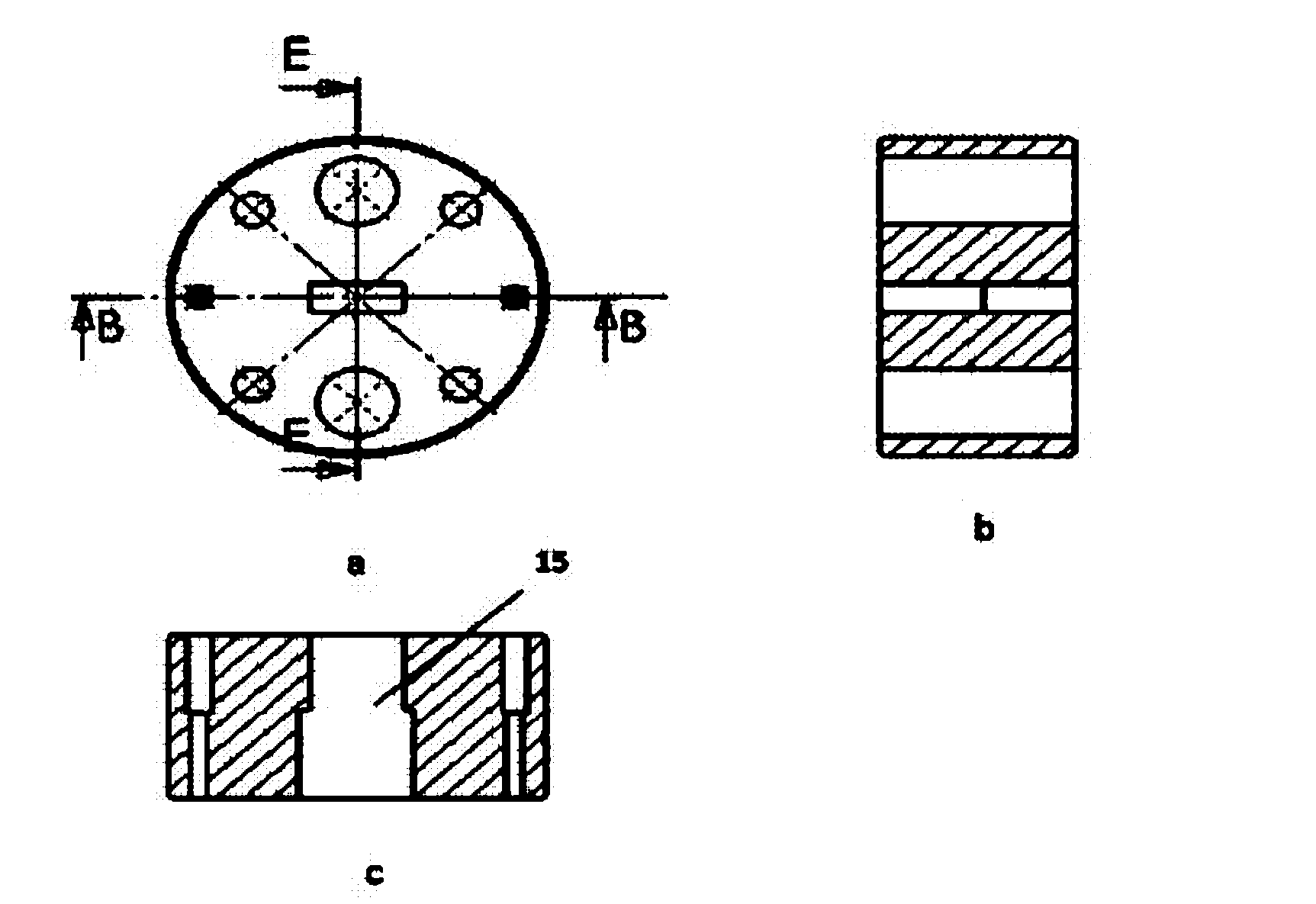

Backpressure equal-channel angular extruding mould

A mold and back pressure technology, applied in the field of material processing and extrusion, can solve the problems of complicated operation, low extrusion efficiency, no back pressure device, etc., and achieve good tissue uniformity, increase cross-sectional area, and improve extrusion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 7. After the mold and the sample reach the predetermined temperature, set the pressure of the back pressure, put the sample into the extrusion groove between the two guide rods, and squeeze the sample for the first pass, and the same pass can be carried out Multiple samples are continuously extruded, and the next sample is extruded from the previous sample from the horizontal channel, which is easy to operate and does not need to dismantle the mold. After 1-4 passes of extrusion, 4 samples are extruded in each pass. After 1-4 passes, the plasticity of the sample has been improved, so the 5-8 passes of the sample can be extruded at a lower temperature without cracks. Reduce the temperature of the mold and the sample, and extrude at a lower temperature for 5-8 passes. When the difficult-to-deform magnesium alloy is extruded under the traditional ECAP die and process, it can only be extruded at a relatively high temperature, and the sample will break when the temperature ...

Embodiment 2

[0041] Experimental results: According to Jin Li's doctoral thesis, through two-step ECAP deformation, 1-4 passes at 225°C, and 5th pass at 180°C, the grains are refined to about 1um. When extruding with the present invention, a back pressure of 50Mpa is applied during extrusion, and the 1-4 passes are extruded at 225°C, the extrusion temperature of the 5th pass can be reduced to 150°C, and the grains are refined to about 0.7μm , Yield strength increased from 230Mpa to 290Mpa. , Example 2: Equal channel angle extrusion rare earth magnesium alloy GW103

[0042] GW103 is a rare earth magnesium alloy with relatively high hardness and poor plasticity. It needs to be extruded at a higher temperature when extruded with a traditional mold. The mold is easily damaged due to excessive pressure, and the strength and structure of the mold are also high. .

[0043] Cut the sample into a square sample of 12 × 12 × 12mm as in Example 1, install the mold according to the steps in Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com