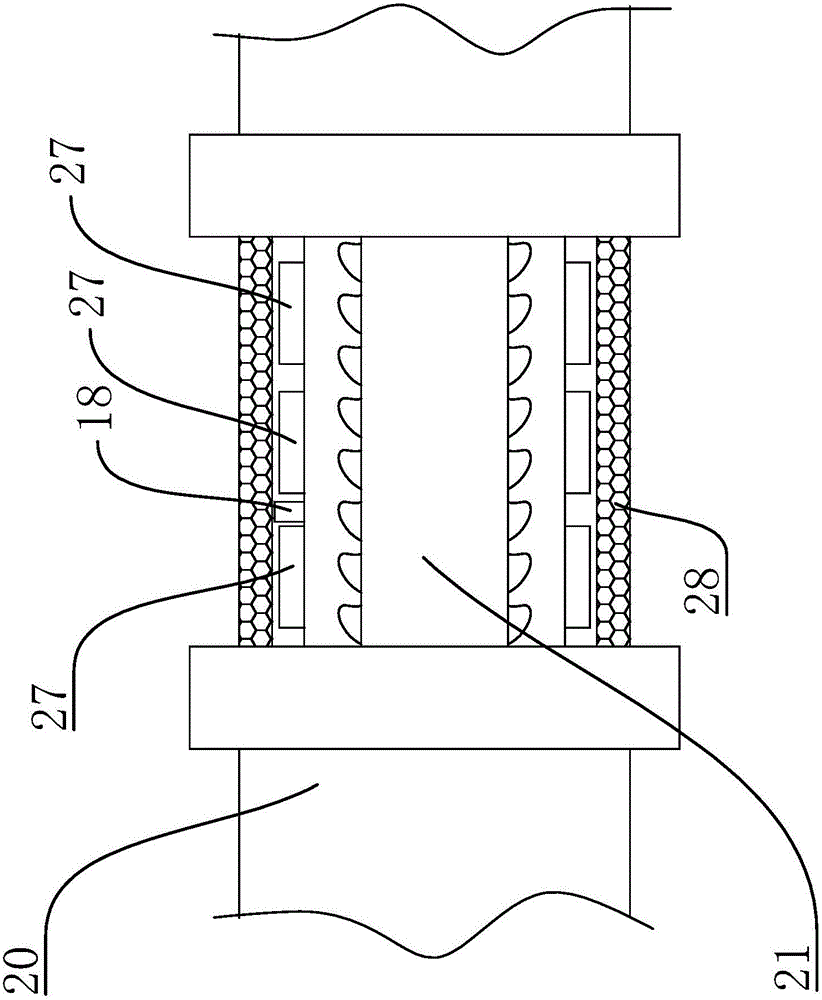

High-rigidity propellant management device for large surface tension storage box

ActiveCN103590924AImprove extrusion efficiencyImprove collection effectRocket engine plantsStreamflowAdaptive capacity

A high-rigidity propellant management device for a large surface tension storage box comprises a middle bottom, a liquid channel, a gas discharge channel, small collectors of the middle bottom, a gas discharge cup, a large collector of the middle bottom and a bubble trap, wherein one end of an angular collector of the liquid channel is connected with the middle bottom; the other section of the angular collector of the liquid channel is connected with the bubble trap; the bubble trap is fixed at an outlet of the storage box; the large collector of the middle bottom is positioned in the middle of the middle bottom; the small collectors of the middle bottom are distributed at the periphery of the large collector of the middle bottom; the gas discharge channel is placed on the upper portion of the middle bottom; one end of the gas discharge channel is welded to the edge of the middle bottom; and the other end of the gas discharge channel is suspended. The high-rigidity propellant management device of the large surface tension storage box overcomes the technical shortcomings of the existing small-capacity net-type storage box, can carry a large amount of propellant, and is high in reliability; the adaptive capacity of a large satellite is strengthened; propellant which does not clamp gas and meets the requirement on flow can be provided for an engine or a thruster in a microgravity environment; and the high-rigidity propellant management device is used for managing the propellant in the microgravity environment of space.

Owner:BEIJING INST OF CONTROL ENG

Domestic vertical type noodle maker

ActiveCN104542788AAccelerate the mixing speedImprove mixing efficiencyMixing/kneading with vertically-mounted toolsDough extruding machinesEngineeringExtrusion

The invention discloses a domestic vertical type noodle maker which comprises a base, a stirring cup, a stirring rod, a dough extrusion cylinder, a screw rod, a mold head and a control unit, wherein the base is provided with motors; the stirring cup is connected with the base; the stirring rod comprises a rod body as well as upper stirring teeth and lower stirring teeth which are arranged on the rod body; a dough inlet is formed in the communicating part of the stirring cup and the dough extrusion cylinder; a dough cutting rod is arranged on the inner wall of the stirring cup; the dough cutting rod is positioned between the upper stirring teeth and the lower stirring teeth; the stirring rod rotates to drive the upper stirring teeth and the lower stirring teeth to rotate and mix and stir flour with water to make dough; the dough cutting rod cooperates with the upper stirring teeth and the lower stirring teeth to cut off or tear and deform the dough into dough pieces which are smaller than the dough inlet; when the upper stirring teeth and / or the lower stirring teeth rotate to the dough cutting rod, the projects of the dough cutting rod and the upper stirring teeth and / or the lower stirring teeth in the horizontal direction are at least partially overlapped. By adopting the mode, the effects of no residue, high possibility of dough feeding and high processing efficiency can be achieved.

Owner:JOYOUNG CO LTD

Al-Zn-Mg-Cu aluminum alloy profile with high stress corrosion resistance and preparation method thereof

ActiveCN110184513AImprove mechanical propertiesAccelerated corrosionStress relievingUltimate tensile strength

The invention aims to provide an Al-Zn-Mg-Cu aluminum alloy profile with high stress corrosion resistance and a preparation method thereof. The aluminum alloy material is prepared from, by mass, smaller than or equal to 0.1% of Si, smaller than or equal to 0.1% of Fe, 0.12%-0.14% of Cu, 0.23%-0.25% of Mn, 0.75%-0.8% of Mg, 0.15%-0.17% of Cr, 5.7%-5.8% of Zn, 0.16%-0.19% of Zr, 0.02%-0.04% of Ti, wherein the ratio of Fe to Si ranges from 1.8 to 2.5, and the ratio of Zn to Mg is controlled to range from 7.1 to 7.7. The preparation method comprises the steps of smelting, refining, essence melting, casting, homogenization annealing, extruding, solid solution quenching, stress relieving and aging treatment. According to the Al-Zn-Mg-Cu aluminum alloy profile with the high stress corrosion resistance and the preparation method thereof, the material shows good mechanical strength and stress corrosion resistance, and the material is especially suitable for aluminum alloy structural members which are prone to stress corrosion and failure, in particular to aluminum alloy structural members subjected to tensile stress at the bottom of a rail transit or a vehicle body.

Owner:广西南南铝加工有限公司

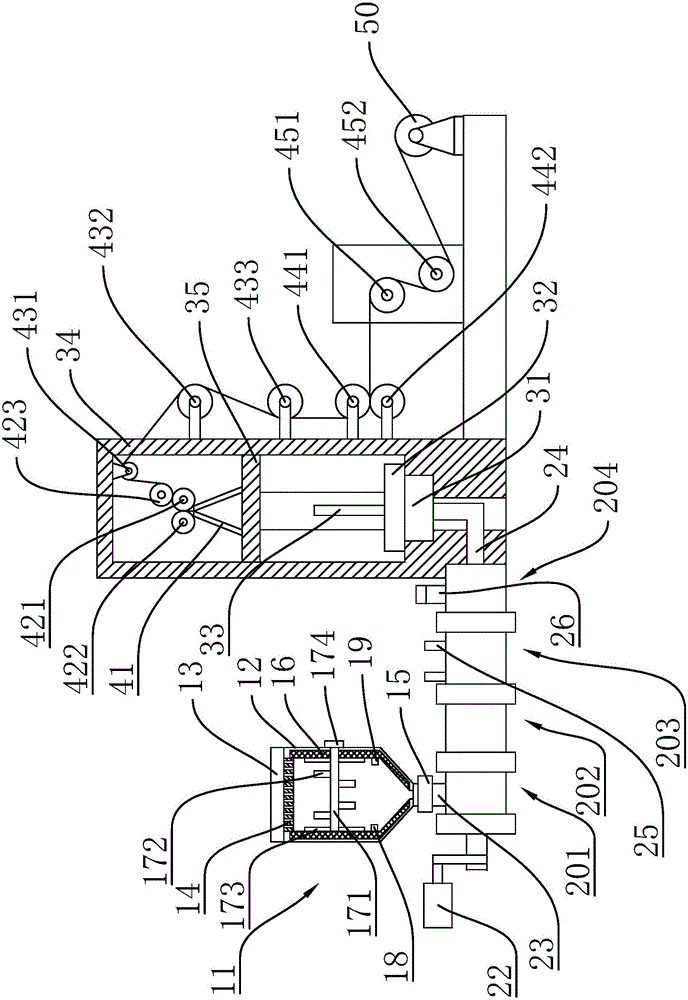

Film blowing machine with improved winding mechanism

The invention provides a film blowing machine with an improved winding mechanism. Th film blowing machine comprises an extrusion mechanism, a film blowing mechanism, a traction mechanism and the winding mechanism. The film blowing mechanism comprises a die head, an air ring and a rack. The air ring is arranged on the die head. The die head and the air ring are fixedly arranged at the lower end of the rack. The traction mechanism is arranged at the upper end of the rack. The extrusion mechanism is provided with a discharge outlet connected with the die head. The winding mechanism comprises a winding shaft, a belt and a motor, wherein the winding shaft is used for winding thin films. The motor is in transmission connection with the winding shaft through the belt. The thin films blown out from the die head are conveyed to the winding shaft through the traction mechanism. A press shaft capable of pressing the thin films is arranged above the winding shaft. The winding mechanism further comprises a support frame and elastic suspended arms. The press shaft is connected to the support frame through the elastic suspended arms. According to the film blowing machine with the improved winding mechanism, deviation of the thin films in the winding process can be avoided, and dislocation of an upper layer and a lower layer of a thin film is prevented.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

Oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as preparation method and application thereof

The invention discloses an oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve and a preparation method thereof. The label sleeve consists of the following components in parts by weight: 60 to 80 parts of matrix resin, 15 to 25 parts of linear low-density polyethylene, 5 to 15 parts of polymer compatilizer, 32 to 70 parts of phosphorous nitrogen series expansible halogen-free flame retardant, 0 to 30 parts of inorganic flame retardant, 3 to 5 parts of titanium white powder, 1 to 3 parts of lubricant, 0.8 to 2 parts of antioxidant and 1 to 2 parts of sensitizer. The preparation method comprises the following steps of: mixing the raw materials uniformly, extruding with a double-screw extruder, drawing, air cooling and granulating; extruding into a pipe through a screw extruder with a neck mould and a core mould, radiating, expanding, stretching, cooling, sizing, printing the label by using a heat transfer printer to obtain the oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve. The preparation method is simple; and the product has excellent flame-retardant performance and good oil resistance, produces little smoke, permanently preserves the label, and keeps good mechanical property, electric insulating performance and heat resistance.

Owner:广州凯恒科塑有限公司

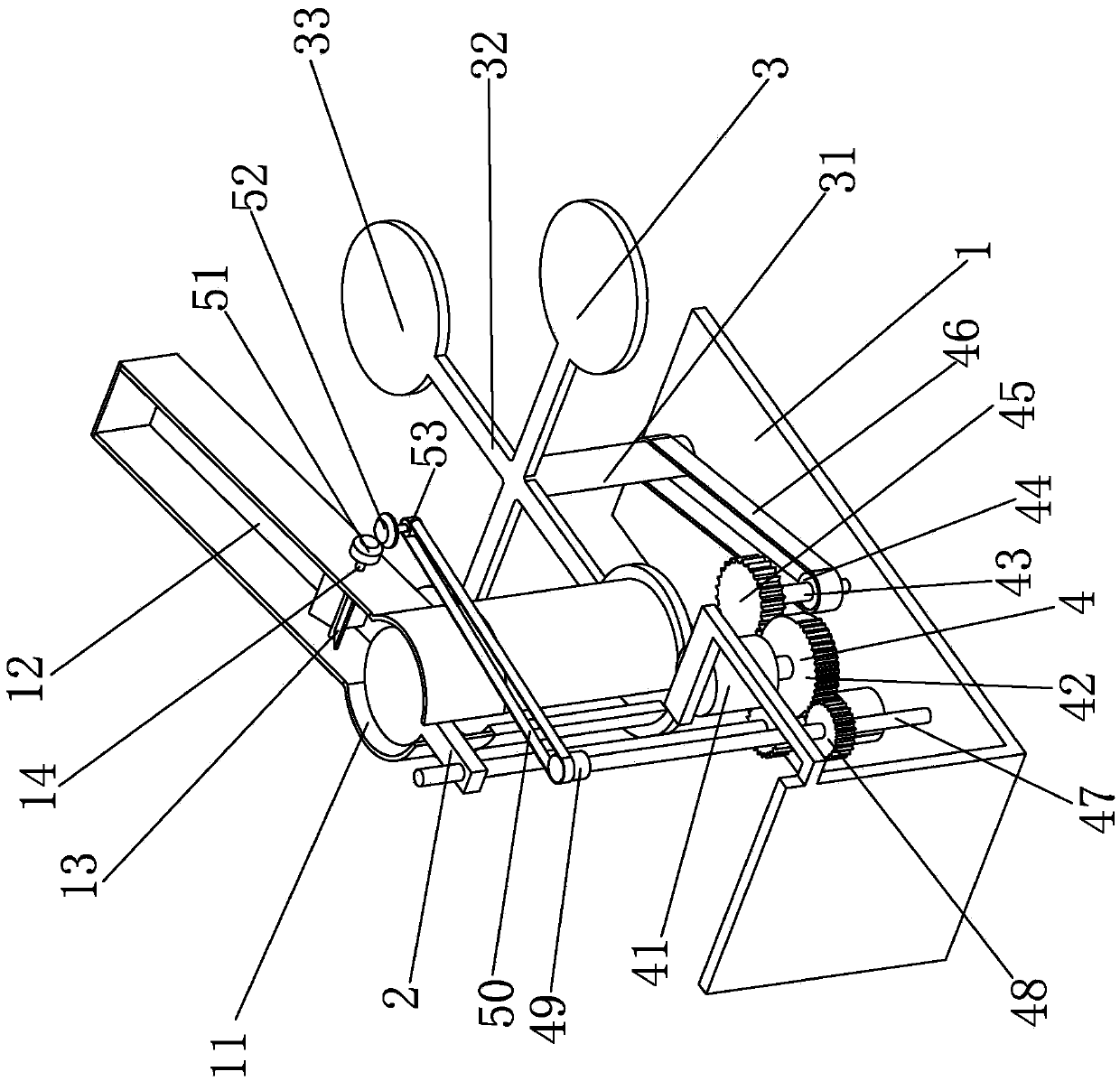

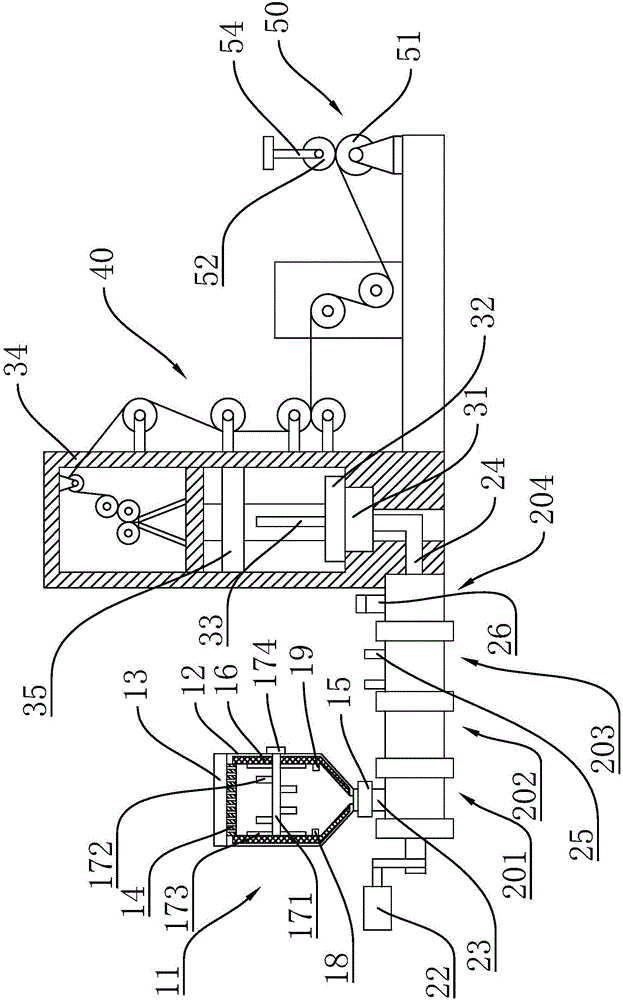

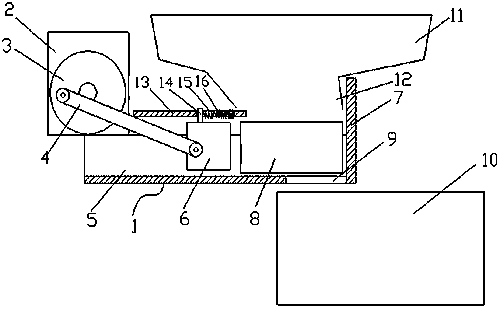

Granular terminal automatic feeding and crimping device

PendingCN108879282AImprove extrusion efficiencyRealize linkageLine/current collector detailsEngineeringElectrical and Electronics engineering

The invention relates to a granular terminal automatic feeding and crimping device and a working method thereof. The granular terminal automatic feeding and crimping device comprises a vibration disc,a terminal falling pipe, a terminal positioning rotating shaft, a movable sliding table and a crimping assembly; the terminal falling pipe is vertically arranged below a discharge hole of the vibration disc, so that a terminal to be crimped in the vibration disc can vertically enter the terminal falling pipe; the terminal positioning rotating shaft is rotatably arranged on the movable sliding table; a terminal inserting hole is formed in the terminal positioning rotating shaft in the radial direction of the terminal positioning rotating shaft, and the terminal inserting hole is formed below the outlet of the terminal falling pipe in the initial state, so that the to-be-crimped terminal in the terminal falling pipe can enter the terminal inserting hole in falling off, and the crimping partof the terminal is arranged outside the terminal inserting hole; the crimping assembly comprises a crimping jaw; and the crimping jaw is arranged on one side of the terminal positioning rotating shaft, so that after the terminal to be crimped enters the terminal inserting hole and after the terminal positioning rotating shaft rotates, the crimping part of the terminal arranged outside the terminal inserting hole can enter the crimping jaw by moving the movable sliding table.

Owner:张晓波

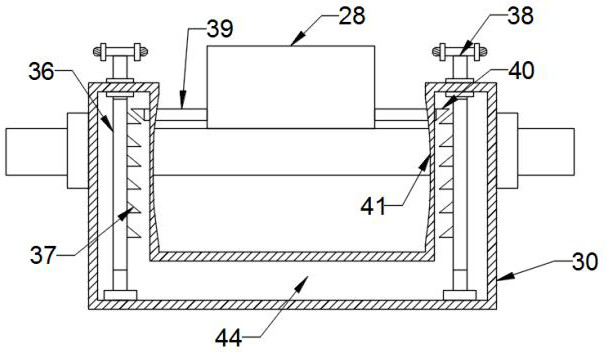

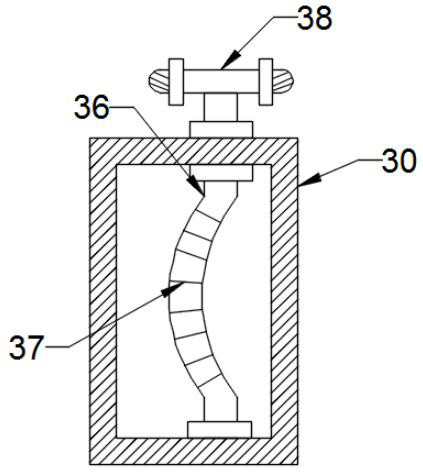

Biomass waste residue squeezer

InactiveCN102493250ASolve the problem of easy slipping in extrusionSmall shapePulp de-wateringLitterSludge

The invention discloses a biomass waste residue squeezer which is provided with a power box, a transmission shaft, a bearing seat, a conical screw shaft, a filtering net barrel, a lining net barrel, a reinforcing rib frame, a shell and an anti-skidding cylinder, and is characterized in that: the filtering net barrel, the lining net barrel, the reinforcing rib frame and the shell form a multi-layer combined type conical shell; a feed port is arranged at a big end of the conical shell, and a discharge port is arranged at a small end; the anti-skidding cylinder is arranged at the discharge port at the small end of the conical shell; and the section of the cylinder opening is a regular hexagon. The biomass waste residue squeezer disclosed by the invention is developed and designed based on the biomass raw materials such as papermaking waste residue, and has unique structure, high squeezing efficiency and large dehydration dryness; and the biomass waste residue squeezer not only can be used for dehydrating and drying the papermaking waste residue, but also can realize powerful efficient dehydration of other biomass garbage such as sawdust, waste slurry, sludge and the like, thereby having a wide application range.

Owner:湖南骏泰新材料科技有限责任公司

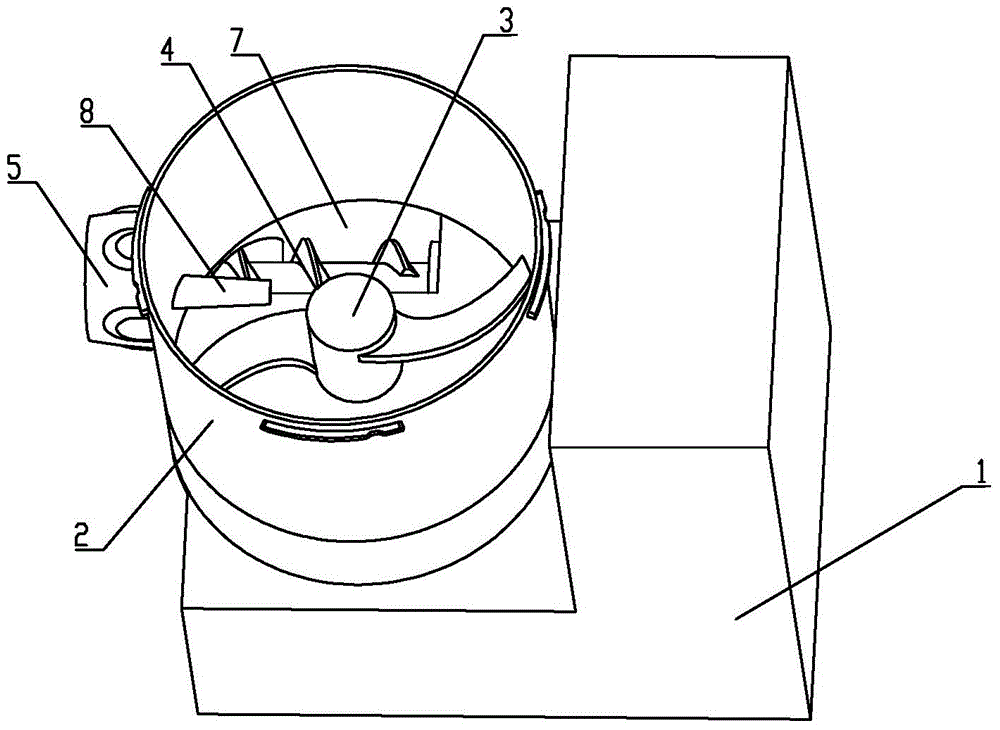

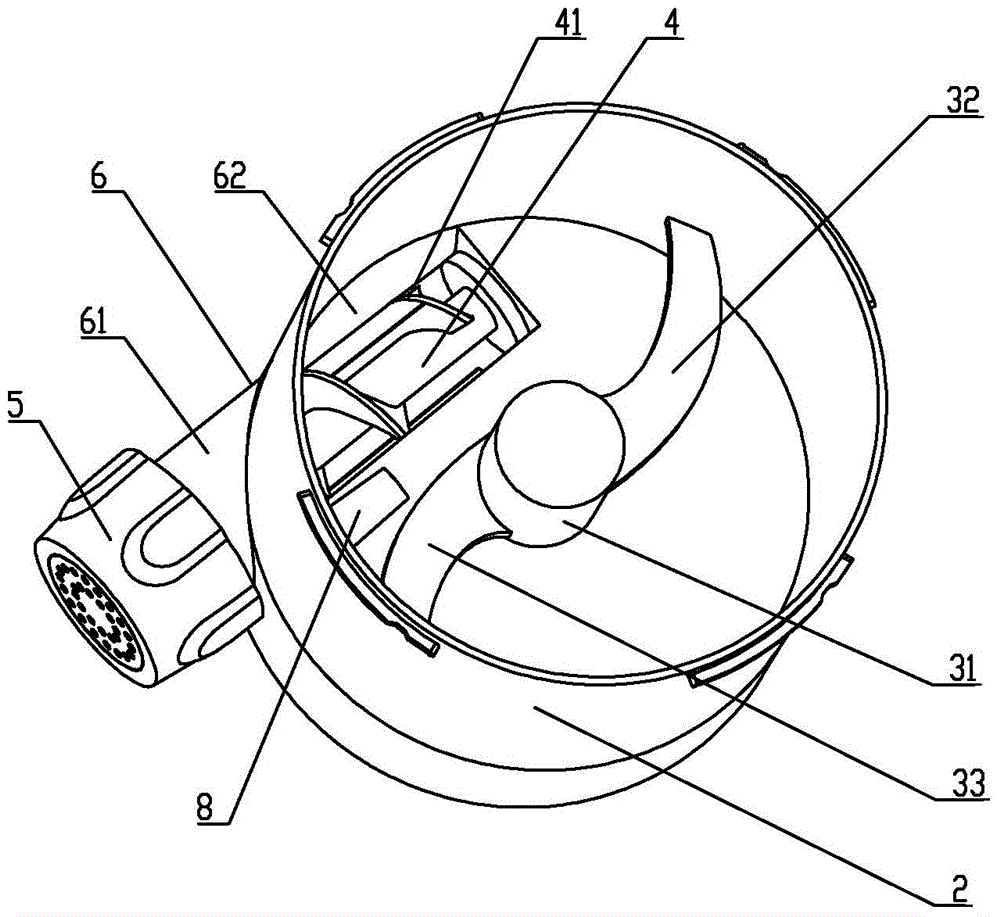

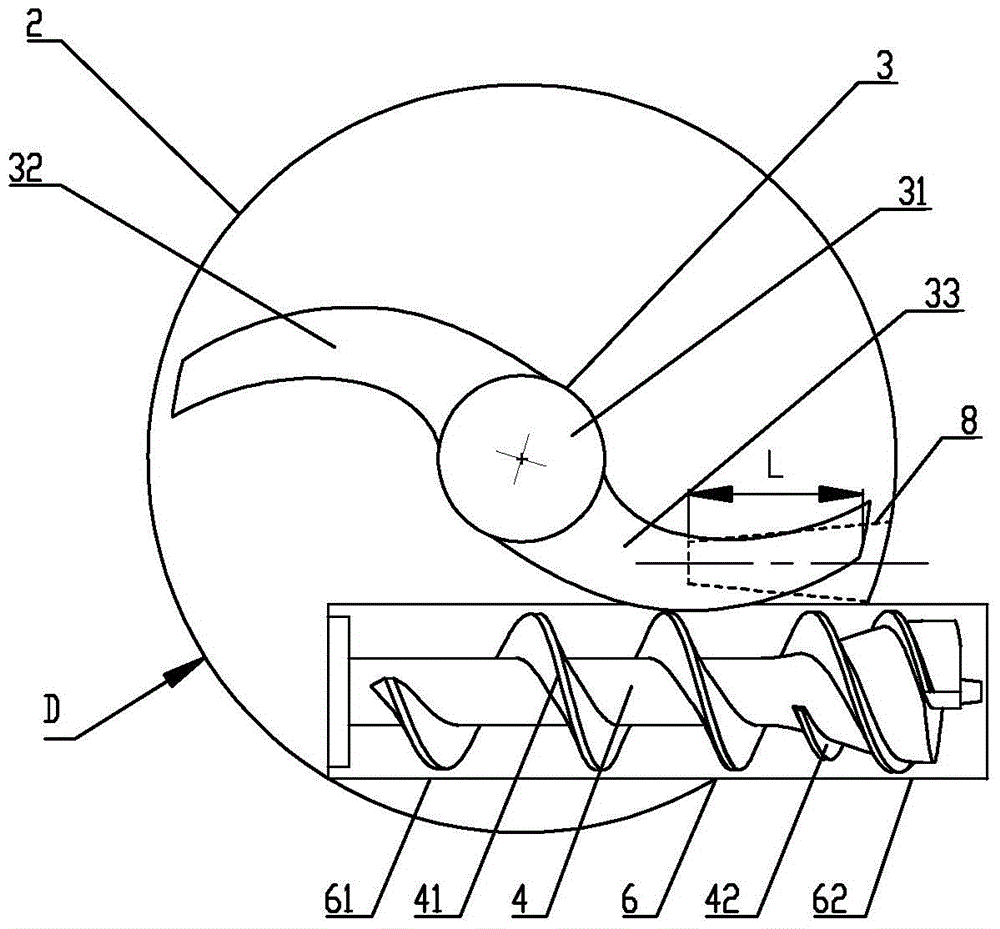

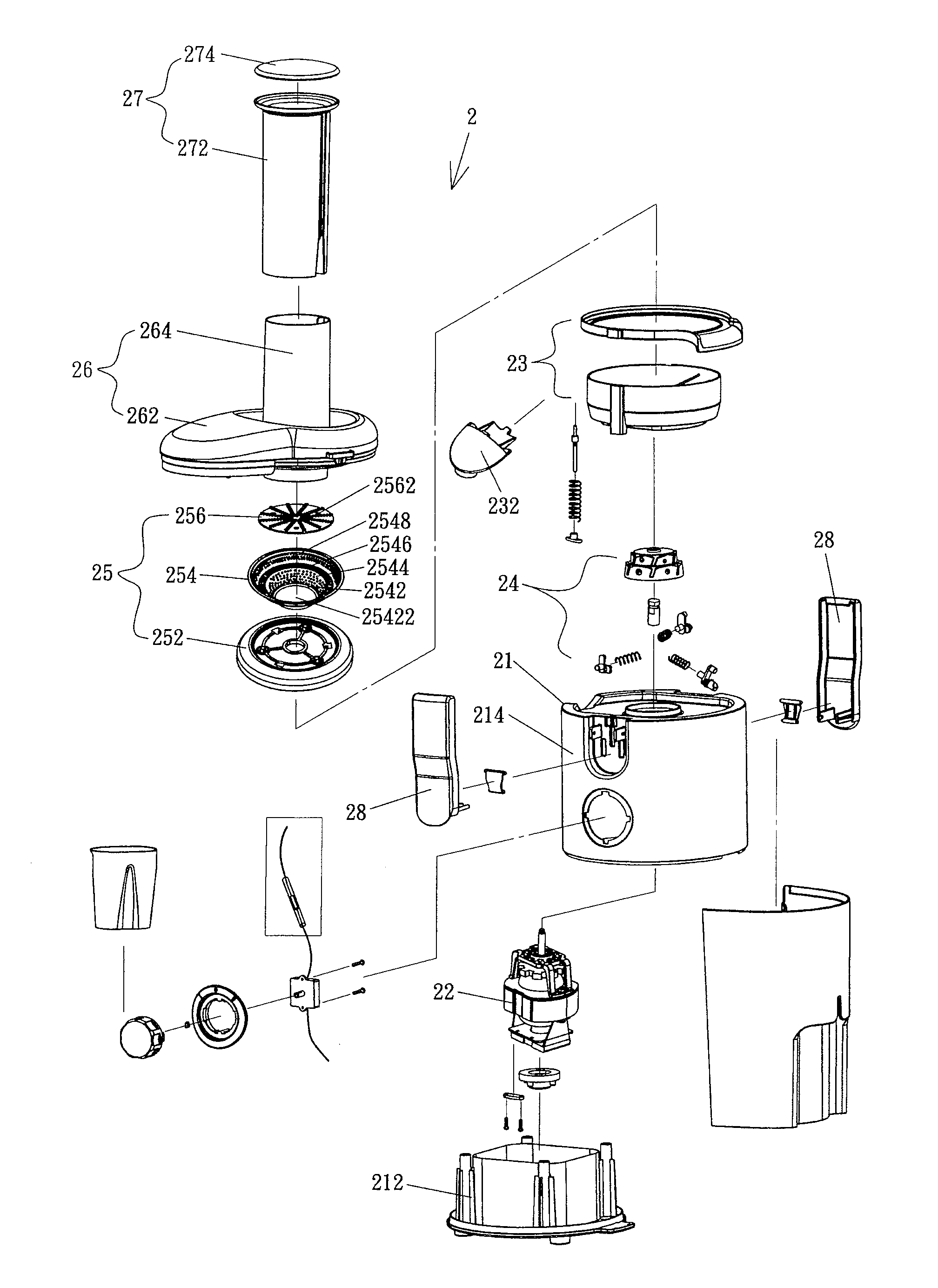

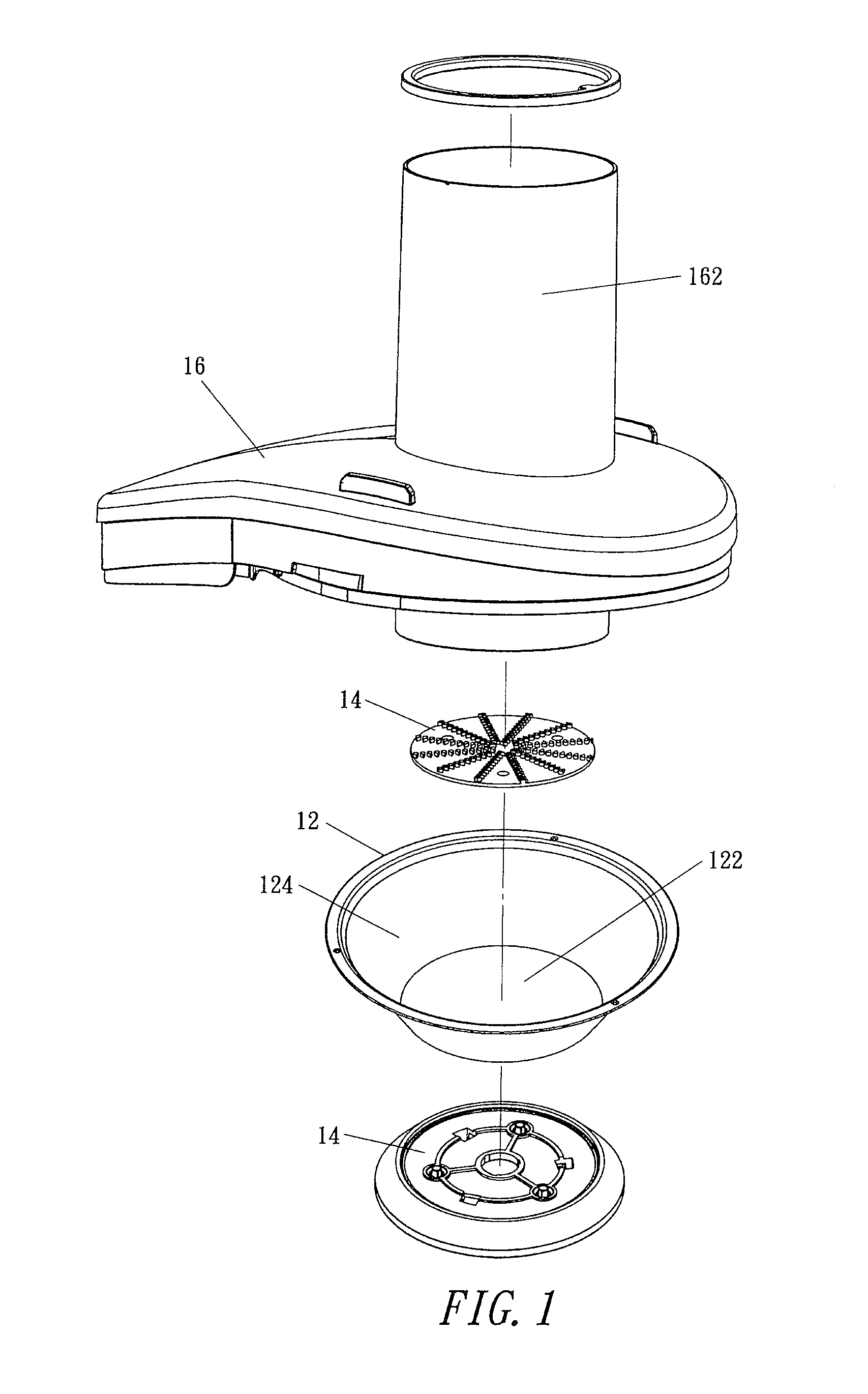

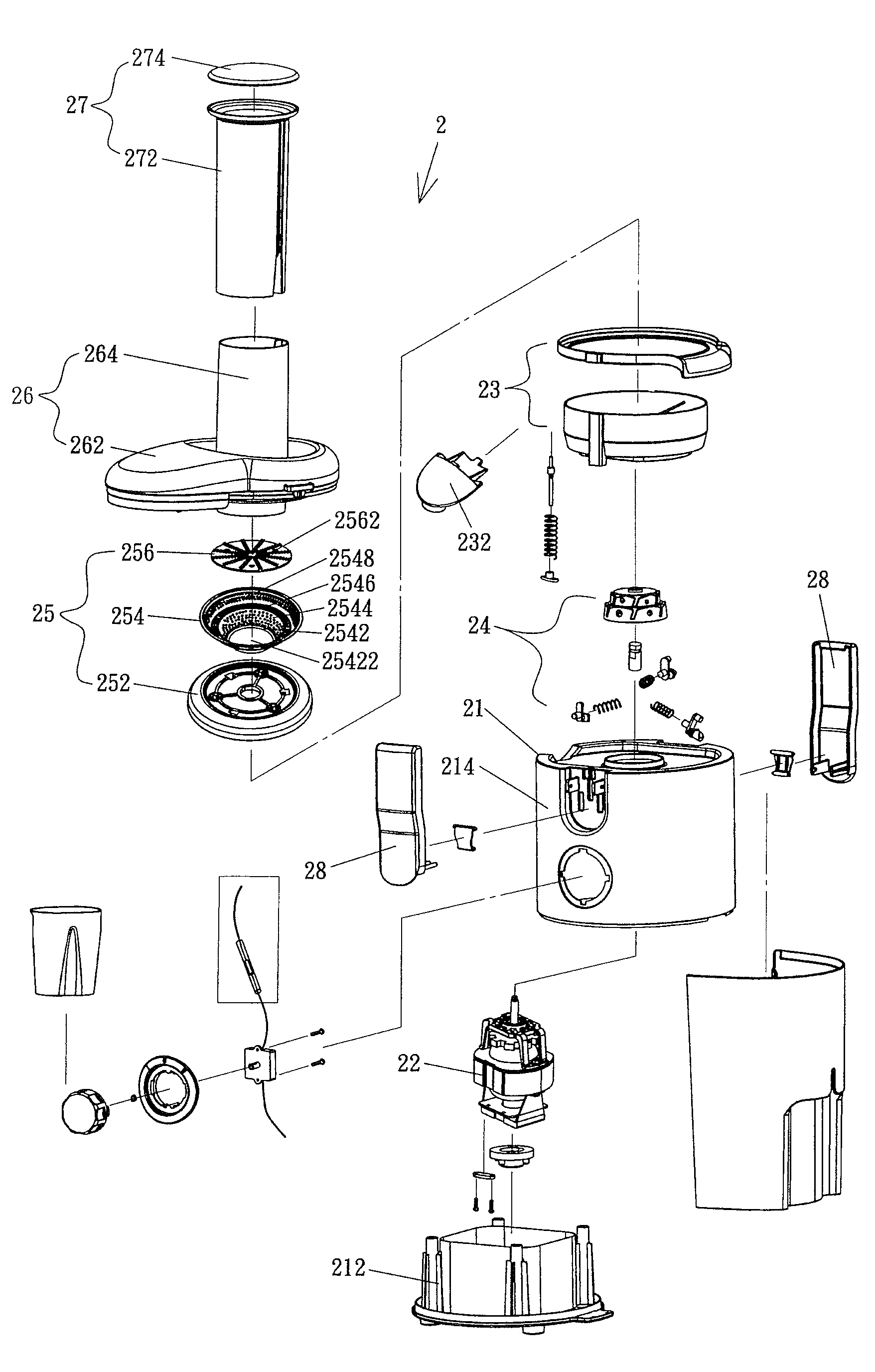

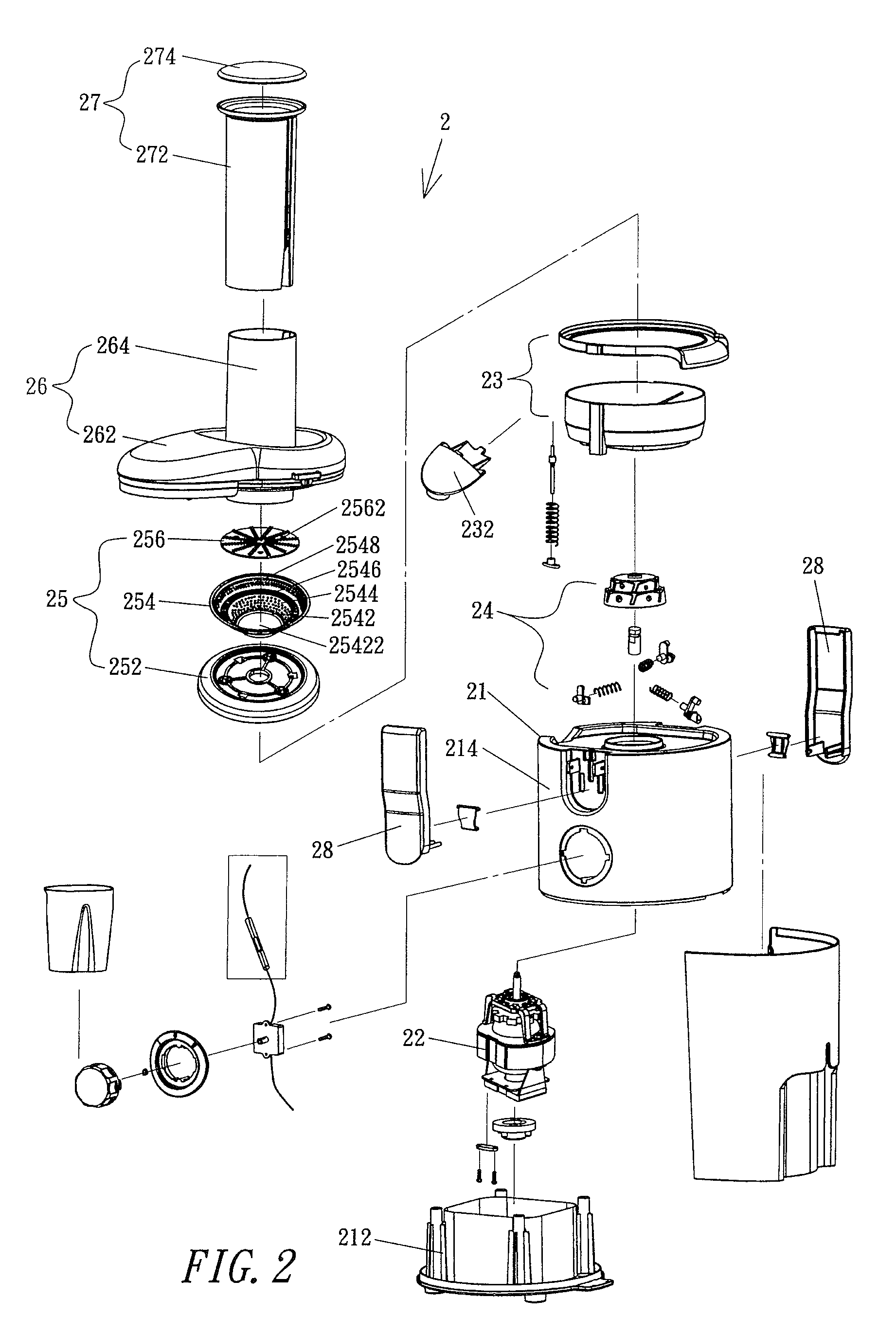

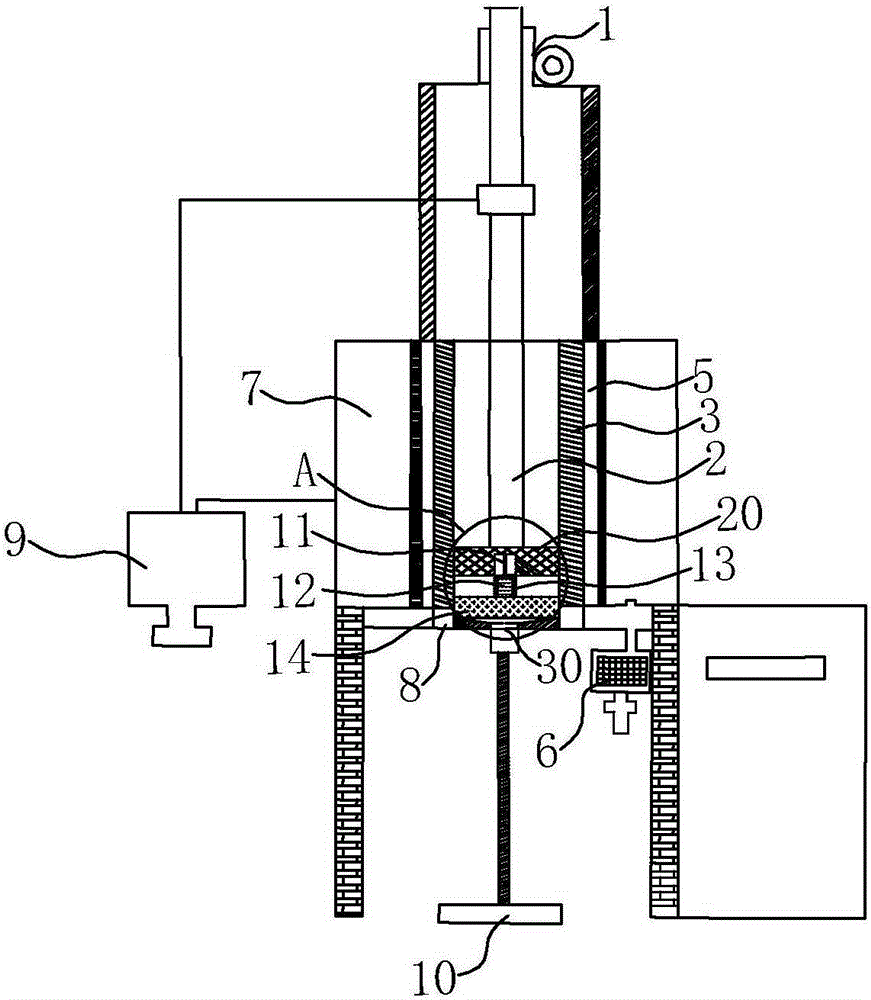

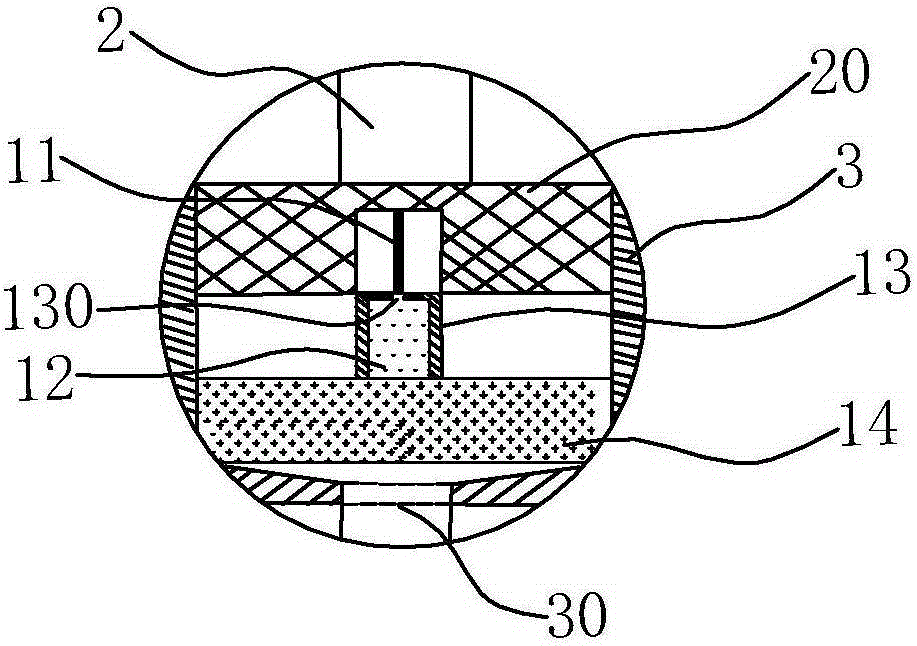

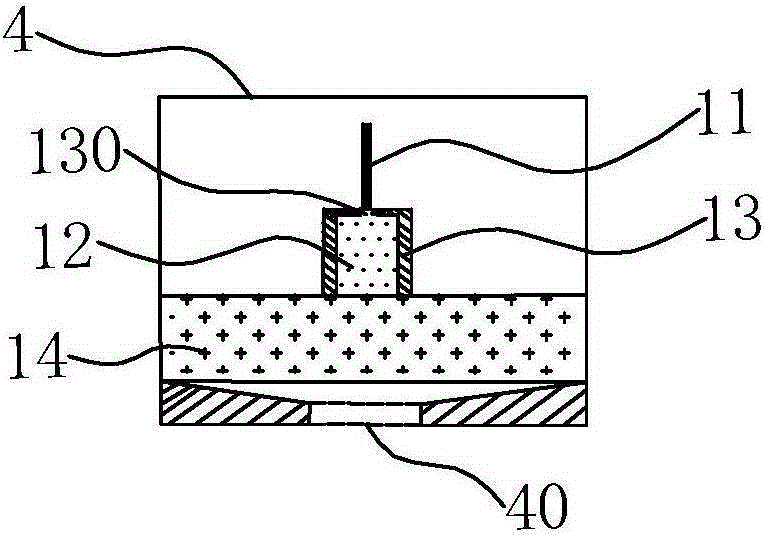

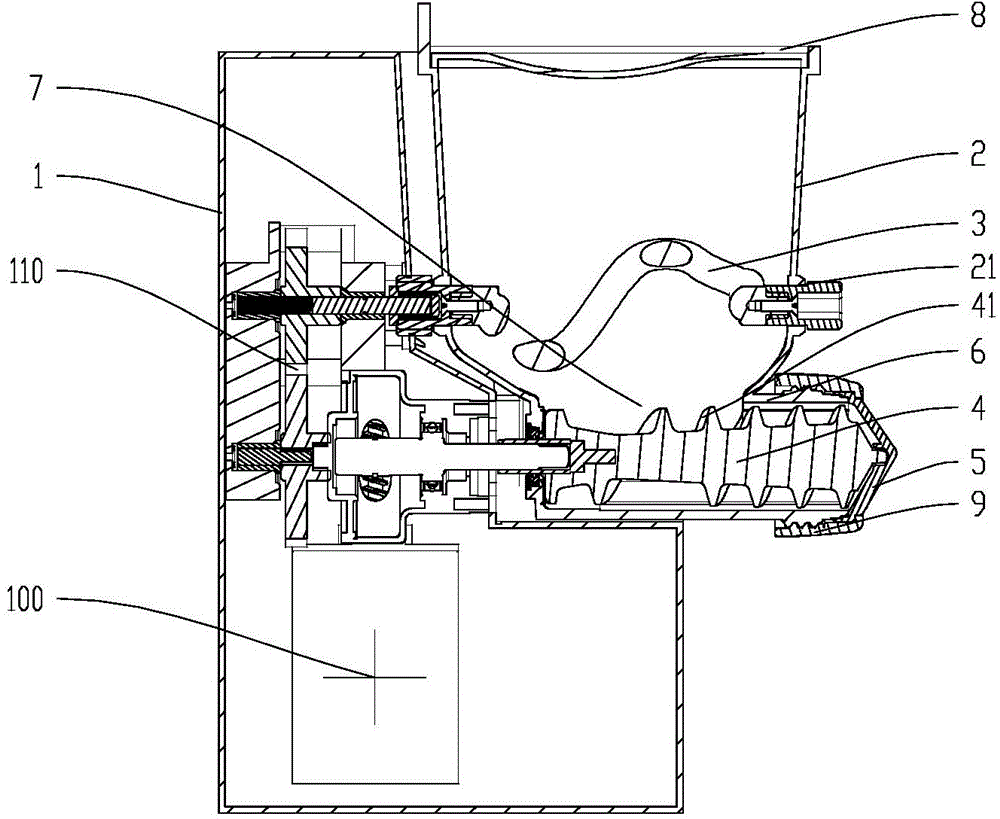

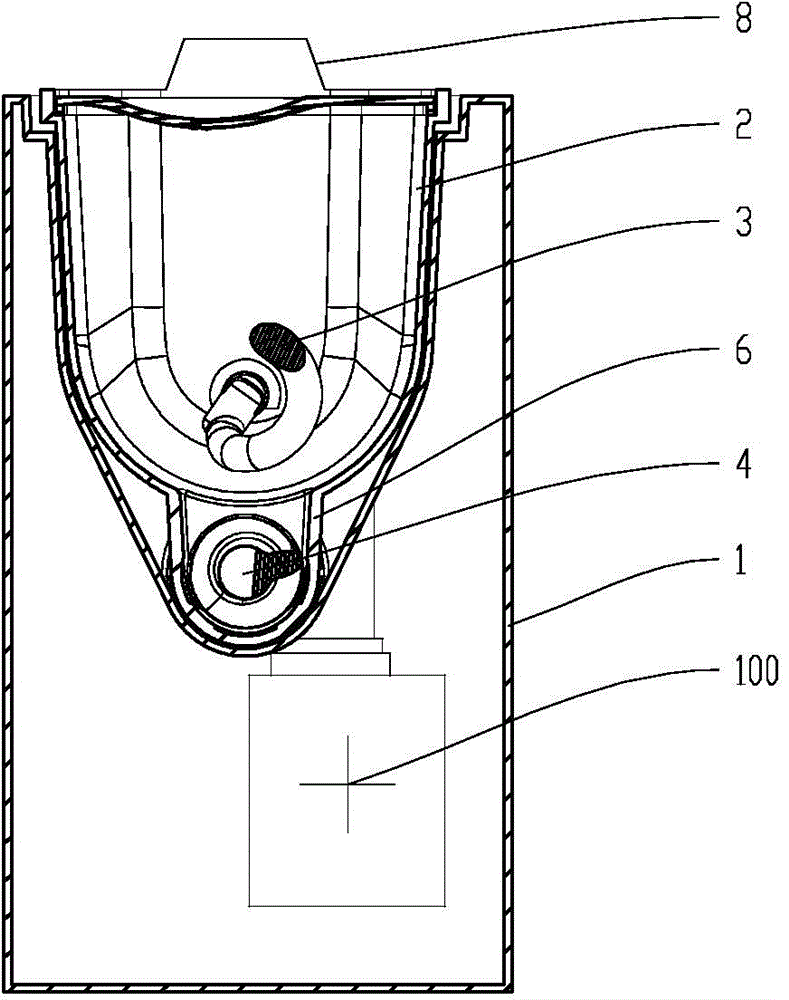

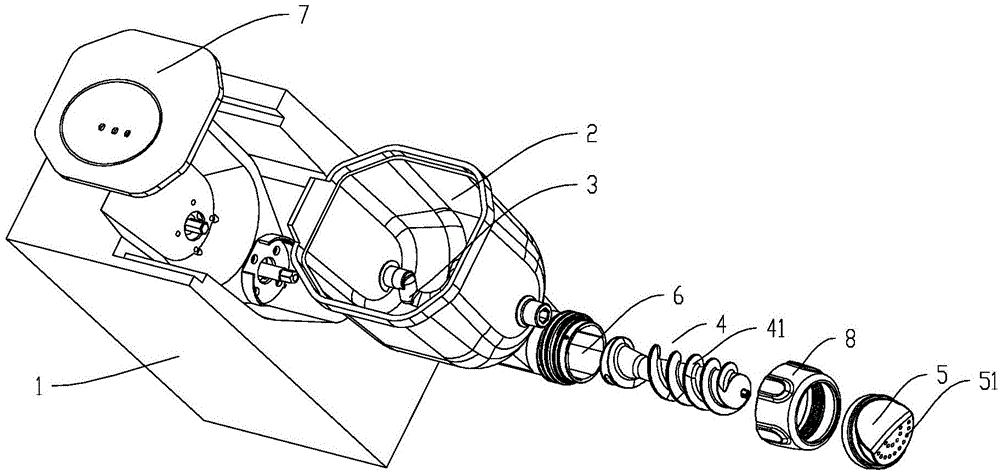

Juice Machine and Filter Thereof

InactiveUS20120192729A1Increase the juice yieldEnhance juice juice squeezing efficiencyJuice extractionCentrifugesEngineeringFlywheel

A juice machine includes a cutter module, and the cutter module includes a cutter turntable, a filter, and a cutter flywheel. The filter includes a bottom plate, a first side plate protruded and tilted upwardly from an external periphery of the bottom plate, a filter plate horizontally extended from the top of the first side plate, a tilted second side plate protruded upwardly from an edge of the filter plate, an opening formed at the center of the bottom plate, a plurality of first meshes formed on the first side plate, a plurality of second meshes formed on the filter plate, a plurality of third meshes formed on the second side plate. Therefore, the weight of the filter can be decreased to provide a stable filter and reduce vibrations and noises. The juice machine can enhance both juice squeezing efficiency and juice yield.

Owner:YA HORNG DONG GUAN ELECTRONICS +1

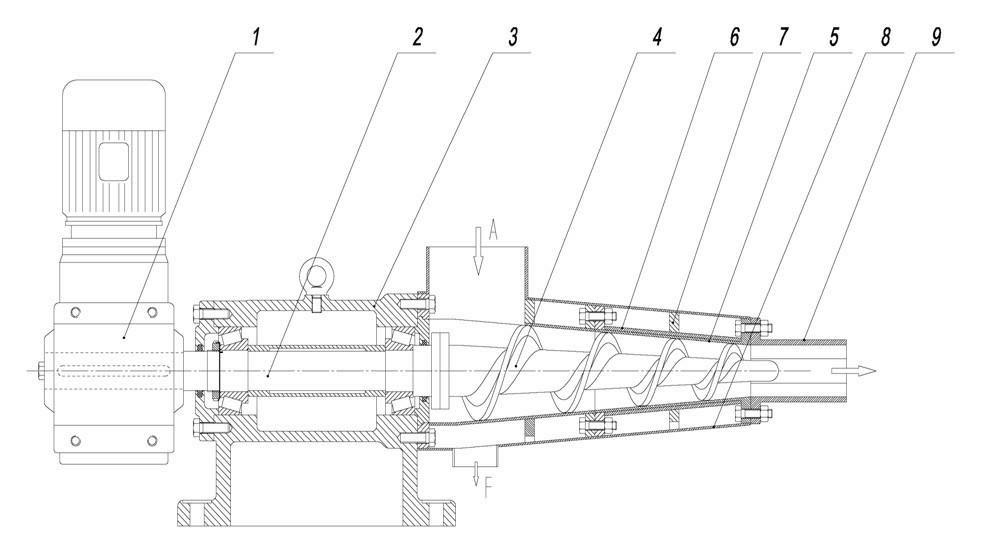

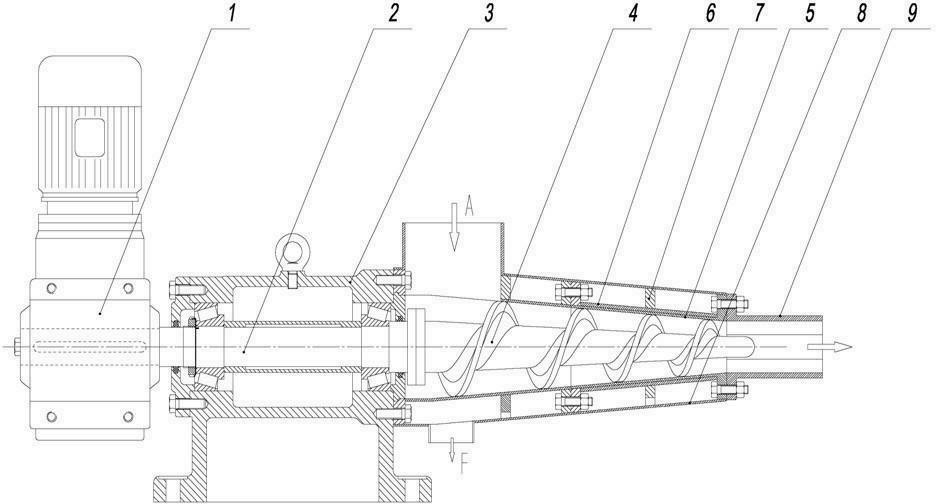

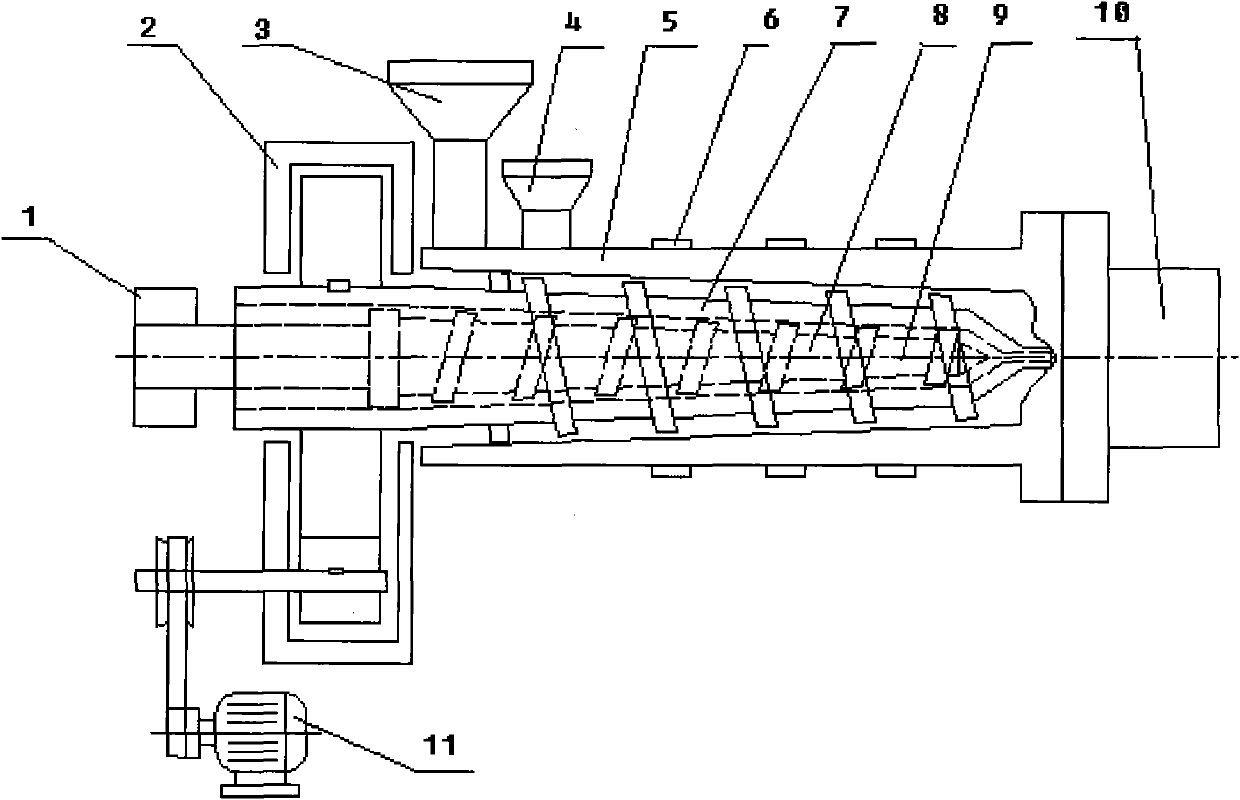

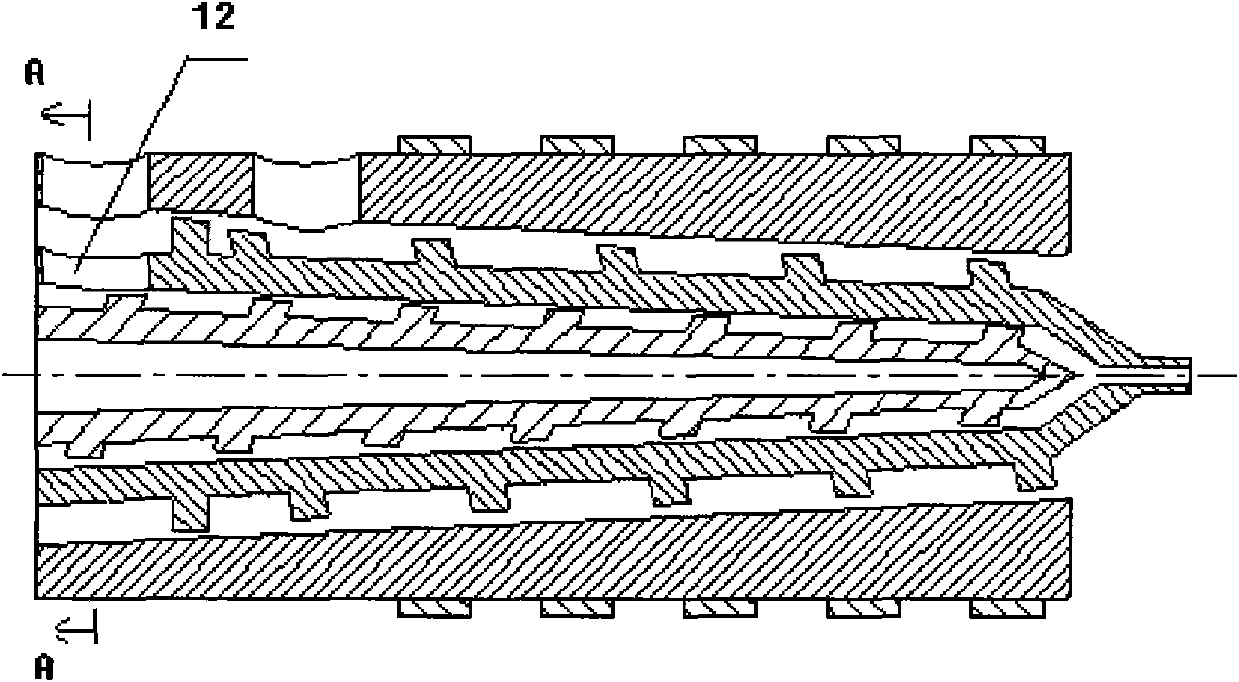

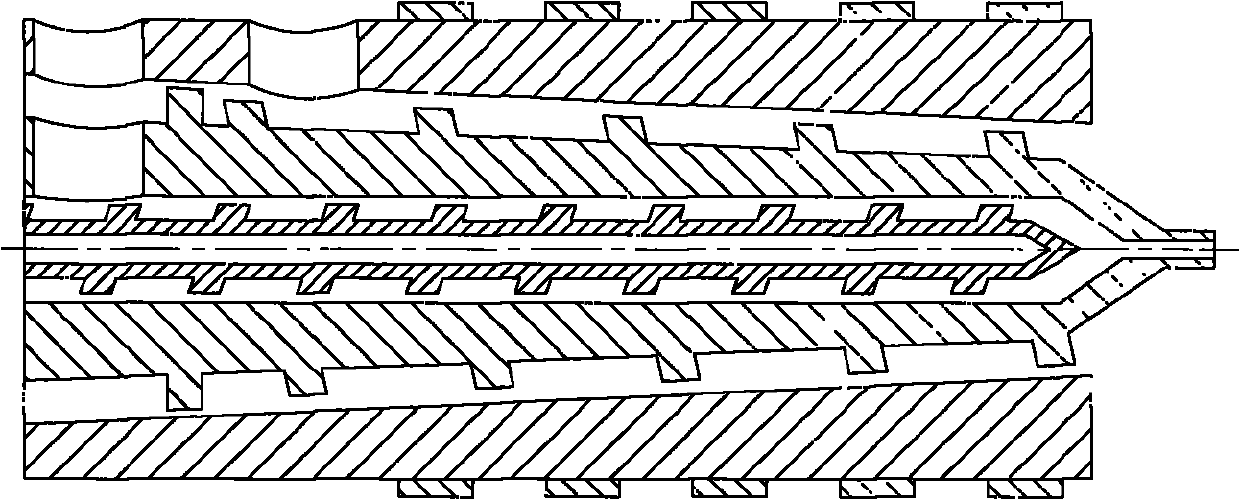

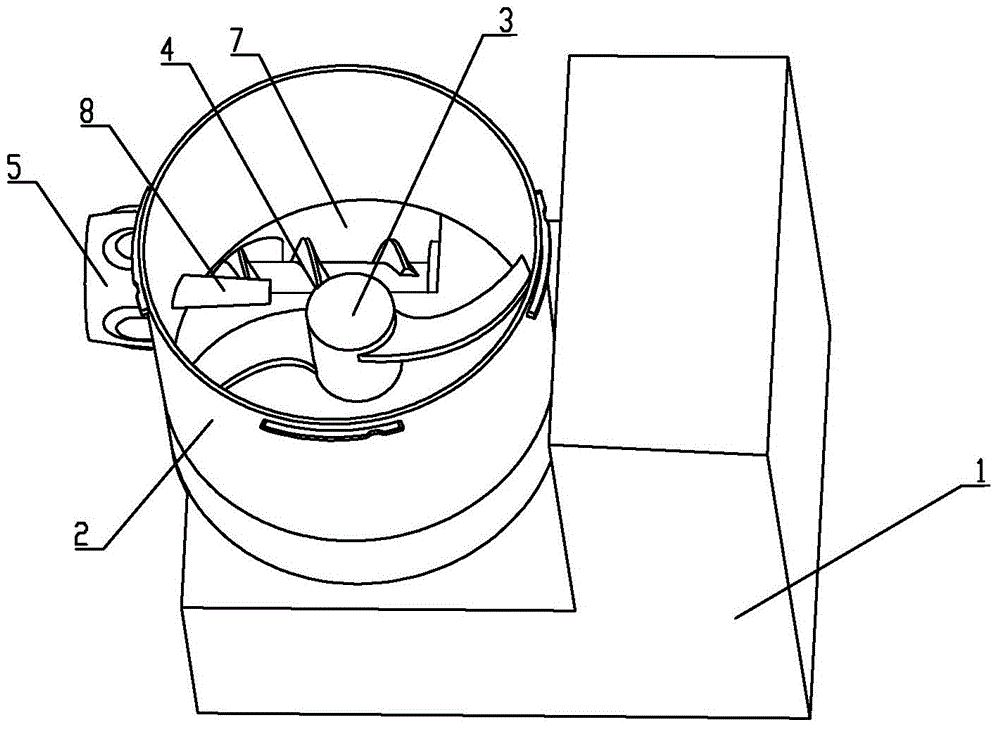

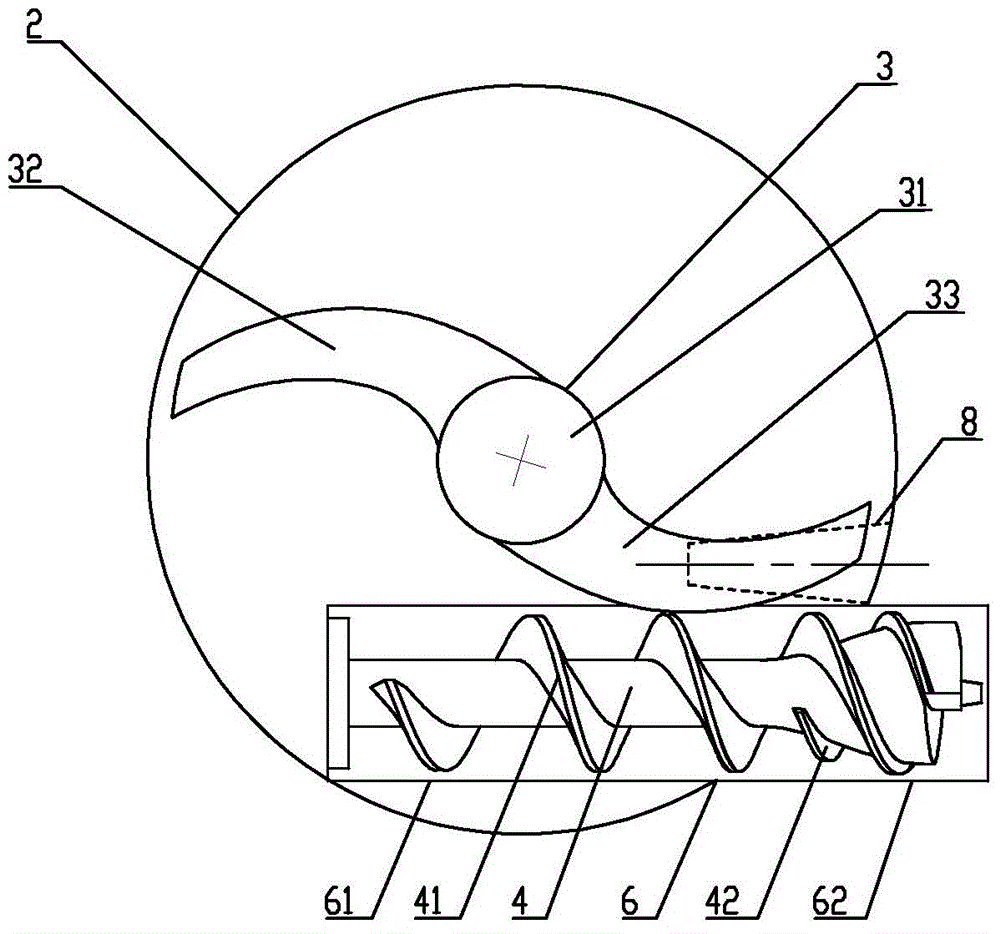

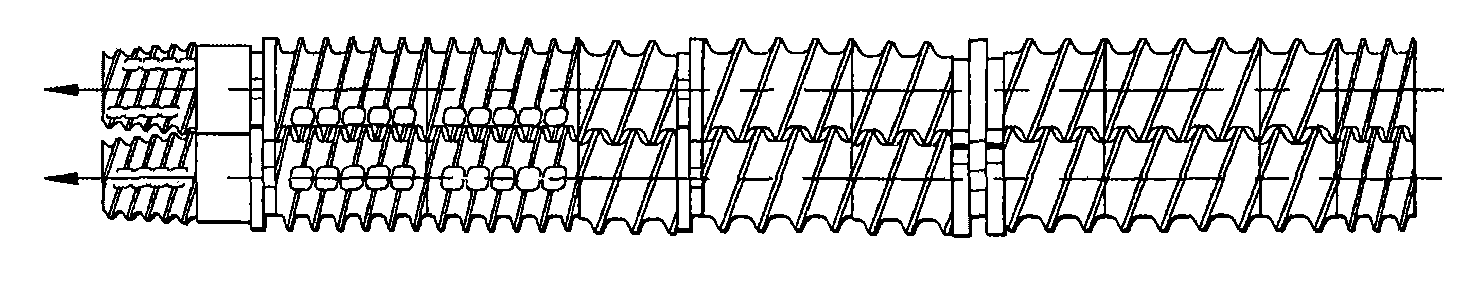

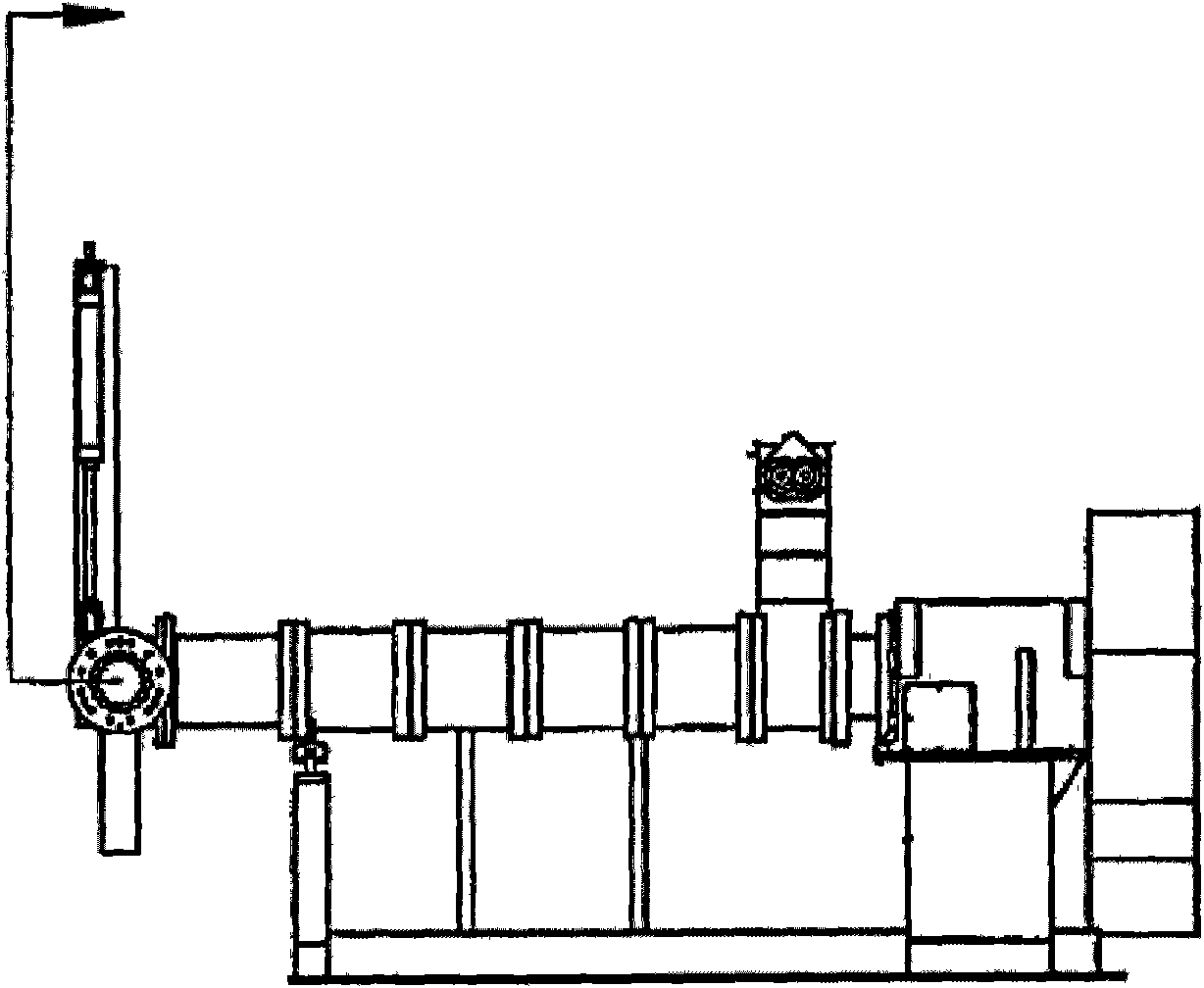

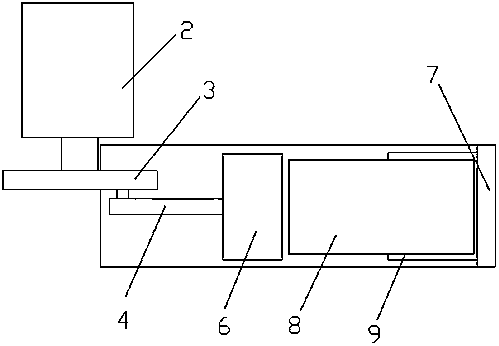

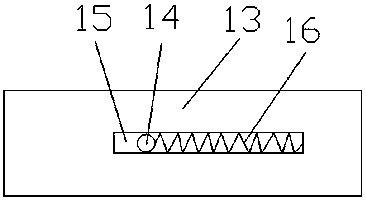

Compound co-extrusion conical screw extruder

The invention relates to a compound co-extrusion conical screw extruder which mainly consists of a charging device, a cylinder, screws, an extruder head, a motor and a driving device. The embedded inner screw and outer screw are arranged in the cylinder. The screwing directions of the inner screw and the outer screw are opposite, and the inner screw and the outer screw do reverse opposite rotation. The two screws can adopt three combination methods that: the inner screw is a conical screw, and the outer screw is a parallel screw; the inner screw is a parallel screw, and the outer screw is a conical screw; and the inner screw and the outer screw are all the conical screws. The embedded screws are connected with the same extruder head. The invention realizes single-machine double-layer co-extrusion, thereby decreasing the quality of the co-extruder hosts, saving the investment and land occupation space of equipment, simultaneously exerting the advantages of the conical screws and enhancing the extruding efficiency and the product processing quality.

Owner:BEIJING UNIV OF CHEM TECH

Juice Machine and Lid Thereof

A juice machine includes a lid, and the lid includes an upper casing, a feeding barrel, and a block member. The feeding barrel is installed on the upper casing, and the feeding barrel is hollow inside. The block member is surrounded around an external side of the bottom of the feeding barrel. The juice machine can enhance both juice squeezing efficiency and juice yield.

Owner:YA HORNG DONG GUAN ELECTRONICS +1

High-efficiency noodle making method of household noodle maker

ActiveCN104542789AStir wellImprove kneading effectMixing/kneading with vertically-mounted toolsDough extruding machinesPulp and paper industryExtrusion

The invention discloses a high-efficiency noodle making method of a household noodle maker. The noodle maker comprises a motor base with a motor, a stirring cup connected with the motor base, a stirring rod, a dough extruding cylinder, a screw rod, a die head and a control unit, wherein the stirring rod is longitudinally arranged in the stirring cup and consists of a rod body and upper stirring teeth and lower stirring teeth arranged on the rod body, the dough extruding cylinder is horizontally arranged on one side below the stirring cup, the screw rod is arranged in the dough extruding cylinder, the motor drives the stirring rod and the screw rod to rotate, a dough inlet is formed in the position at which the stirring cup and the stirring cup are communicated, and a noodle cutting rod is arranged on the inner wall of the stirring cup. The noodle making method comprises a dough kneading step and an extrusion forming step, the mutual shearing action of the upper and lower stirring teeth and the noodle cutting rod is added during the dough kneading step and the extrusion forming step, so that the dough is blended sufficiently and evenly, in addition, the dough is shorn or torn off to form a dough easily entering the dough inlet and facilitate dough feeding, the dough extrusion efficiency can be promoted, and no dough residue in the stirring cup can also be guaranteed.

Owner:JOYOUNG CO LTD

Extrusion die-casting machine and extrusion die-casting process thereof

The invention discloses an extrusion die-casting machine and an extrusion technology and die-casting technology combined extrusion die-casting process of the extrusion die-casting machine. The extrusion die-casting machine further comprises a small-stroke extrusion oil cylinder arranged on the outer side of a fixed die seat plate, a piston of the small-stroke extrusion oil cylinder moves to push an extrusion rod and directly extrudes a metal forming material stored in a storage space at the front part of the extrusion rod, so that the metal forming material enters a mold cavity, and performs local extrusion forming on the thickness direction of a semi-solid casting formed in the mold cavity. The extrusion die-casting machine has the advantage of being high in production efficiency, and meanwhile, has the function of reducing or eliminating shrinkage porosities and shrinkage cavities in thick part of a casting through an extruding method, so that the performance of the casting is obviously improved, and the machine is particularly suitable for manufacturing large-scale die castings. According to the extrusion die-casting machine and the extrusion die-casting process thereof, the structure is simple, the production cost is relatively low, and the effects of being stable and reliable are achieved; and the process method is convenient to operate, high in universality, easy to popularize and apply in the industry and wide in market application prospect.

Owner:广东鸿特精密技术肇庆有限公司

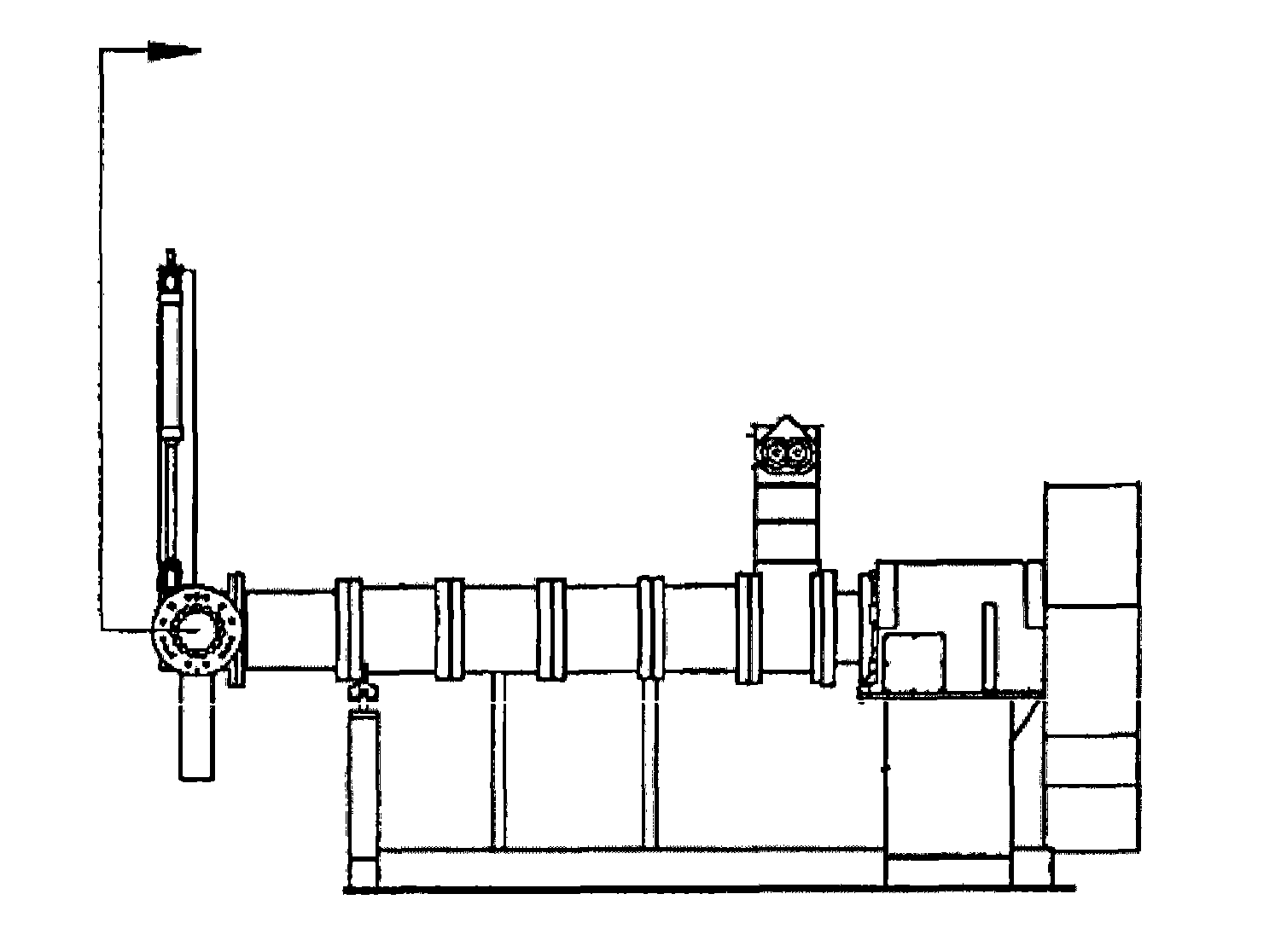

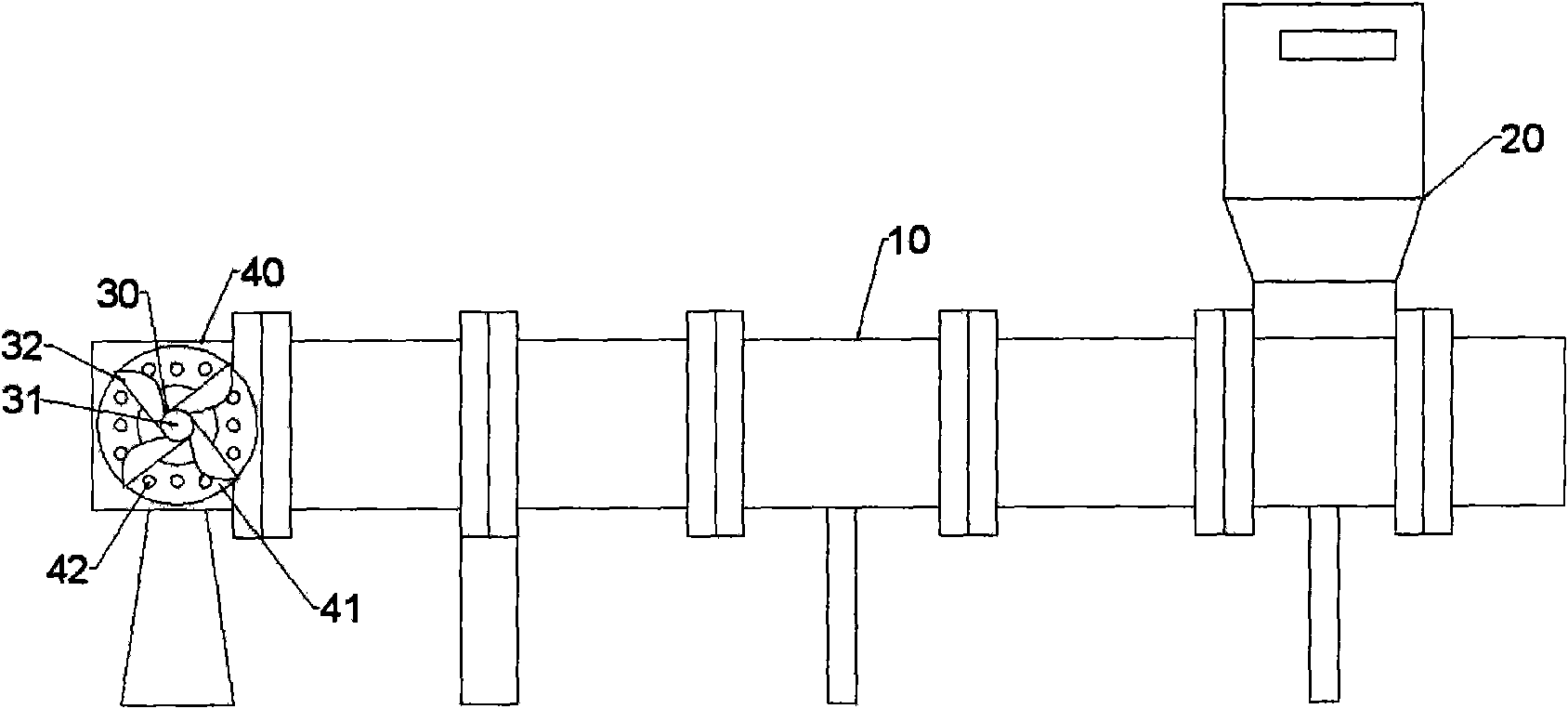

Integrated extrusion molding equipment

InactiveCN101878945AAccurately obtainedCleaning during cuttingFood shapingDomestic articlesEngineeringHigh pressure water

The invention provides integrated extrusion molding equipment, which comprises a feeding device (20), a screw extruder (10), an extrusion die (40), a rotary motor box (50), a coating device, a conveying device (70) and a cut-off device (90) in turn. The screw extruder (10) comprises a plurality of screws which are closed and occluded one another; the extrusion die (40) has two extrusion discs (41); the conveying device (70) comprises a driving roller and a conveyor belt (72) with adhesiveness; and the cut-off device (90) is arranged between the adjacent conveyor belts, and comprises a jet orifice (91) and high-pressure jet (92) emitted from the jet orifice to cut strip continuous materials (200) into sectional materials (210) with fixed lengths. The sectional treatment of the extrusion molding materials is realized through the conveying device with height fall and a high-pressure water jet system, products with specified lengths can be accurately obtained, and the cutting process is clean and safe.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

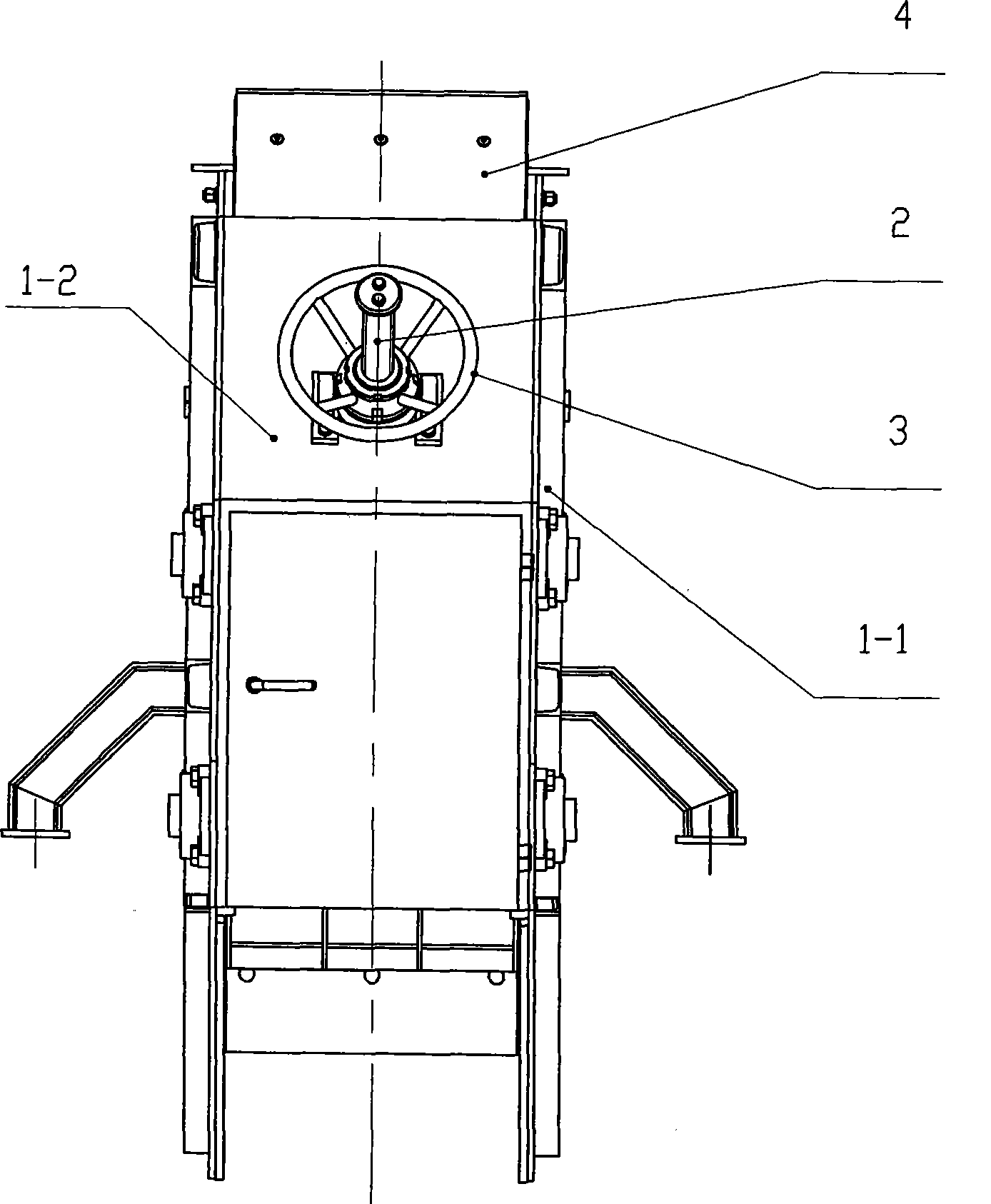

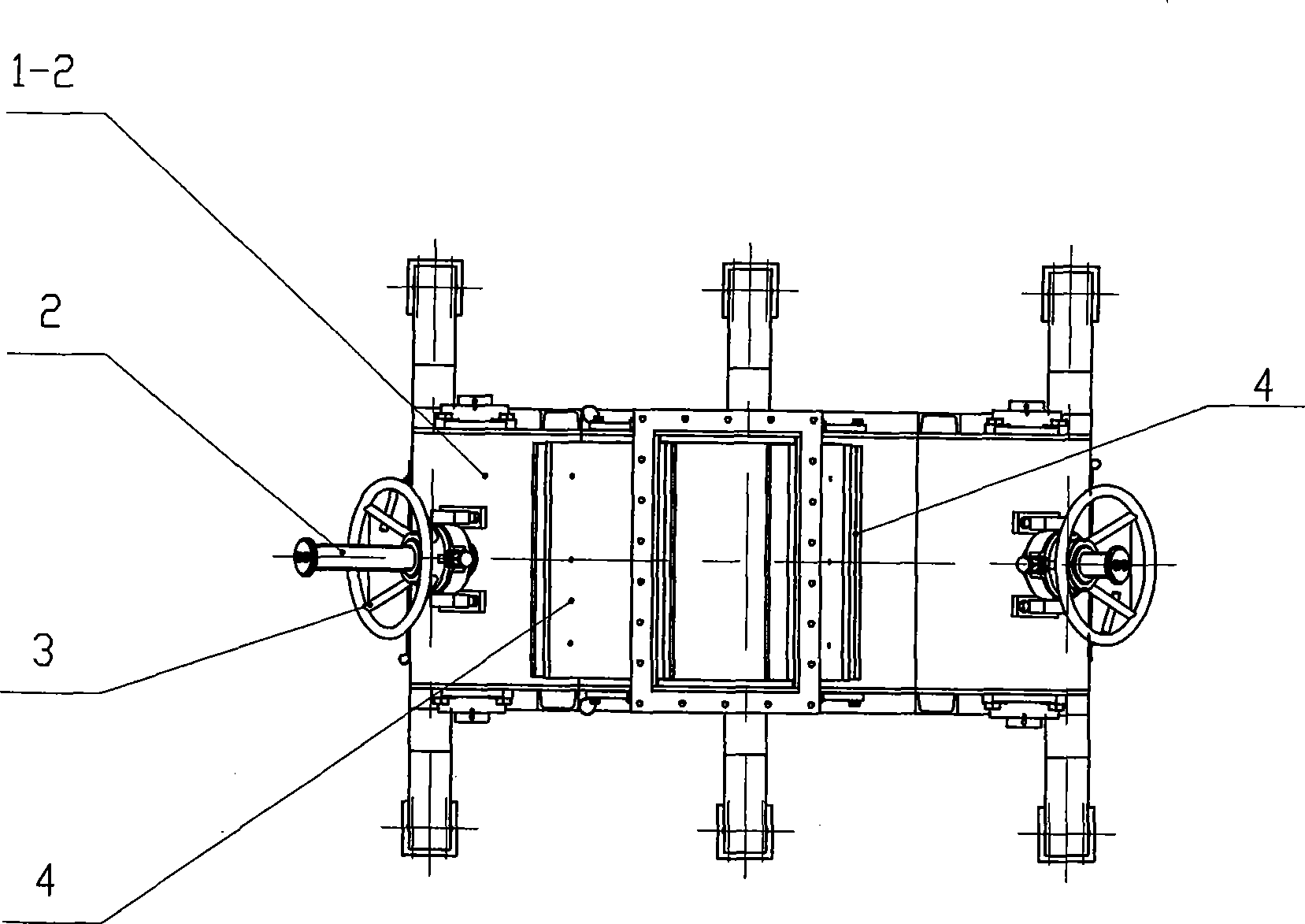

Feed apparatus of calender press

InactiveCN101362110AEliminate material leakage at the end of the rollEliminate entryGrain treatmentsSheet steelEngineering

The invention relates to a feeding device of a roller press, which is characterized in that a hand wheel nut of an adjusting mechanism is fixed on an end sheathing by a screw; a shaft at one end of a supporting mechanism is fixed on a side sheathing of a shell body by a bearing; four steel plates of the shell body are connected as a whole by welding; the other end of the supporting mechanism is articulated with an adjusting plate; an adjusting screw of the adjusting mechanism is engaged with internal screw thread of the adjusting mechanism the other end of which is connected with the adjusting plate through a hinge; and a feed deflector is articulated with the adjusting plate. The feeding device of the roller press can well eliminate feed leakage at the roller end which is common in the existing roller press and the feed can be shaped into better feed cakes after being pressed with obviously improved pressing efficiency; the feeding device can also ensure that the feed of different particles can enter a squeeze roller with a convenient and flexible adjusting method and obvious effects; as the feed leaking at the roller end is eliminated, the wear of a J-shaped skeletonless sealing ring of the bearing of the squeezer roller is greatly reduced, which can prevent external dust from entering the bearing and prolong the service life of the bearing.

Owner:WUXI TIANSHAN CEMENT

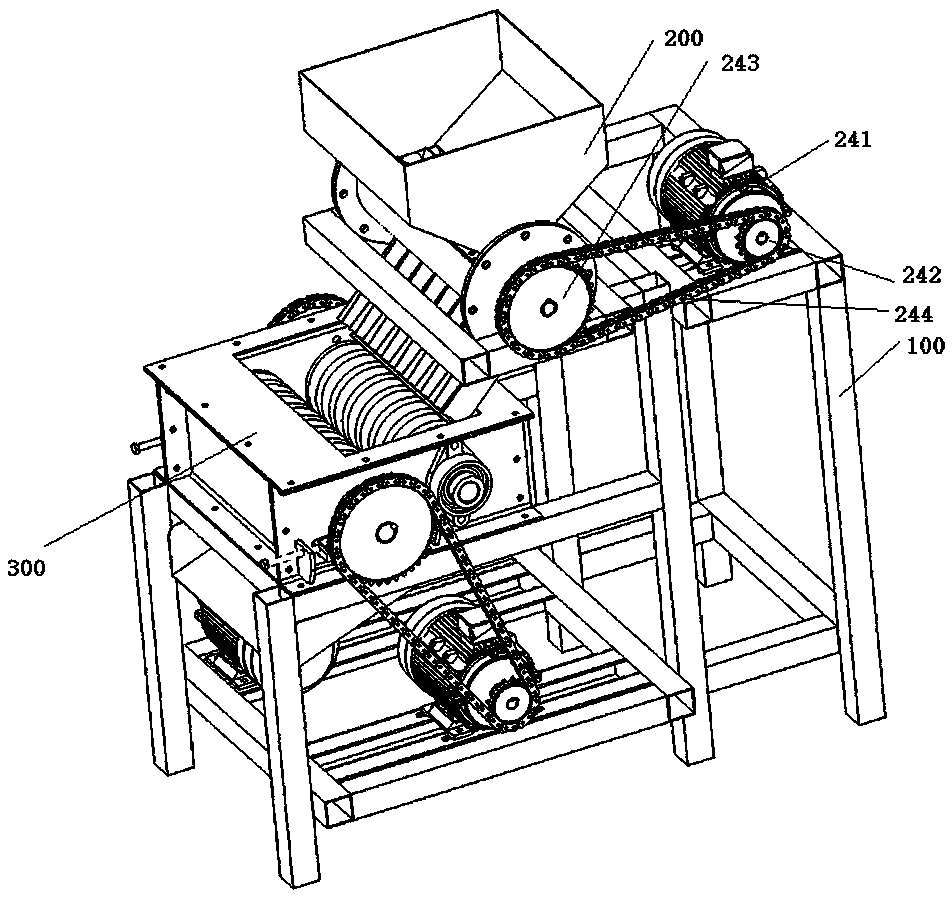

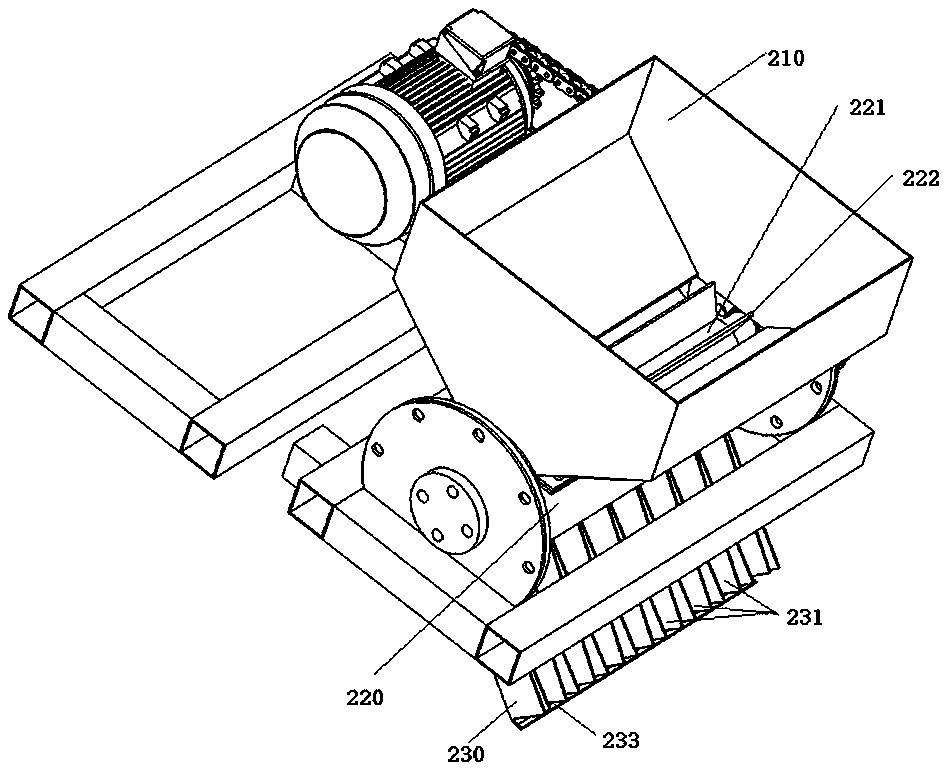

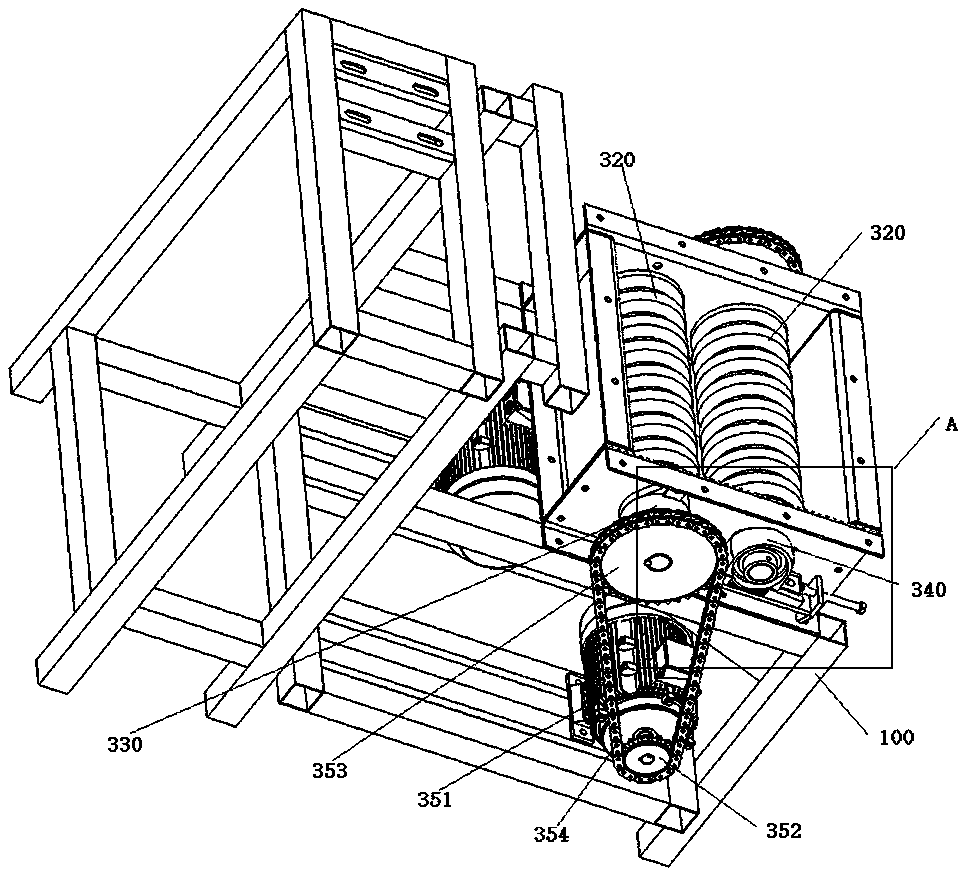

Hull breaking machine based on pretreated walnuts

The invention discloses a hull breaking machine based on pretreated walnuts, and relates to the field of walnut deep processing equipment. The hull breaking machine comprises a rack, an impeller feeding device and an opposite roller extrusion device; the impeller feeding device conducts feeding through an impeller to enable the walnuts to fall into the opposite roller extrusion device orderly, sothat the feeding efficiency is ensured; rollers of the opposite roller extrusion device are structurally optimized, V-shaped annular grooves in the rollers of the opposite roller extrusion device areformed alternately with roller sections to avoid mutual interference of the walnuts and improve the hull breaking efficiency, meanwhile one of the rollers is fixedly arranged, and the other roller isadjustable so as to adapt to hull breaking of the walnuts with different sizes and increase the kernel exposure rate; the impeller feeding device and the opposite roller extrusion device are both driven in a chain transmission mode, the driving speed of the impeller feeding device and the driving speed of the opposite roller extrusion device are matched to enable the materials to be smooth, the work continuity of the hull breaking machine is ensured, and the efficiency is improved; the outer surfaces of the rollers are wrapped with a PVC belt, jumping of the walnuts during falling is reduced,the extrusion efficiency is improved, meanwhile the adaptability of the walnuts in an extrusion work area is improved through the PVC belt, and the high kernel exposure rate is achieved.

Owner:SHIHEZI UNIVERSITY

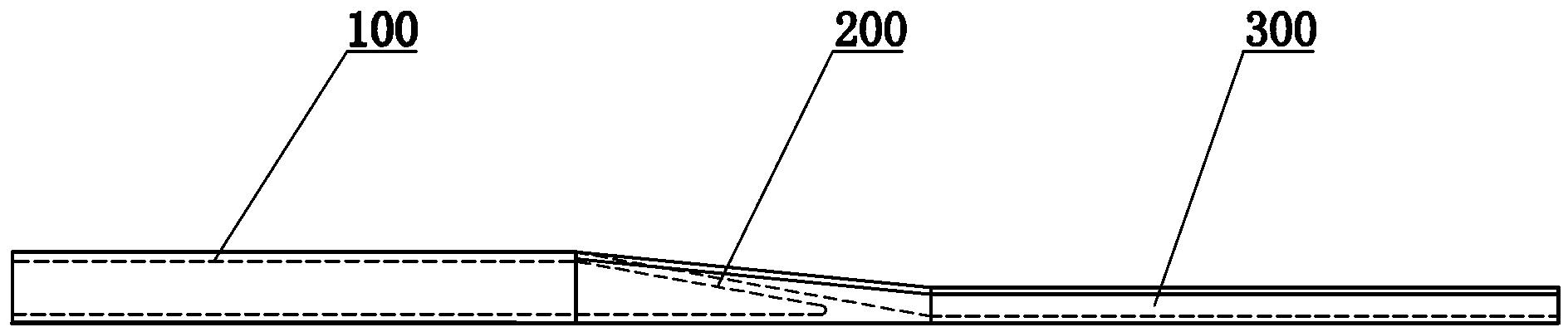

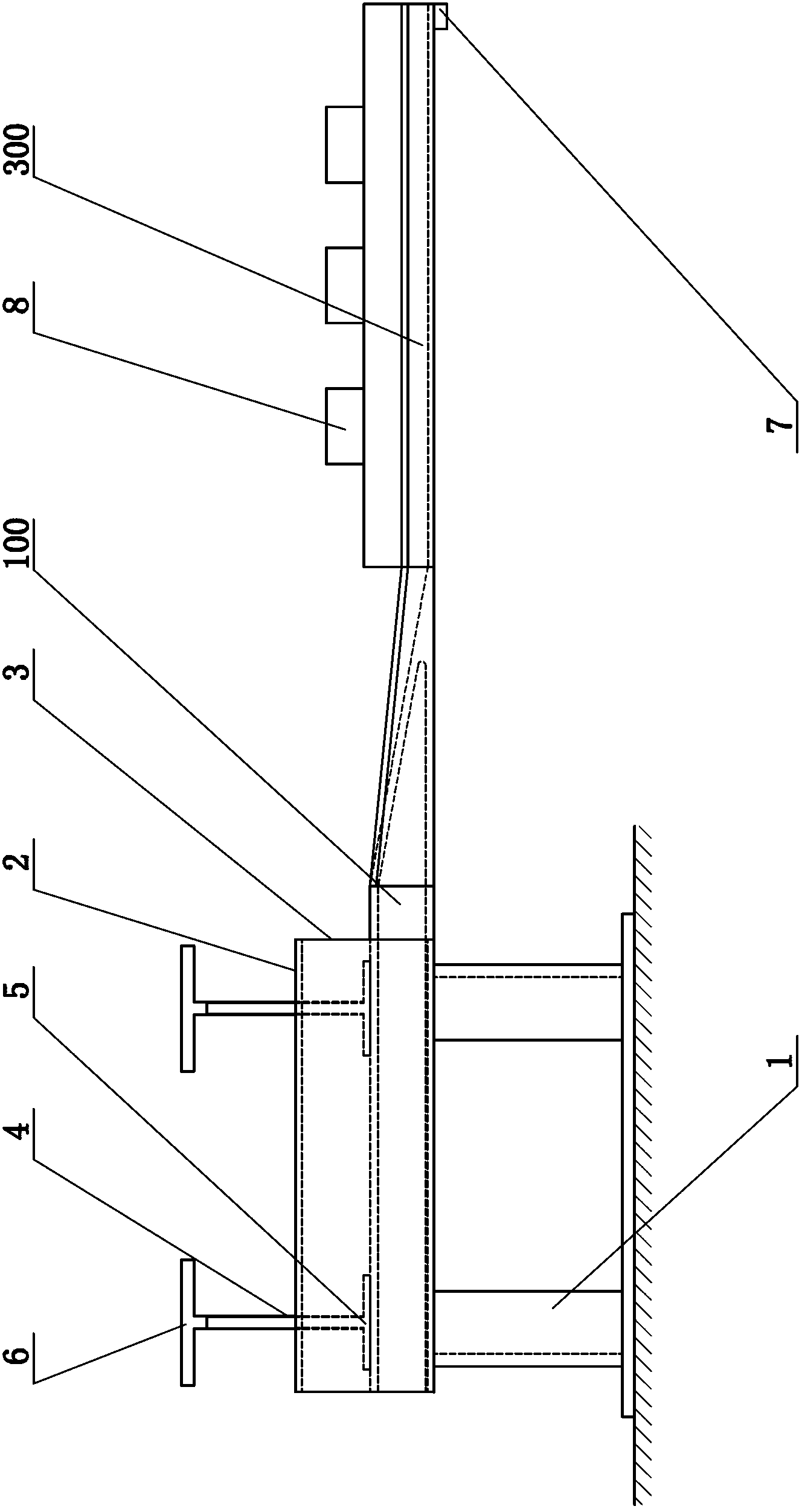

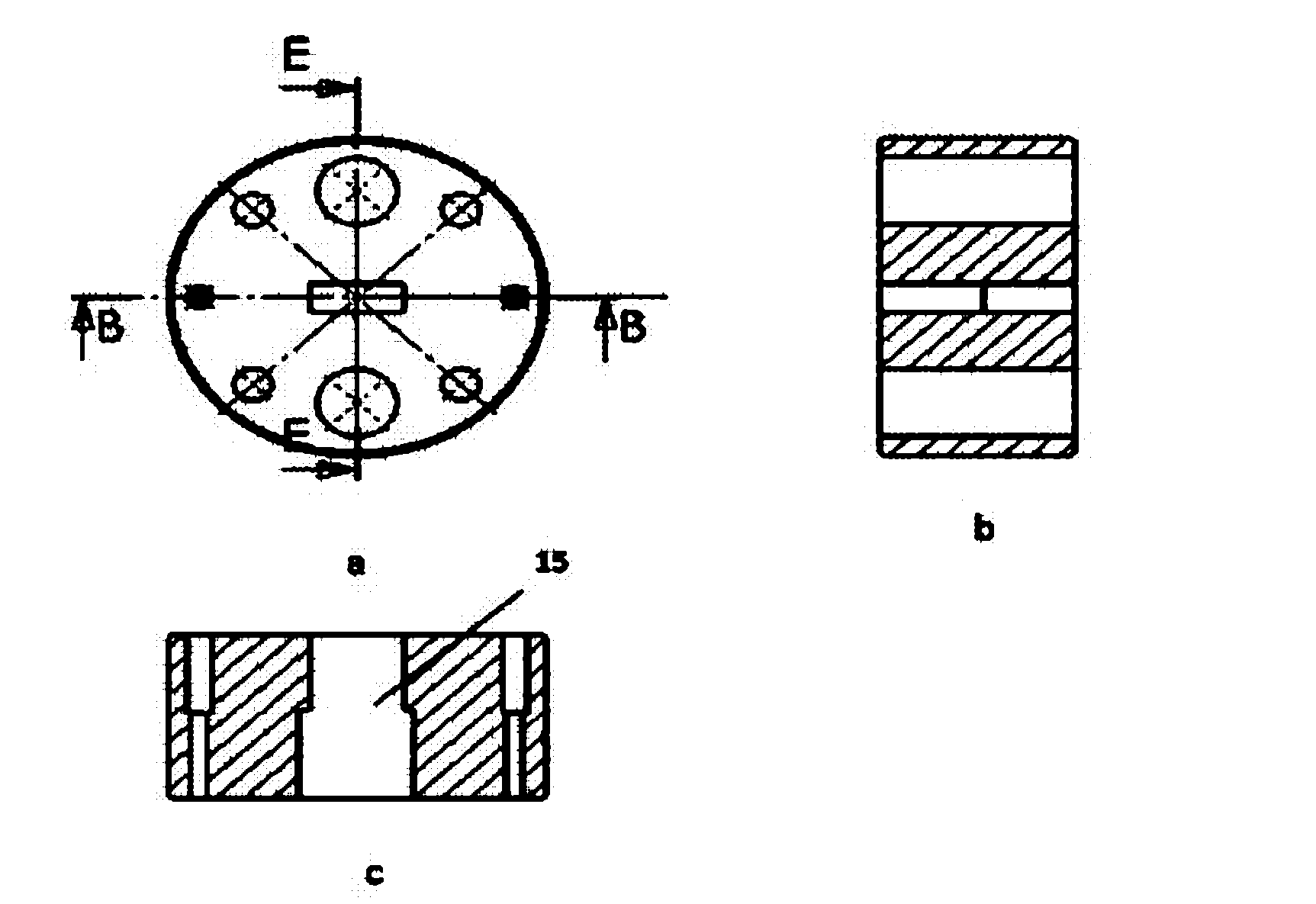

Fiber core-cladding ratio adjustable optical fiber preform extrusion method and device

The invention relates to a fiber core-cladding ratio adjustable optical fiber preform extrusion method and device. The method includes: drying a alcohol washed fiber core chalcogenide glass ingot and cladded chalcogenide glass ingot, and putting the fiber core chalcogenide glass ingot and the cladded chalcogenide glass ingot into a vacuum container; selecting an extrusion head center push rod meeting the demand, and selecting a protective casing pipe corresponding to the center push rod; putting the fiber core chalcogenide glass ingot into the protective casing pipe, putting the protective casing pipe and the cladded chalcogenide glass ingot into an extrusion die in order, and putting the extrusion die into an extrusion cylinder; performing vacuum pumping on the vacuum chamber to a vacuum degree lower than 10<-2>Pa, supplementing inert gas to the vacuum chamber until the air pressure inside the chamber is equal to the external atmospheric pressure; setting the temperature of a heating furnace group, an annealing furnace and the extrusion die, after softening the chalcogenide glass, carrying out pushing and traction by a pushing mechanism and a traction device to obtain an extrusion rod, and subjecting the extrusion rod to annealing treatment to obtain the optical fiber perform meeting the requirement, thus realizing preparation of optical fiber preforms of arbitrary fiber core-cladding ratio.

Owner:NINGBO UNIV

Processing technology for magnesium alloy and aluminum alloy sections

The invention discloses a processing technology for magnesium alloy and aluminum alloy sections, wherein a processing mode comprising the steps of hot shearing, hot peeling and front-located die no-residue extrusion is adopted. The processing technology has the advantages of overcoming the influence of heating and extrusion processing on the performance and the quality of the sections, shortening the extrusion time, increasing the extrusion efficiency, reducing the processing cost of the magnesium alloy and the aluminum alloy sections and obviously improving the economic benefit.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

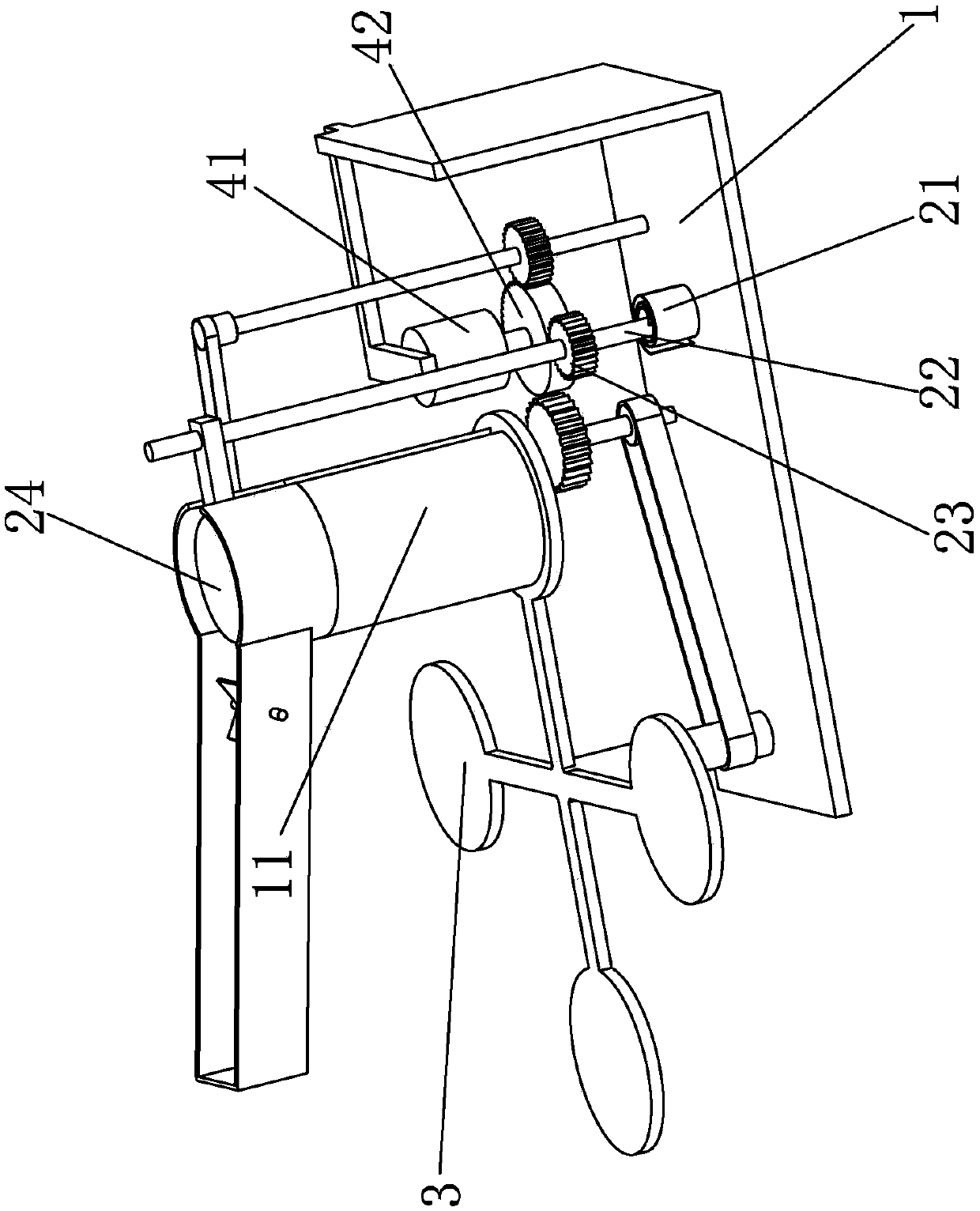

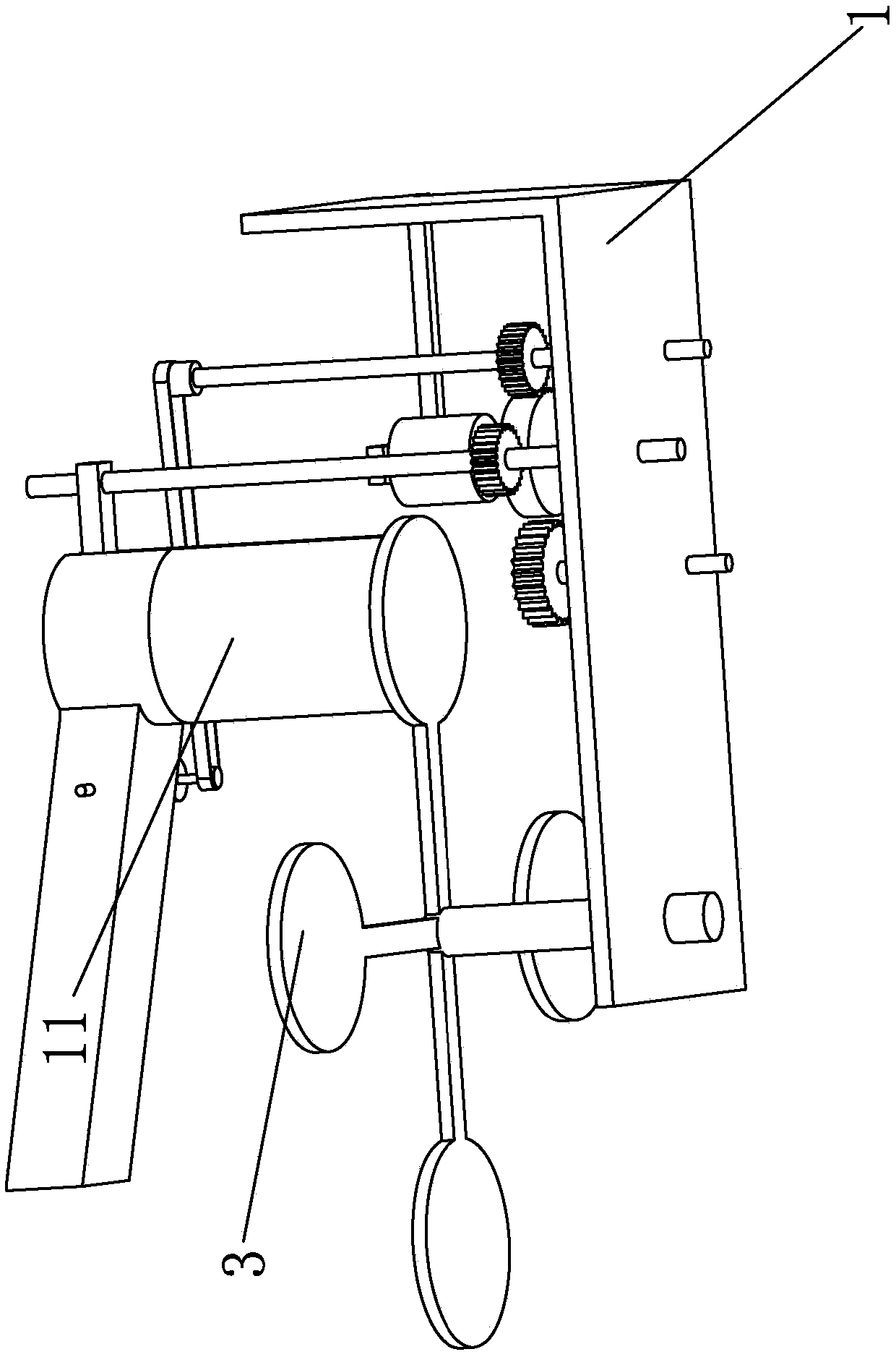

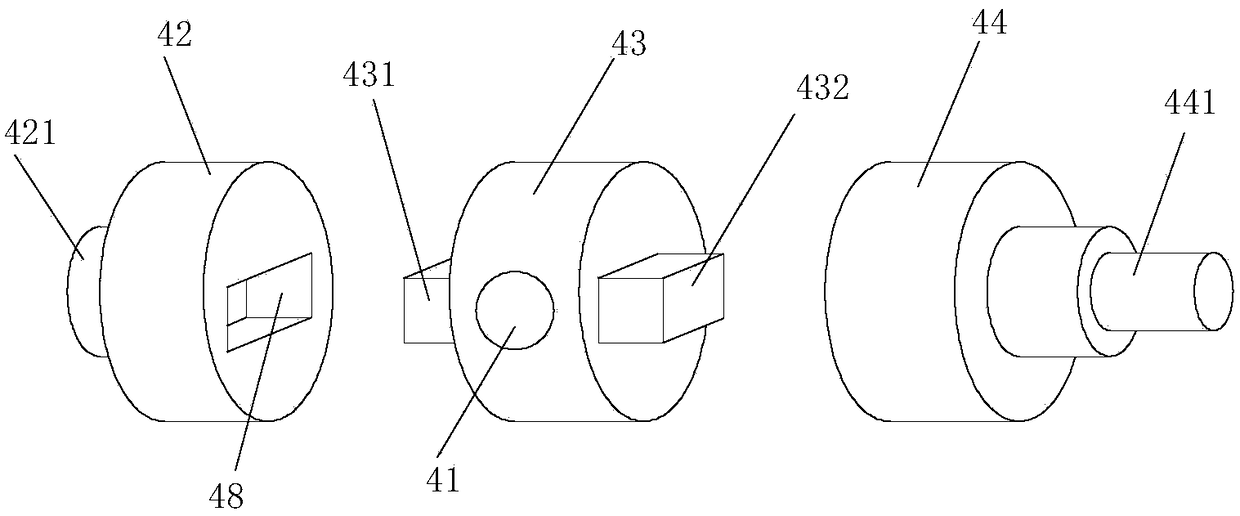

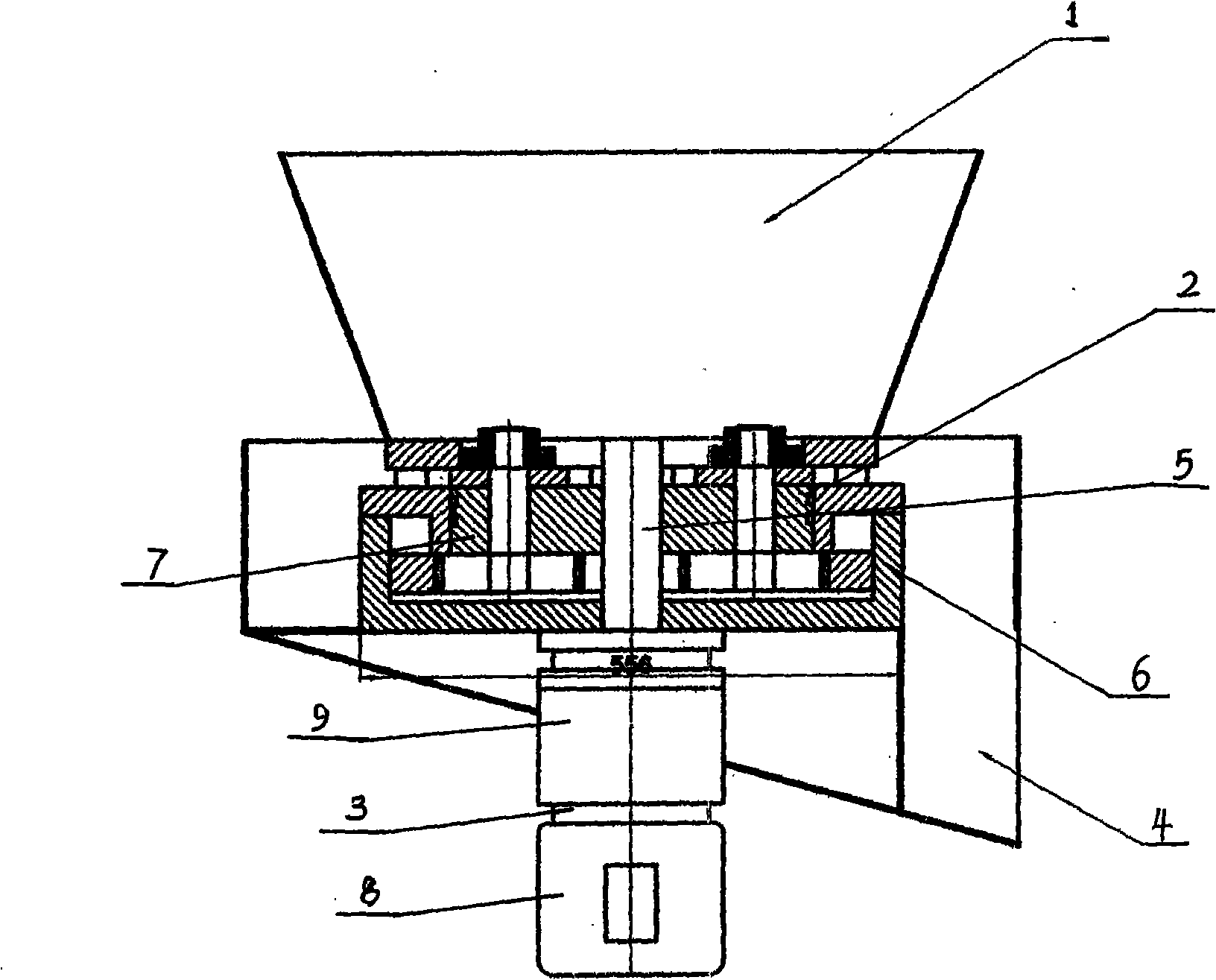

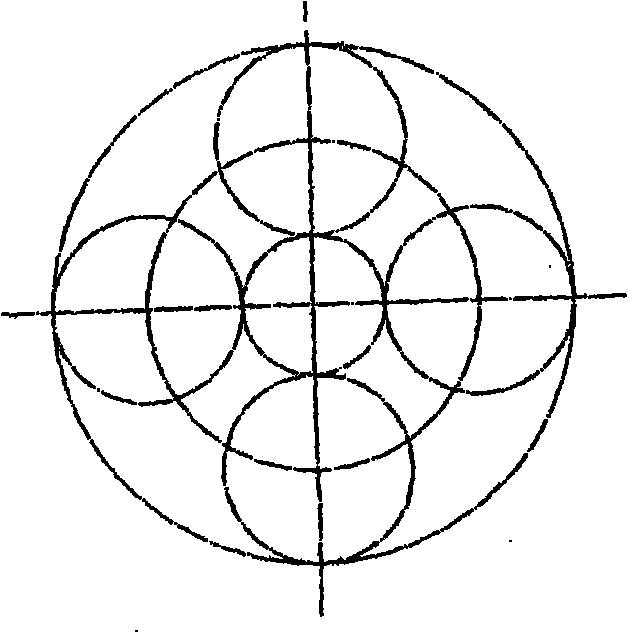

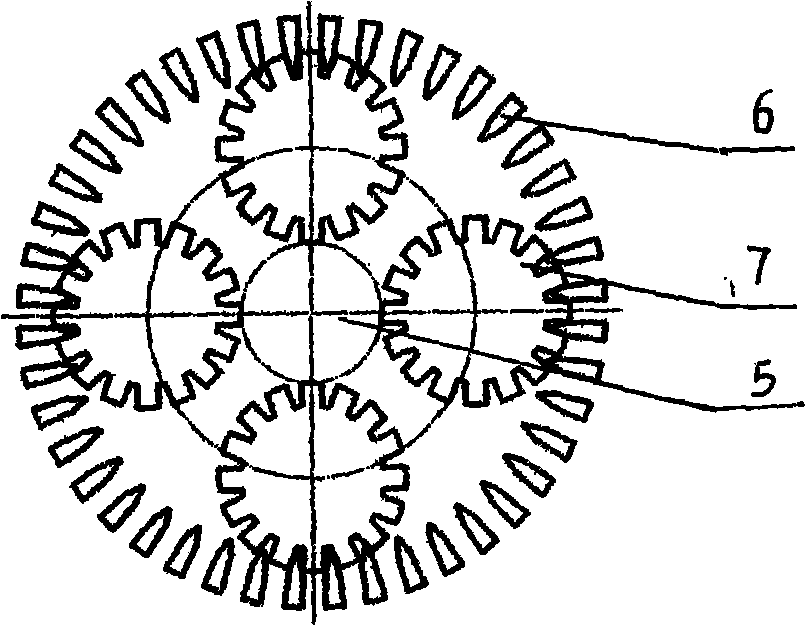

Epicyclic transmission type straw block making machine

The invention relates to a planetary transmission type straw stalk compressing machine, which belongs to the technical field of the agricultural machinery. The straw stalk compressing machine is composed of a feeding hopper, an extruding mechanism, a power input mechanism and a discharging outlet, wherein the feeding hopper is connected with the extruding mechanism; the discharging outlet is also connected with the extruding mechanism; the extruding mechanism is connected with the power input mechanism; the extruding mechanism comprises a gear shaft and a forming die; the gear shaft is positioned in the middle of the forming die and connected with the power output shaft of the power input mechanism; concave-convex engaging teeth are circularly produced in the circumference of the forming die; paired gears are installed between the gear shaft and the forming die, and are engaged with the gear shaft and the forming die. The straw stalk compressing machine has the advantages that the required power is small, the structure is simple, and the production cost is low, so that the compressing machine is suitable for field operation in households.

Owner:郑春山

Film blowing machine with improved extrusion mechanism

The invention provides a film blowing machine with an improved extrusion mechanism. The film blowing machine comprises the extrusion mechanism, a film blowing mechanism, a drawing mechanism and a winding mechanism, wherein the extrusion mechanism is composed of a hopper, an extrusion cylinder, a screw rod and a transmission motor; the extrusion cylinder is provided with a feeding hole and a discharge hole; the hopper is arranged above the extrusion cylinder and is connected with a feeding hole of the extrusion cylinder; a feeding valve is arranged between the hopper and the feeding hole; the hopper is composed of a hopper cylinder body and a dust cover which covers the hopper cylinder body; the hopper cylinder body is composed of a hopper outer cylinder and a hopper inner cylinder; heating pipes are embedded between the hopper outer cylinder and the hopper inner cylinder; at least one rotary frame for stirring a material is arranged in the hopper inner cylinder; the film blowing mechanism is composed of a die head, an air ring and a rack; the air ring is arranged on the die head; a discharge hole of the extrusion mechanism is connected with the die head of the film blowing mechanism; the die head and the air ring are fixedly arranged at the lower end of the rack separately; the drawing mechanism is arranged at the upper end of the rack; and a film blown out from the die head is transported to the winding mechanism through the drawing mechanism.

Owner:ZHEJIANG HUIFENG FILM TECH CO LTD

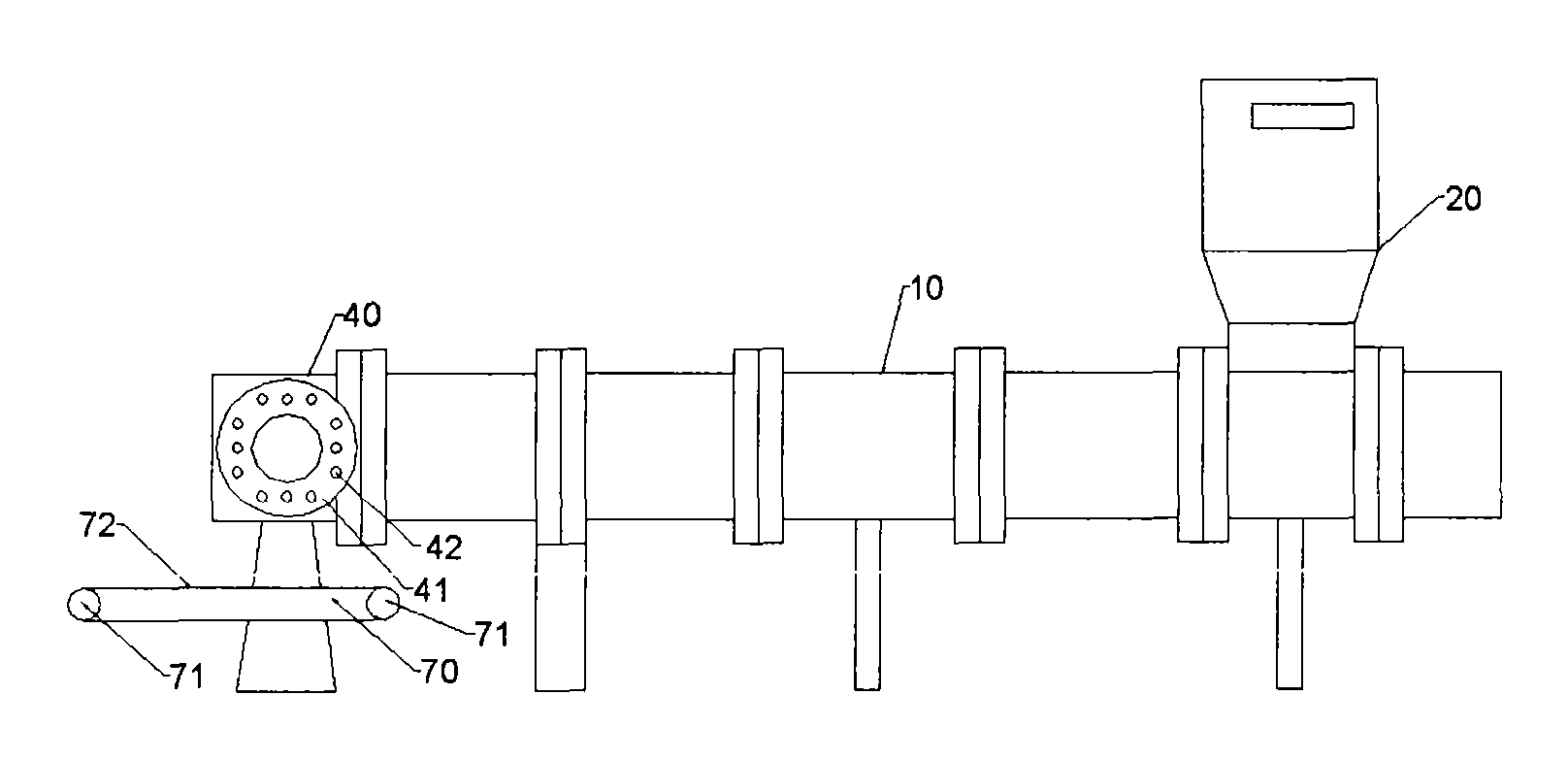

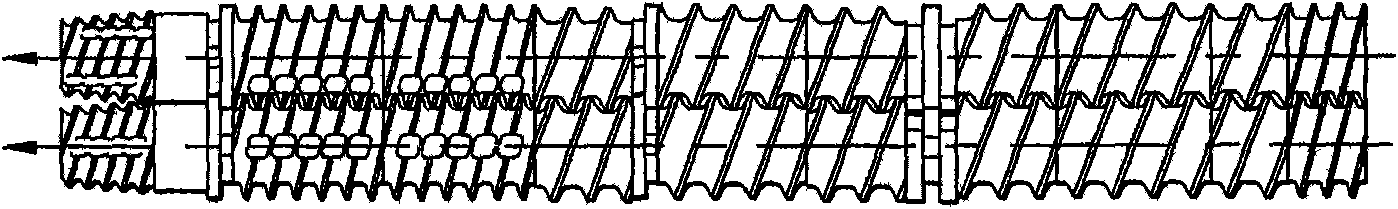

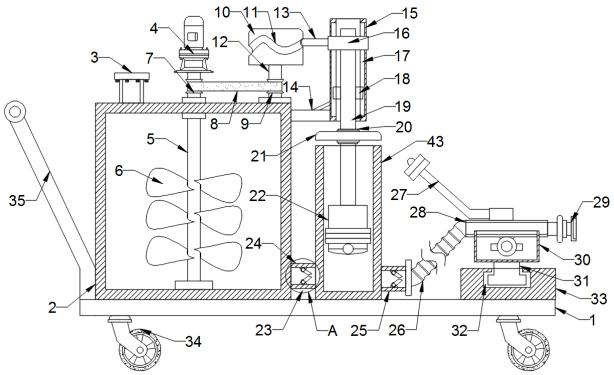

Expanded food forming processing equipment

The invention provides expanded food forming processing equipment, comprising feeding devices (20), screw extruders (10), an extrusion die (40), cutting devices (30), rotary motor boxes (50), a coating device (60) and a conveyor belt (70) in sequence, wherein the coating device (60) is a vertical liquid film coating device, comprising an upper oil storage tank (61), a lower oil storage tank (62), an oil pump (69) and an oil transport pipeline (68); the middle part of the coating device is provided with a hollow coating frame (64); and liquid stream (67) formed by a plurality of tightly arranged oil nozzles (66) at the top of the coating frame (64) forms the liquid film for coating the surfaces of the materials passing through the coating frame. By coating oil (mainly all kinds of edible oil, especially soybean oil, olive oil and other vegetable oil) on the extruded and cut products, the equipment ensures the products to have better integral shape before being dried and can effectively prevent cracking and breaking caused by instant high temperature in the predrying process.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

Noodle machine

ActiveCN105454345AAvoid residueResidual amount, avoid waste avoidMixing/kneading with vertically-mounted toolsDough extruding machinesEngineeringScrew thread

The present invention discloses a noodle machine, which comprises a base with a motor, a stirring assembly and an extrusion assembly, wherein the stirring assembly comprises a stirring cup connected to the base and a stirrer, the stirrer is transversely arranged inside the stirring cup, the extrusion assembly comprises a screw rod, a mold head and a noodle extrusion cylinder connected to the stirring cup, the screw thread is transversely arranged inside the noodle extrusion cylinder and is provided with threads, the motor drives the stirrer and the screw rod to rotate, the communication position of the stirring cup and the noodle extrusion cylinder is provided with a noodle inlet, and the stirrer is spiral and is rod-shaped, and is further provided with an extrusion pushing part for extruding ingredients and making the ingredients enter the noodle extrusion cylinder. According to the present invention, the stirrer is curved, such that the water and the dough are completely mixed during the ingredient stirring so as to ensure the dough making effect; and the extrusion pushing part is arranged, such that the extrusion pushing part participates into the dough making during the dough making so as to improve the dough making effect, and the dough is pushed during the dough entering so as to make the dough output rapid and convenient and avoid dough residue.

Owner:JOYOUNG CO LTD

Preparation method of reaction sintered silicon carbide cantilever paddle

The invention discloses a preparation method of reaction sintered silicon carbide cantilever paddle, and belongs to the technical field of silicon carbide cantilever paddle. The preparation method comprises the steps as follows: preparing an extrusion forming mould of a silicon carbide cantilever paddle fixing region; extruding a pipe blank in the fixing region and segmentally cutting the pipe blank; drying the cut pipe blanks in the fixing region; preparing ramming forming moulds of a silicon carbide cantilever paddle transition region and a load region; preparing integral blank bodies in the transition region and the load region; drying the integral blank bodies in the transition region and the load region; trimming biscuits; bonding the pipe blanks in the fixing region with the integral blank bodies in the transition region and the load region to finish preparation of a blank body of the silicon carbide cantilever paddle; sintering. Compared with a conventional slip casting process, for the method disclosed by the invention, the blank body forming rate is increased and the preparation cost is saved through using a bonding combination structure; the process is simple, the finished product rate is high, and the prepared silicon carbide cantilever paddle is high in strength, pore-free, good in heat conductivity, resistant to acid and base corrosion, pollution-free at a high temperature, deformation-free, large in load capacity and long in service life.

Owner:WEIFANG HUAMEI FINE TECHN CERAMICS

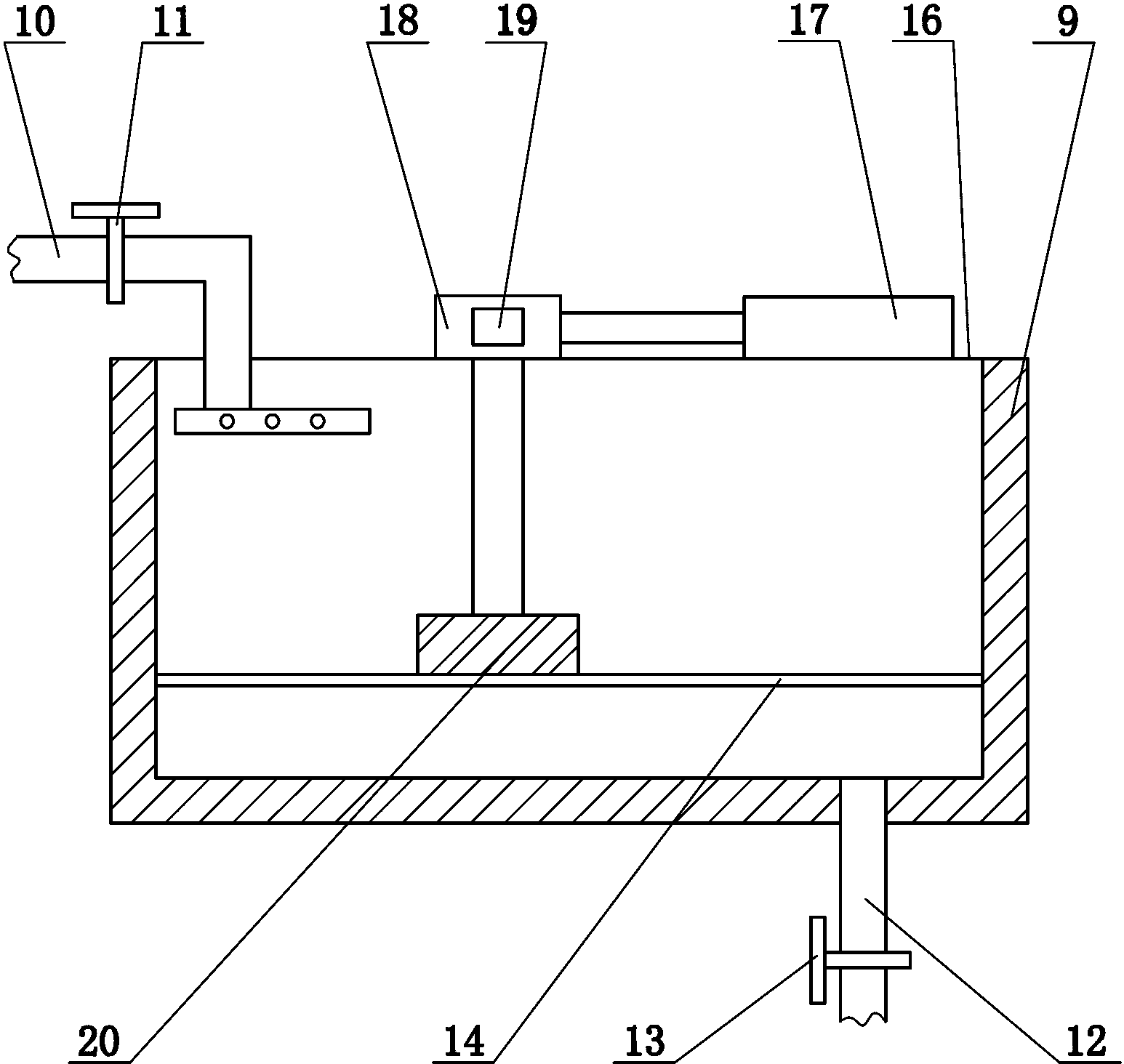

Concrete pouring mechanism

ActiveCN112065052AImprove extrusion efficiencyGuaranteed extrusion efficiencyBuilding material handlingArchitectural engineeringElectric machinery

The invention relates to the technical field of civil engineering construction, and particularly relates to a concrete pouring mechanism. The concrete pouring mechanism solves the problems that in theprior art, the working radius range of concrete pumping cannot be reached, local construction of civil engineering is needed, a small amount of concrete is poured temporarily, and time and labor arewasted when concrete is mixed and transferred by workers in construction. The concrete pouring mechanism comprises a base, wherein a stirring box is fixedly connected to one side of the top of the base; the bottom of the stirring box is fixedly connected with the top of the base; the top of the stirring box is fixedly connected with a driving motor through a bolt; and a stirring rod is arranged inan inner cavity of the stirring box. According to the concrete pouring mechanism, concrete is pushed in the pushing mode of stirring blades and the suction mode of a piston, the flexibility of the conveying direction of the concrete is improved through a universal rotating mechanism of a long-strip-shaped discharging nozzle, and the pouring speed of the concrete is increased; and the stirring blades in the stirring box continuously operate, so that segregation of aggregate is effectively avoided, and the uniformity of concrete material composition is guaranteed.

Owner:YANCHENG INST OF TECH

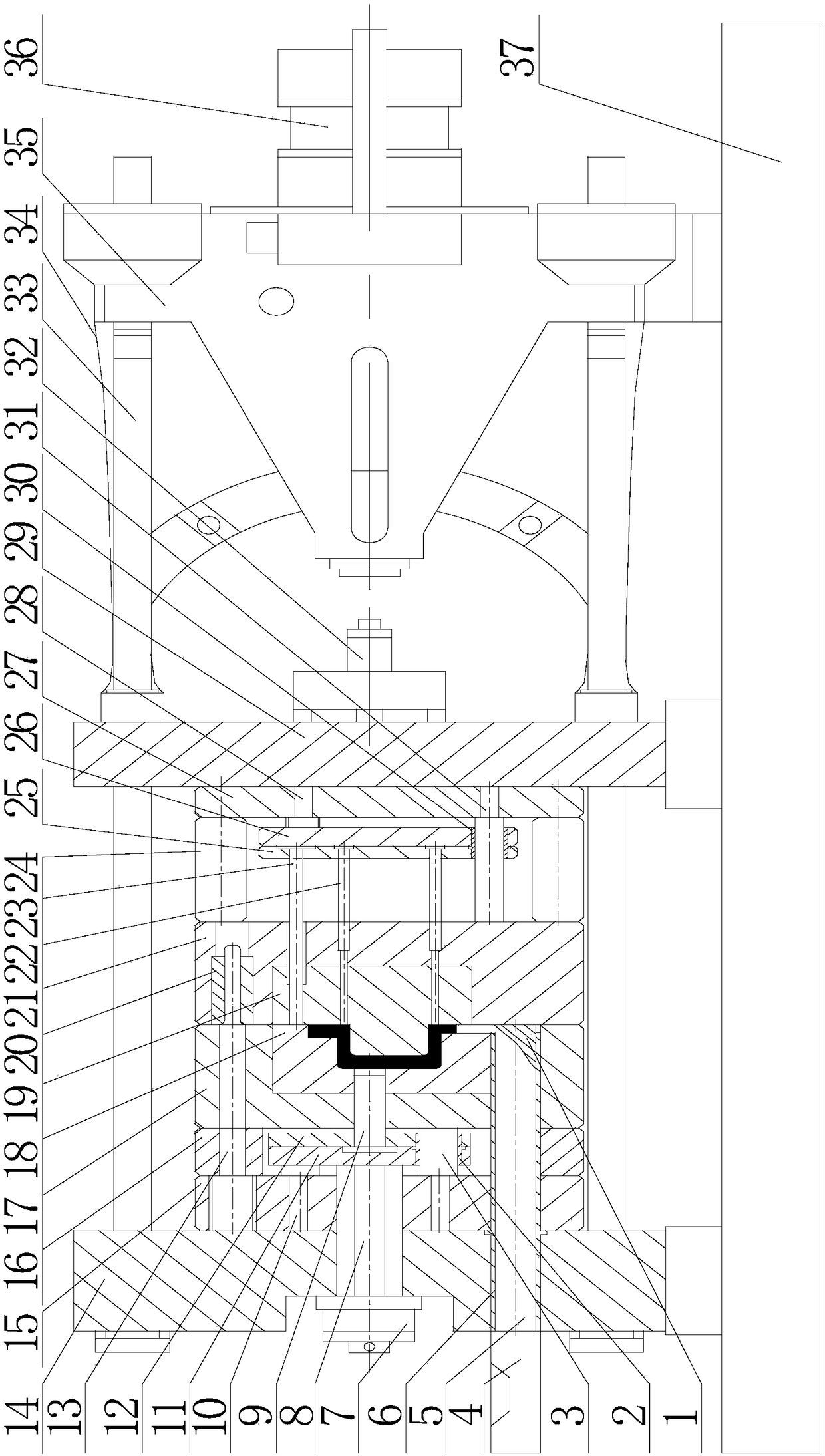

Backpressure equal-channel angular extruding mould

ActiveCN102615133AIncrease the cross-sectional areaIncrease stiffnessExtrusion diesPunchingEngineering

The invention discloses a backpressure equal-channel angular extruding mould which comprises a pressing plate, a guide pillar, a knocking bar, a convex mould, a guide sleeve, a spring, a concave mould, a mould base, a double-fork type punching head, a heating ring, a positioning slide block, a backpressure ejecting rod and an ejecting rod bracket, wherein the rigidity and strength of punching head are increased by the double-fork type punching head; the positioning slide block capable of sliding back and forth is arranged in a horizontal channel, so that the last sample can be conveniently taken out from the horizontal channel; and backpressure is applied to the sample by a backpressure device in an ejecting rod pressurizing form during an extruding process, so that the extruding temperature is efficiently reduced, the grain is refined and the comprehensive mechanical property of magnesium alloy is improved.

Owner:SHANGHAI JIAO TONG UNIV

Waste ring-pull can squashing equipment and working method thereof

The invention relates to waste ring-pull can squashing equipment and a working method thereof. The waste ring-pull can squashing equipment is characterized in that the waste ring-pull can squashing equipment comprises a machine base and a vertical rotating disc arranged on the machine base and driven by a motor to rotate; the far center portion of the vertical rotating disc and the first end of apush rod are hinged; a guide rail groove channel and a press head arranged in the guide rail groove channel are further arranged on the machine base; the rear portion of the press head and the secondend of the push rod are hinged; a vertical plate is arranged at the end of the guide rail groove channel; the position, located between the press head and the vertical plate, in the guide rail groovechannel is filled with a to-be-extruded workpiece; a material falling opening capable of being opened is arranged at the bottom of the guide rail groove channel; and a containing barrel is arranged below the material falling opening. The waste ring-pull can squashing equipment is simple in structure, reasonable in design and low in manufacturing cost, and people can conveniently carry out squashing treatment on ring-pull cans.

Owner:柳德清

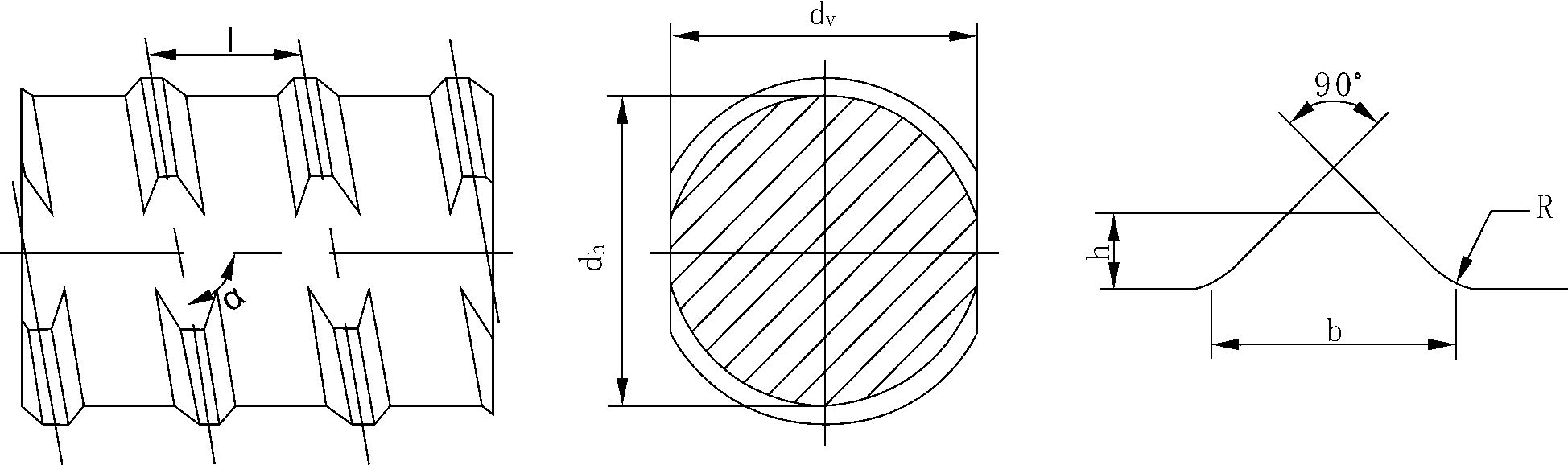

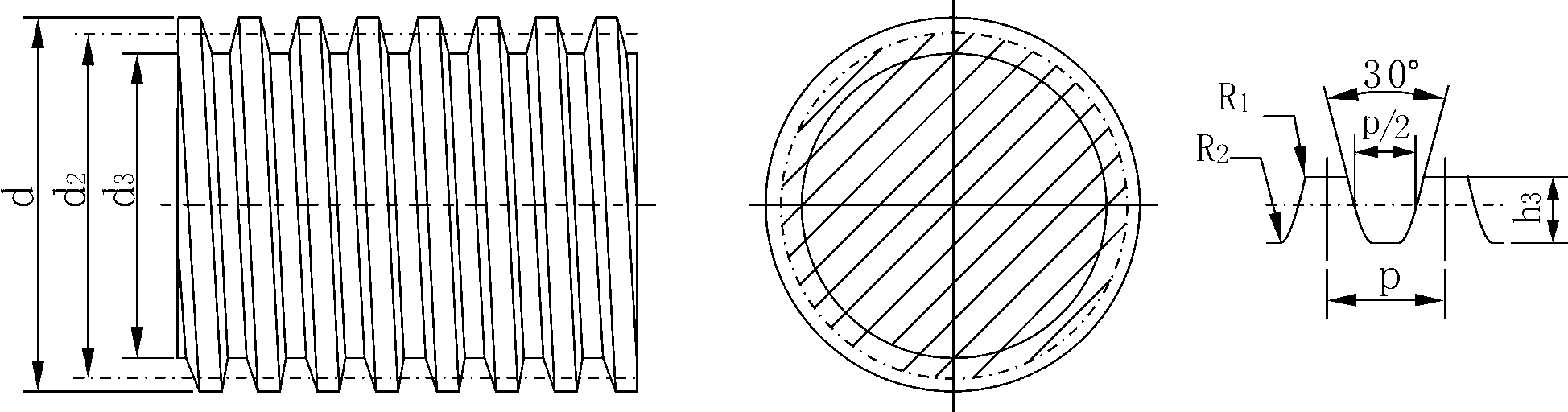

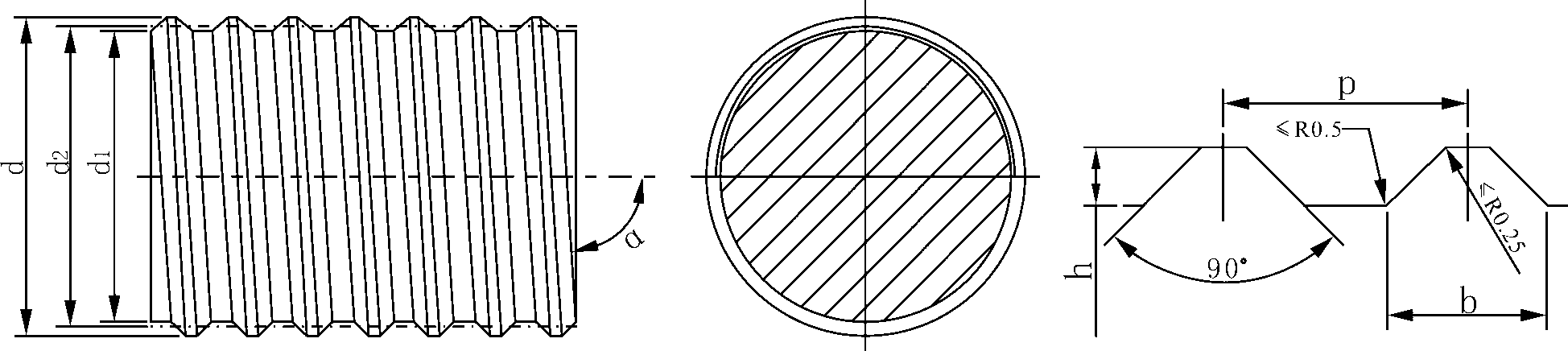

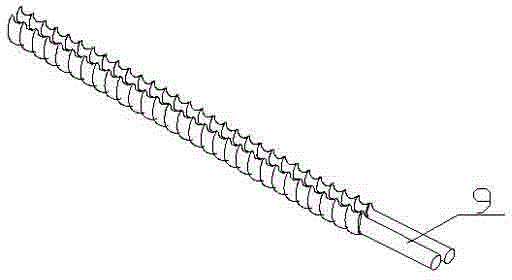

Method for manufacturing high-strength screws with fine threads for wind-driven generator foundations

InactiveCN103286246AReduce resistanceImprove extrusion efficiencyScrew-threads articlesWind drivenMedium frequency

The invention discloses a method for manufacturing high-strength screws for wind-driven generator foundations. The method includes steps of cutting selected steel materials into blanks with proper lengths according to requirements; straightening the blanks; performing medium-frequency induction heat treatment on the blanks; performing ultrasonic flaw detection and eddy current flaw detection on the blanks; rolling each workpiece by a cold extrusion thread rolling machine with two parallel annular thread rolling cylindrical dies to form continuous fine threads in the workpiece. The method for manufacturing the high-strength screws for the wind-driven generator foundations has the advantages that the thread rolling efficiency is high, the thread rolling stability is good, the fine threads rolled by the method are high in bearing capacity and good in self-locking property, and strength requirements of operation of wind-driven generators are met.

Owner:湖北德克特种异型高强螺栓有限公司

Double-screw extruding equipment for producing thin film

The invention discloses double-screw extruding equipment for producing a thin film. The double-screw extruding equipment comprises sealing barrels, sealing seats, an exhausting device, a sealing ring and double-screw shafts, wherein the double-screw extruding equipment is composed of nine sections of the sealing barrels; the sealing seats are arranged in front and back of the sealing barrels; the double-screw shafts are arranged in nine sections of the sealing barrels and penetrate through the sealing barrels, and penetrate through the final section of the sealing barrel by the sealing ring; the exhausting device is arranged on the second section of the sealing barrel from left to right; a vent hole is formed in the fourth section of the sealing barrel from left to right; a secondary feeding hole is formed in the side face of the sixth section of the sealing barrel from left to right and a vent hole is formed in the secondary feeding hole; and a vent hole is formed in the ninth section of the sealing barrel from left to right. The double-screw extruding equipment has the advantages that the structure is compact, the extrusion efficiency is high, the cost of raw materials is saved, the maintenance cost is reduced and the service life is prolonged.

Owner:淮北丰盛泰重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com