Perovskite precursor solution for improving stability of perovskite solar cell

A perovskite precursor, solar cell technology, applied in the field of solar energy to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The perovskite precursor solution for improving the stability of perovskite solar cells is composed of: bromomethylamine 14.1 mg, iodoformamidine 155.4 mg, lead iodide 554.3 mg, cesium iodide 47 mg, 3,4 -Dichloroaniline is 7.86 mg (ie 1.02%), 200mL dimethyl sulfoxide, 800mL N,N-dimethylformamide.

[0031] The preparation method is as follows:

[0032] (1) Add N,N-dimethylformamide into dimethyl sulfoxide, and stir the solution evenly;

[0033](2) Weigh formamidine iodide and cesium iodide, add them to the solution stirred in step (1), stir for 10 minutes, then add methyl bromide to the solution, raise the temperature of the solution to 50°C, and stir for 10 minutes ;

[0034] (3) Add lead iodide to the solution prepared in step (2), then add 3,4-dichloroaniline into the solution and stir until dissolved; keep the solution at a constant temperature of 50°C during the entire adding and stirring process;

[0035] (4) Continue stirring the solution prepared in step (3) a...

Embodiment 2

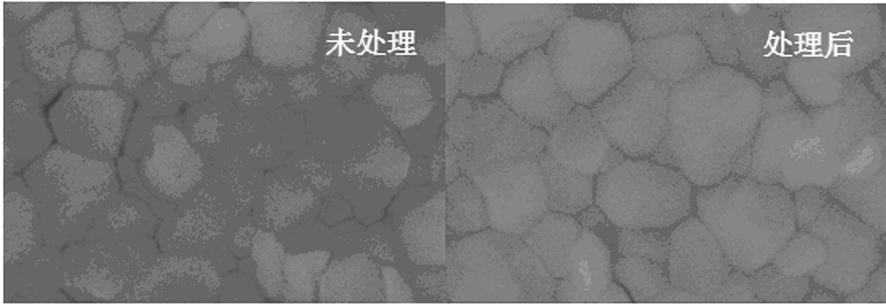

[0041] The light-absorbing layer of the solar cell is prepared by spin-coating the perovskite precursor solution for improving the stability of the perovskite solar cell in Example 1 on the substrate, and thermally annealing at 150° C. for 30 minutes to obtain the light-absorbing layer of the solar cell. crystal morphology see figure 1 ; Spin coating is two steps, first spin coating at 1000 rpm for 10 seconds, then spin coating at 6000 rpm for 30 seconds, and add 200 microliters of ether dropwise 15 seconds before the end of spin coating on a rotating perovskite film.

[0042] The substrate is coated with TiO 2 FTO glass or with SnO 2 ITO glass; the above operations were carried out in a glove box with water and oxygen content below 2PPM.

Embodiment 3

[0044] A perovskite solar cell comprises a conventional substrate, an electron transport layer, a hole transport layer, an electrode and a perovskite layer, and the perovskite layer is composed of the perovskite precursor for improving the stability of the perovskite solar cell of embodiment one Solution preparation.

[0045] The preparation method of above-mentioned solar cell is as follows:

[0046] The perovskite precursor solution for improving the stability of perovskite solar cells in Example 1 is spin-coated on the substrate, and thermally annealed at 150°C for 30 minutes to obtain the light-absorbing layer of the solar cell. Spin-coating is two steps, first at 1000 rpm Spin coating at a speed of 6000 rpm for 10 seconds, then spin coating at a speed of 6000 rpm for 30 seconds, add ether dropwise before the end of spin coating; then prepare a hole transport layer on the light-absorbing layer, and then place the prepared device in a high vacuum In the electrode evaporati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com