Double-component high-strength building epoxy structural adhesive and preparing method thereof

An epoxy structural adhesive, high-strength technology, used in epoxy resin adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of decreased colloid strength, inability to stick to steel adhesive, insufficient elasticity, etc., and achieve no decrease in strength. , The effect of convenient construction and paste, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The two-component high-strength architectural epoxy structural adhesive provided in this example is mainly composed of component A and component B mixed in a weight ratio of 1.8:1; wherein:

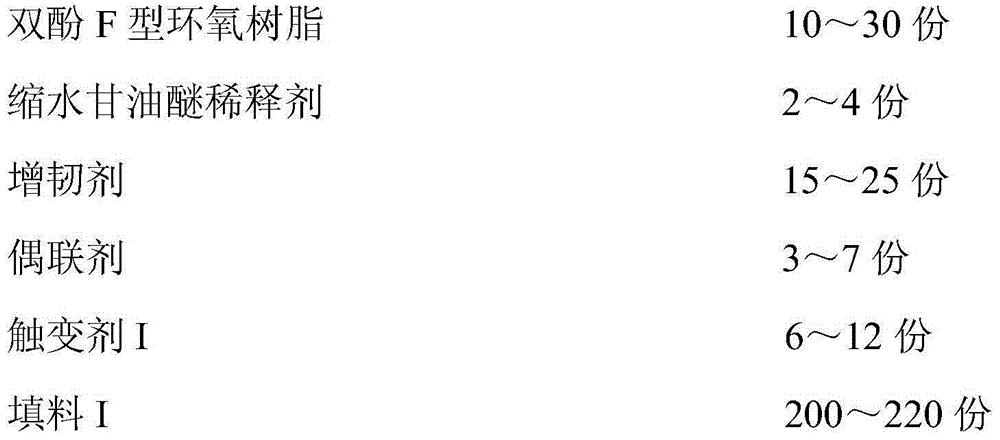

[0032] The A component mainly consists of the following raw materials by weight:

[0033]

[0034] The B component mainly consists of the following raw materials by weight:

[0035]

[0036] Preparation:

[0037] 1) Prepare A component and B component respectively: Wherein,

[0038] Preparation of component A: first weigh the raw materials in component A according to the above weight, and then mix bisphenol A type epoxy resin, bisphenol F type epoxy resin, n-butyl glycidyl ether, liquid nitrile rubber and coupling Add the agent into the mixer and stir evenly, then add the fumed silica thixotropic agent, and finally add the quartz powder until it is evenly stirred, then pack it;

[0039] Preparation of component B: Weigh the raw materials in component B according to the abo...

Embodiment 2

[0042] The high-strength architectural epoxy structural adhesive provided in this example is composed of component A and component B mixed in a weight ratio of 2.5:1; wherein:

[0043] The A component consists of the following raw materials by weight:

[0044]

[0045] The B component consists of the following raw materials by weight:

[0046]

[0047]

[0048] Preparation:

[0049] 1) Prepare A component and B component respectively: Wherein,

[0050] Preparation of component A: first weigh each raw material in component A according to the above weight, and then mix bisphenol A type epoxy resin, bisphenol F type epoxy resin, polyethylene glycol diglycidyl ether, polysulfide rubber and Add the joint agent into the mixer and stir evenly, then add fumed silica thixotropic agent, finally add talcum powder and calcium carbonate until evenly stirred, and pack;

[0051] Preparation of component B: Weigh the raw materials in component B according to the above ratio, then ...

Embodiment 3

[0054] The high-strength architectural epoxy structural adhesive provided in this example is composed of component A and component B mixed in a weight ratio of 2:1; wherein:

[0055] The A component consists of the following raw materials by weight:

[0056]

[0057]

[0058] The B component consists of the following raw materials by weight:

[0059]

[0060] Preparation:

[0061] 1) Prepare A component and B component respectively: Wherein,

[0062] Preparation of component A: First, weigh each raw material in component A according to the above weight, and then mix bisphenol A epoxy resin, bisphenol F epoxy resin, polypropylene glycol diglycidyl ether, sea-island structure toughener and coupler Add the coupling agent into the mixer and stir evenly, then add the fumed silica thixotropic agent, and finally add talc powder and quartz powder until the mixture is evenly stirred, then pack;

[0063] Preparation of component B: Weigh the raw materials in component B acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com