Extrusion die-casting machine and extrusion die-casting process thereof

A technology of die casting machine and extrusion rod, applied in the fields of die casting and squeeze casting, can solve the problems of inability to eliminate pores, shrinkage holes, shrinkage porosity casting defects, difficult to accurately control the reserved gap, and insignificant extrusion effect, etc. Achieve the effect of reducing mold cost, low manufacturing cost and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

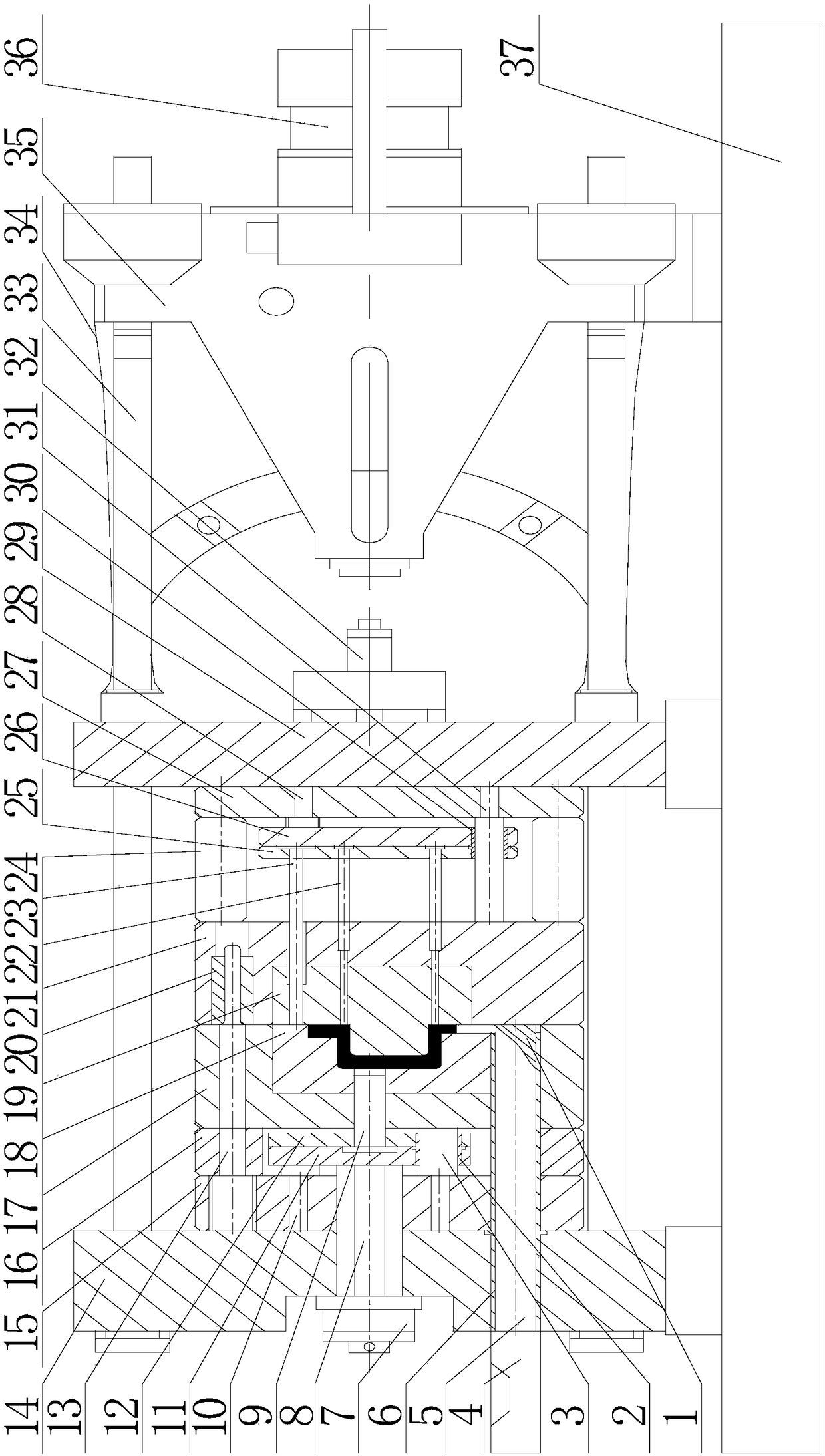

[0027] figure 1 It is a structural schematic diagram of an extrusion die-casting machine according to Embodiment 1 of the present invention, the front view, and the section between the fixed mold seat plate and the movable mold seat plate. Such as figure 1 As shown, the fixed mold seat plate 14 (also called the static mold seat plate or head plate), the movable mold seat plate 29 (also called the movable mold seat plate or the middle plate), and the tail plate 35 of the extrusion die casting machine in this embodiment are Installed on the body base 37 of the extrusion die-casting machine successively from left to right, the fixed mold base plate 14 is fixed on the upper left side of the body base 37, the tail plate 35 is fixed on the upper right side of the body base 37, and the movable mold base plate 29 is fixed on the upper right side of the body base 37. Between the mold base plate 14 and the tail plate 35, four connecting guide columns 33 connect the fixed mold base plat...

Embodiment 2

[0040] The design and process flow of a squeeze die-casting machine are basically the same as in Embodiment 1. The difference from Embodiment 1 is that this embodiment is provided with a plurality of The extrusion rods 9 correspond to the positions where the casting needs to be extruded and fed. The casting in this embodiment is a wheel-shaped part with 6 symmetrically distributed ribs, and there are 6 thick and large positions that are prone to shrinkage and shrinkage defects. The hot joint positions need to be squeezed and fed at the 6 thick and large positions . The specific method is: 6 extruding rods 9 are installed on the extruding push plate 11, corresponding to 6 thick and large positions of the casting. When closing the mold, the hydraulic system of the die-casting machine drives the piston 8 of the extrusion cylinder 7 to move to the left, and drives the six extrusion rods 9 fixed on the extrusion push plate 11 to move linearly to the left to reach the leftmost posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com