Easily melted foamed polyethylene bead with strong temperature tolerance and preparation method thereof

A technology for foaming polyethylene and polyethylene, which is applied in the field of preparation of polyethylene foam beads, can solve the problem of surface unevenness, affect the melt strength of pre-expanded particles, and deteriorate the surface flatness of EPE molding parts. Deformation resistance and other issues, to achieve high temperature resistance, shorten the molding time, and ensure smooth penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

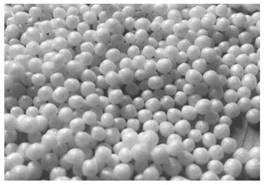

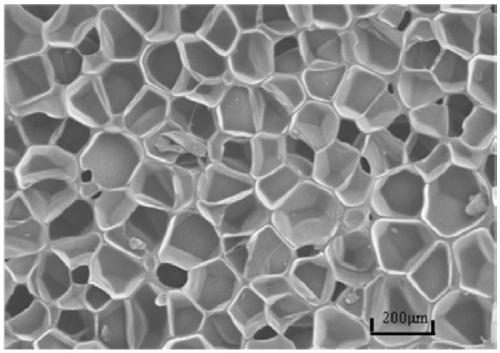

Image

Examples

Embodiment

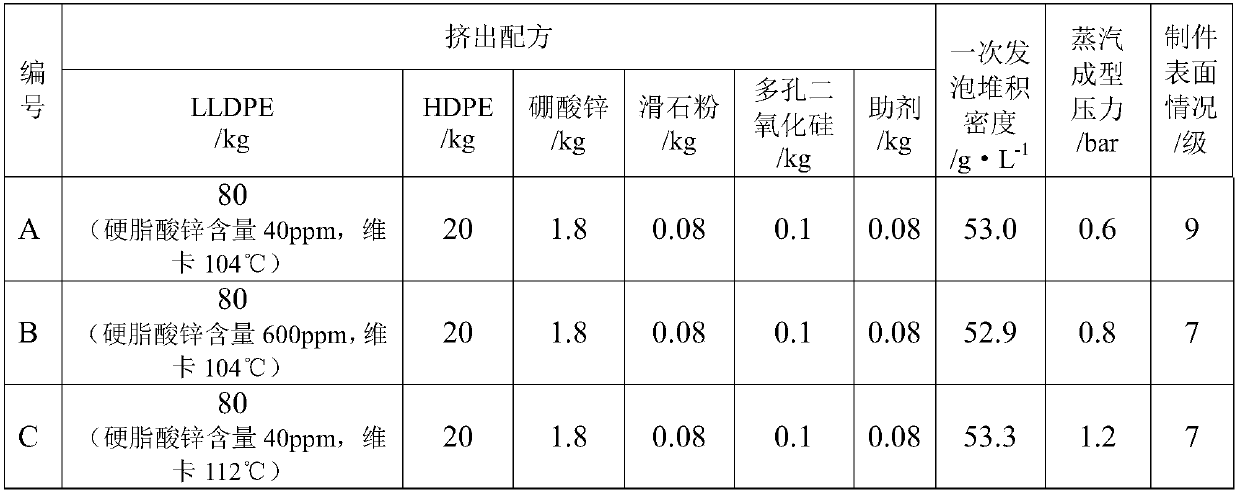

[0025] Examples A-F were made according to the formula in the table below, and the first-time EPE beads were directly sampled for sheet forming test. Place the molded board (46cm×35cm×6cm) in a drying room at 70°C for 5 hours, then cool it naturally for 3 hours, and compare the surface conditions of the board. it is good.

[0026]

[0027]

[0028]It can be seen from the above table that the selection of PE raw materials is particularly important. Changes in the content of acid absorbing agents and fluctuations in the Vicat softening point of low-density polyethylene have a greater impact on the final molding pressure of EPE beads and the surface condition of molded parts. . At the same time, the synergistic effect of zinc borate, talcum powder, and silicon dioxide, the three inorganic foaming aids, and the amount of color masterbatch and compound flame retardant have a synergistic effect to a certain extent. The primary product prepared by the same foaming procedure T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com