High-efficiency noodle making method of household noodle maker

A noodle machine, household technology, applied in the direction of dough extruder, dough forming machinery or equipment, application, etc., can solve the problems of inability to achieve full automation, residual dough or dough, poor customer experience, etc., to achieve kneading dough. Good effect, soft and full, avoid the effect of stall or burn-in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

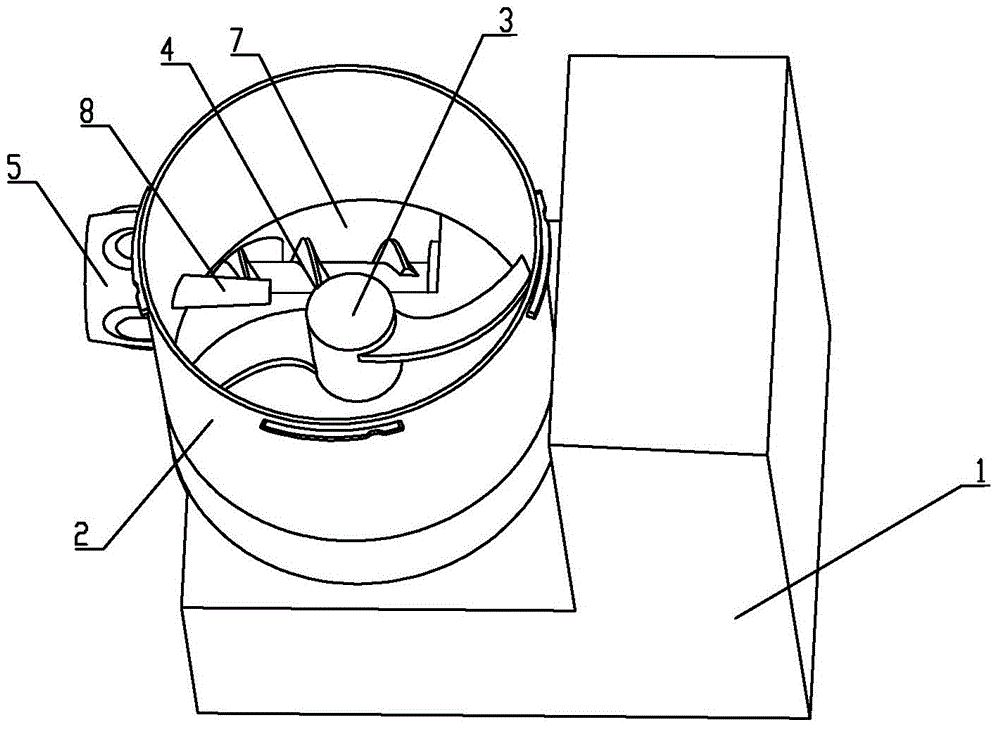

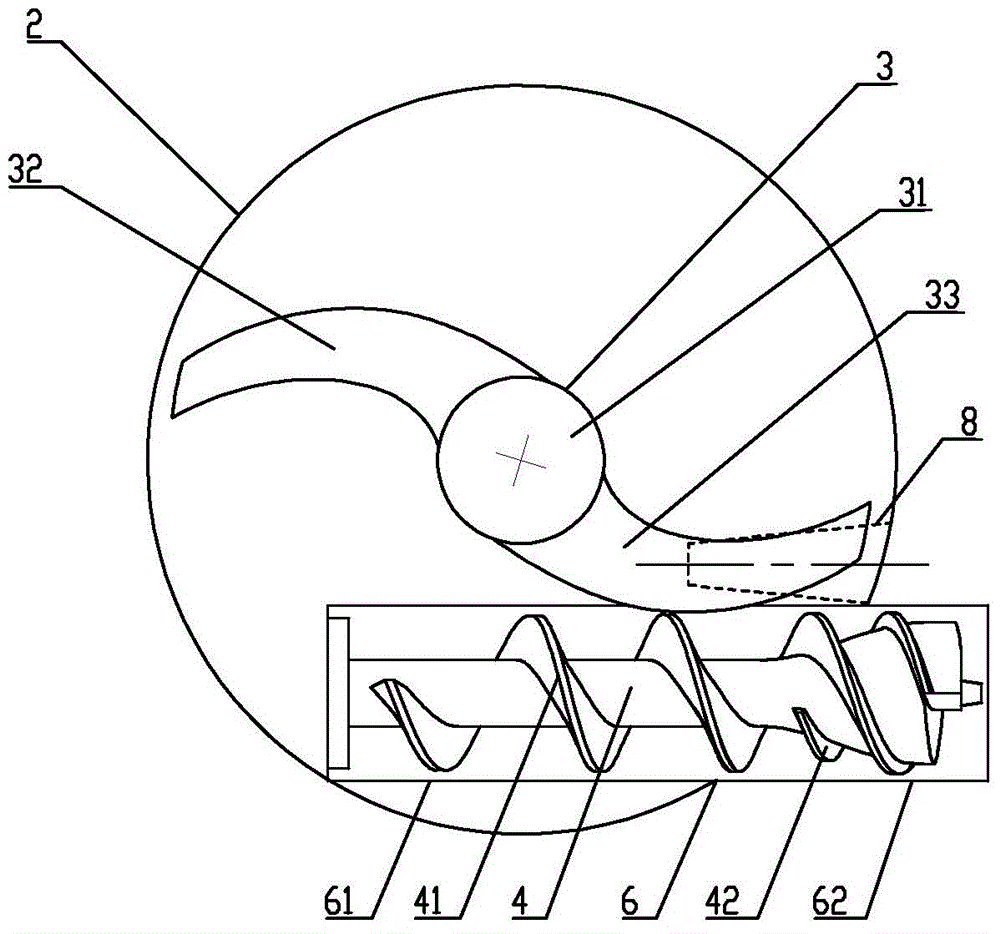

[0038] In the structure of the above-mentioned household noodle machine, the motor is one, and the motor includes a first output shaft and a second output shaft, the first output shaft is in transmission connection with the stirring rod 3, and the second output shaft is in transmission connection with the screw rod 4, The noodle making method of the present embodiment, its specific technological process is as follows:

[0039] (1) The customer adds flour and water into the mixing chamber of the noodle machine, presses the normal noodle button, and the noodle machine starts to work;

[0040] (2) Dough mixing step: the first output shaft drives the stirring rod 3 to rotate in the forward direction, the second output shaft drives the screw rod 4 to rotate in the forward direction, and the upper and lower stirring teeth (32, 33) of the stirring rod 3 stir the flour and water , when the mixture of flour and water is driven by the upper and lower stirring teeth (32, 33) to the vicin...

Embodiment 2

[0048] The difference between this embodiment and the first embodiment is that a dough kneading step is also provided before the extrusion molding step.

[0049] The noodle making method of the present embodiment, its specific technological process is as follows:

[0050] (1) The customer adds flour and water into the mixing chamber of the noodle machine, presses the high-gluten noodle button, and the noodle machine starts to work;

[0051] (2) Dough mixing step: the first output shaft drives the stirring rod 3 to rotate in the forward direction, the second output shaft drives the screw rod 4 to rotate in the forward direction, and the upper and lower stirring teeth (32, 33) of the stirring rod 3 stir the flour and water , when the mixture of flour and water is driven by the upper and lower stirring teeth (32, 33) to the vicinity of the noodle cutting rod 8, under the action of the noodle cutting rod 8, the reverse movement continues to return to the vicinity of the upper and ...

Embodiment 3

[0060] The difference between the present embodiment and the second embodiment is that, after the kneading step, there is also a resting step.

[0061] The noodle making method of the present embodiment, its specific technological process is as follows:

[0062] (1) The customer adds flour and water into the mixing chamber of the noodle machine, presses the high-gluten noodle button, and the noodle machine starts to work;

[0063](2) Dough mixing step: the first output shaft drives the stirring rod 3 to rotate in the forward direction, the second output shaft drives the screw rod 4 to rotate in the forward direction, and the upper and lower stirring teeth (32, 33) of the stirring rod 3 stir the flour and water , when the mixture of flour and water is driven by the upper and lower stirring teeth (32, 33) to the vicinity of the noodle cutting rod 8, under the action of the noodle cutting rod 8, the reverse movement continues to return to the vicinity of the upper and lower stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com