Method for preparing ultra-fine cobalt blue pigment under low-temperature

A blue, low-temperature technology, applied in the field of material science, can solve problems such as high crystallization temperature and complex process, and achieve the effects of low preparation cost, cheap and easy-to-obtain raw materials, and simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

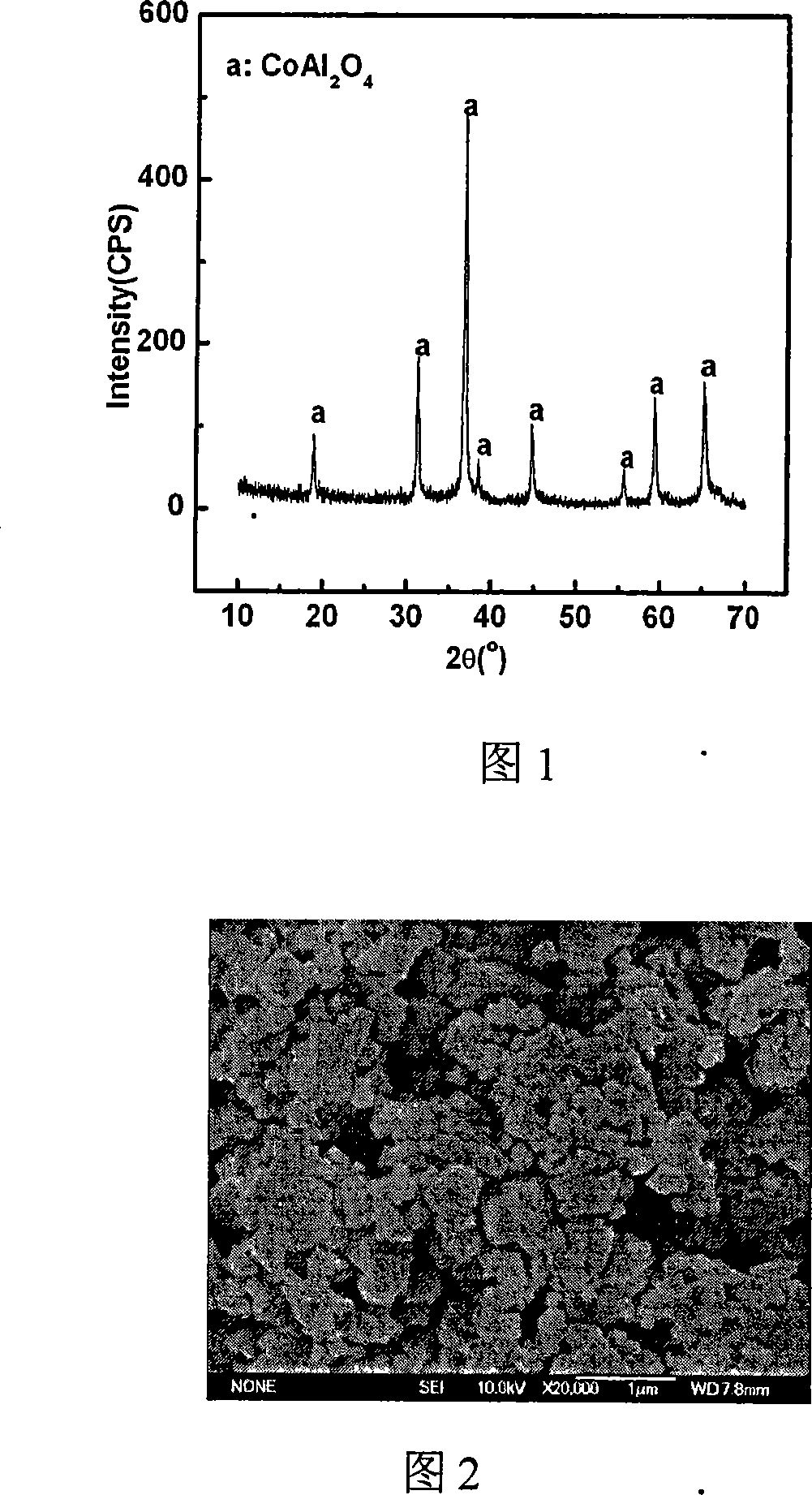

[0010] Embodiment 1: first, three cobalt tetroxide and chromium oxide are pressed by chemical general formula Co 1 Cr 2 o 4 Proportioning is carried out to obtain the reactant, secondly, KOH and NaOH with 100% of the mass of the reactant are added to the reactant and mixed evenly to obtain a mixture; finally, the mixture is calcined at 900° C. for 1 hour, the calcined product is ground, washed, and filtered. Can. It can be seen from Figure 1 that the main crystal phase of the obtained color material is spinel-type cobalt aluminate, and no other impurity phases exist; it can be seen from Figure 2 that the synthetic color material has a small particle size and a small distribution. Between 400nm. The grain development is better and the agglomeration is lighter.

Embodiment 2

[0011] Embodiment 2: at first, tricobalt tetroxide, aluminum hydroxide, zinc oxide and chromium oxide are according to general chemical formula Co 0.5 Zn 0.5 Al 1 Cr 1 o 4 Proportioning is carried out to obtain the reactant, secondly, NaOH and KOH with 150% of the mass of the reactant are added to the reactant and mixed uniformly to obtain a mixture; finally, the mixture is calcined at 800° C. for 2 hours, and the calcined product is ground, washed, and filtered. Can.

Embodiment 3

[0012] Embodiment 3: at first, tricobalt tetroxide, aluminum hydroxide and zinc oxide are according to general chemical formula Co 0.2 Zn 0.8 Al 2 o 4 Proportioning is carried out to obtain the reactant, secondly, KCl with 80% of the mass of the reactant is added to the reactant and mixed uniformly to obtain a mixture; finally, the mixture is calcined at 1000° C. for 1.6 hours, the calcined product is ground, washed and filtered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com