Anti-shrinkage modified EVA foam shoe material and preparation method thereof

An anti-shrinkage and anti-shrinkage agent technology, applied in footwear, applications, apparel, etc., to overcome high temperature resistance, reduce the value of residual stress, and reduce the trend of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

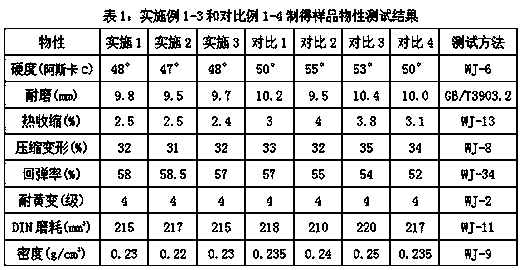

Examples

Embodiment 1

[0020] This embodiment provides an anti-shrinkage modified EVA foam shoe material, which is composed of the following components in parts by weight: 43 parts of Formosa Plastics 7470, 5 parts of Formosa Plastics 7350, 6 parts Taipoly 3312, 7 parts of Dow 3745, 10 parts of anti-shrinkage agent 203#, 1 part of zinc oxide, 7 parts of wear-resistant agent, 2 parts of filler, 0.3 parts of active agent, 0.65 parts of handover Joint agent, 2.3 parts of blowing agent, 4 parts of titanium dioxide. Among them, the anti-wear agent is a pre-dispersed masterbatch anti-wear agent, such as the model 662 anti-wear agent produced by Haili Company; the filler is talcum powder; the active agent is stearic acid; the crosslinking agent is dicumyl peroxide. DCP; Azodicarbonamide AC is selected as foaming agent; DuPont 103# is selected as titanium dioxide. The melt index of Formosa Plastics 7470 is 4.0g / 10min, the VA content is 26%, the melting point is 76°C, and the softening point is 48°C; the me...

Embodiment 2

[0022] This embodiment provides an anti-shrinkage modified EVA foam shoe material, which is composed of the following components in parts by weight: 40 parts of Formosa Plastics 7470, 6 parts of Formosa Plastics 7350, 8 parts Taipoly 3312, 7 parts of Dow 3745, 11 parts of anti-shrinkage agent 203#, 1.3 parts of zinc oxide, 8 parts of wear-resistant agent, 3 parts of filler, 0.4 parts of active agent, 0.6 parts of cross-linking agent Joint agent, 2.5 parts of blowing agent, 3.5 parts of titanium dioxide. Among them, the anti-wear agent is a pre-dispersed masterbatch anti-wear agent, such as the model 662 anti-wear agent produced by Haili Company; the filler is talcum powder; the active agent is stearic acid; the crosslinking agent is dicumyl peroxide. DCP; Azodicarbonamide AC is selected as foaming agent; DuPont 103# is selected as titanium dioxide. The melt index of Formosa Plastics 7470 is 4.0g / 10min, the VA content is 26%, the melting point is 76°C, and the softening point ...

Embodiment 3

[0024] This embodiment provides an anti-shrinkage modified EVA foam shoe material, which is composed of the following components in parts by weight: 42 parts of Formosa Plastics 7470, 5 parts of Formosa Plastics 7350, 7 parts Taipoly 3312, 8 parts of Dow 3745, 12 parts of anti-shrinkage agent 203#, 1.5 parts of zinc oxide, 6 parts of wear-resistant agent, 2.5 parts of filler, 0.5 parts of active agent, 0.7 parts of cross-linking agent Joint agent, 2.0 parts of blowing agent, 3 parts of titanium dioxide. Among them, the anti-wear agent is a pre-dispersed masterbatch anti-wear agent, such as the model 662 anti-wear agent produced by Haili Company; the filler is talcum powder; the active agent is stearic acid; the crosslinking agent is dicumyl peroxide. DCP; Azodicarbonamide AC is selected as foaming agent; DuPont 103# is selected as titanium dioxide. The melt index of Formosa Plastics 7470 is 4.0g / 10min, the VA content is 26%, the melting point is 76°C, and the softening point ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com