Dressing method of grinding pad

A technology for grinding pads and grinding areas, which is applied to the components of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems of reduced grinding removal rate and poor surface uniformity of grinding pads, and achieve improved Grinding removal rate, reduced replacement frequency, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

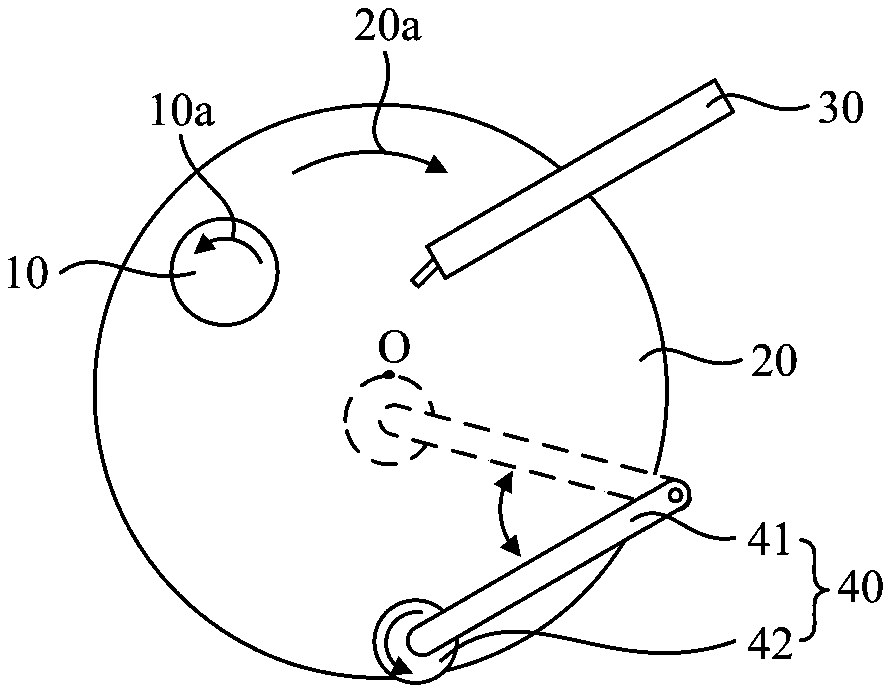

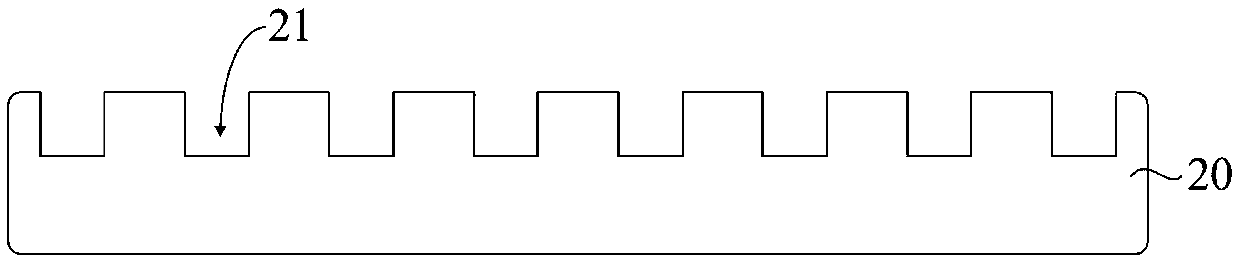

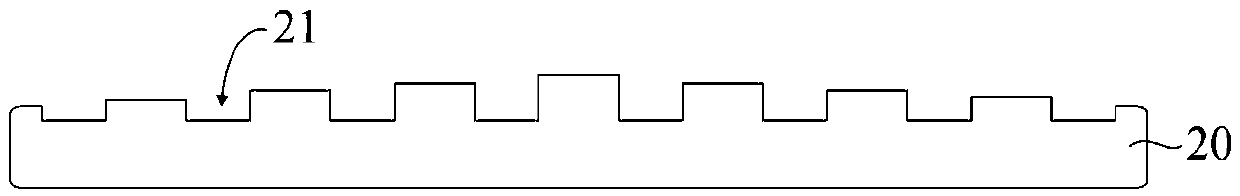

[0026] The grinding pad dressing method of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The advantages and features of the present invention will become clearer from the following description. It should be noted that the drawings are all in a very simplified form and use inaccurate proportions, which are only used to facilitate and clearly illustrate the purpose of the embodiment of the present invention. In addition, the components in some drawings are different from those in other drawings. Components may be the same, although these components can be easily identified in all drawings, but in order to make the description of the drawings clearer, this specification will not mark all the same components with the same reference numerals in each figure.

[0027] At present, chemical mechanical polishing (CMP) equipment is widely used in the manufacturing process of semiconductor elements, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com