High-rigidity propellant management device for large surface tension storage box

A surface tension storage tank and management device technology, which is applied in the field of high-rigidity propellant management devices for large surface tension storage tanks, can solve the problems of no PMD detailed structural design of storage tanks, failure to meet propellant management requirements, and small discharge flow, etc. Achieve the effects of enhancing environmental adaptability, high propellant collection capacity, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

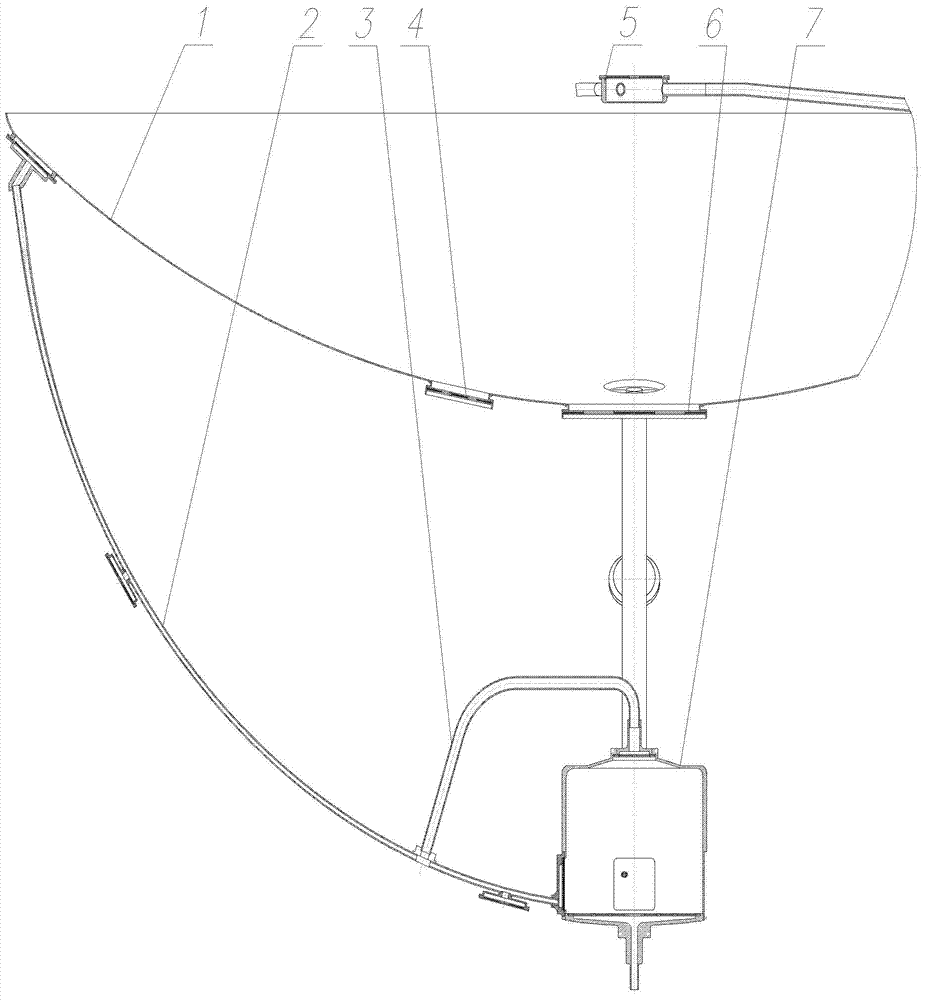

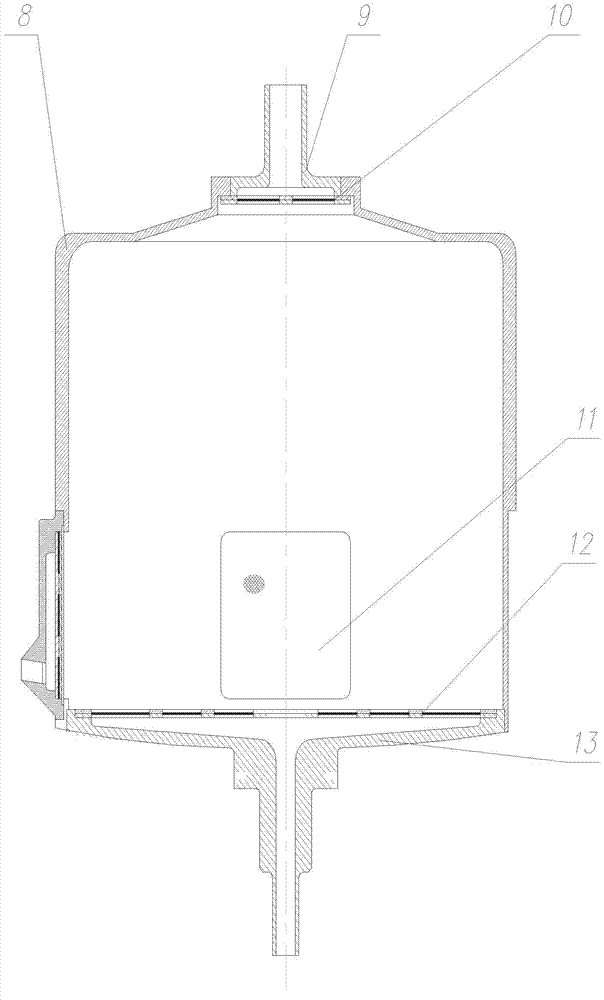

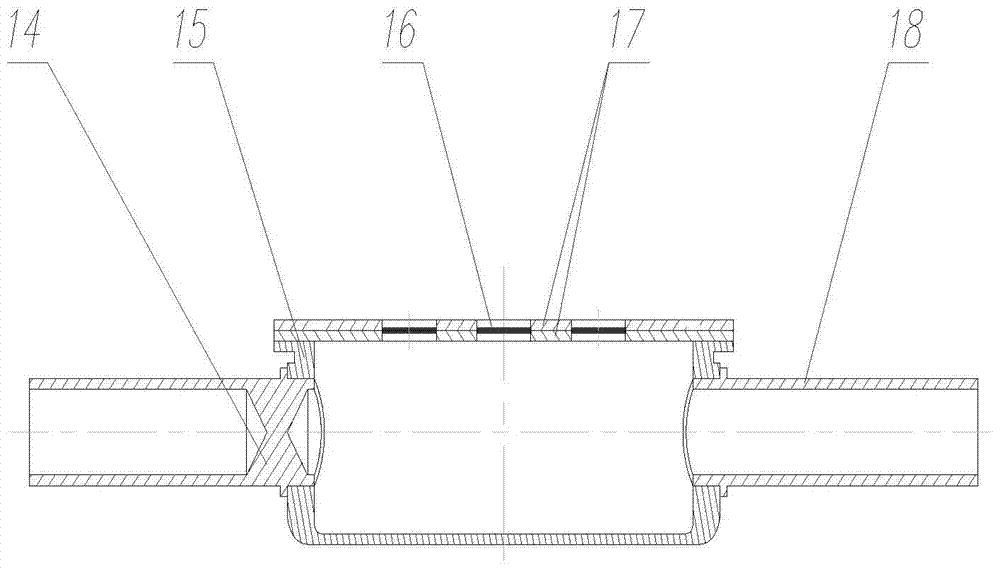

[0023] Such as figure 1 A high-rigidity PMD of a large surface tension tank is shown, which is placed on the inner surface of the surface tension tank and maintains a certain gap with the inner surface, and is used to collect the propellant in the tank, prevent the pressurized gas from entering, and push the propellant along the The channel is transported to the outlet of the bubble trap to ensure that the propellant in the storage tank flows into the outlet of the storage tank along the channel and enters the thruster. The device includes the following components: a middle bottom 1, a liquid channel 2, an air release channel 3, a small middle bottom collector 4, an air release cup 5, a middle bottom large collector 6, and an air bubble trap 7. Among them, the middle bottom 1 is placed in the lower half of the storage tank; one end of the corner collector of the liquid channel 2 is connected to the middle bottom 1, and the other section is connected to the bubble trap 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com