Granular terminal automatic feeding and crimping device

A technology for automatic feeding and crimping equipment, applied in connection, electrical components, circuits, etc., can solve problems such as low work efficiency, complex equipment structure, unfavorable terminal positioning, etc., to improve efficiency, improve extrusion efficiency, and improve labor efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

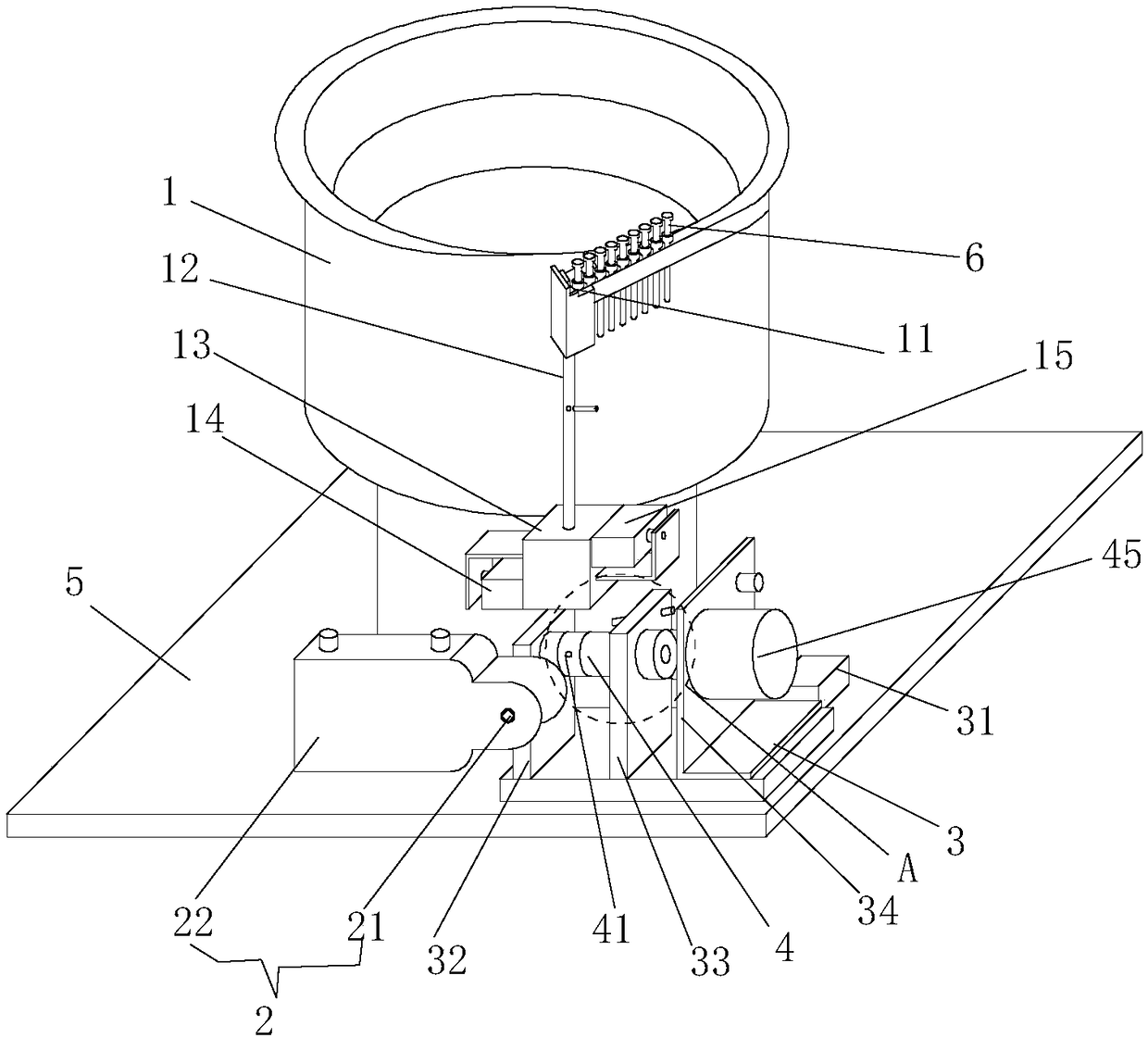

[0037] Such as figure 1 As shown, the automatic feeding and crimping equipment for bulk terminals in this embodiment includes a base 5 and a vibrating plate 1 placed on the base 5, the terminals to be crimped are placed in the vibrating plate 1, and the discharge port of the vibrating plate 1 Below 11, a terminal drop tube 12 is vertically arranged, and the inner diameter of the terminal drop tube 12 matches the maximum diameter of the terminal to be crimped with a small gap, so that the terminals in the vibrating plate 1 can be sorted and output by the vibrating plate 1, and then they can enter the terminals vertically in sequence. The drop tube 12, and due to the limitation of the inner diameter of the terminal drop tube 12, the terminals entering the terminal drop tube 12 are arranged end-to-end in sequence. Nylon straps are embedded in the inner wall of the vibrating plate 1 to prevent the terminals from directly contacting the metal inner wall of the vibrating plate 1 dur...

Embodiment 2

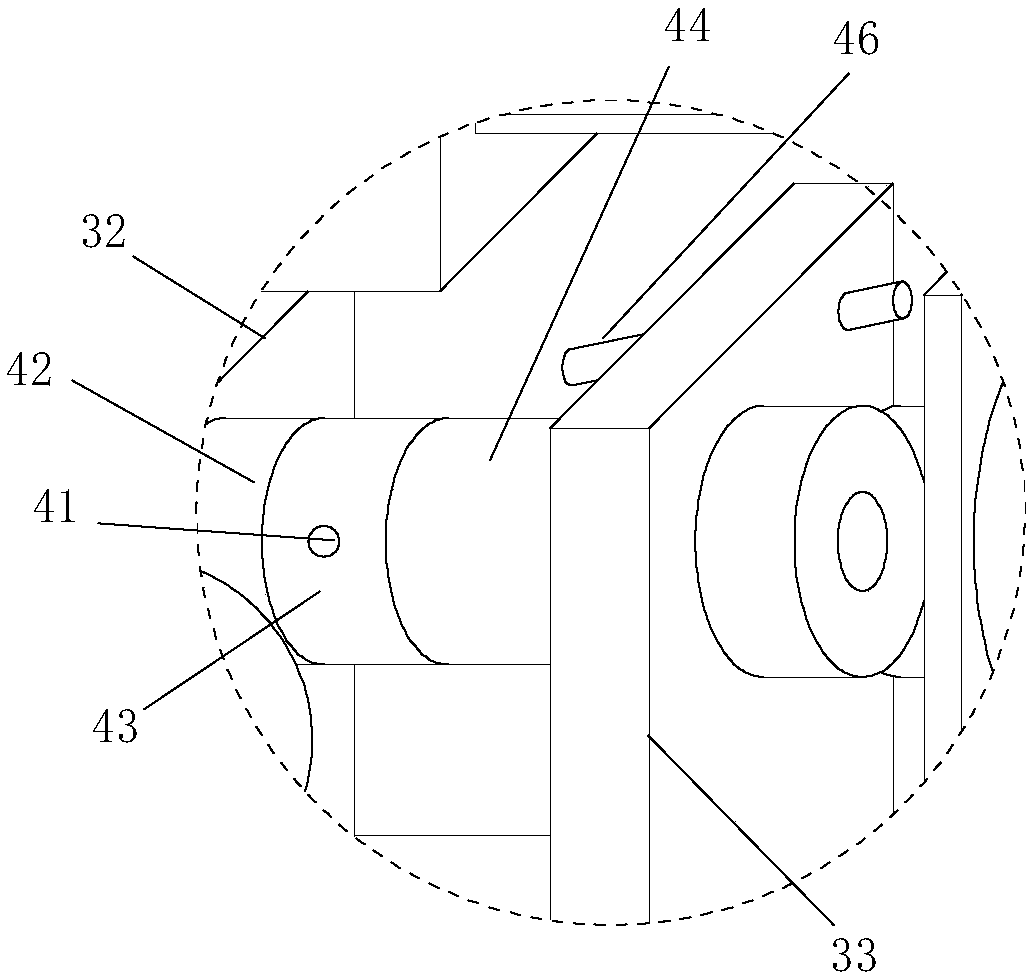

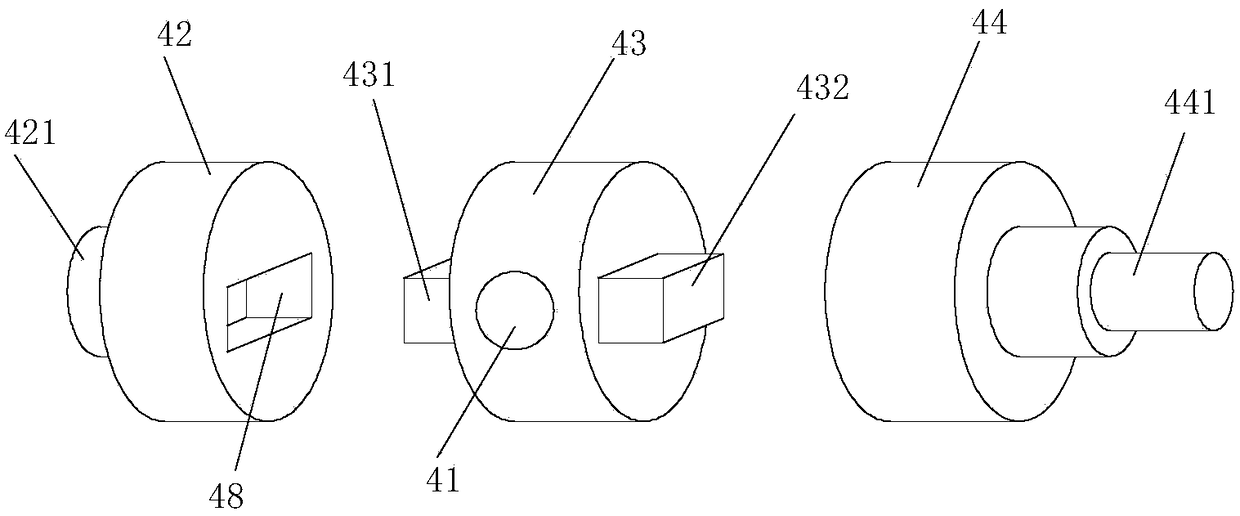

[0049] On the basis of Embodiment 1, the automatic feeding and crimping equipment for bulk terminals in this embodiment has the following deformations: the automatic feeding and crimping equipment for bulk terminals in this embodiment is suitable for performing crimping on terminals with crimping parts placed at the front Feed crimping, such as Image 6 As shown, the terminal ferrule of this embodiment also includes a threaded portion 463, a slot 464, a through hole 462 and a tapered hole 461. By adjusting the axial lengths of the tapered hole 461 and the through hole 462, the tapered hole 461 An accommodating cavity 465 suitable for arranging the terminal tail end and the reducing section is formed in the terminal ferrule 46 .

[0050] When the three-stage terminal positioning rotating shaft 4 is in the initial state, the opening of the terminal ferrule 46 is placed directly below the opening at the bottom end of the terminal accommodating groove, and the terminal ferrule 46 ...

Embodiment 3

[0053] The bulk terminal automatic feeding and crimping equipment described in Example 1 is suitable for terminals with crimping parts placed at the tail end, such as aviation pins 6, such as Figure 7As shown, the aviation pin 6 includes a pin reducing section 63 in the middle, the front part of the pin reducing section 63 is the front end 62 of the pin, and the rear part of the pin reducing section 63 is the tail end crimping part 61.

[0054] The automatic feeding and crimping method for aviation pins includes the following steps:

[0055] A. Close the lower stopper cylinder 14 of the terminal accommodating groove, open the upper stopper cylinder 15, start the vibrating plate 1, and arrange the aviation pins 6 in the vibrating plate 1 in an orderly manner, so that the tail ends of the aviation pins 6 The crimping part 61 is on the top, the front end 62 of the pin is on the bottom and reaches the discharge port one by one, and enters the terminal drop tube 12 and the termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com