Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Poor uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

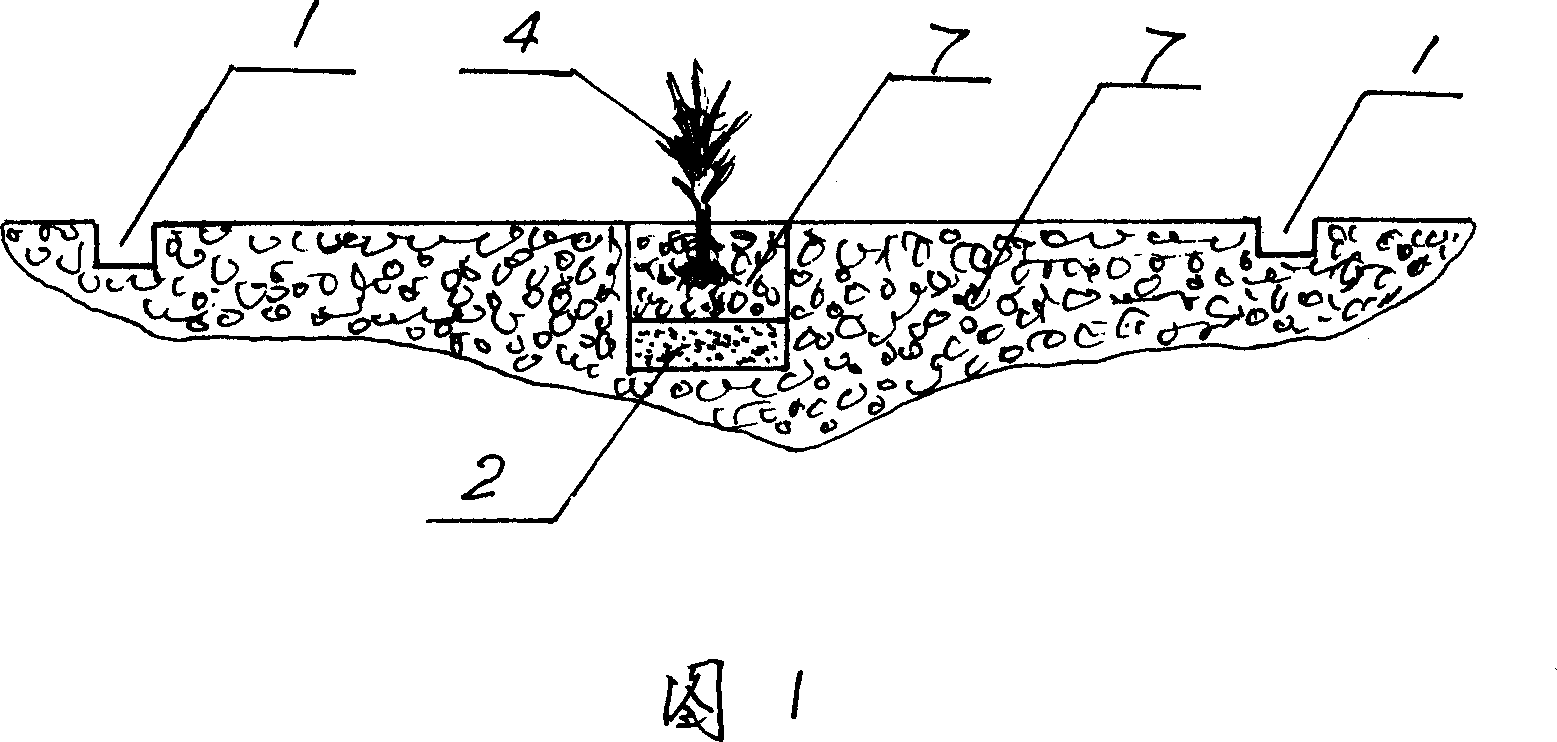

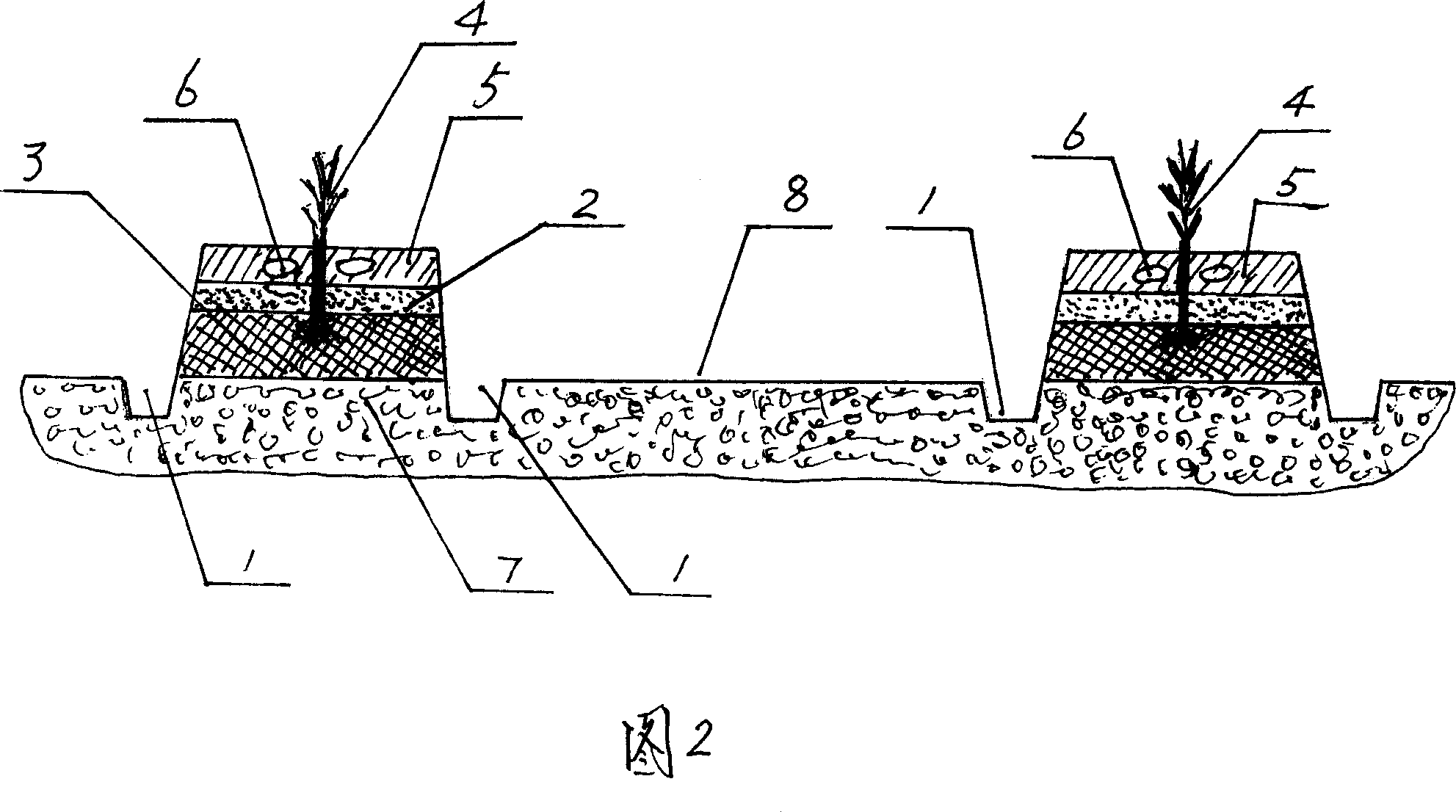

Ridge shallow-growing root-limiting cultivating method of vine

InactiveCN1954662AEnsure differentiationPromote growthCultivating equipmentsViticultureDrip irrigation

A method for culturing grape vine by limiting the growth of its root includes such steps as ridging in a field, digging drain canals at both side of each ridge, applying organic fertilizer onto the surface of each ridge, mixing it with soil to become nutritive soil layer, planting the seedlings of grape vine in it in shallow planting mode, growing new root, covering an organic fertilizer layer, covering a layer of straw or stalk, and laying the water tube in it for drip irrigation. Its advantages are short culture period and high quality of grape.

Owner:马纲

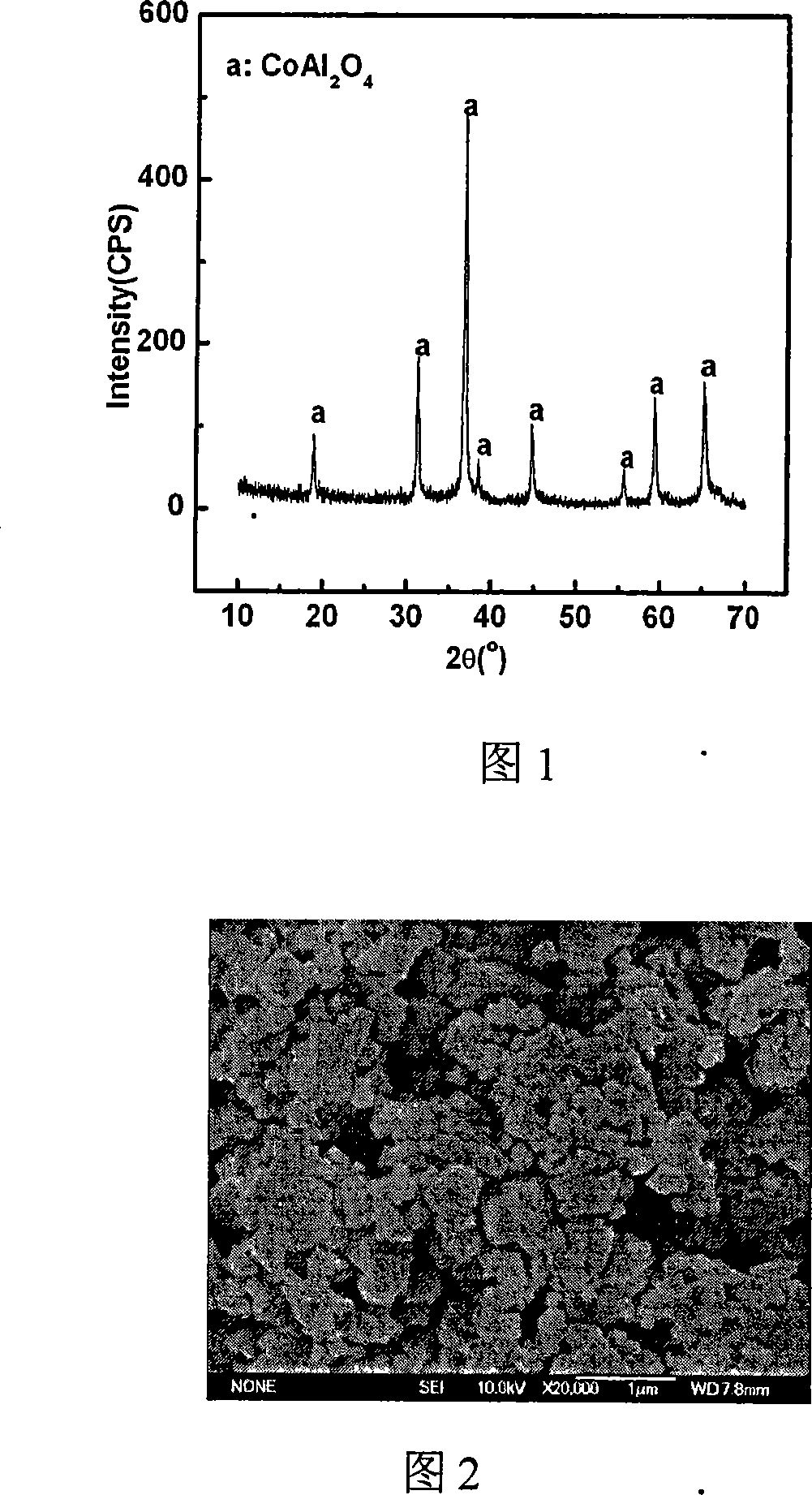

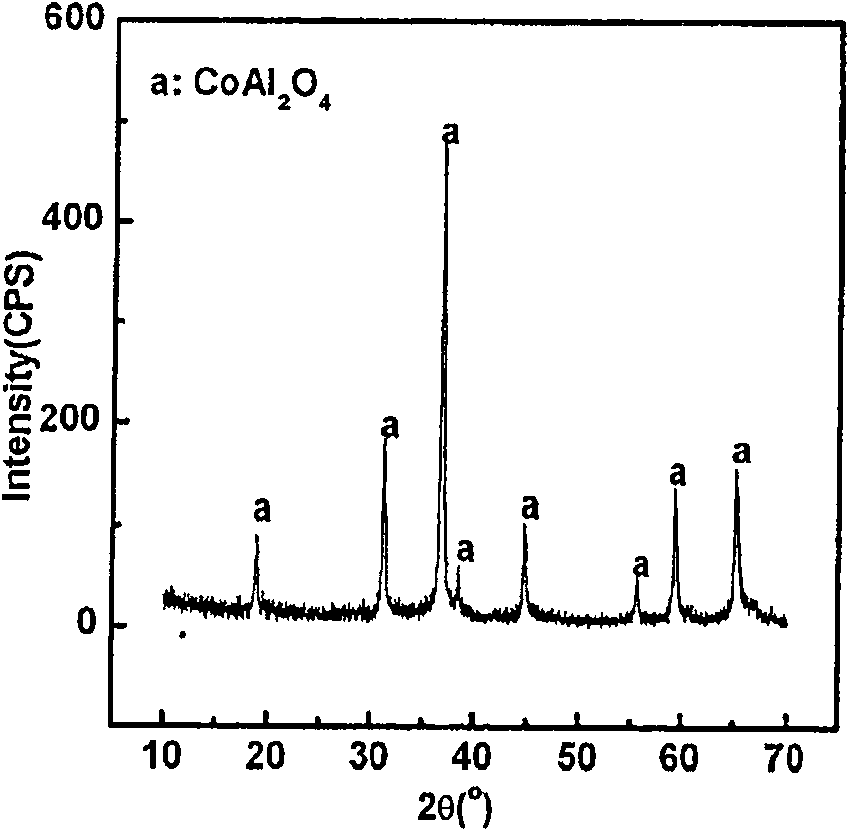

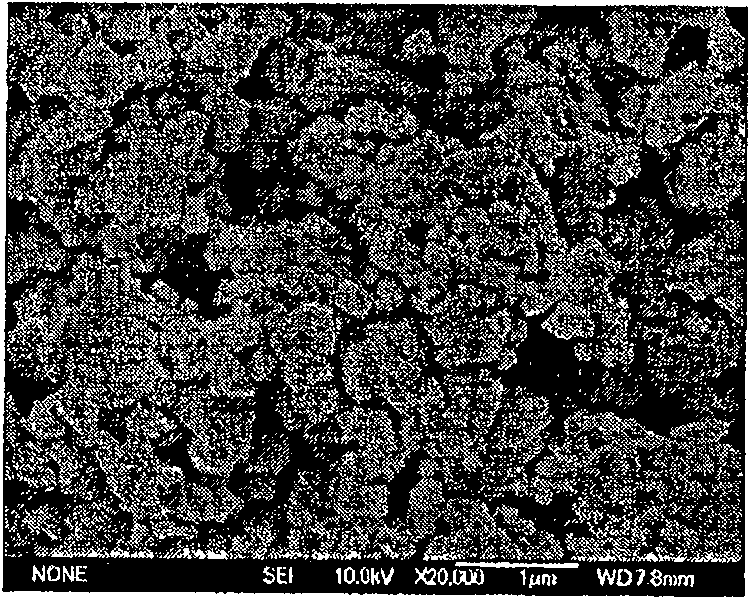

Method for preparing ultra-fine cobalt blue pigment under low-temperature

InactiveCN101117452AGood grain developmentImprove hair colorPigmenting treatmentAluminium oxides/hydroxidesFiltrationAluminium hydroxide

A method for preparing superfine cobalt blue colorant at low temperature comprises the following steps: firstly, cobaltosic oxide, aluminium hydroxide, zinc oxide and chromic oxide are mixed according to the general chemical formula of Co1-xZnxAl2-yCryO4 to obtain reactants, wherein x is more than or equal to 0 and is less than 1, while y is more than or equal to 0 and is less than or equal to 2; secondly, one sort or more sorts of KOH, NaOH, KCl, NaCl, Li2SO4 and Na2SO4 are added into the reactants to obtain mixture after being mixed uniformly; finally, the mixture is calcined 1 to 2 hours at the temperature ranging from 800 DEG C to 1,000 DEG C and then the calcined products is under the treatments of grinding, cleaning and filtration. The invention possesses simple technical process and equipment, convenient operation, cheap and easily obtained raw material and low cost for preparing colorant; moreover, the colorant obtained through adopting the preparing method is characterized in high development degree of crystal grain, ideal chromophoric effect of colorant, fine granularity, less agglomeration and good homogeneity etc.; meanwhile, the introduction of salt can lower synthesis temperature.

Owner:SHAANXI UNIV OF SCI & TECH

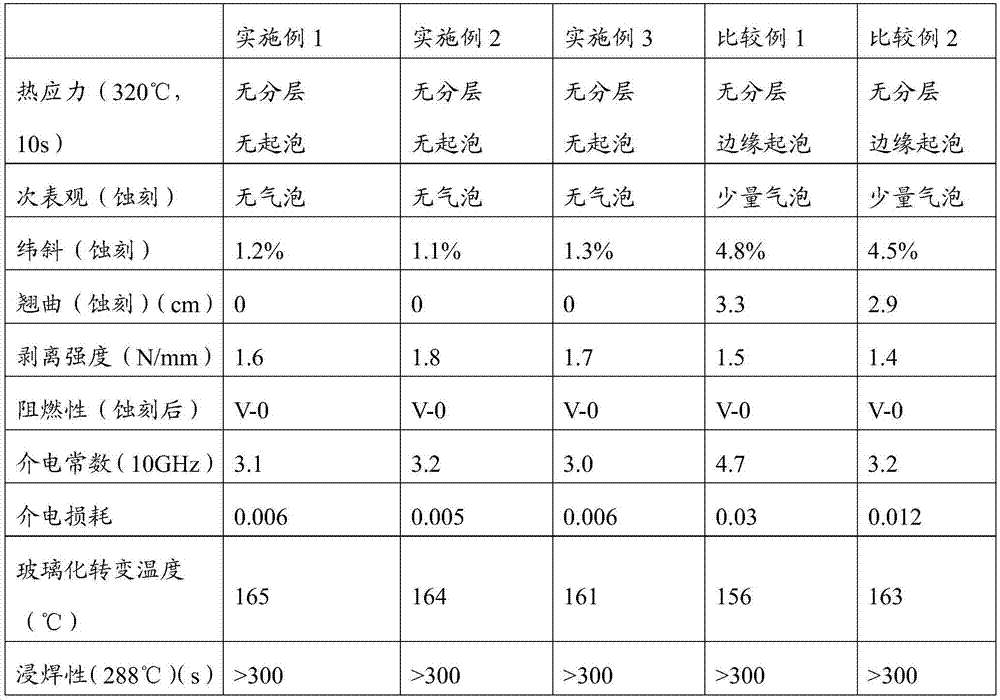

Ultrathin copper clad laminate and production method thereof

ActiveCN105437668ASmall sizeDimensionally stableLamination ancillary operationsSynthetic resin layered productsCross-linkDielectric loss

The invention relates to the technical field of copper clad laminates and particularly relates to an ultrathin copper clad laminate suitable for high-frequency and high-speed transmission. The ultrathin copper clad laminate comprises a copper foil, a piece of setting cloth and an insulating layer which is arranged between the copper foil and the setting cloth, wherein the insulating layer is formed by curing resin glue liquid which comprises the following components in parts by weight: 50-100 parts of first epoxy resin, 0-50 parts of second epoxy resin, 1-35 parts of a cross-linking curing agent, 0-5 parts of a cross-linking curing accelerator and 0-100 parts of filler; the first epoxy resin is dicyclopentadienephenol epoxy resin and / or biphenyl epoxy resin; and the second epoxy resin is bisphenol A epoxy resin and / or AF epoxy resin. According to the invention, by adopting the setting cloth, the defects such as warping and instable size frequently occurring in an ultrathin copper clad laminate are solved; the copper clad laminate is produced by pressing the setting cloth and the copper foil coated with the resin glue liquid and has relatively low dielectric constant and causes relatively low dielectric loss; and the invention also relates to a production method of the ultrathin copper clad laminate.

Owner:GUANGDONG SHENGYI SCI TECH

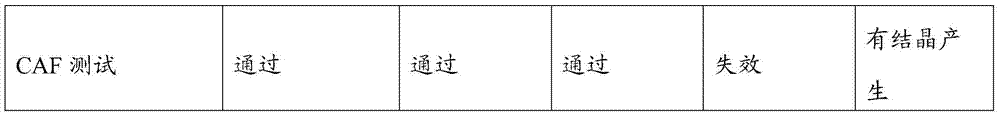

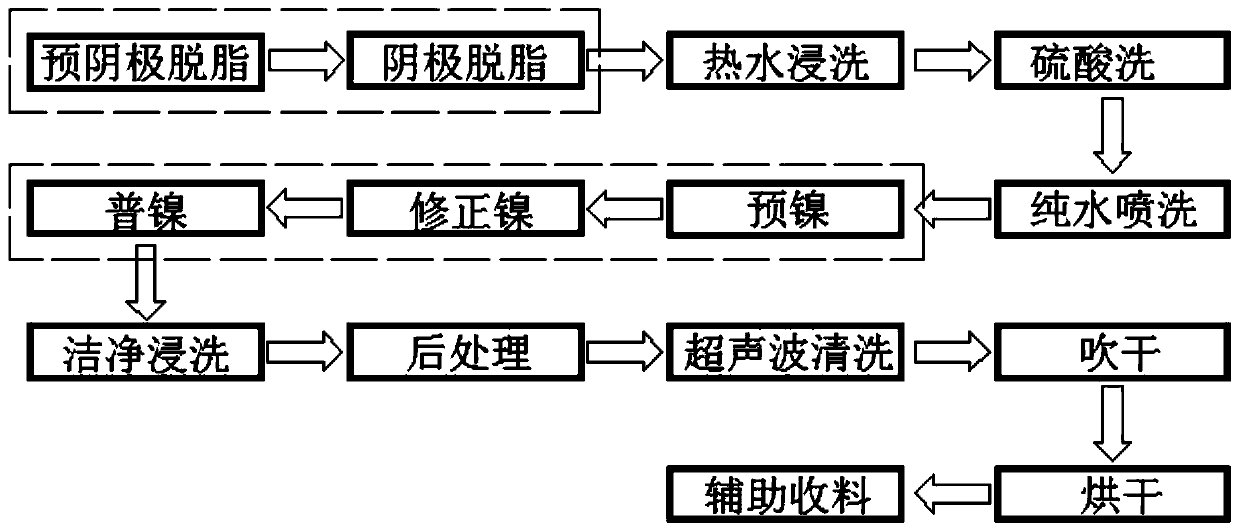

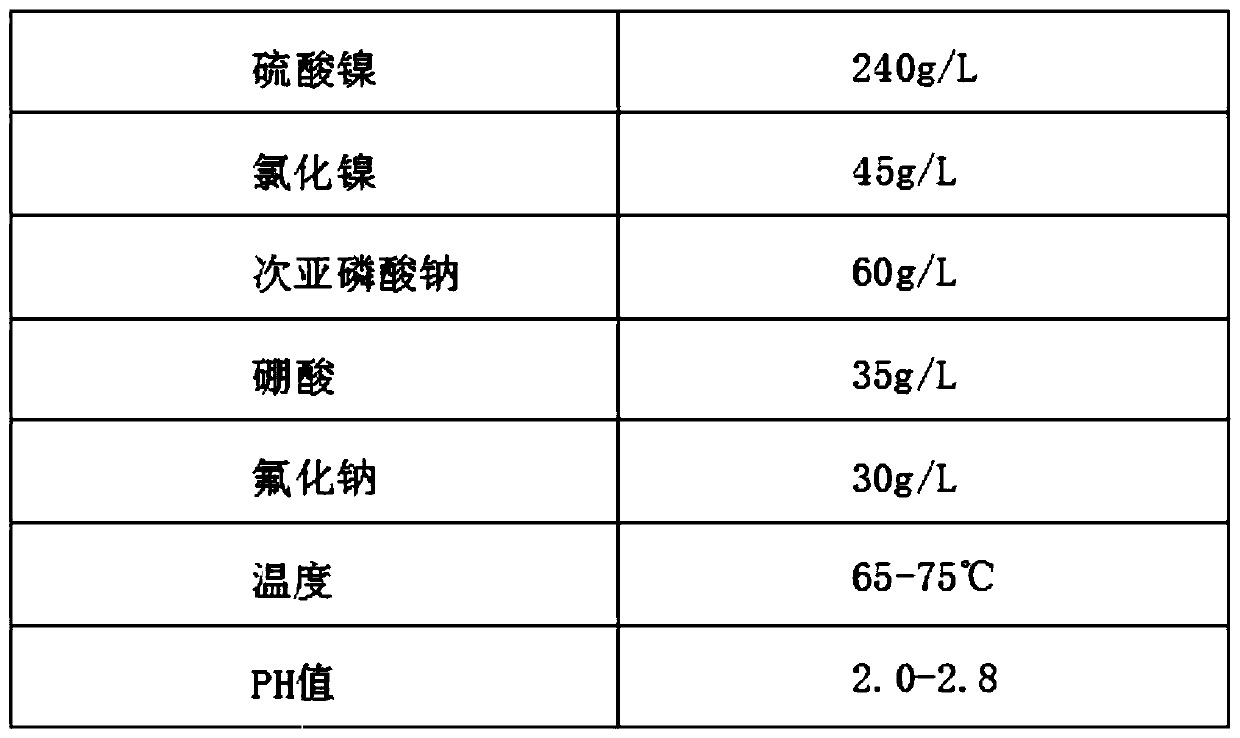

Process for optimizing nickel-plated appearance of ultra-wide stainless steel plate

The invention discloses a process for optimizing the nickel-plated appearance of an ultra-wide stainless steel plate and belongs to the technical field of nickel plating. The process for optimizing the nickel-plated appearance of the ultra-wide stainless steel plate comprises the following steps: step 1, degreasing; step 2, immersion washing with hot water; step 3, washing with sulfuric acid; step4, spray washing with pure water; step 5, nickel pre-plating; step 6, corrective nickel plating; step 7: general nickel plating; step 8, cleaning and immersion washing; step 9, post-treatment; step 10, ultrasonic washing; step 11, blow-drying; step 12, oven-drying; and step 13, auxiliary collecting. By the adoption of the process, the nickel and phosphorus alloying process can be added between the pre-plating operation and the plating operation on a general nickel-plated layer; accordingly, not only can the plated layer deposition speed be improved, but also a lattice of the nickel-plated layer can be remarkably improved, the lattice being compact in structure can be refined, and the plated layer porosity can be reduced; and then, the appearance uniformity and glossiness of the general nickel-plated layer can be guaranteed, the plated layer density, uniformity and bonding strength can be improved, and the corrosion-resistant property can be improved.

Owner:东莞市康圣精密合金材料有限公司

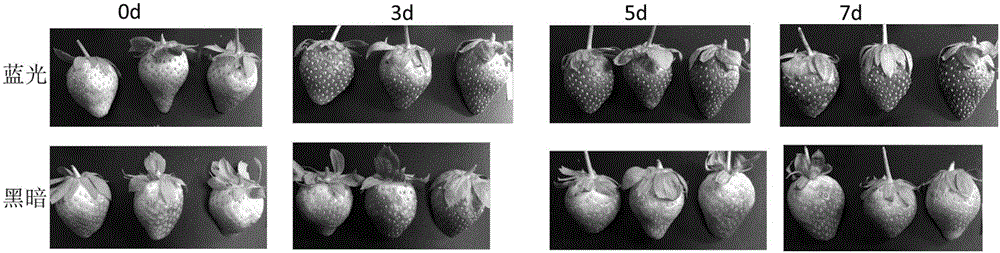

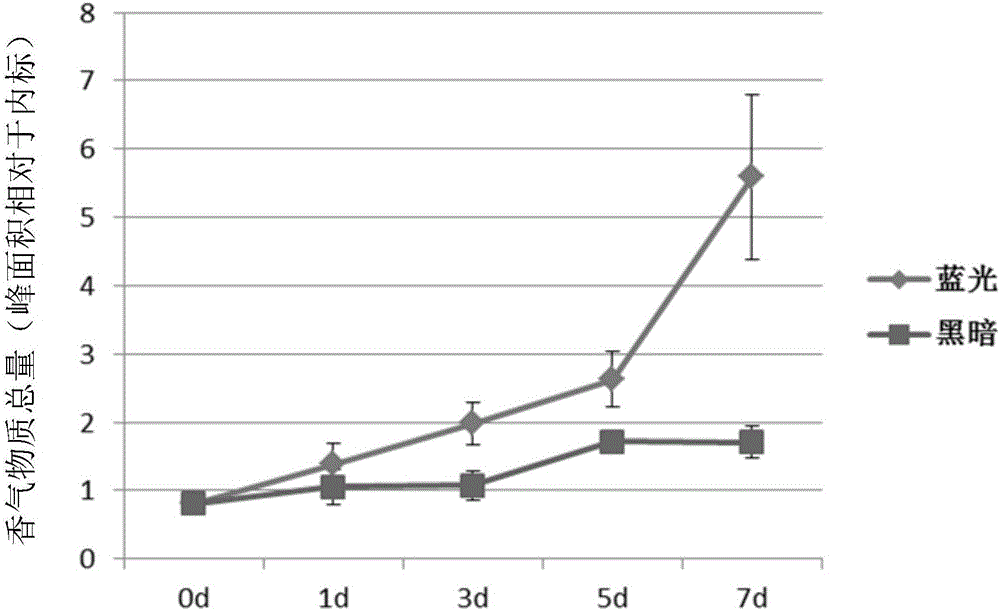

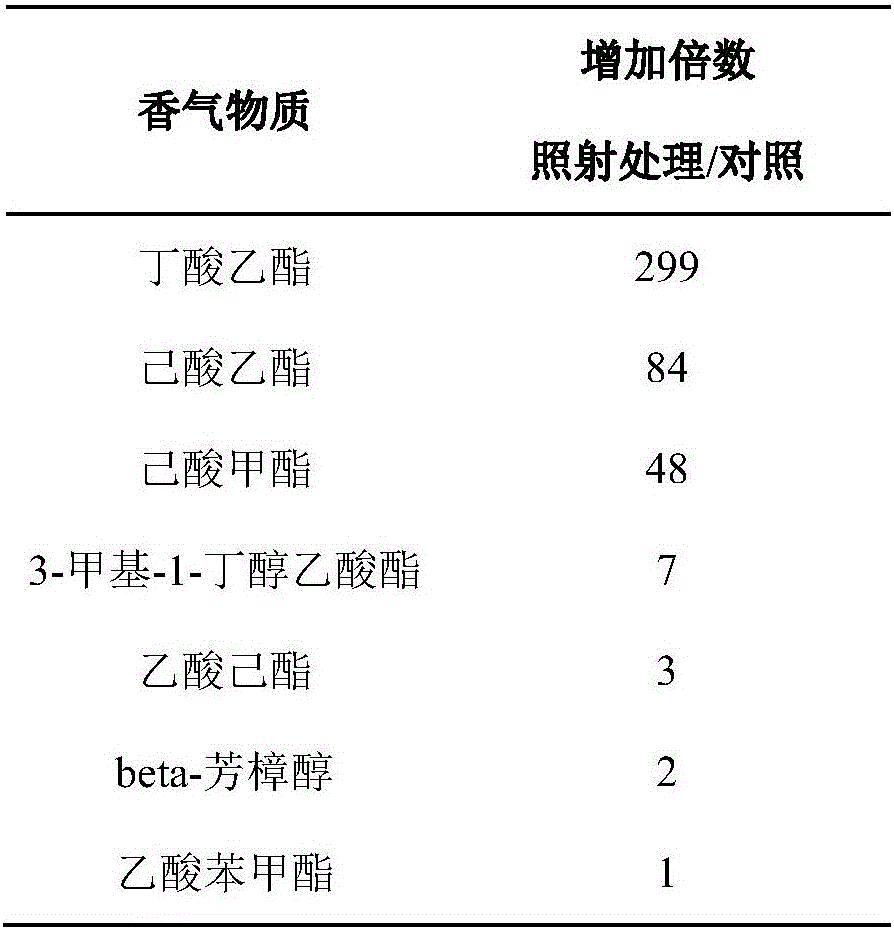

Method for promoting aroma and coloring of strawberry fruits

InactiveCN105660823AIncrease aromaGood colorFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingFood flavorAroma aroma

The invention discloses a method for promoting aroma and coloring of strawberry fruits. With a method combining an LED blue light source and low-temperature treatment, picked non-completely ripe strawberry fruits are irradiated by utilizing blue light with the wavelength of 460nm and the illumination intensity of 5,200lux under the condition that the temperature is 4 DEG C and the relative humidity is 80%, and the irradiated strawberry fruits are red in color and obvious in aroma, so that the refreshing time of the strawberry fruits is prolonged, the flavor quality, comprising coloring and aroma, of the strawberry fruits is improved, and the quality of the picked strawberry fruits within the refreshing time is totally improved. An integrated technology adopted by the method comprises illumination treatment and temperature treatment which are both pollution-free green physical technologies; and the method has the advantages of low cost, high uniformity, simplicity for operation and the like.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

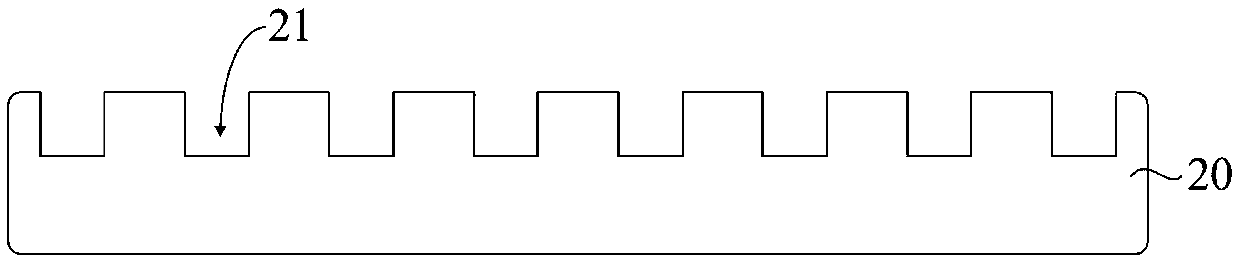

Dressing method of grinding pad

InactiveCN110722457AImprove completenessExtended service lifeAbrasive surface conditioning devicesMechanical engineeringMaterials science

The invention relates to a dressing method of a grinding pad. The grinding pad is dressed by using a dressing disc of a grinding pad dresser, wherein during the dressing of a grinding area, in the direction from the center of the grinding pad to the edge, the downward pressure exerted by the dressing disc on the grinding area gradually decreases, and the dressing degree of the grinding pad is different with different downward pressure. According to the dressing method of the grinding pad, the problem that the homogeneity of the grinding pad becomes poor after a period of grinding process in the existing CMP process can be improved, grinding liquid is advantageously and evenly distributed in a groove of the grinding pad, the grinding removal rate can be increased, and the service life of the grinding pad is prolonged.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

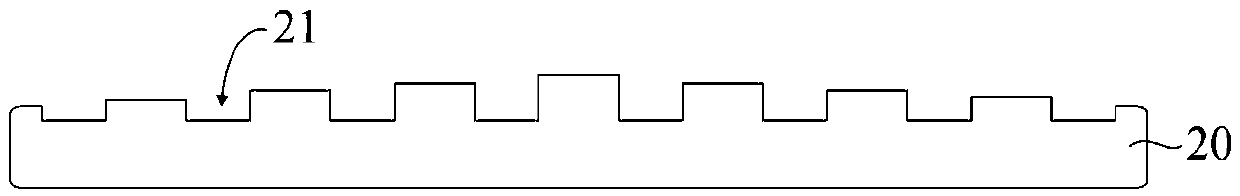

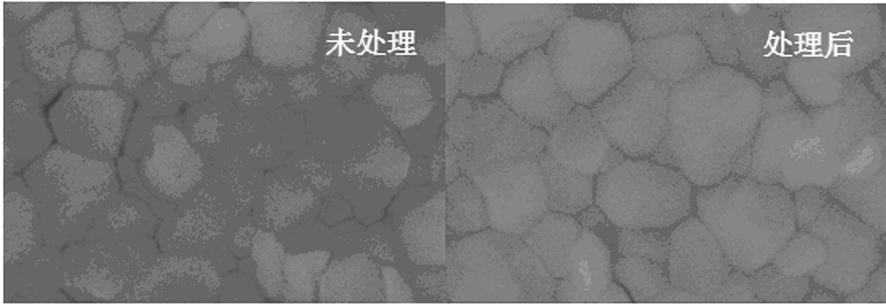

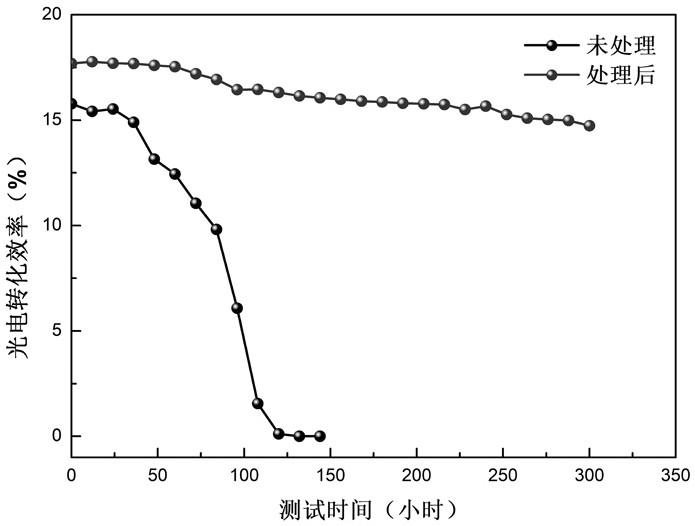

Perovskite precursor solution for improving stability of perovskite solar cell

ActiveCN111740015AImprove stabilityPoor uniformityFinal product manufactureSolid-state devicesSolar batteryCesium iodide

The invention discloses a perovskite precursor solution for improving the stability of a perovskite solar cell, and the method comprises the steps of adding ioformamidine and cesium iodide into a solvent, adding bromomethylamine after stirring, adding lead iodide and 3, 4-dichloroaniline after stirring, and obtaining the perovskite precursor solution for improving the stability of the perovskite solar cell through stirring; spin coating the perovskite precursor solution for improving the stability of the perovskite solar cell on a substrate, and obtaining a perovskite thin film through thermalannealing as a light absorption layer of the solar cell. The perovskite precursor solution for improving the stability of the perovskite solar cell prepared by the invention replaces an existing perovskite layer, the defects in the existing perovskite mineralization technology are solved, and a perovskite stability improvement means that has low requirements for the process environment, is convenient in preparation method, can realize the long-time stable performance in a common environment and is used for the cell preparation process, is provided.

Owner:SUZHOU UNIV

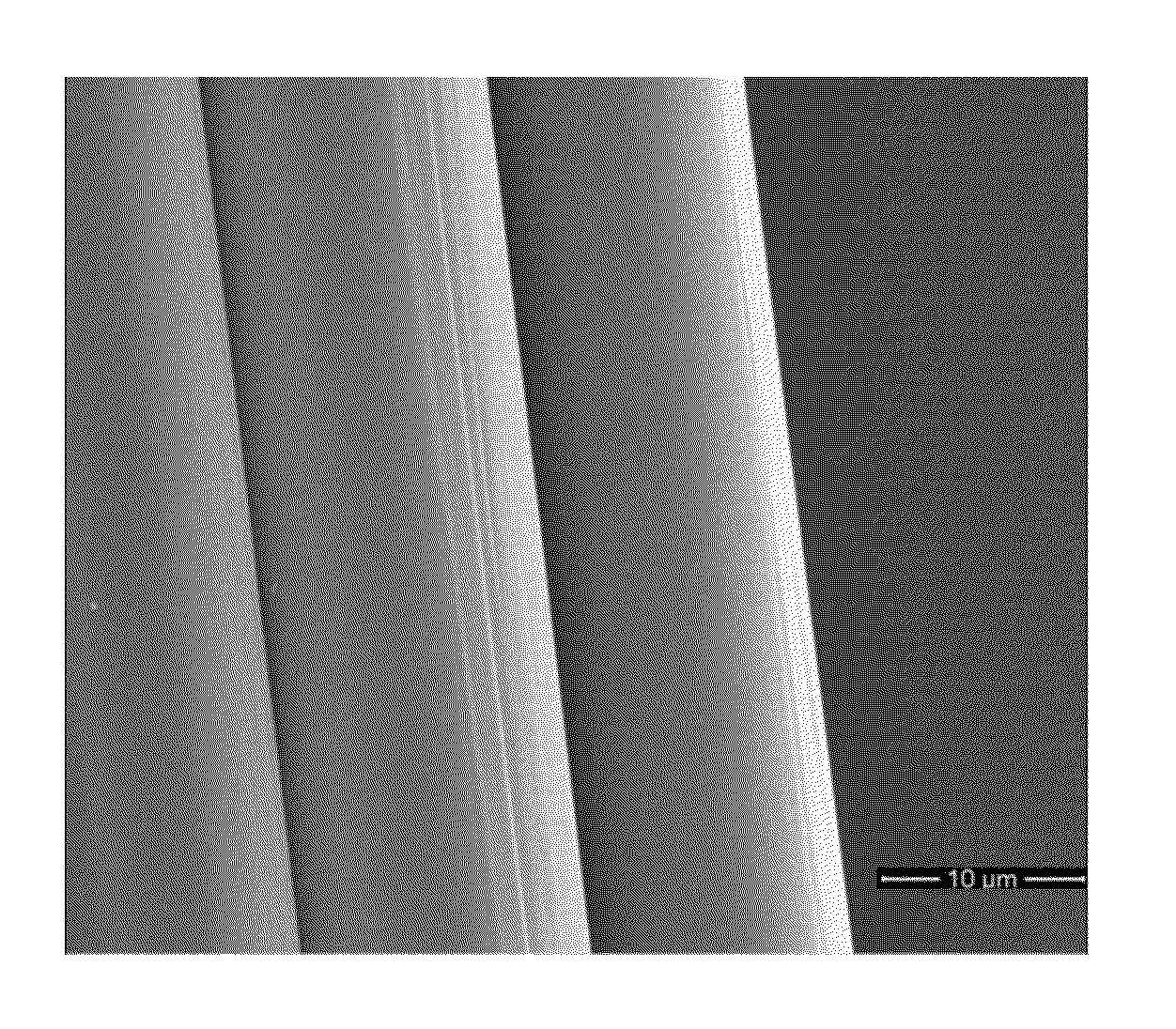

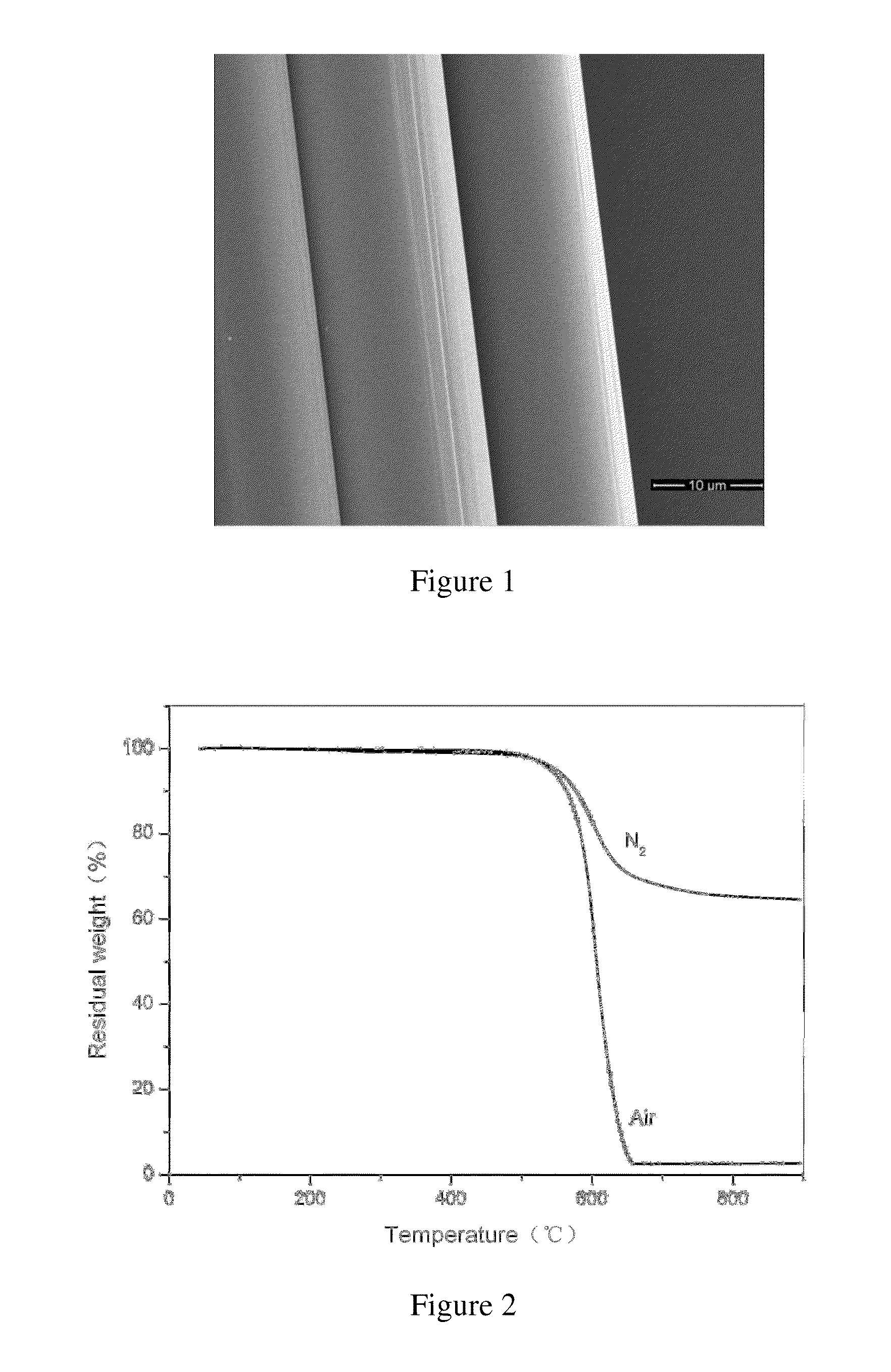

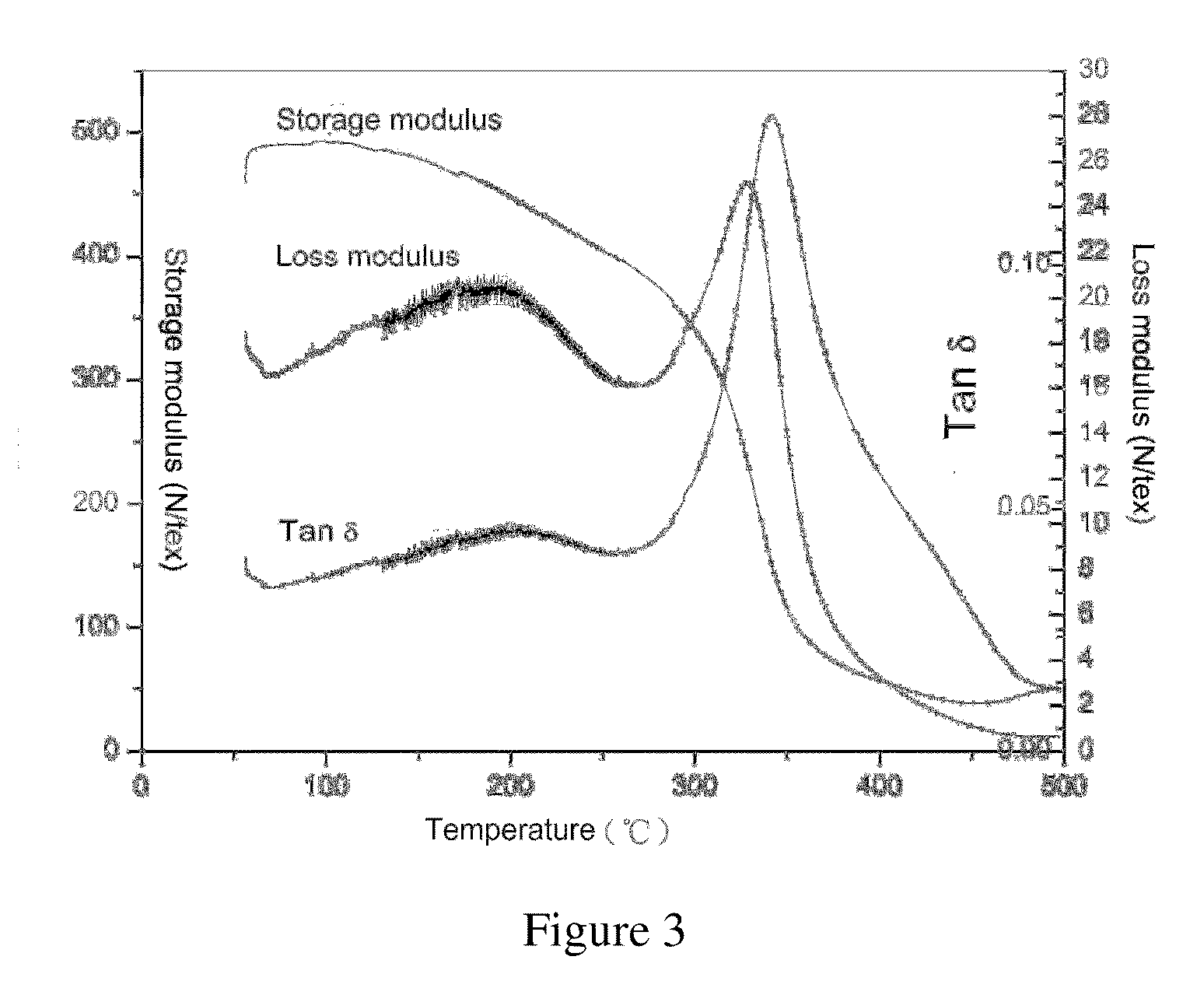

Polyimide fiber with high strength and high modulus and its preparation method

ActiveUS20130137846A1Improve mechanical propertiesPerformance requirementArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberBPDA

A high-strength high-modulus polyimide fiber and its preparation method pertain to the technical field of high-performance organic fiber. This fiber includes the polyimide (PI) fiber made from 3,3′,4,4′-biphenyl tetracarboxylic diandhydride (BPDA), p-phenylenediamine (pPDA) and 2-(4-aminophenyl)-1H-benzimidazol-5-amine (BIA), wherein the molar ratio between PPDA and BIA is 1:10˜3:1. During the synthesis, other diamine and diandhydride monomers may also be added. In the preparation process, the gradient temperature reaction method and one-step continuous preparation method are adopted, the synthesis and processing difficulty caused by the increase of the content of BIA is overcome, the problem of poor uniformity and stability of fiber is solved and PI fiber with high strength and high modulus is obtained. Its strength may reach 4.5 GPa and modulus may reach 201 GPa. Moreover, the sources of the raw materials are extensive, the spinning process is continuous, the cost is low, the efficiency is high and industrial production may be realized.

Owner:BEIJING UNIV OF CHEM TECH

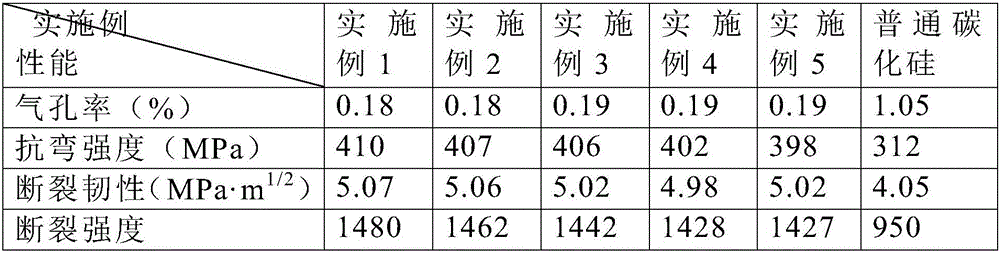

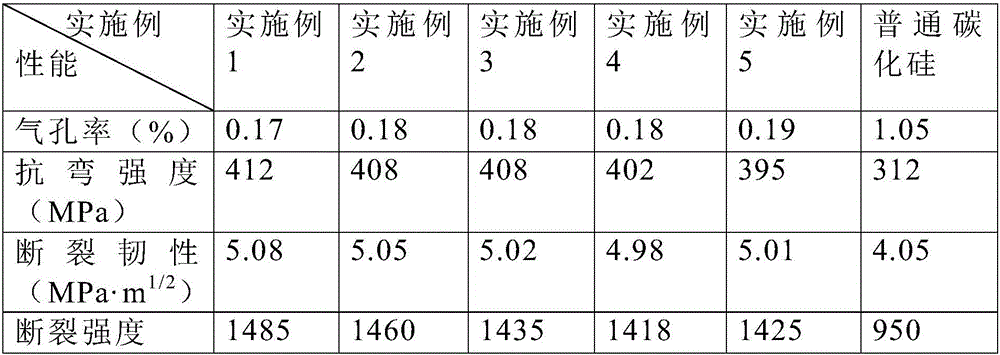

Preparation method of high-density silicon carbide composite

The invention relates to a preparation method of a high-density silicon carbide composite and belongs to the technical field of composite processing. The method comprises steps as follows: main materials become a slurry finished product after being treated, the main materials comprise SiC granules and B4C granules, and the B4C granules are taken as a sintering aid; auxiliary materials are added to the slurry finished product, pre-casting slurry is prepared, and the auxiliary materials comprise acrylamide, methylene bisacrylamide and ammonium polyacrylate; ammonium persulfate is added to the pre-casting slurry, the mixture is stirred uniformly and subjected to forming, and a blank body is obtained; the blank body is firstly subjected to solvent degreasing and then subjected to thermal degreasing; the degreased blank body is sintered under the vibration pressure at the temperature of 2,000-2,100 DEG C, and the high-density silicon carbide composite is obtained finally. The prepared silicon carbide composite is uniform and stable in structure and quality, high in density and high in controllability and also has better toughness and strength.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

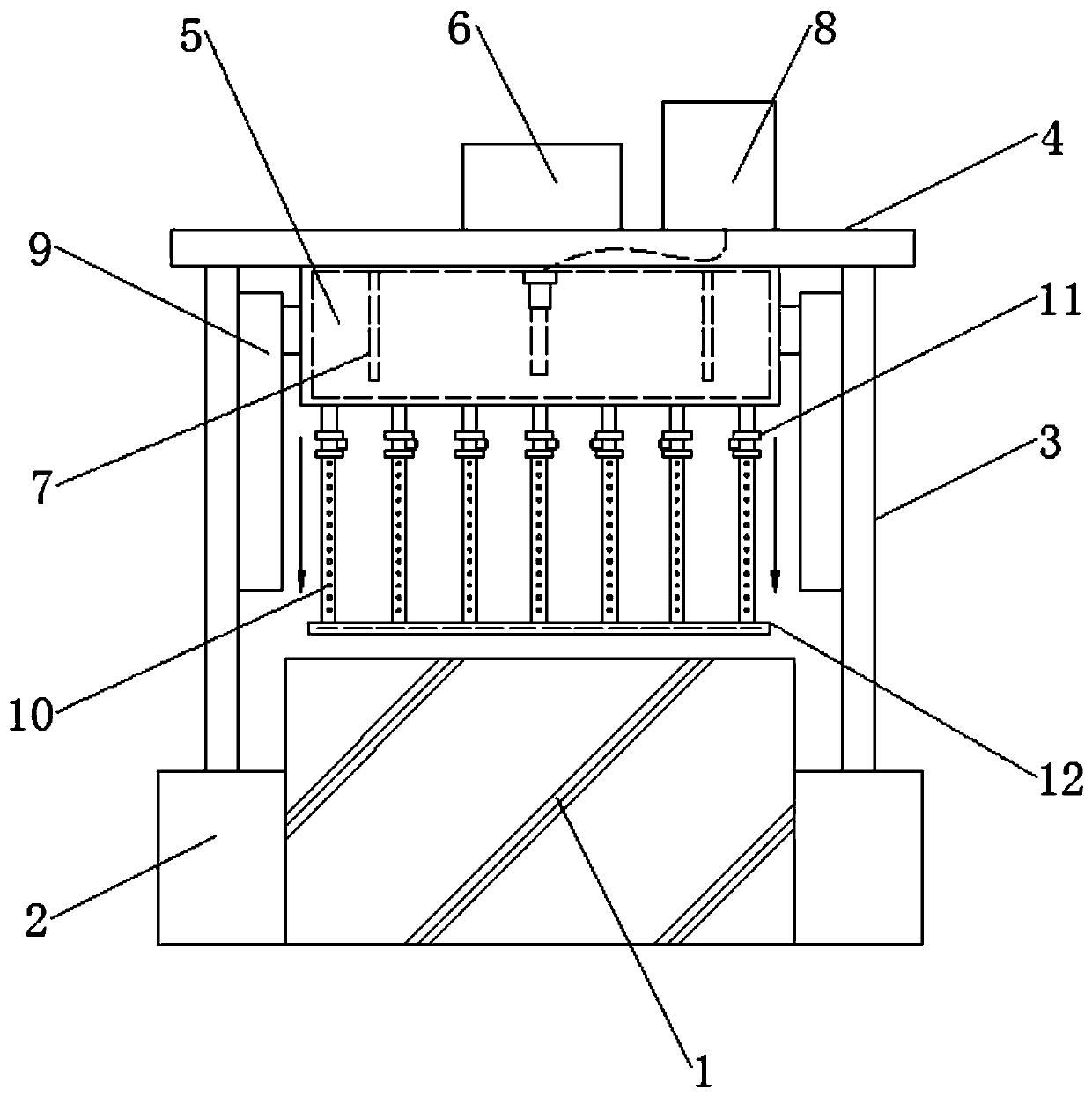

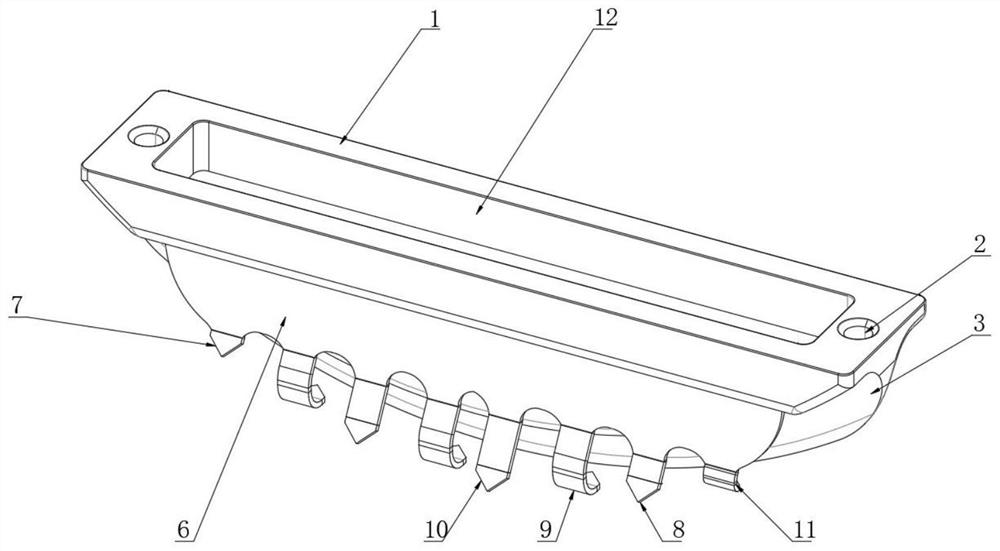

Modular backwash assembly and method for using the same

ActiveUS20190151779A1Improve sound transmission efficiencyEasy to cleanWater treatment parameter controlSpecific water treatment objectivesMechanical engineeringUltrasonic generator

A modular backwash assembly and method for using the same is disclosed, the modular backwash assembly comprises a filter brick body, an ultrasonic generator and an ultrasonic connecting component, the filter brick body is provided at an upper portion with a square trench and a cover, the square trench is provided with a plurality of stiffeners and fillers, and a conductive channel is provided on the periphery of the square trench and is provided with an ultrasonic conductive medium therein. The invention has the advantages of firm structure and durable, the gas distribution uniformity may be increased up to 96% and the turbidity average is below the specification 10 NTU.

Owner:NANJING UNIV +1

Preparation method of silicon carbide composite material

The invention relates to a preparation method of a silicon carbide composite material and belongs to the technical field of composite material processing. The preparation method comprises treating main materials to obtain a slurry finished product, wherein the main materials comprise SiC particles and B4C particles as sintering aids, adding auxiliary materials into the slurry finished product to obtain slurry before casting, wherein the auxiliary materials comprise acrylamide, methylene bisacrylamide and ammonium polyacrylate, adding ammonium persulfate into the slurry before casting, carrying out uniform stirring, carrying out injection molding to obtain a blank, degreasing the blank through a solvent, carrying out hot degreasing and sintering the degreased blank under oscillation pressure at a temperature of 2000-2100 DEG C to obtain the silicon carbide composite material finished product. The silicon carbide composite material has uniform and stable structure and quality, high density, good controllability and good toughness and strength.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

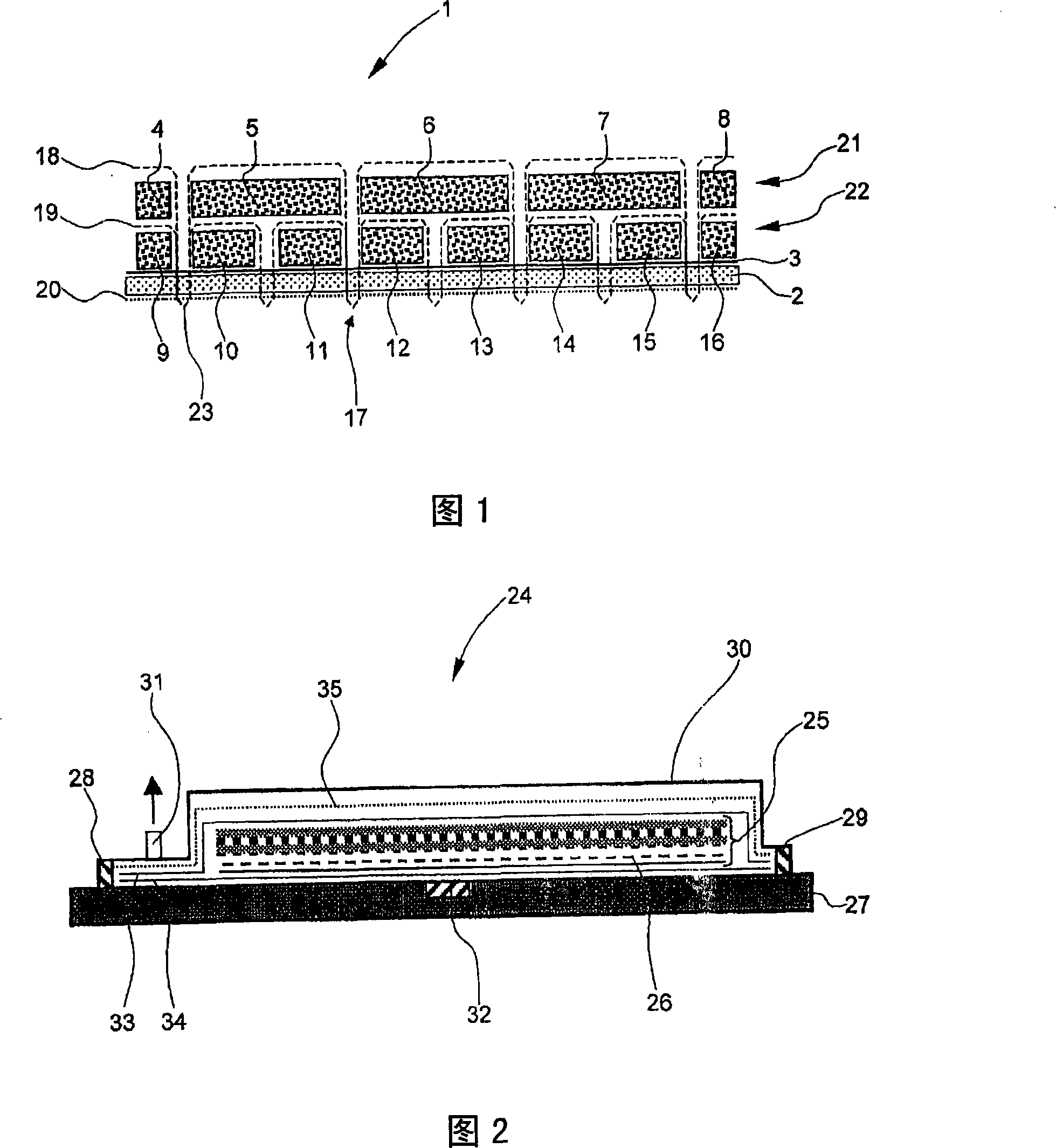

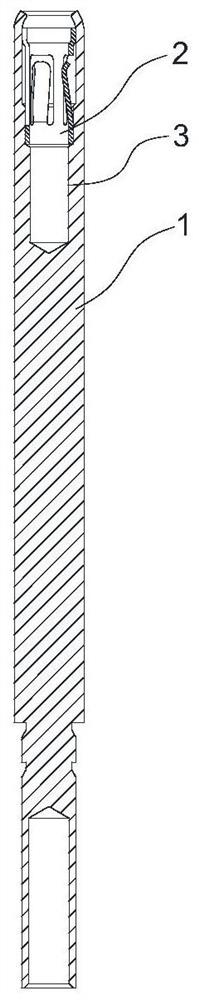

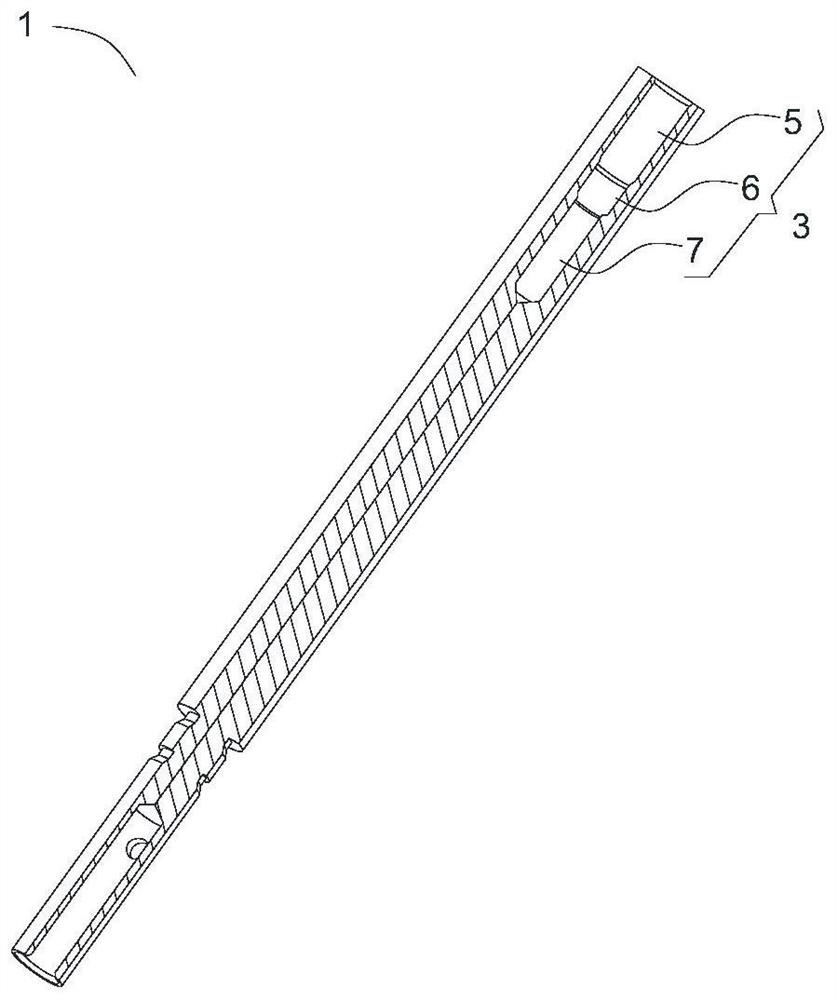

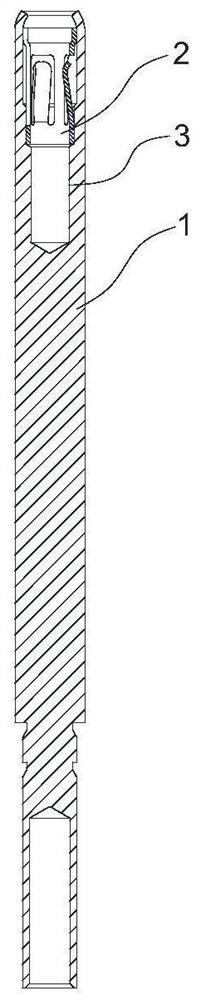

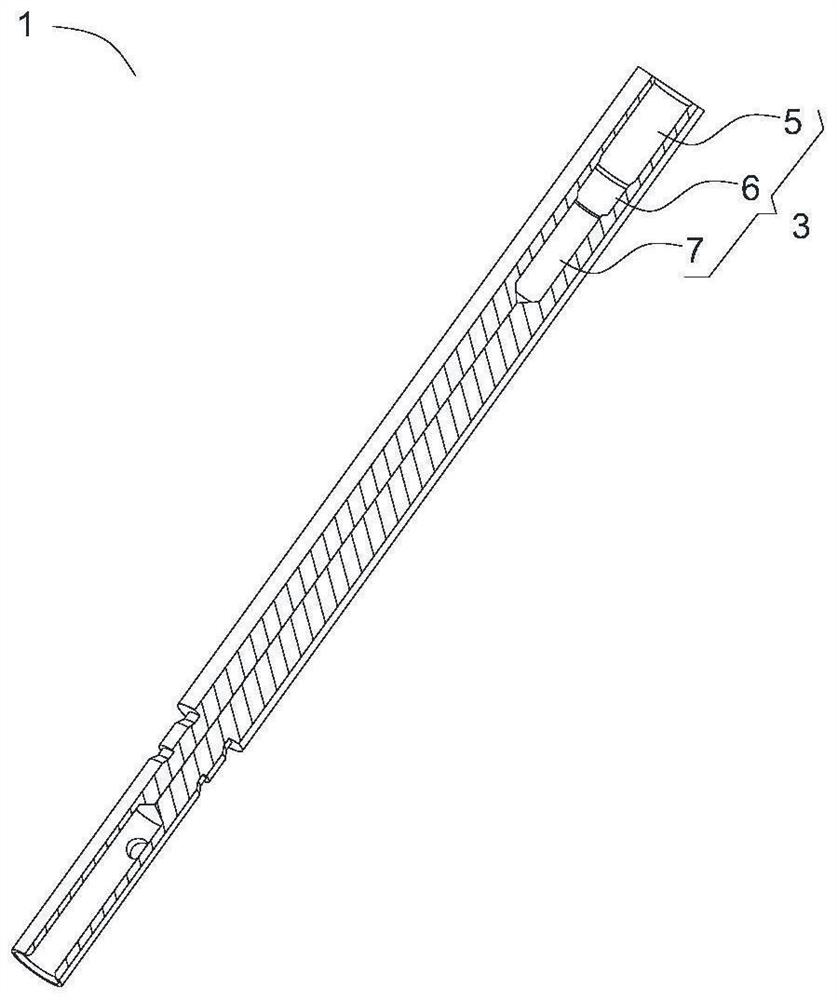

Method for producing in a tfp method one-or multi-layer layer fibre preforms and a support layer

InactiveCN101228022AEasy to disengageEasy to separateSynthetic resin layered productsVehicle componentsFiber bundleHot melt

The invention relates to a method for the production of single or multilayer fiber preforms using the TFP process by means of fiber bundles (4-16), approximately arranged so that they are oriented by force flow and placed on a backing layer ( 2) and connected by fixing wires (17) in order to form a fiber preform (1, 25) with the desired material thickness without affecting the backing layer (2). According to the invention, the release layer (3, 26) is applied to the backing layer (2) at least in certain regions, and when the TFP process is completed, the fiber preform (1, 25) is introduced into the holding device (24) , wherein at least some of the fixing filaments (17) are melted by supplied heat, and then, the backing layer (2) separated from the fiber preform (1, 25) by the release layer (3, 26) is separated from the fiber preform (1 , 25) Break away. The fiber preforms (1, 25) formed by the method according to the invention have an optimal fiber structure without cracks for practically any desired material thickness and are destined for the compounding of load-bearing parts which have to withstand high mechanical loads Production of components. The invention also relates to a bedding layer for the production of a fiber preform (1, 25), and to a fiber preform (1, 25) formed according to the method of the invention.

Owner:AIRBUS OPERATIONS GMBH

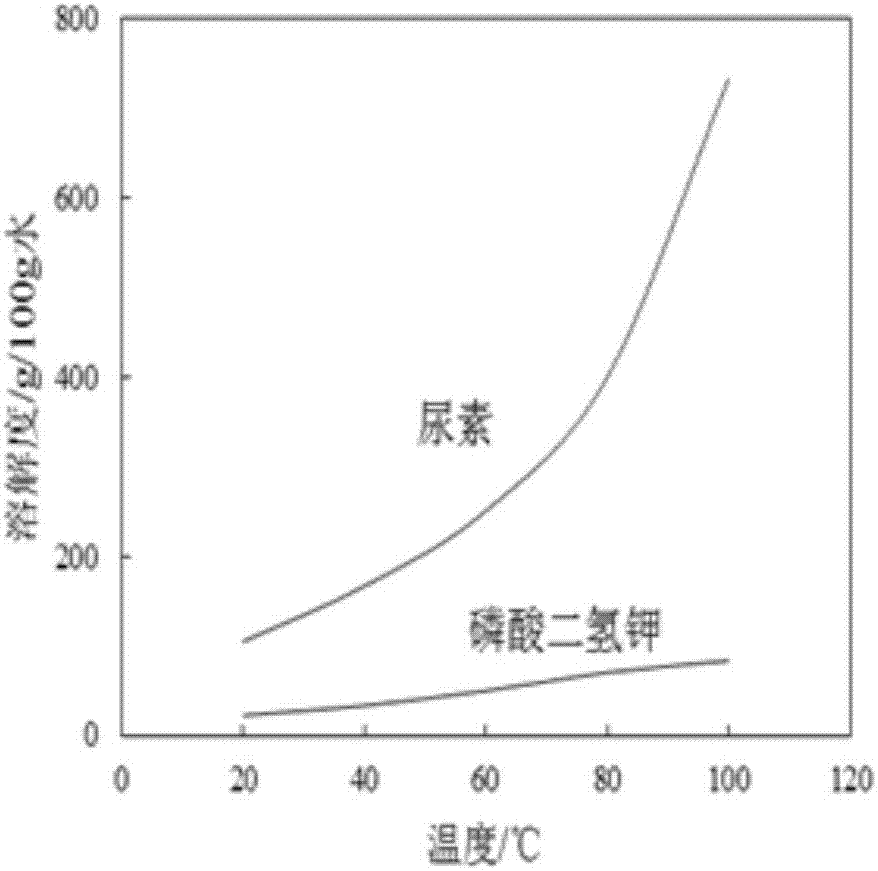

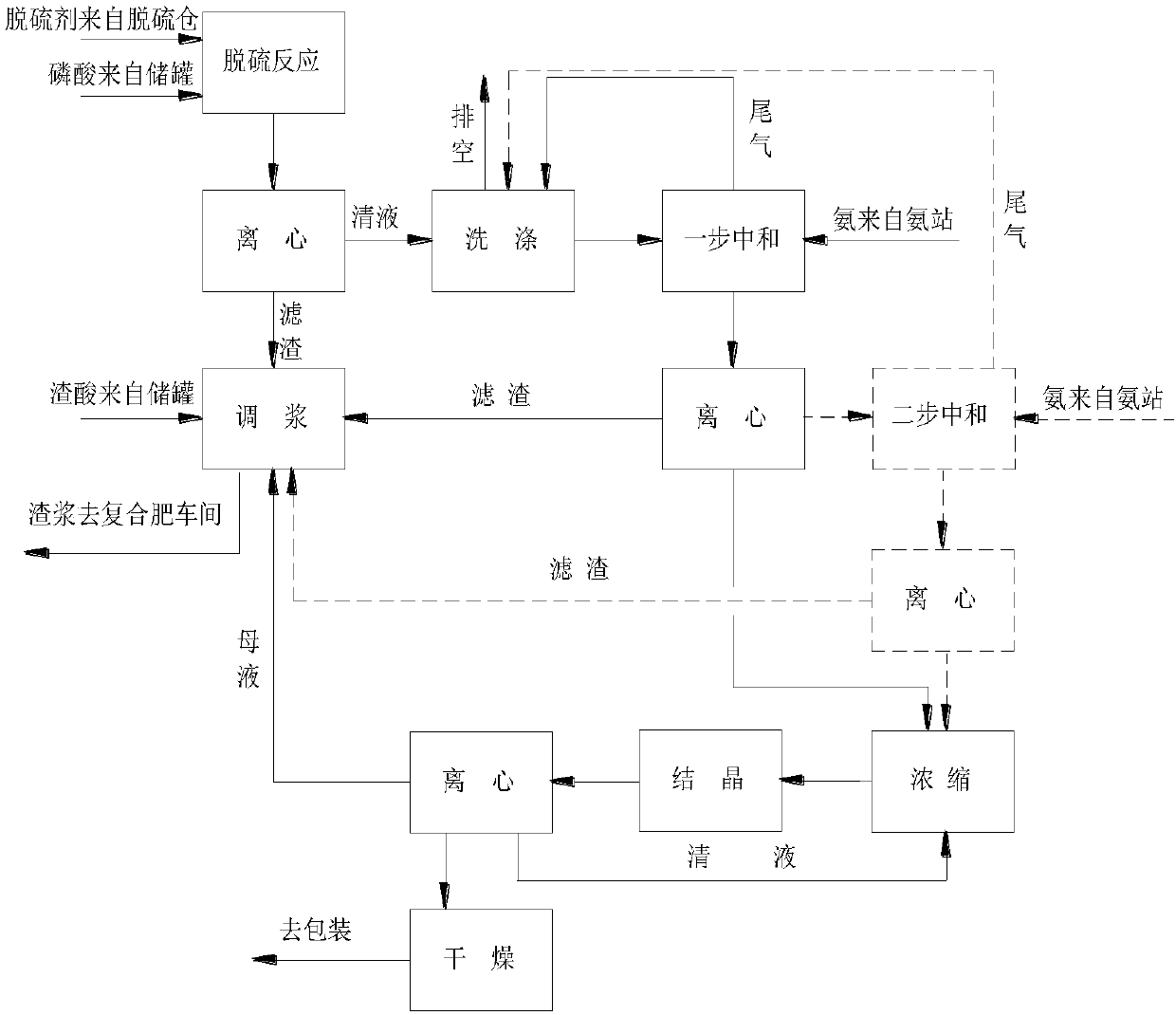

Production method of industrial-grade potassium dihydrogen phosphate coproduced water-soluble fertilizer

InactiveCN107324301ARealize coupled productionHigh acidity requirementsUrea derivatives preparationOrganic compound preparationPhosphateTrace element

The invention provides a production method of an industrial-grade potassium dihydrogen phosphate coproduced water-soluble fertilizer. The production method comprises the following steps: by taking wet-process phosphoric acid as a raw material, extracting high-purity nitrogen-phosphorus compound salt intermediate-urea phosphate from wet-process phosphoric acid, purifying the wet-process phosphoric acid, producing master liquor by utilizing the industrial-grade potassium dihydrogen phosphate, and preparing nitrogen-phosphorus-potassium ternary water-soluble fertilizer. Through continuous operation of a production device, high-nitrogen, high-phosphorus and high-potassium type water-soluble fertilizer having constant-quality and high-efficiency products and containing medium and trace elements in uniform and multiple formulas can be produced so as to meet different market demands, the raw materials for production are mainly wet-process phosphoric acid, urea and potassium hydroxide, the cost of the raw materials is low, the technological route is simple, and the industrial-grade potassium dihydrogen phosphate production technology can be effectively coupled.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

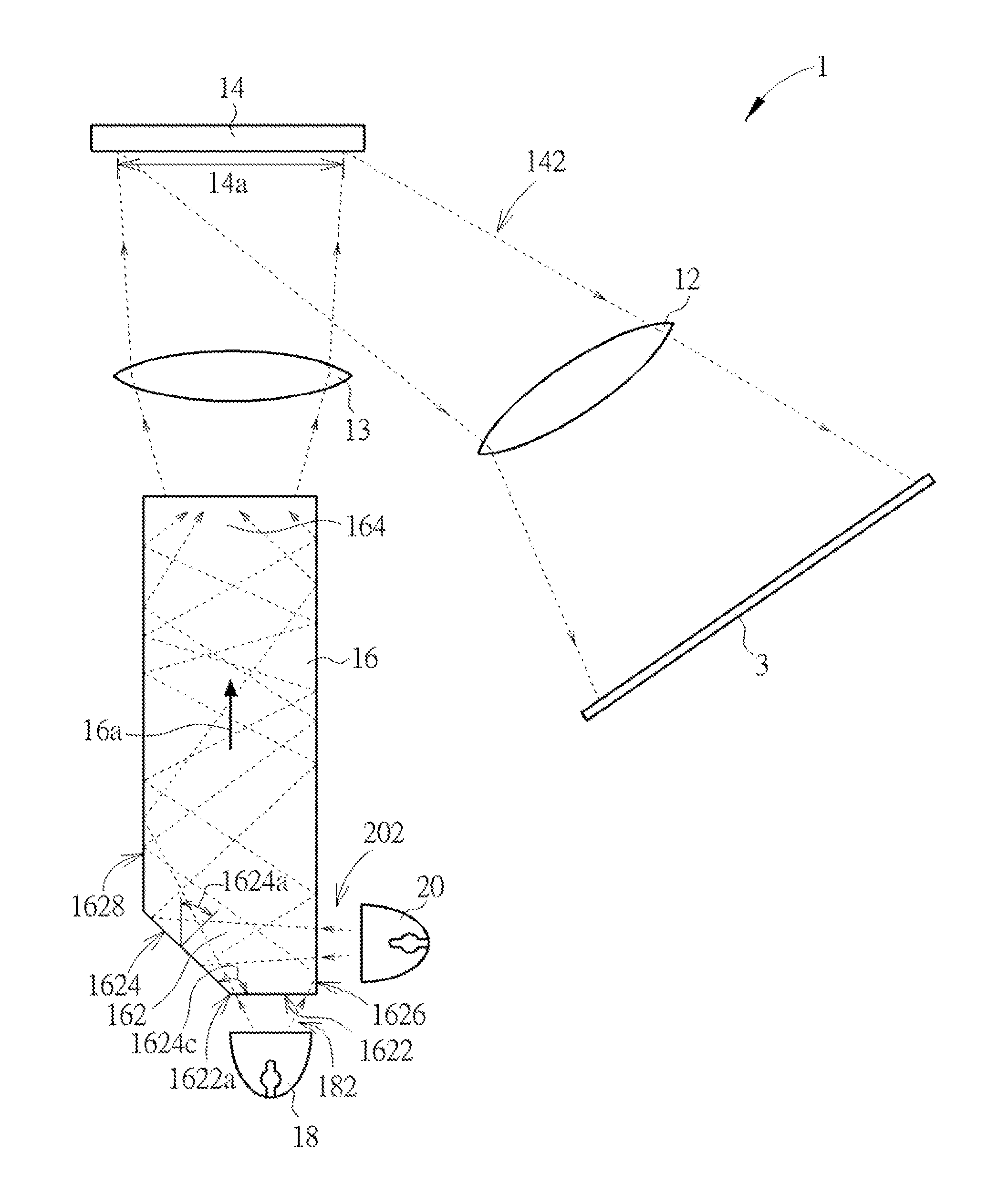

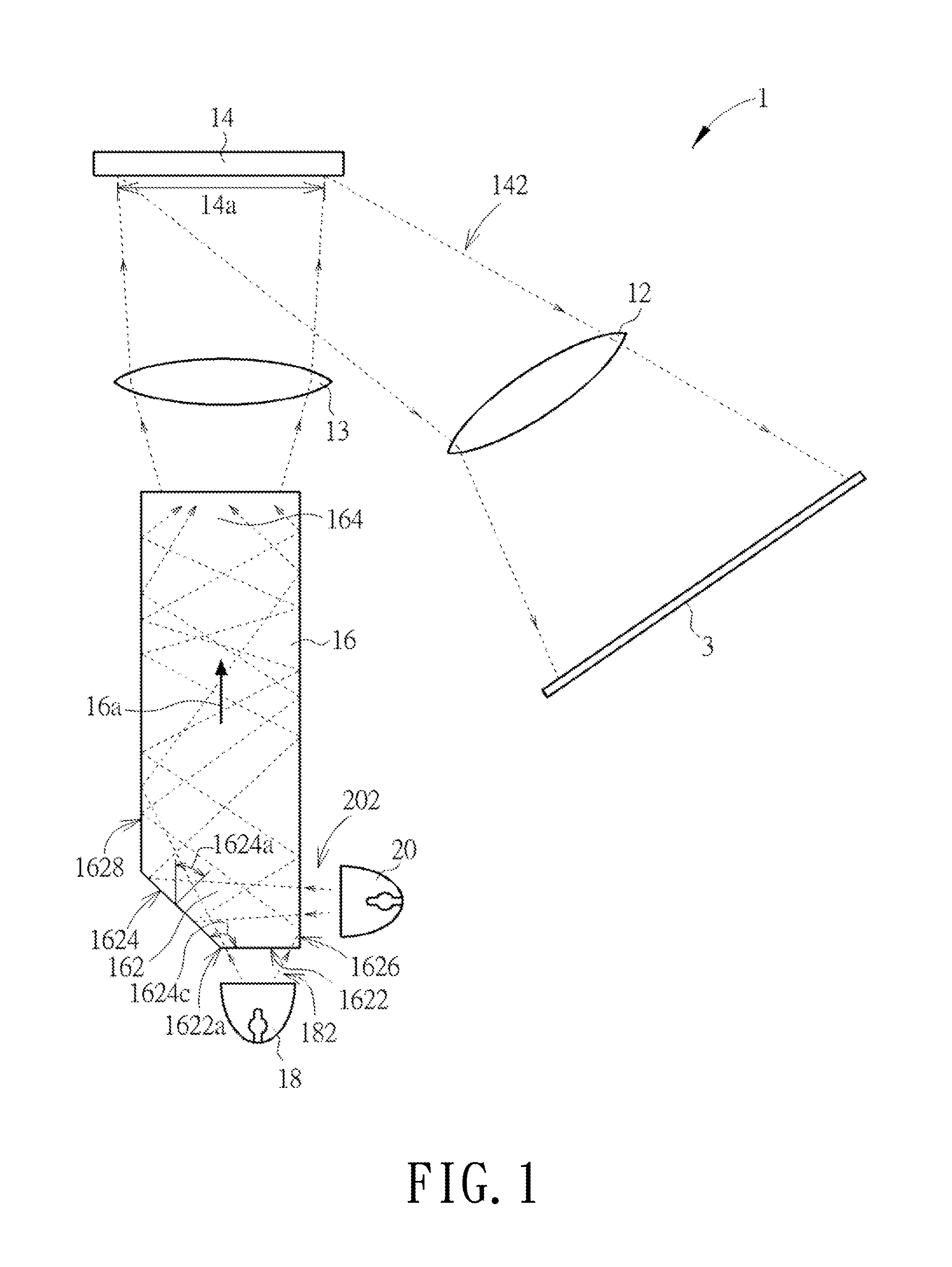

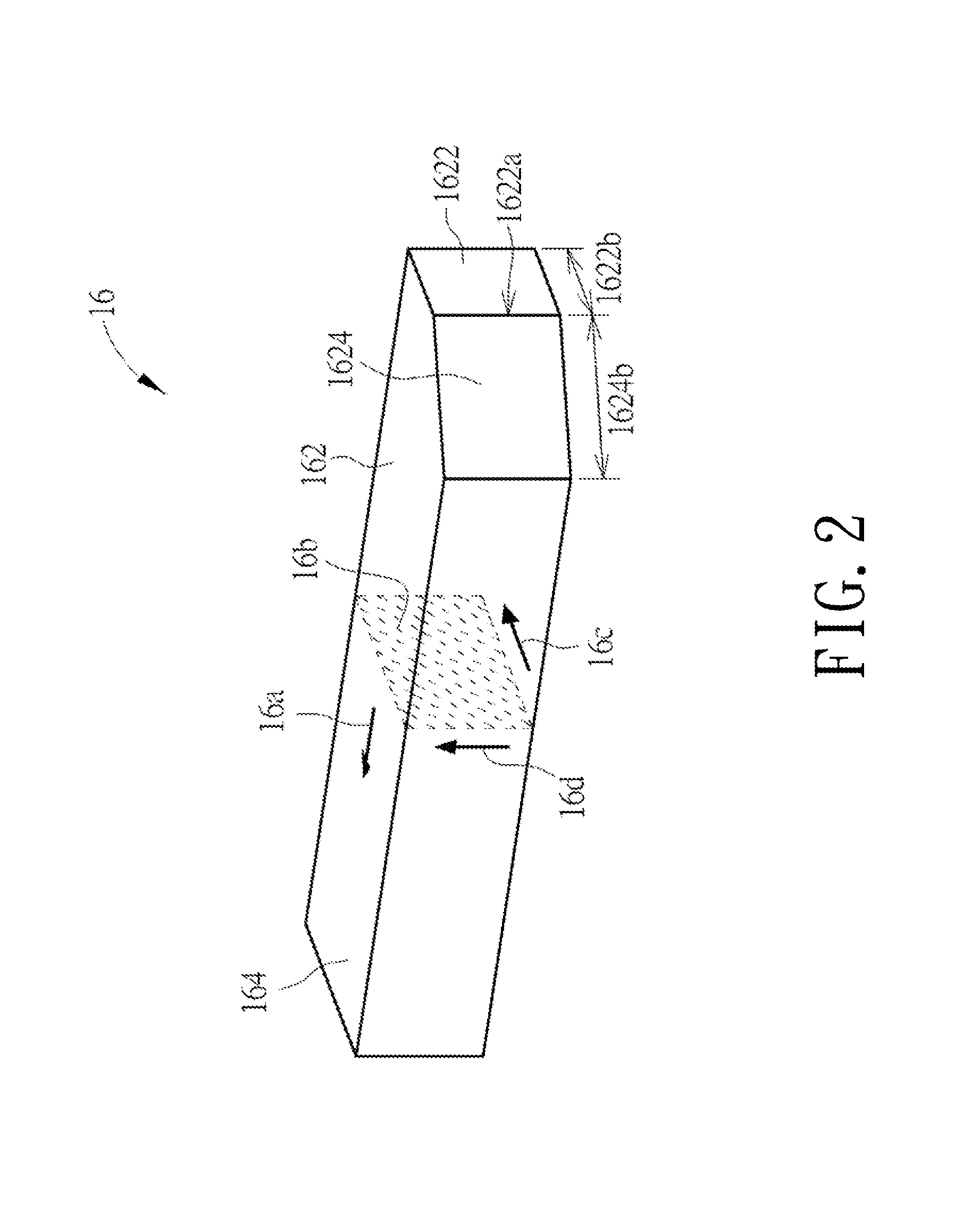

Projection system

ActiveUS20150124226A1High homogenizationPoor uniformityProjectorsColor photographyCamera lensProjection system

A projection system includes a projection lens, an image modulation device, a light-guiding rod and two light sources. The light-guiding rod is defined with an axial direction and has a first end and a second end. The first end has a transmission surface and a reflection surface. The ratios of the widths of the transmission and reflection surfaces to the panel width of the image modulation device are 0.13˜0.35. The lights of the first and second light sources are incident into the light-guiding rod through the transmission surface and onto a first side surface and reflected into the light-guiding rod through the first reflection surface, respectively. The light-guiding rod homogenizes the incident lights and transmits the homogenized light to the image modulation device through the second end thereby forming an image light. The projection lens projects the image light.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD +1

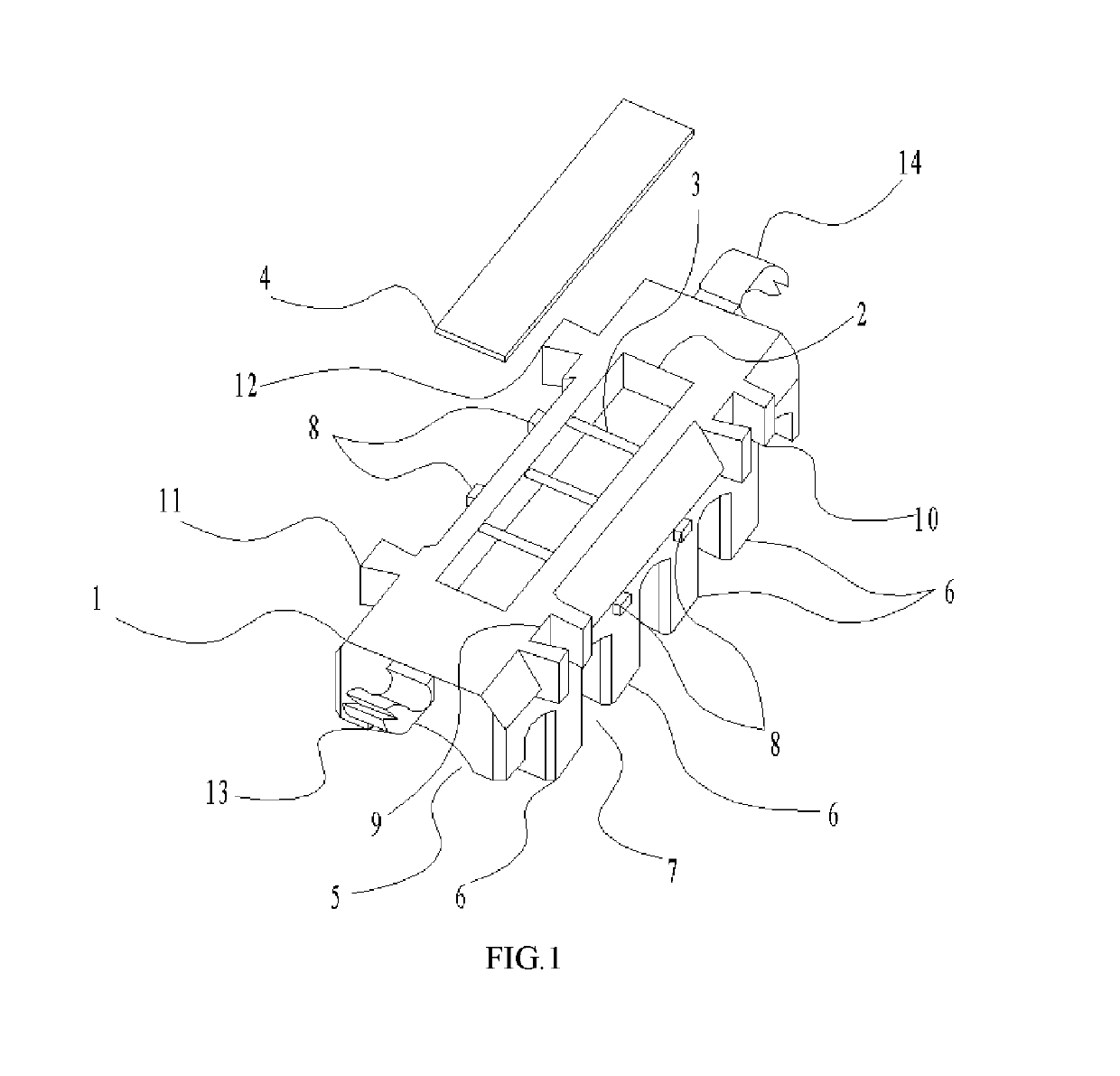

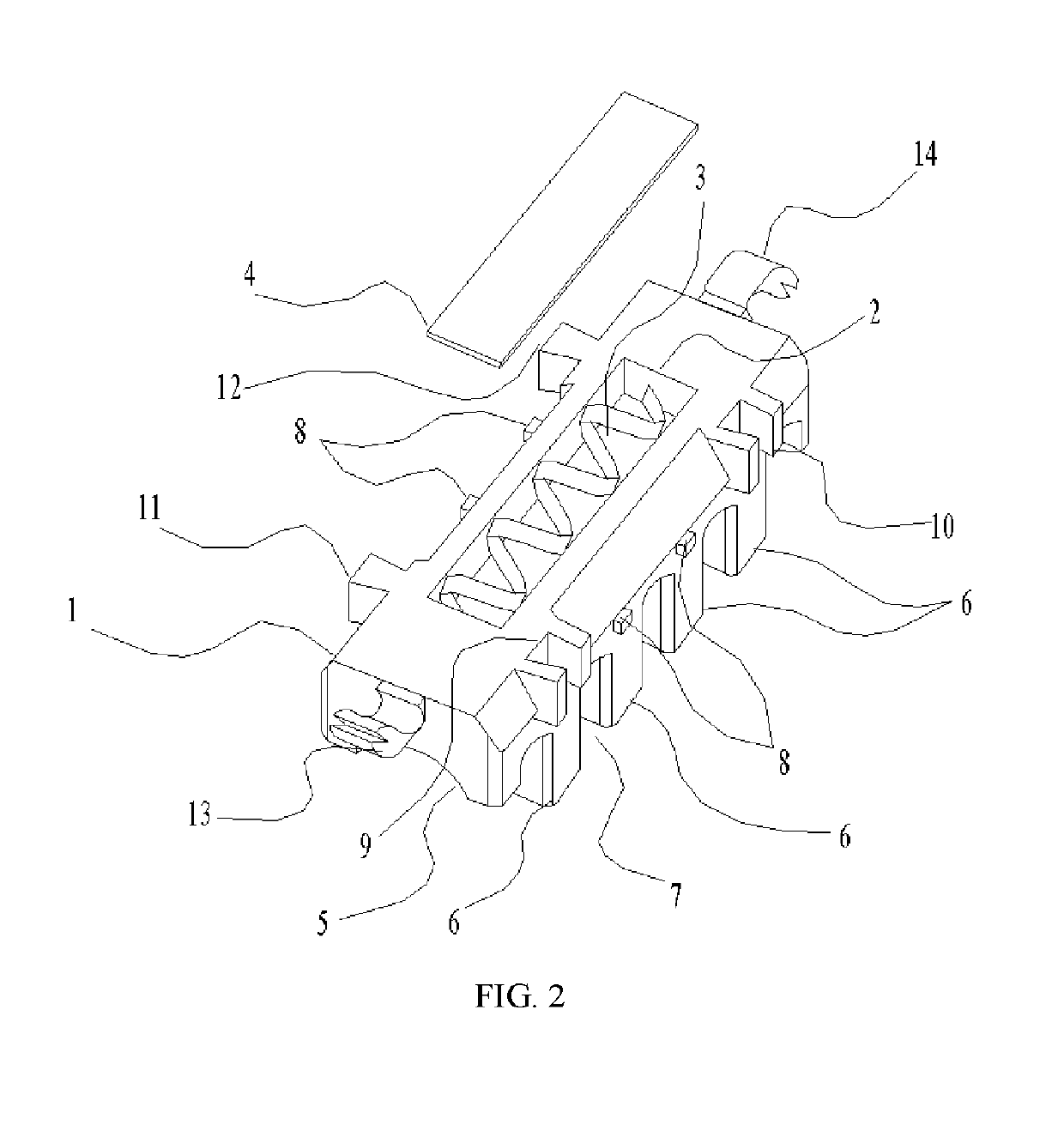

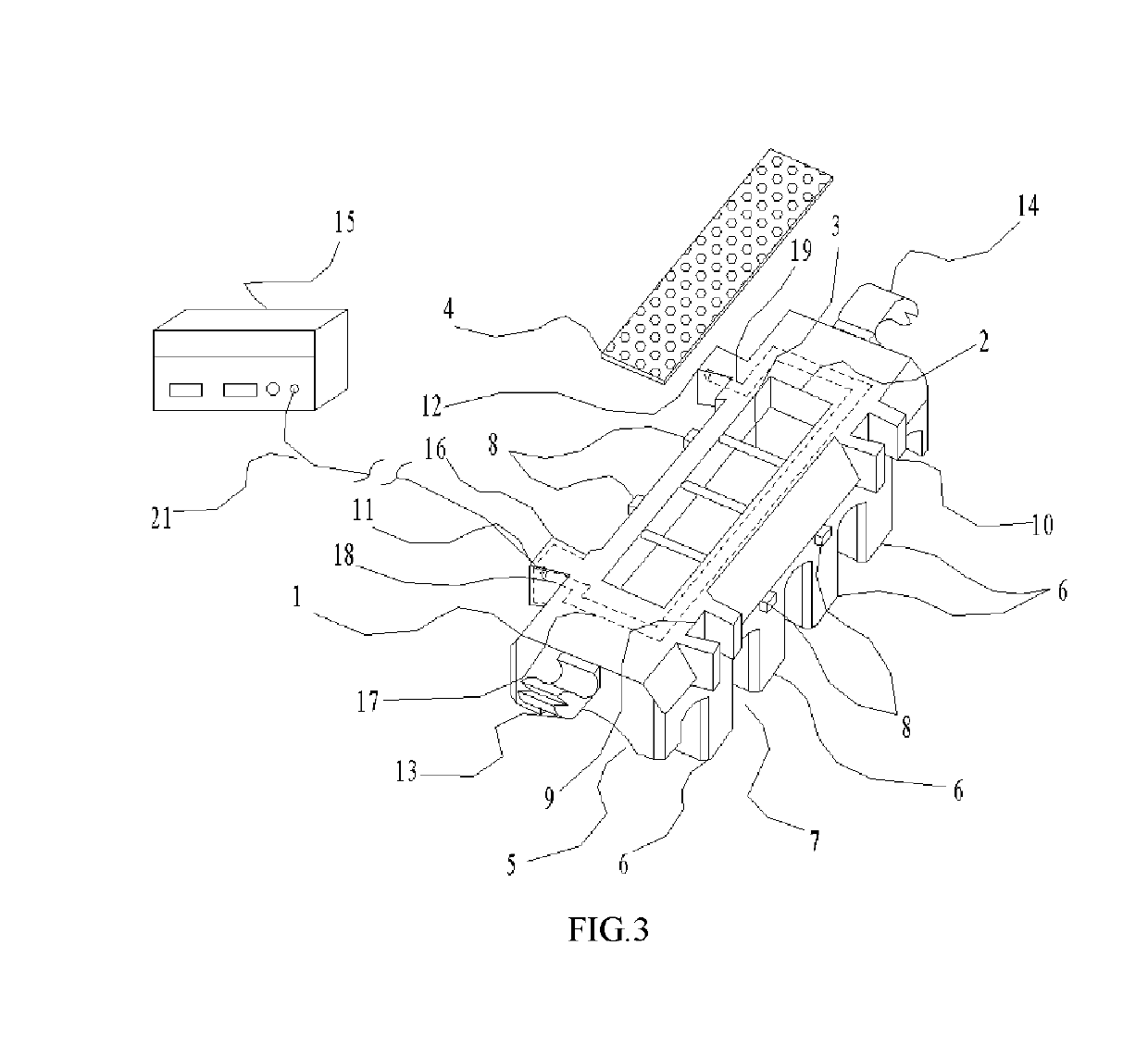

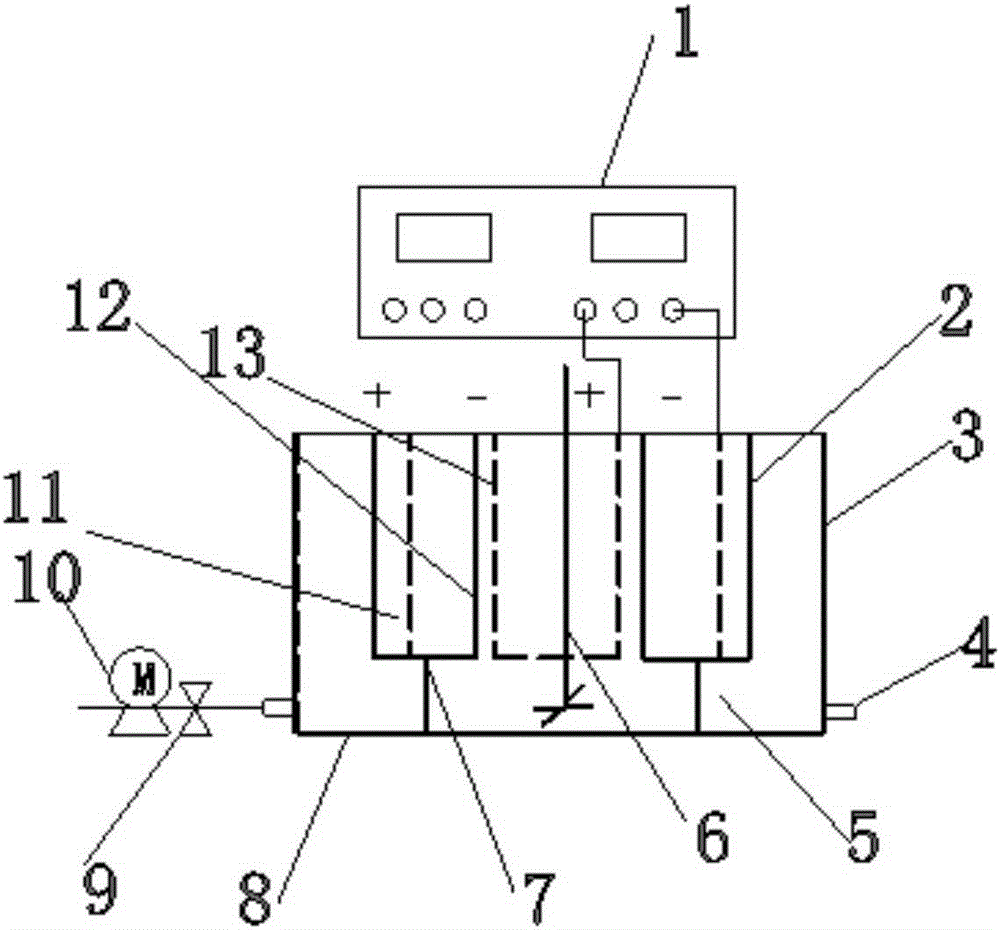

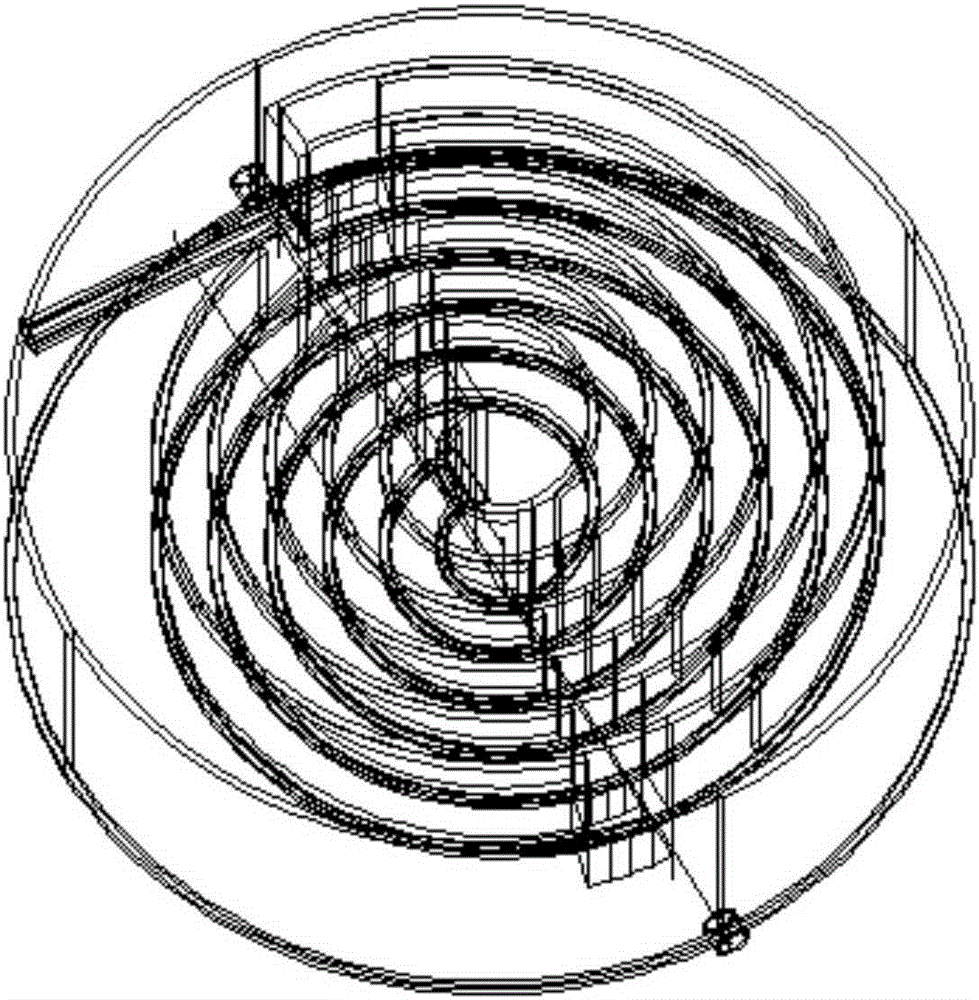

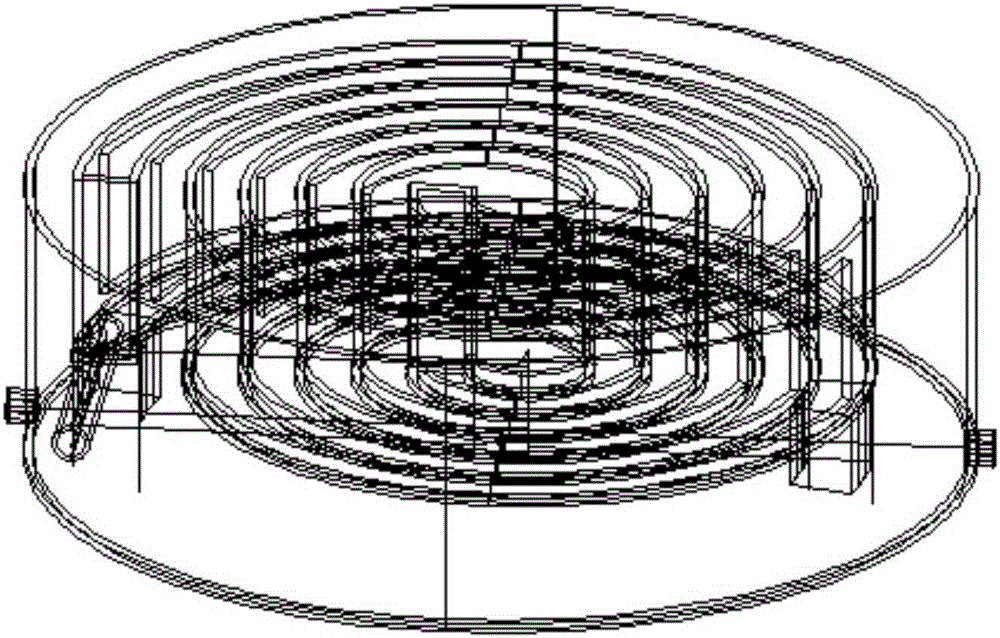

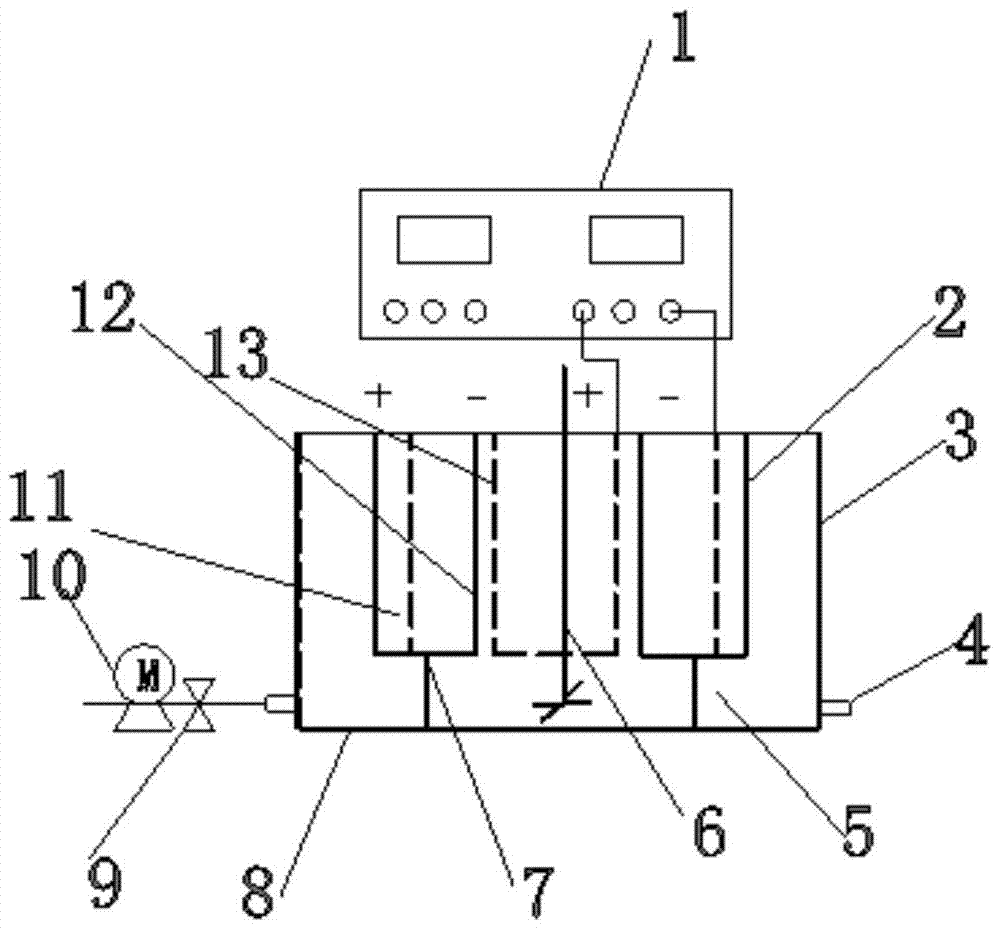

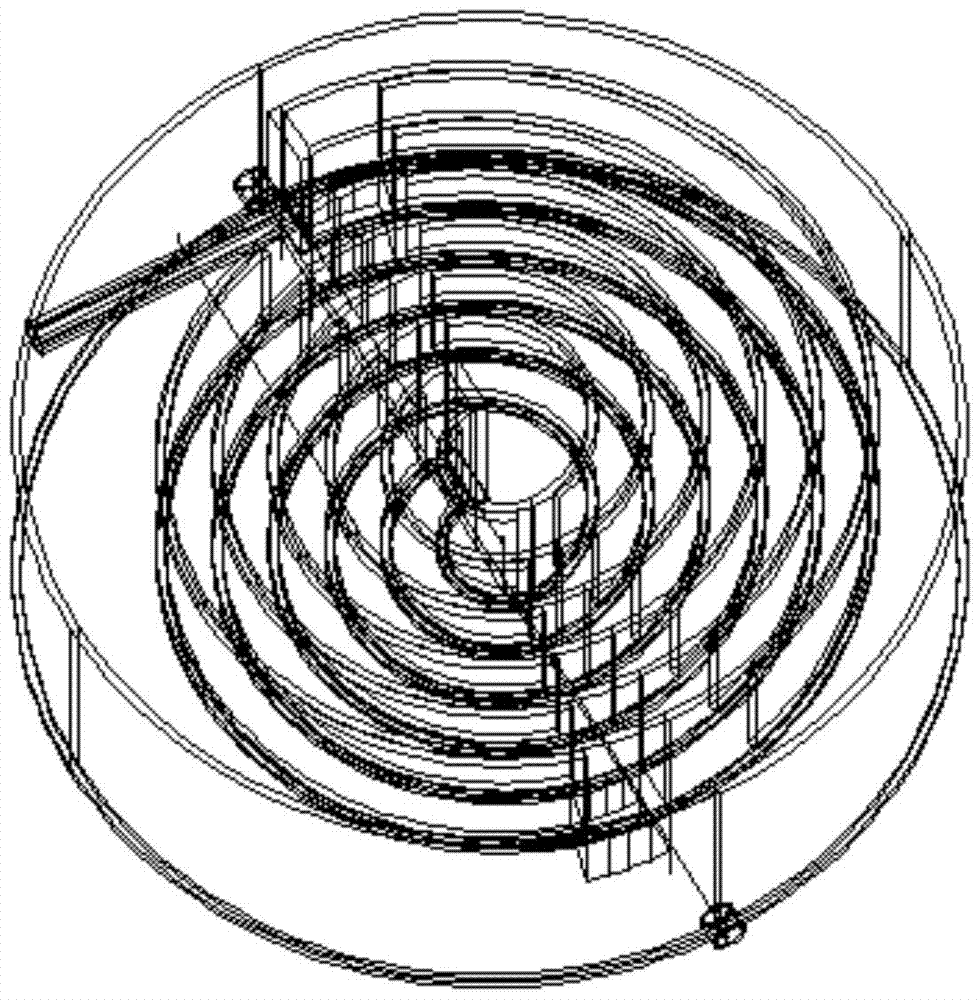

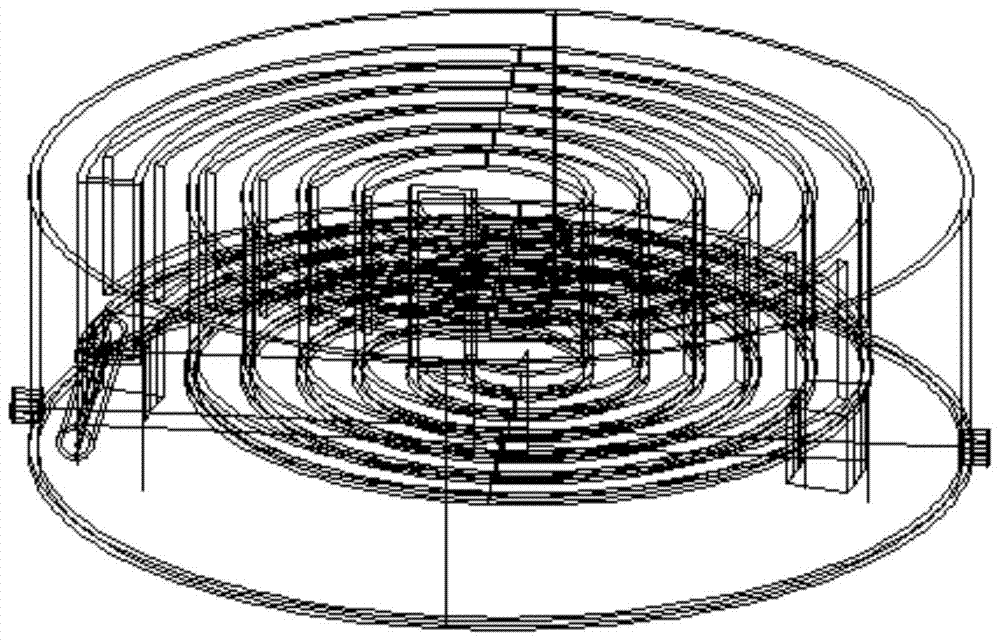

Double-helix device for recovering heavy metals from sludge by adopting electrochemical removal method

ActiveCN105217906AIncrease the effective contact areaGuaranteed uniformitySludge treatmentIon-exchange membranesElectrochemical response

The invention provides a double-helix device for recovering heavy metals from sludge by adopting an electrochemical removal method. The device comprises a helix-type electrochemical reactor, a cathode electrode, an anode electrode and an ion exchange membrane, wherein the helix-type electrochemical reactor is composed of an outer cylinder, a middle helix cylinder, an inner helix cylinder, a circular lower base plate, a helix-type opening upper base plate and a bracket; the area encircled by the inner helix cylinder and the circular lower base plate forms an anode chamber; the anode chamber is communicated with the area formed by the outer cylinder and the middle helix cylinder; the area formed by the upper layer inner helix cylinder, the middle helix cylinder and the helix-type opening upper base plate is a cathode chamber; the ion exchange membrane is adhered on the outer surfaces of the inner helix cylinder and the middle helix cylinder through a glass cement; a resource recovery pipe of the cathode chamber of the electrochemical reactor is positioned on the end plate of the cathode chamber; a feed pipe and a discharge pipe are symmetrically positioned on the outer side of the outer cylinder and are further connected with a booster pump. The double-helix device for recovering heavy metals from sludge by adopting the electrochemical removal method has the advantages of being good in economical efficiency, simple, and convenient and fast, high in processing efficiency and capable of separating and recycling heavy metals from sludge and the like.

Owner:ZHEJIANG UNIV

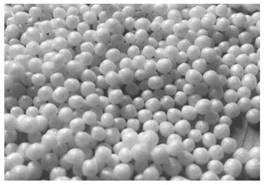

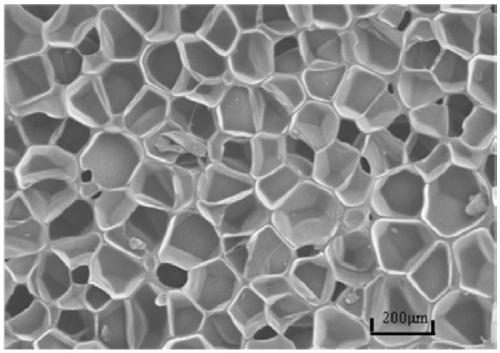

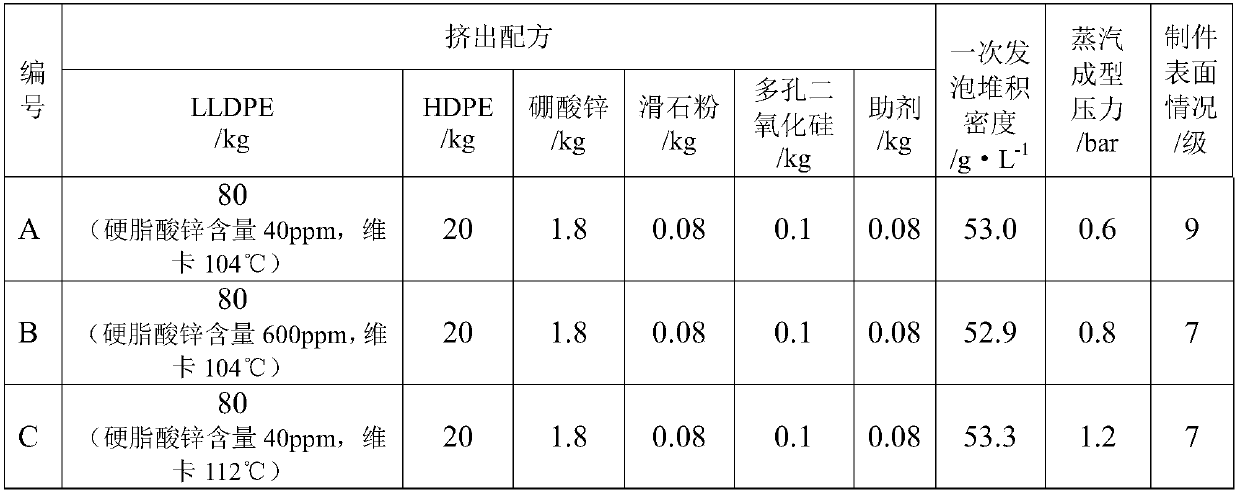

Easily melted foamed polyethylene bead with strong temperature tolerance and preparation method thereof

ActiveCN109651695AIncrease elasticityImprove temperature resistanceLow-density polyethyleneThermal insulation

The invention discloses an easily melted foamed polyethylene bead with strong temperature tolerance and a preparation method thereof. Low density polyethylene with a Vicat softening point of 90 to 105DEG C and high density polyethylene are compounded, at the same time, an inorganic compounding foaming aid is adopted, and through the synergistic effect generated by three components, goals of easily melting and high temperature tolerance are realized. Through the cooperation of formula and technology, the size of inner pores of primarily foamed EPE beads is controlled in a range of 200 to 230 [mu]m, after foaming, no thermal insulation device is needed, and a step of introducing steam with a certain air pressure into a pipe for delivering polypropylene resin particles is not needed either.The moulding steam pressure is obviously reduced, the melting stability between particles is excellent, and the curing degree is 95% or more. Because the inner pores in the beads are increased, and the pore uniformity is increased, the polyethylene bead can tolerate a certain moulding temperature, the stiffness of pores in the surface of a moulded product is improved, and the beauty of the surfaceof a EPE bead moulded product is obviously improved.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

Method for producing industrial-grade ammonium dihydrogen phosphate and co-producing water-soluble fertilizer

ActiveCN108046226AImprove high-end utilizationImprove efficiencyPhosphatesAlkali orthophosphate fertiliserNutrientChemistry

The invention provides a method for producing industrial-grade ammonium dihydrogen phosphate and co-producing a water-soluble fertilizer. According to the present invention, based on the characteristics of the industrial monoammonium mother liquor, waste is turned into treasure; the method is used for producing the high-end fertilizer water-soluble fertilizer; and with the method, the high-end utilization rate of nutrients is increased, the added value of the product is increased, the benefits of the industrial-grade ammonium dihydrogen phosphate and water-soluble fertilizer coupled co-production device are maximized, and the coupled production of the industrial-grade ammonium dihydrogen phosphate and the water-soluble fertilizer is finally achieved.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

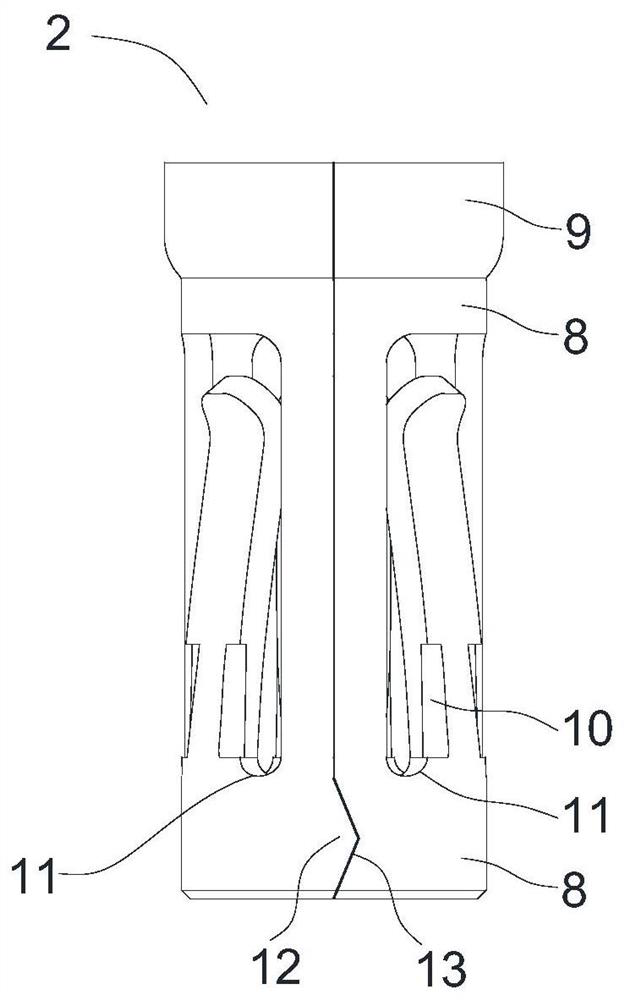

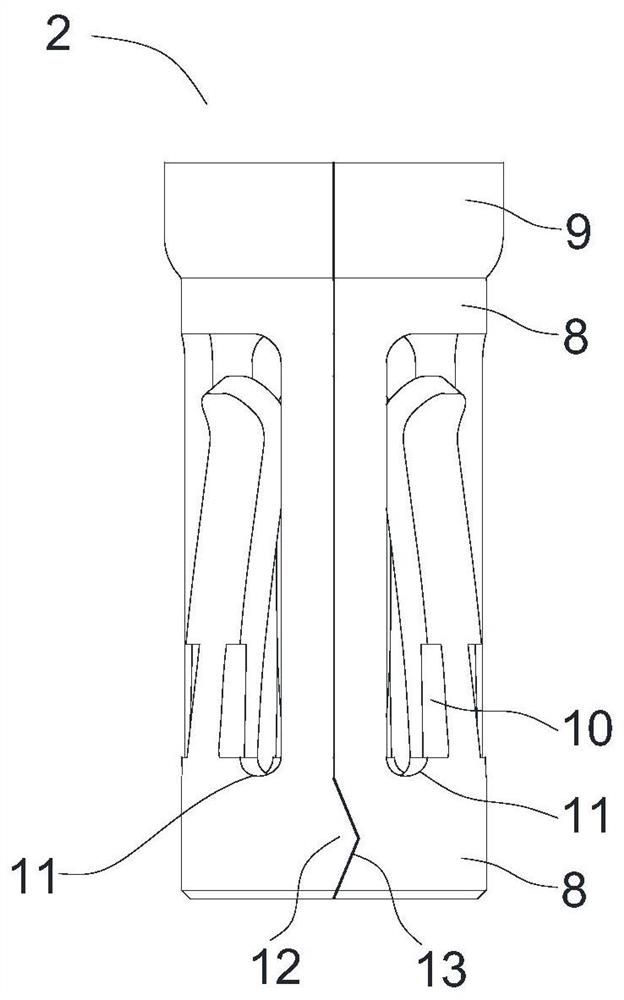

Jack assembly with composite coating, electric connector and electroplating method thereof

ActiveCN112382878AReduce wearImprove wear resistanceElectrolytic coatingsSecuring/insulating coupling contact membersButt jointElectrical connection

The invention provides a jack assembly with a composite coating. The jack assembly comprises a jack and a contact spring coil, a blind hole is arranged at the butt joint end of the jack, and the contact spring coil is arranged in the blind hole. The contact spring coil is fixed in the blind hole by closing an opening of the blind hole, the contact spring coil is provided with a plurality of elastic spring claws, and the coating of the contact spring coil is a gold-graphene composite coating, and the plating layer of the jack is a gold plating layer or a gold-graphene composite plating layer. An electric connector is provided with the jack assembly. According to the jack assembly with the composite coating, the electric connector and an electroplating method of the jack assembly, the gold-graphene composite plating layer is electroplated on the contact spring coil, and the spring claw structure is optimized, so that the mechanical life of the jack assembly is prolonged, and the mechanical life of the electric connector is further prolonged.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Method for preparing carbon fiber precursor

ActiveCN104562264AReduce performance non-uniformity in the radial directionImproved performance non-uniformity in the radial directionMonocomponent synthetic polymer artificial filamentWet spinning methodsCarbon fibersItaconic acid

The invention relates to a method for preparing a carbon fiber precursor, and mainly aims at solving the problems in the prior art that the carbon fiber precursor obtaining by spinning is low in strength and unstable in property caused by poor radial uniformity of properties of a spinning solution due to different radial temperatures in the transportation process. Through the technical scheme that the method for preparing the carbon fiber precursor comprises the following steps: polymerizing a first monomer acrylonitrile, a second monomer itaconic acid through the initiation of an initiator azodiisobutyronitrile in solvent dimethyl sulfoxide to obtain the spinning solution; carrying out vacuum removal on residual gas and bubbles in the spinning solution, and then filtering and mixing to obtain a high-property polyacrylonitrile copolymer spinning solution; and carrying out solidifying, drafting, washing, oiling, compacting by drying, steam drafting and steam heat setting on the spinning solution, and then rolling to obtain the carbon fiber precursor with high strength and stable performance, the problems are relatively well solved, and the method can be applied to industrial production of carbon fibers.

Owner:CHINA PETROLEUM & CHEM CORP +1

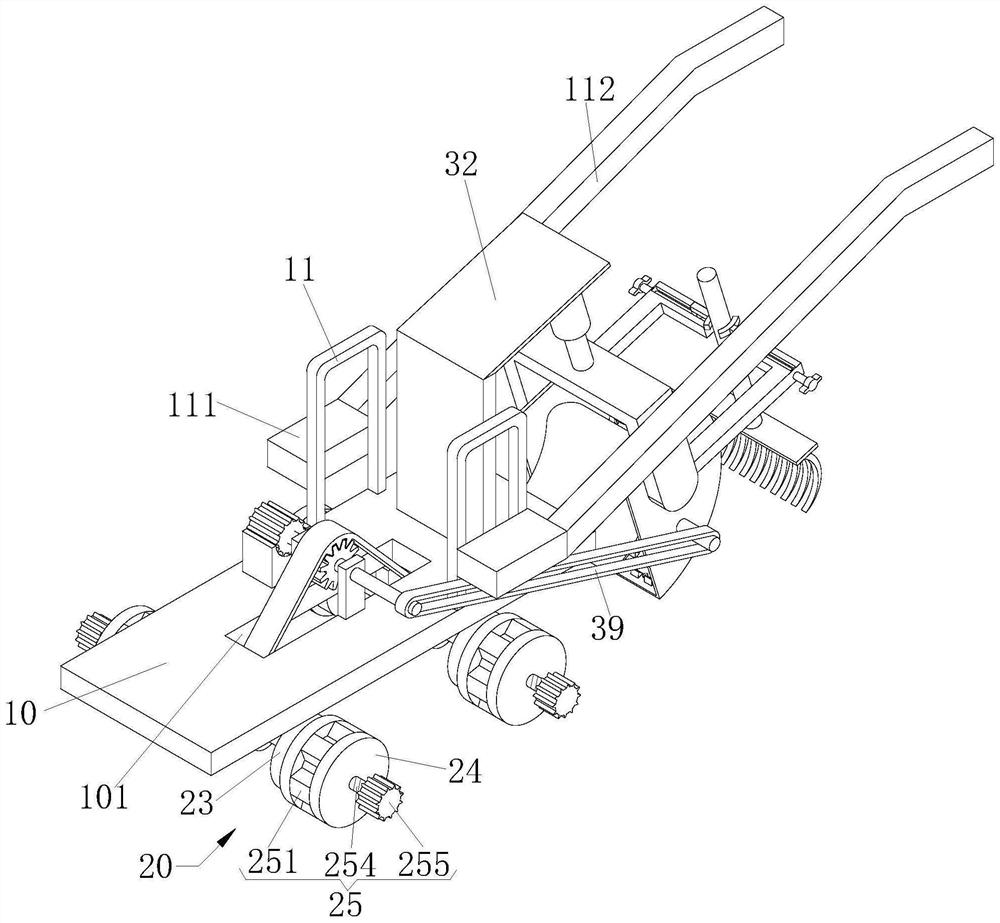

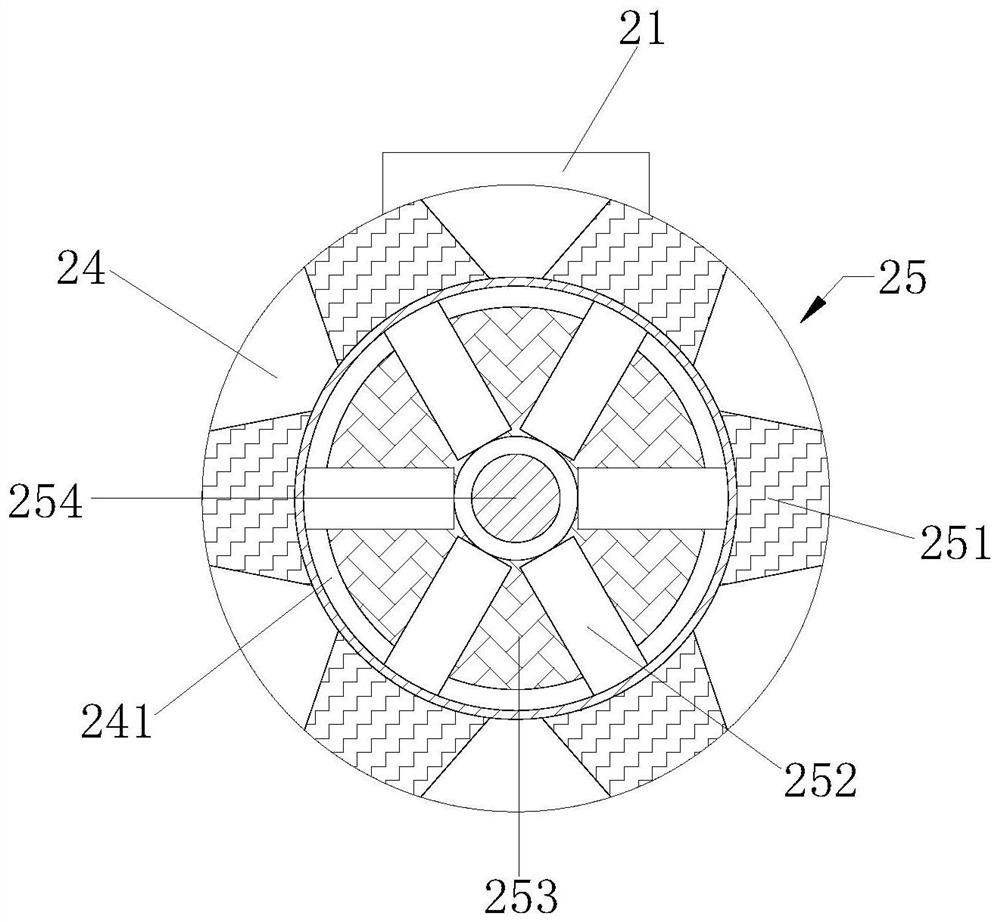

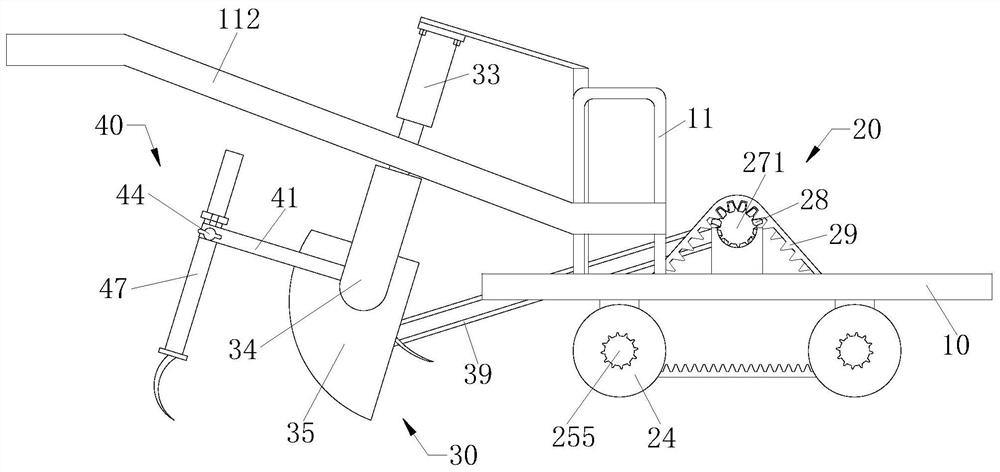

Agricultural ploughing robot

ActiveCN113099746AReduce labor intensityImprove efficiencySpadesPloughsAgricultural engineeringBiology

The invention relates to an agricultural ploughing robot. The agricultural ploughing robot comprises a bottom plate and a transmission device arranged on the outer side of the bottom plate, a ground breaking device is arranged on the left side of the bottom plate, and a uniformizing device is arranged on the outer side of a bucket. Through cooperation of the bucket, leaking holes, iron nails and crushing iron sheets, the bucket can turn over soil in a paddy field to be constructed, when the bucket excavates the soil in the paddy field, water in the paddy field is discharged through the leaking holes, so that the resistance of water flow to the bucket is reduced, and the labor intensity of farmers is reduced; and a crushing roller shaft can drive the crushing iron sheets to rotate synchronously, so that the crushing iron sheets and the iron nails are matched in a staggered mode, soil excavated by the bucket can be crushed, soil separation is more sufficient, the air permeability of the soil is improved, and the soil is kept loose; and the soil adhering to the inner wall of the bucket can be removed through the crushing iron sheets, and the situation that the crushing effect of the crushing iron sheets on the soil is affected after the soil is accumulated is prevented.

Owner:湖南田牧之家农业装备有限公司

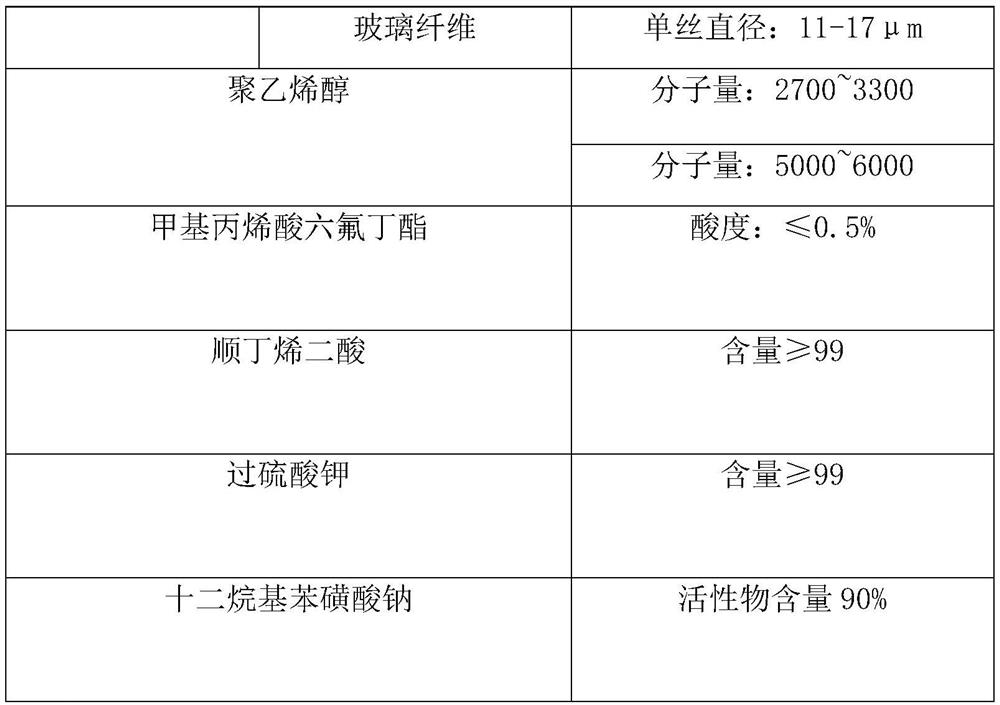

Earphone wire material and preparation process thereof

The invention relates to the technical field of earphone wires, and particularly discloses an earphone wire material and a preparation process thereof. The earphone wire material is prepared from the following raw materials in parts by weight: 50 to 75 parts of TPU resin, 7 to 12 parts of POE, 3 to 6 parts of filler, 8 to 15 parts of polyvinyl alcohol, 5 to 10 parts of hexafluorobutyl methacrylate, 0.2 to 0.4 part of sodium dodecyl benzene sulfonate and 0.1 to 0.5 part of potassium persulfate. The preparation method comprises the following steps: dissolving polyvinyl alcohol in water at 95-100 DEG C, adding an emulsifier and an initiator, stirring and dissolving, adding hexafluorobutyl methacrylate, and reacting at a constant temperature for 45-60 minutes to obtain modified polyvinyl alcohol; banburying and blending modified polyvinyl alcohol, TPU resin, POE and filler at 150-160 DEG C, cooling, crushing, and carrying out extrusion granulation. The earphone wire material can be used as an outer sleeve protection material of an earphone wire metal lead, and has the advantage of relatively better antifouling effect.

Owner:SHENZHEN TARGE IND CO LTD

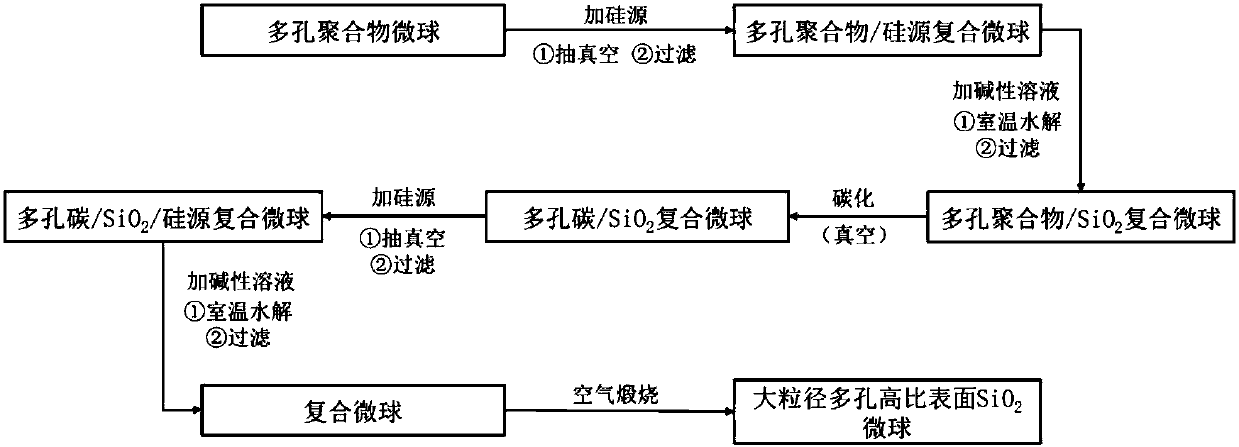

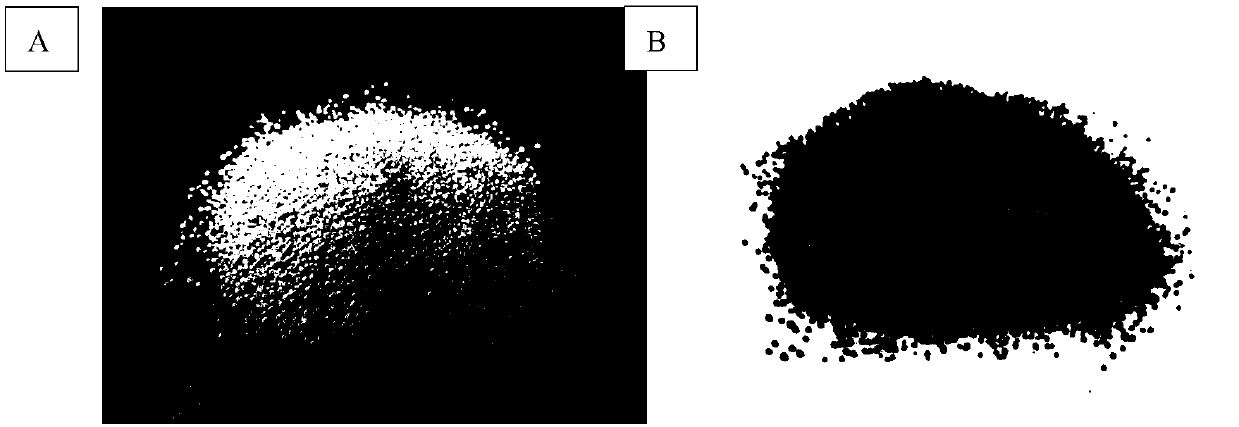

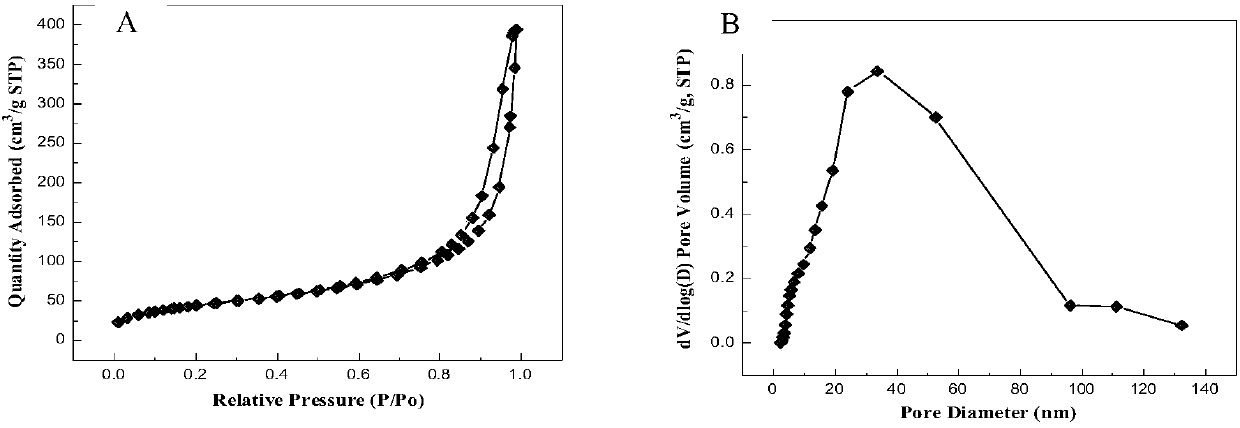

Preparation method of large-particle-size porous high-specific-surface silicon dioxide microspheres

ActiveCN107792858ALarge specific surface areaGuaranteed skeleton strengthSilicaMicrosphereCarbonization

The invention relates to a preparation method of a large-particle-size porous high-specific-surface silicon dioxide microspheres. The preparation method comprises the following steps of: taking industrialized macroporous large-particle-size resin as a template and organic silicon as a silicon source, 'filling' the silicon source into a porous resin channel under a vacuum condition, hydrolyzing thesilicon source under an alkaline condition, then carrying out calcination, and preparing large-particle-size high-specific-surface silicon dioxide microspheres by a method of replacing holes and walls. In the first step, silicon oxide is filled into pore channels of the template resin for one-step carbonization, and the framework of the template resin is carbonized to further bring pore channelssecond filling, thereby ensuring the framework strength of the product namely silicon dioxide microspheres and enrich the pore channels. The silicon dioxide microspheres prepared by the method have the advantages of high specific surface area, easy control of pore channels and particle sizes, good uniformity, simple preparation process, low cost, suitability for large-scale preparation and potential application value in the field of adsorption separation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

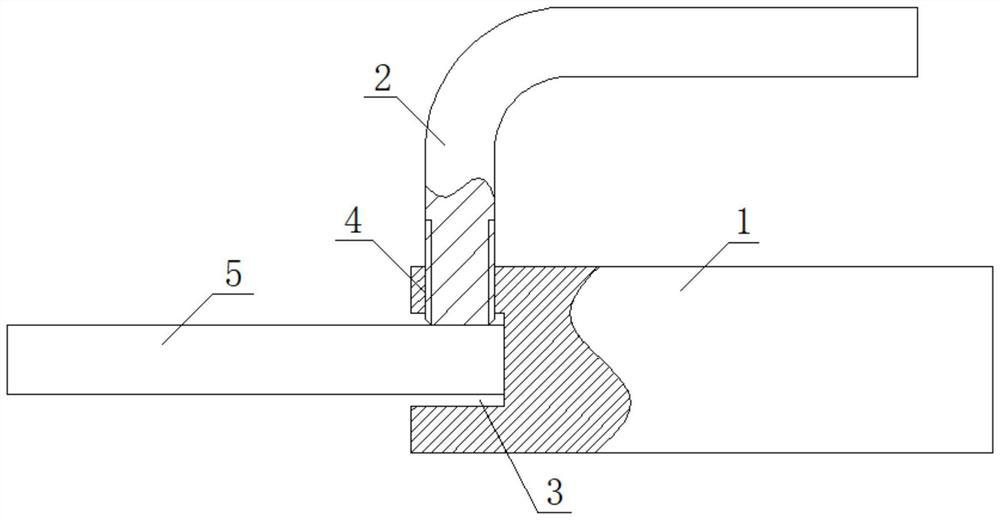

Material sample shearing and fixing device and metal gas content analysis sample preparation method

PendingCN114112585ATackle splashSame lengthPreparing sample for investigationMetallic materialsHardness

The invention discloses a material sample shearing and fixing device and a metal gas content analysis sample preparation method, relates to the field of material processing, and solves the problems of poor homogeneity and potential safety hazards in the existing sample preparation mode. The adopted technical scheme is as follows: the material sample shearing and fixing device comprises a base body and a fastener, the base body is provided with a reference surface, the reference surface is provided with a positioning hole, one side of the positioning hole is provided with a threaded through hole, the fastener comprises a screw-shaped part, and the screw-shaped part is installed in the threaded through hole of the base body. The preparation method of the metal gas content analysis sample comprises the following steps: firstly, processing a metal material into a rod shape and cleaning; secondly, one end of the metal material is fixed, and the other end of the metal material is inserted into the positioning hole and fixed through a fastener; thirdly, the metal material is sheared; and finally, preparing an analysis sample of the metal material. The method is suitable for preparing metal material gas content analysis samples with high hardness such as die steel, high-strength steel and high-temperature alloy.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Method for preparing ultra-fine cobalt blue pigment under low-temperature

InactiveCN100569869CGood grain developmentImprove hair colorPigmenting treatmentAluminium oxides/hydroxidesUltra fineHair Colors

A method for preparing ultra-fine cobalt blue material at low temperature. First, three cobalt tetroxide, aluminum hydroxide, zinc oxide and chromium oxide are mixed according to the general chemical formula Co1-xZnxAl2-yCryO4 to obtain reactants, wherein 0≤x<1, 0≤y≤2; secondly, add one or more of KOH, NaOH, KCl, NaCl, Li2SO4, Na2SO4 to the reactant and mix evenly to obtain a mixture; finally, calcinate the mixture at 800°C-1000°C for 1 -2 hours, grind the calcined product finely, wash and filter. The technical process and equipment of the invention are simple, easy to operate, cheap and easy to obtain raw materials, and low cost of colorant preparation. The pigment obtained by the preparation method of the present invention has the characteristics of good grain development, good color development, fine particle size, light agglomeration, good uniformity, etc., and at the same time, the introduction of salt can reduce the synthesis temperature.

Owner:SHAANXI UNIV OF SCI & TECH

A plug-resistant electrical connector

ActiveCN112382879BReduce wearImprove wear resistanceSecuring/insulating coupling contact membersCoupling contact membersElectrical connectionGraphite

Owner:GUIZHOU SPACE APPLIANCE CO LTD

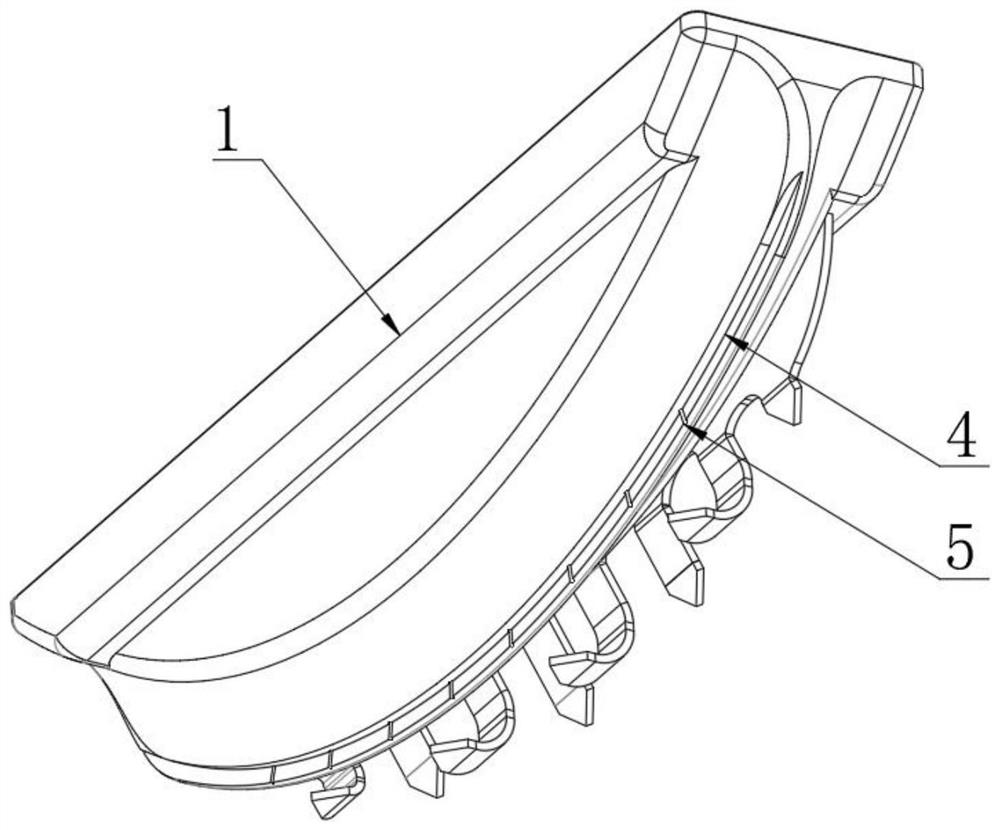

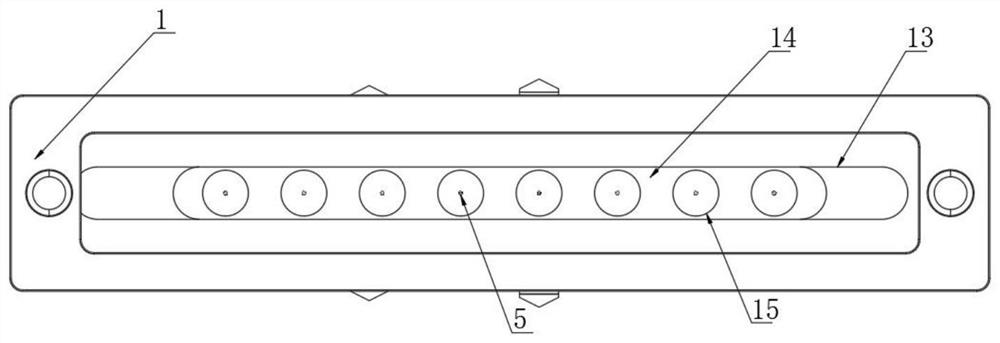

Multi-micropore spray head for electrostatic spinning

PendingCN114318555ASolve the shortage of production capacitySolve problems related to industrializationFilament/thread formingSpinningStructural engineering

An arc-shaped sector knife edge is formed in the single face of the bottom end of a fixing base below an arc-shaped groove, a plurality of spraying holes are formed in the arc-shaped sector knife edge, sector-shaped panels are connected to the bottom ends of the fixing base on the two sides of the arc-shaped groove, triangular plates are connected to the most edge portions of the bottom ends of the sector-shaped panels, and the triangular plates are connected to the most edge portions of the bottom ends of the sector-shaped panels. One end of a fan-shaped panel of the triangular plate is sequentially connected with a short-axis arc-shaped plate, a long-axis triangular plate, a short-axis arc-shaped plate and a long-axis triangular plate. Aiming at the related problems of insufficient capacity, industrialization and the like in the current electrospinning industry, the multi-micropore (micro-gap) spray head is adopted, so that the spinning speed of a single spray head reaches 2-30 times that of a common needle type spray head; according to the flow of a spinning solvent in the nozzle in fluid science, and according to the electric field principle, micropores are directly punched or micro slender gaps are directly machined in the arc sector nozzle, so that the mutual interference between filaments sprayed from the micropores or the micro gaps is reduced, and the filament diameter and the filament surface are uniform.

Owner:江苏飙鲛新材料科技有限公司

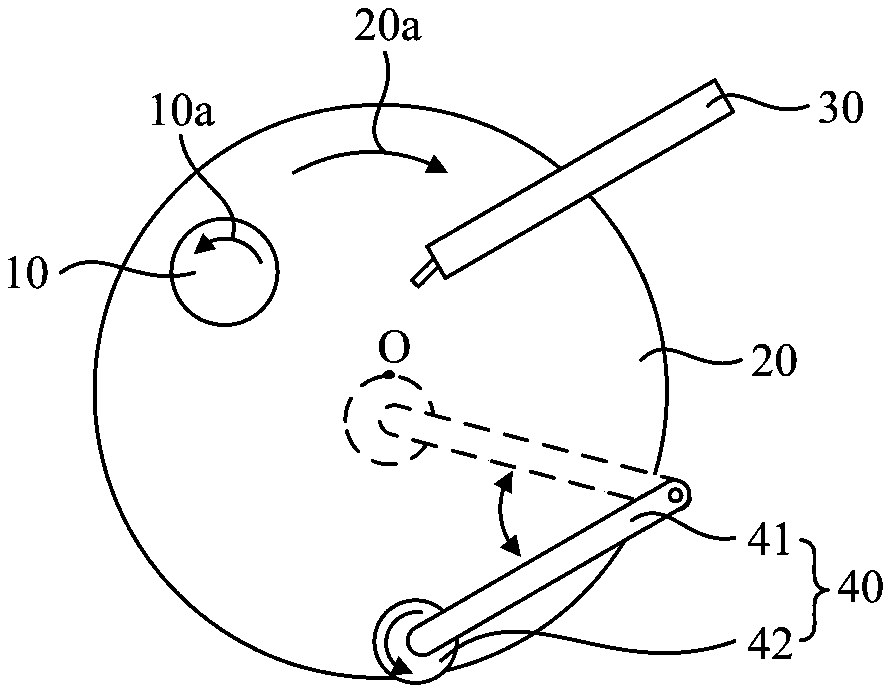

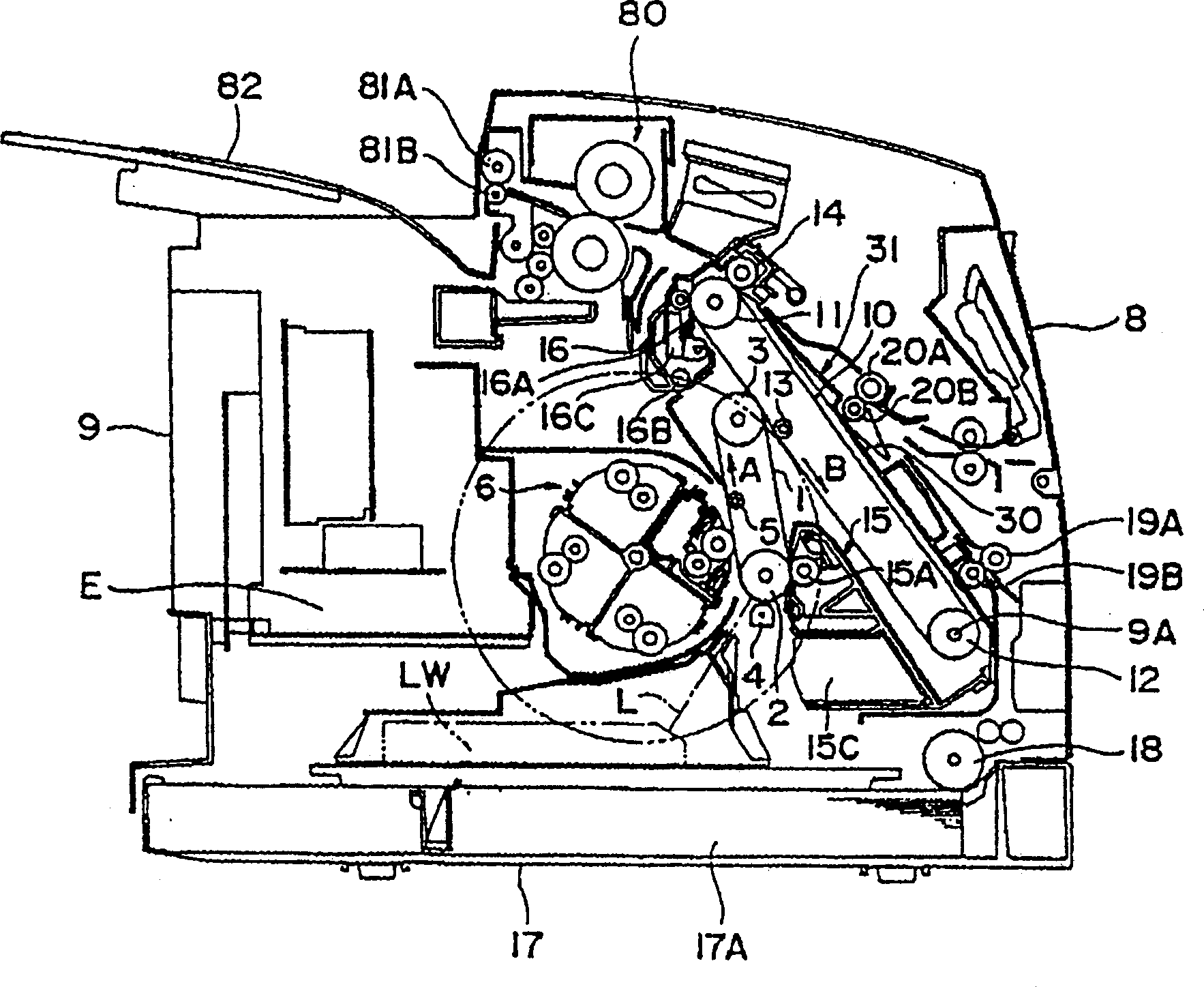

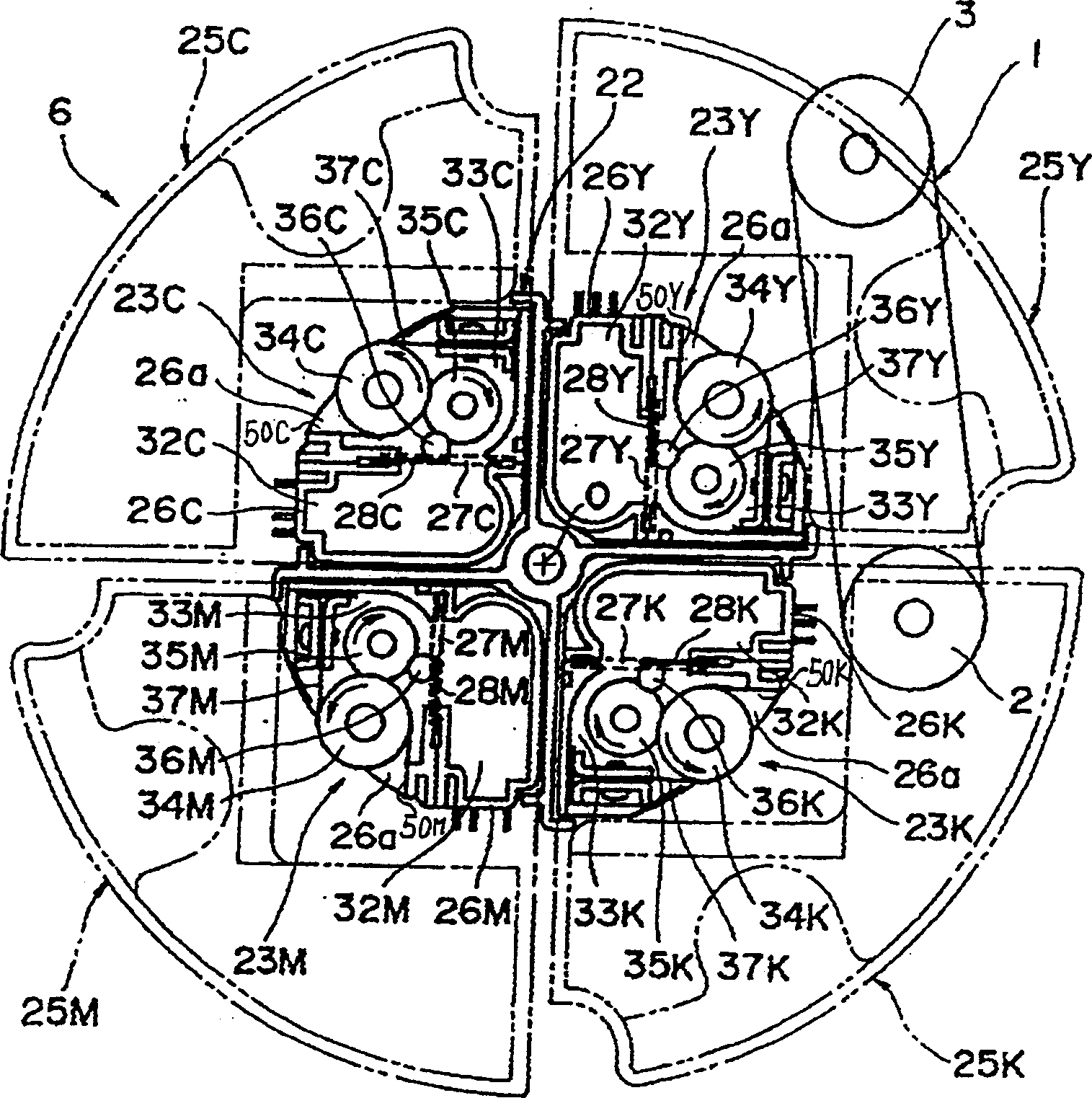

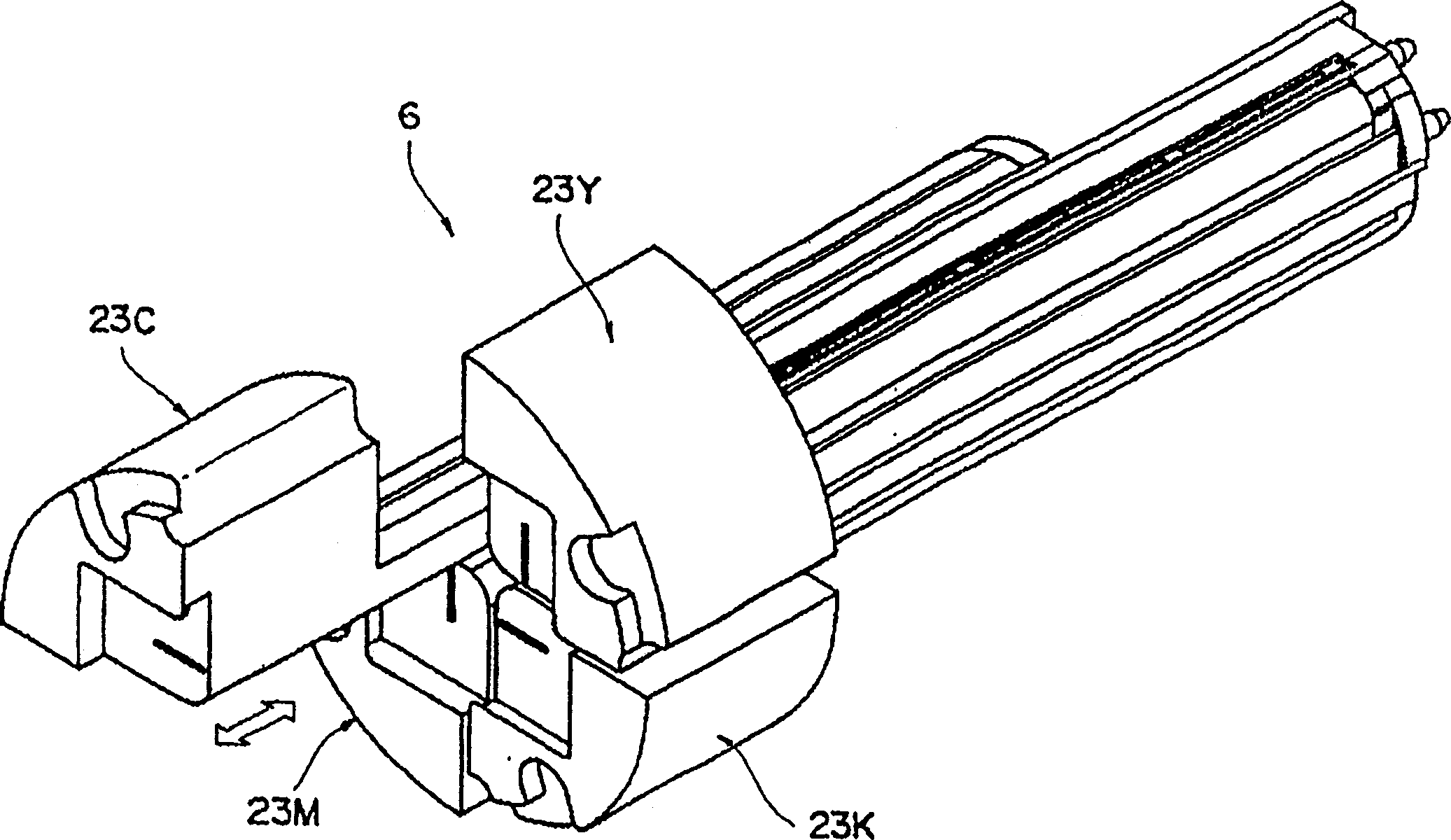

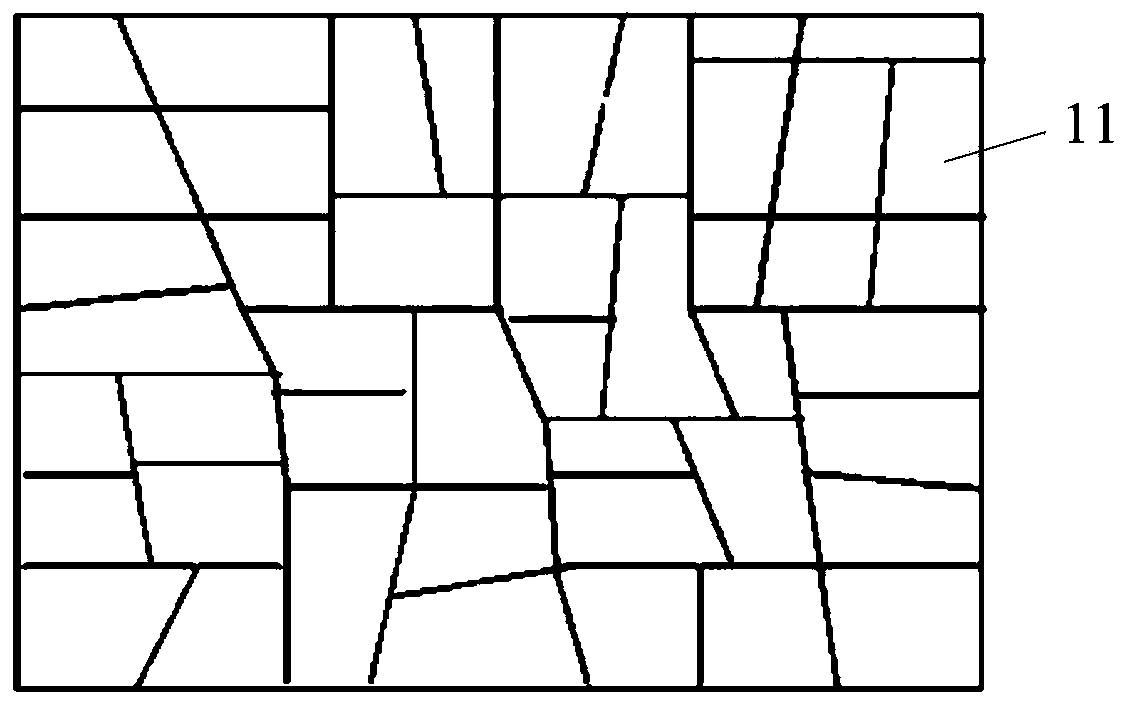

Rotary developing device and image forming device using the developing device

InactiveCN1143181CPoor uniformityAvoid stressElectrographic process apparatusLatent imageImage formation

The invention relates to a rotary type developing device of an image forming device. The inside of a case 26 of a developing device 26 is isolated by an isolating member 28 while leaving a communicative path 27, a developer storage part 32 where the developer is temporarily stored and a developing part 33 where the developer fed through the communicative path 27 is stuck to a photoreceptor belt 1 are provided. Then, a plurality of developing units 23 consisting of the developing device and developer container are provided, and either one of the developing units 23 is selected by rotation and moved to a developing position to develop an electrostatic latent image formed on the photoreceptor belt. To prevent an image from being deteriorated in uniformity and being deteriorated due to surface soiling or the like by preventing toner from being stressed and stably feeding developer in a rotary type developing device of an image forming device.

Owner:RICOH KK

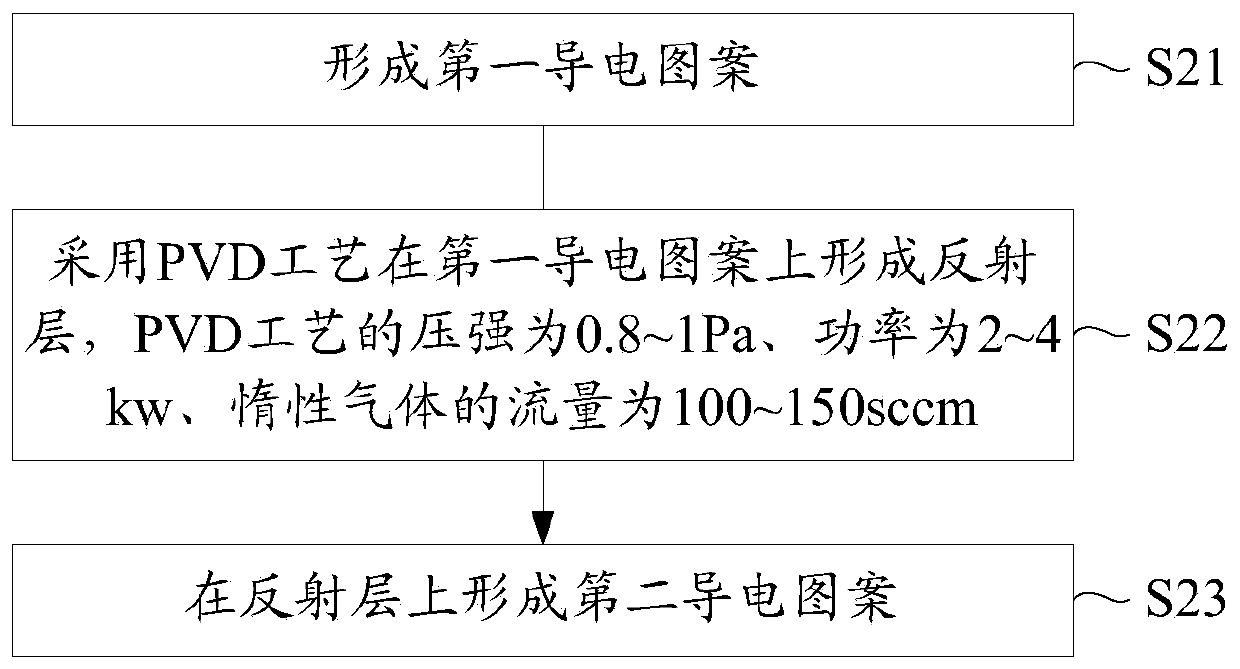

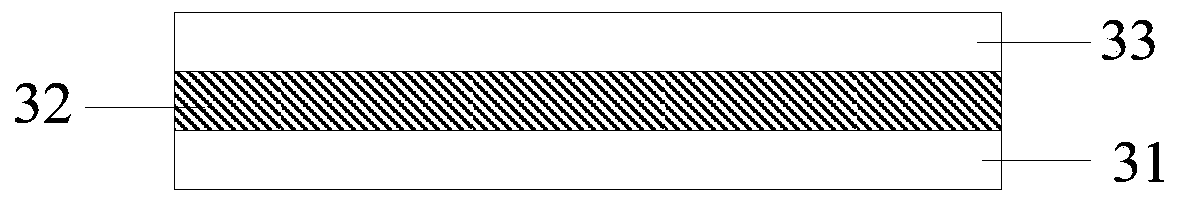

OLED anode and manufacturing method thereof, manufacturing method of OLED substrate

ActiveCN108305959BArrange neatlyPoor uniformitySolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryReflective layer

The invention discloses an OLED anode, a manufacturing method thereof, and a manufacturing method of an OLED substrate. The manufacturing method of the OLED anode includes: forming a first conductive pattern; forming a reflective layer on the first conductive pattern by using a physical vapor deposition PVD process, the pressure of the PVD process is 0.8-1Pa, the power is 2-4kw, and the inert gas The flow rate is 100-150 sccm; a second conductive pattern is formed on the reflective layer. Based on this, the present invention can reduce the uniformity of crystal grain size in the reflective layer, increase the reflectivity of the reflective layer to visible light, and improve the luminous efficiency of the OLED panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

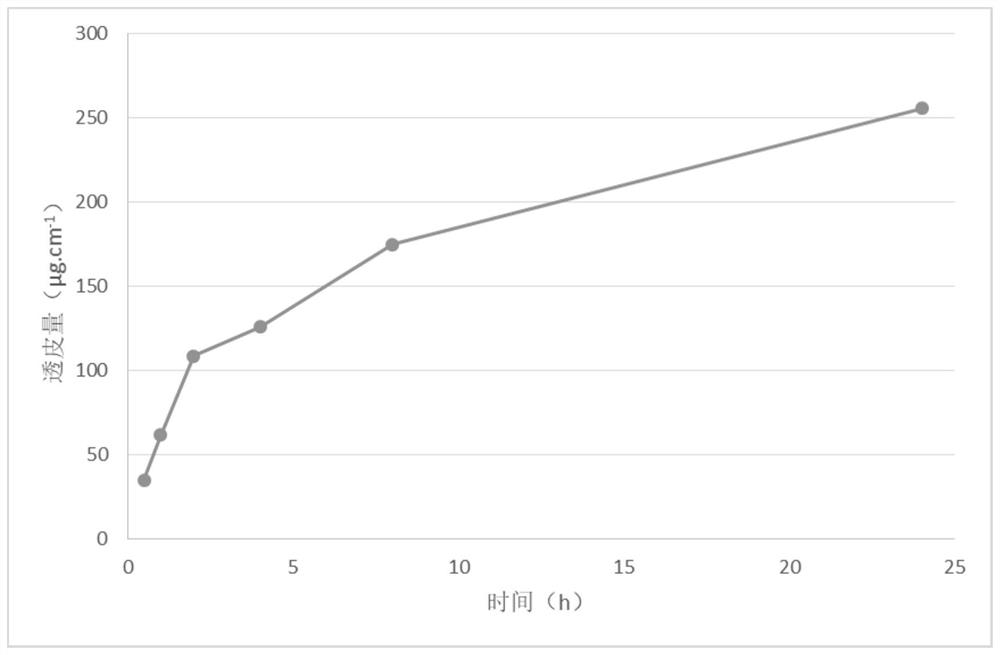

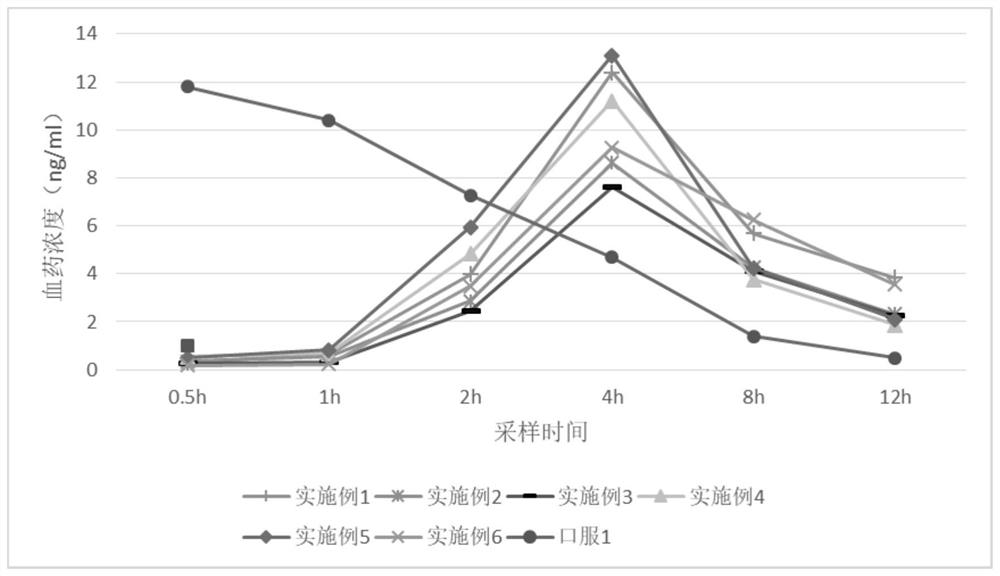

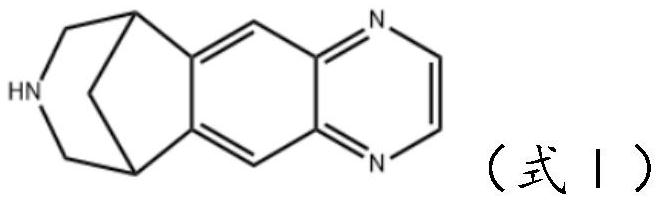

Varenicline transdermal solution as well as preparation method and application thereof

InactiveCN113116814AImprove solubilityImprove uniformityNervous disorderAntipyreticPatient complianceGlycerol

The present invention relates to a varenicline transdermal solution. The transdermal solution comprises varenicline or a pharmaceutically acceptable salt thereof and a pharmaceutically acceptable carrier, wherein the pharmaceutically acceptable carrier is selected from any one or a combination of a penetration enhancer, a humectant, a preservative and a solvent, and the solvent is selected from any one or a combination of glycerol, propylene glycol, ethanol and water. The solution is absorbed through skin, has the advantages of being long-acting, high in bioavailability, good in patient compliance, convenient to carry and use, flexible in medication position, capable of achieving postaural targeted administration, free of skin irritation and the like, and the effectiveness and safety of the medicine and the medication compliance of the patient are remarkably improved.

Owner:江苏山信药业有限公司

A double-layer spiral electrochemical device for removing and recovering heavy metals in sludge

ActiveCN105217906BIncrease the effective contact areaIncreased membrane exchange areaSludge treatmentElectrochemical responseSludge

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com