A plug-resistant electrical connector

A plug-resistant technology for electrical connectors, applied in the field of plug-resistant electrical connectors, can solve problems affecting mechanical life, cracking, etc., and achieve the effects of improving mechanical life, improving wear resistance, and reducing coating wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

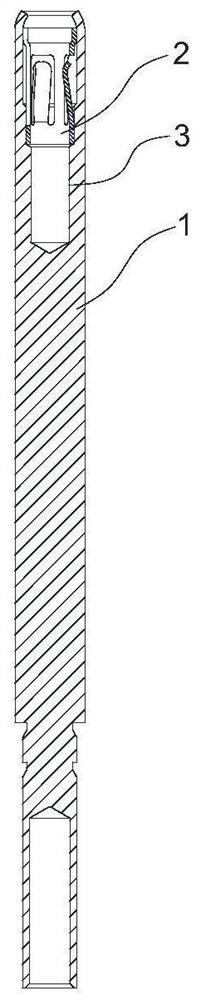

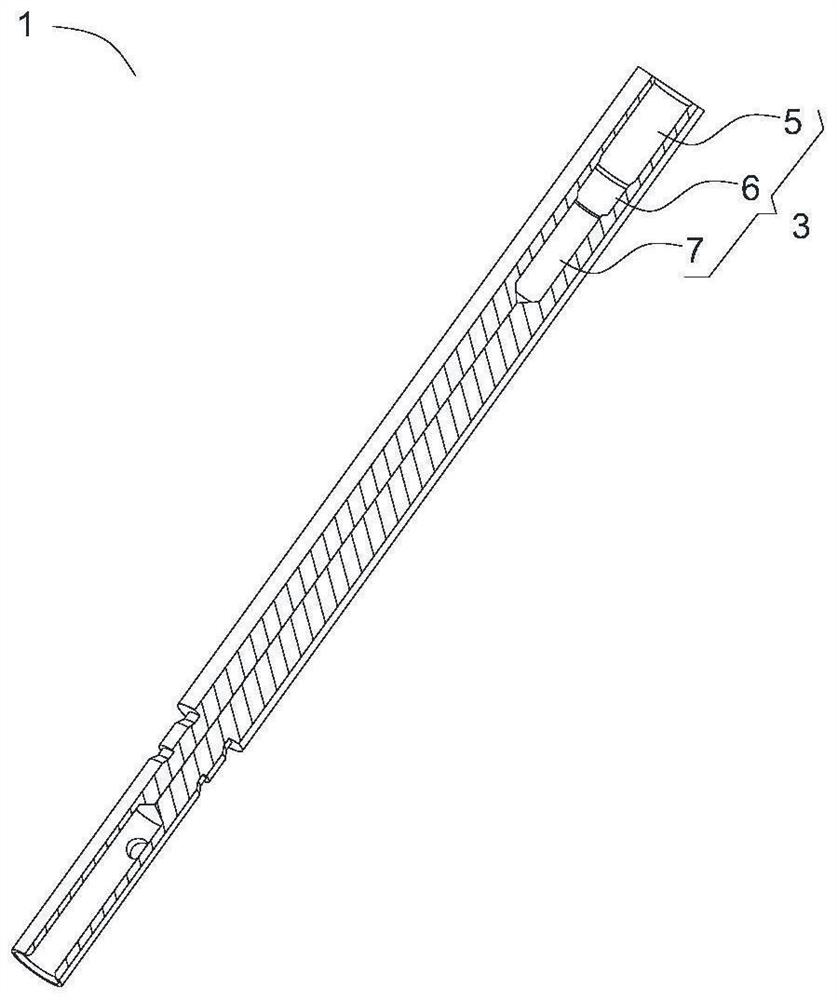

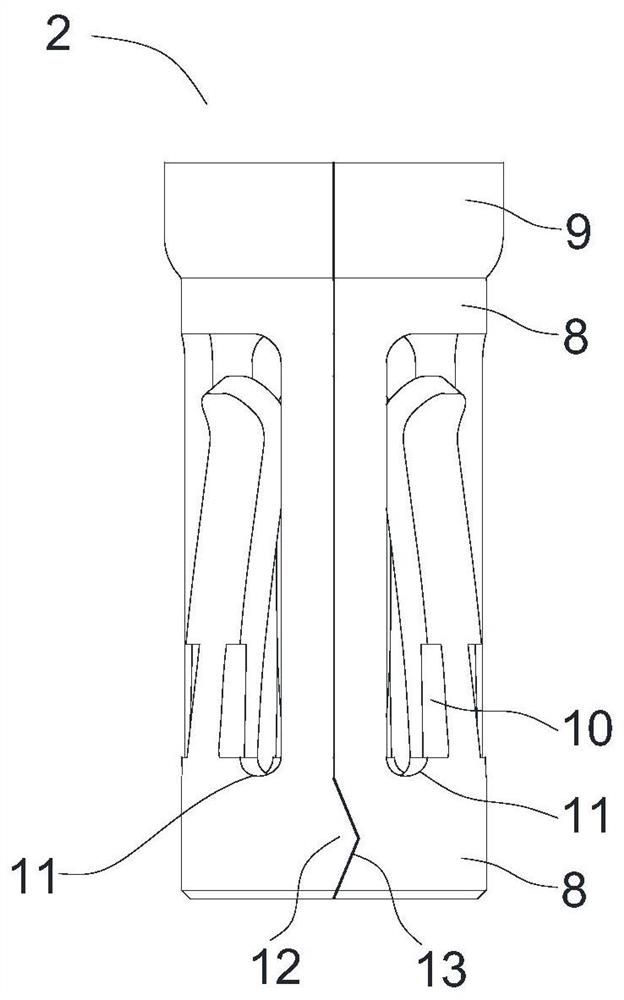

[0023] like Figure 1 to Figure 6 As shown, a plug-resistant electrical connector includes a jack fitting and a base, the jack fitting is installed in the base, the jack fitting includes a jack 1, a contact coil 2, and the jack 1 is butted One end is provided with a blind hole 3, and the contact coil 2 is installed in the blind hole 3, and the opening of the blind hole 3 is closed to fix the contact coil 2 in the blind hole 3, and the contact coil 2 is provided with several elastic claws 4, and the contact spring The coating of ring 2 is gold-graphene composite coating, and the coating of socket 1 is gold coating or gold-graphene composite coating. Using the excellent electrical conductivity and self-lubricating properties of graphene, under the condition of ensuring contact pressure, Reduce the friction coefficient to reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com