Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improve foamability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surfactant composition

InactiveUS6946430B2Improve foamabilityImprove performanceInorganic/elemental detergent compounding agentsCosmetic preparationsSulfonateActive agent

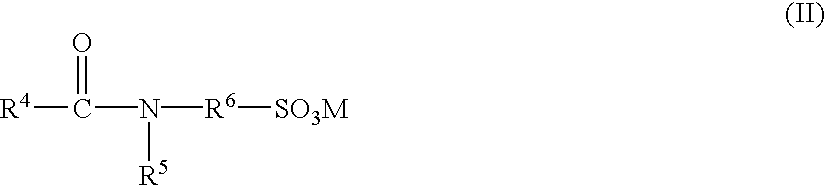

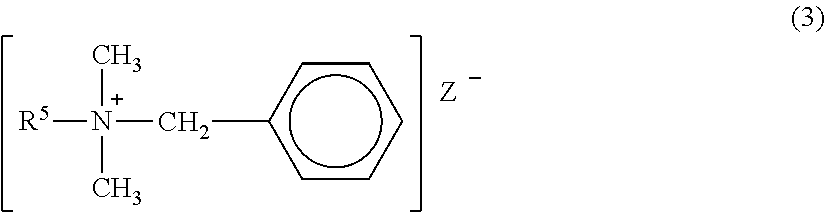

To provide a surfactant composition with an excellent foamability and thickening performance and further an excellent storage stability, it comprises the following components (a) and (b):(a) at least one anionic surfactant selected from (1) sulfonate-type anionic surfactants having amide group or ester group, (2) carboxylate-type anionic surfactants and (3) phosphate-type anionic surfactants and(b) a compound expressed by the formula (I): where R1CO— is an acyl group having 6 to 24 carbon atoms, R2 is an alkyl group having 1 to 3 carbon atoms and R3 is an alkylene group having 1 to 6 carbon atoms or an alkenylene group having 2 to 6 carbon atoms.

Owner:KAO CORP

Aqueous hair cleansing agent

InactiveUS20120022037A1Less causativeImprove combabilityAntibacterial agentsBiocideChemistryPolyoxyethylene alkyl ether

The present invention relates to an aqueous hair cleansing agent which includes the following components (A), (B): (A) sulfate-type anionic surfactant having a specific structure, (B) polyoxyethylene alkyl ether-type nonionic surfactant having a specific structure, and water, wherein ratio of weight represented by (B) / ((A)+(B)) is 1% to 25%.

Owner:KAO CORP

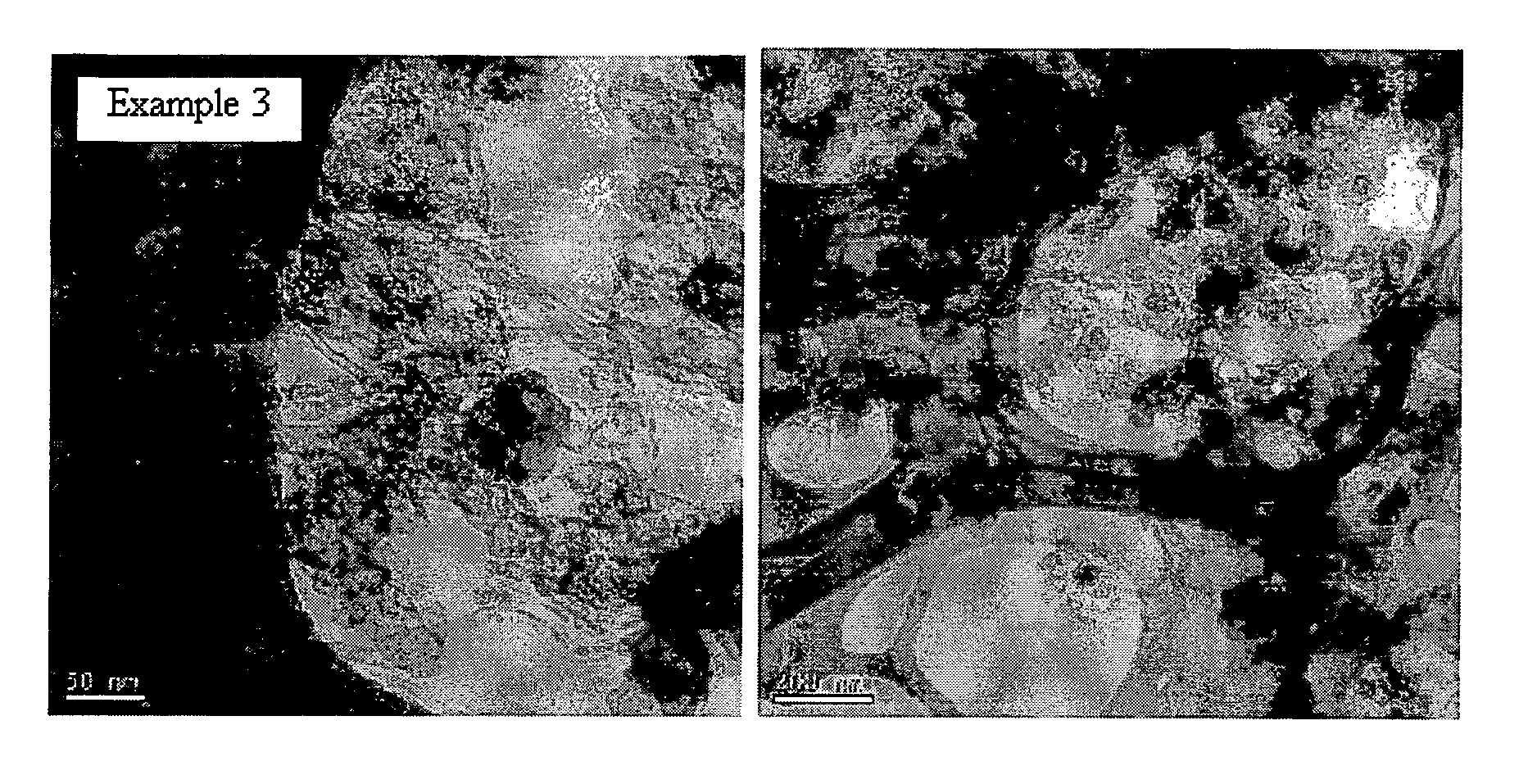

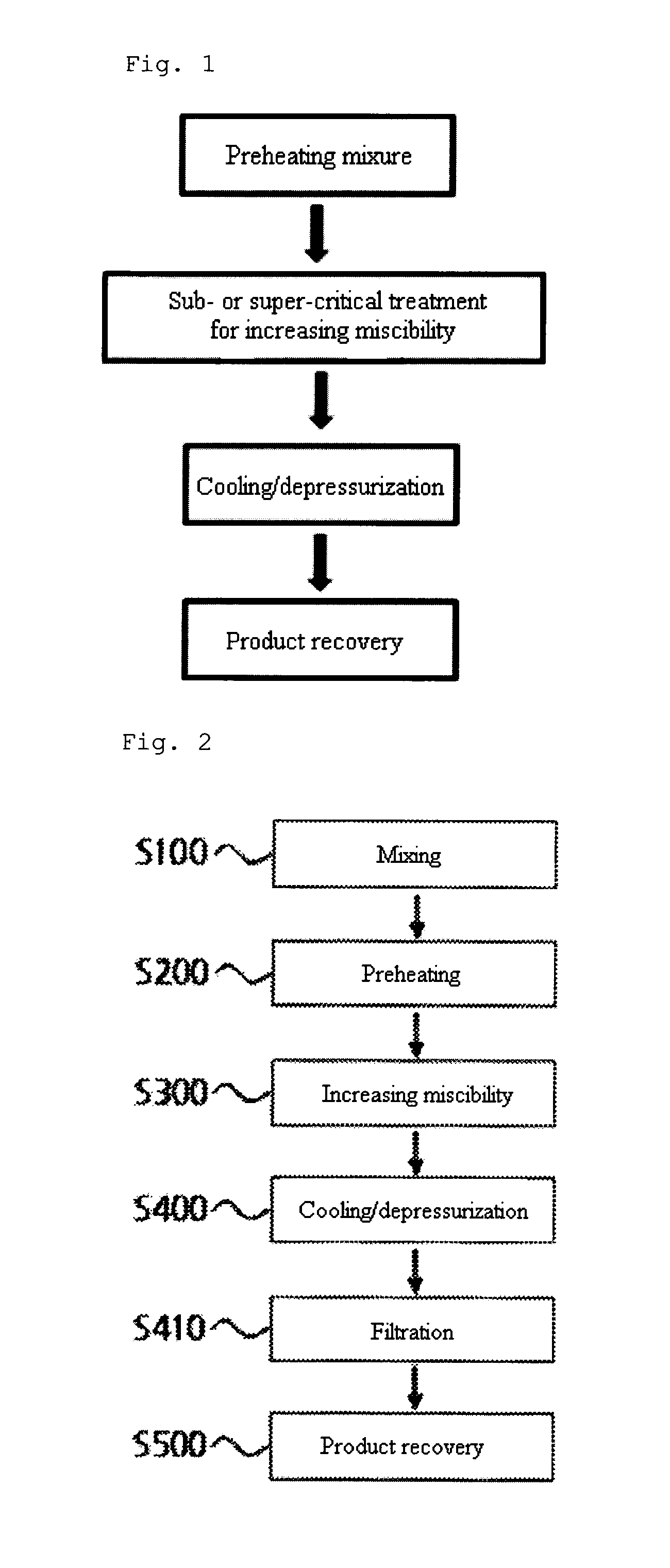

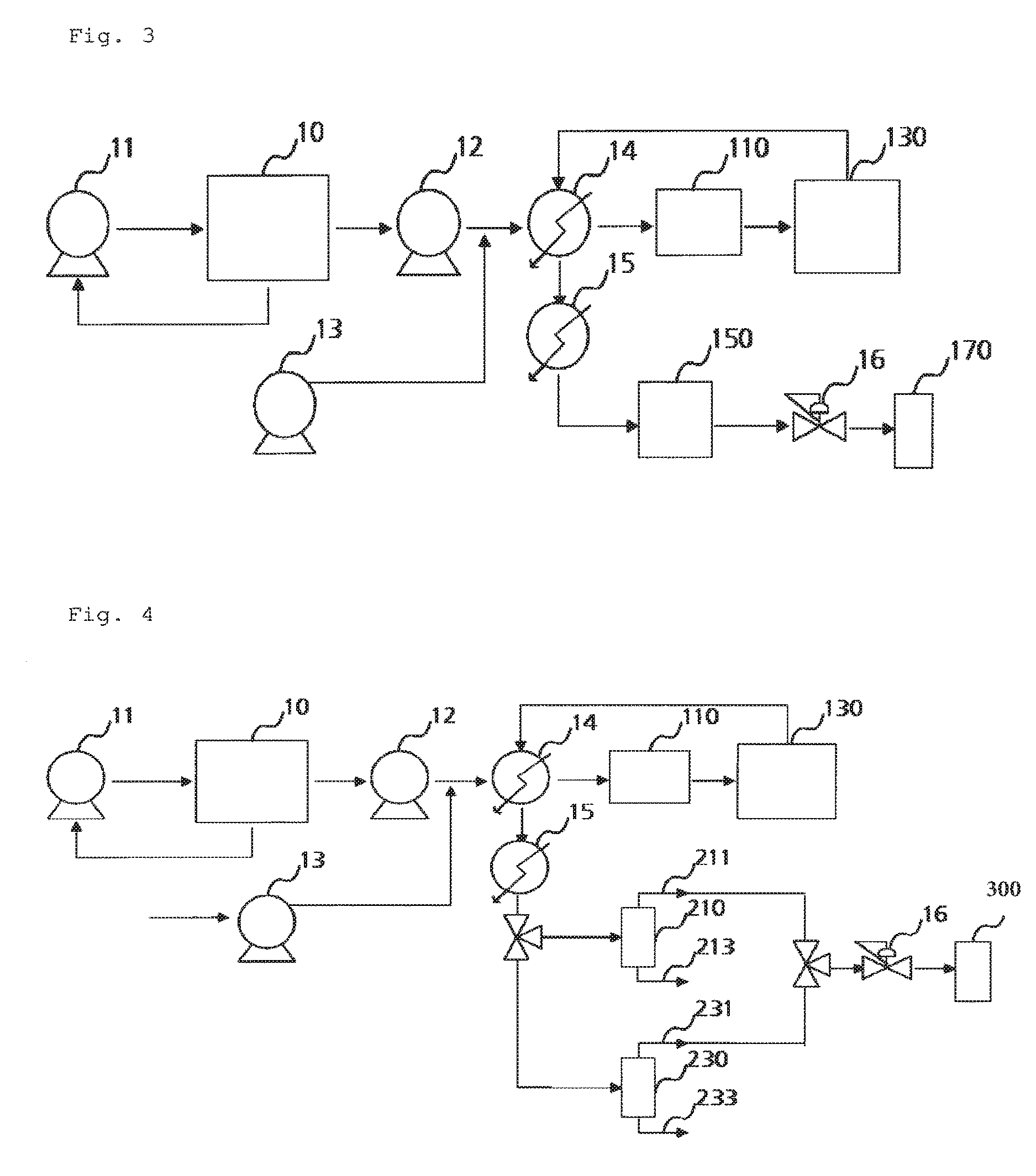

Blending Improvement Carbon-Composite having Carbon-Nanotube and its Continuous Manufacturing Method and Apparatus

ActiveUS20120112134A1Good dispersionImprove conductivityNon-metal conductorsMaterial nanotechnologyCarbon compositesCritical condition

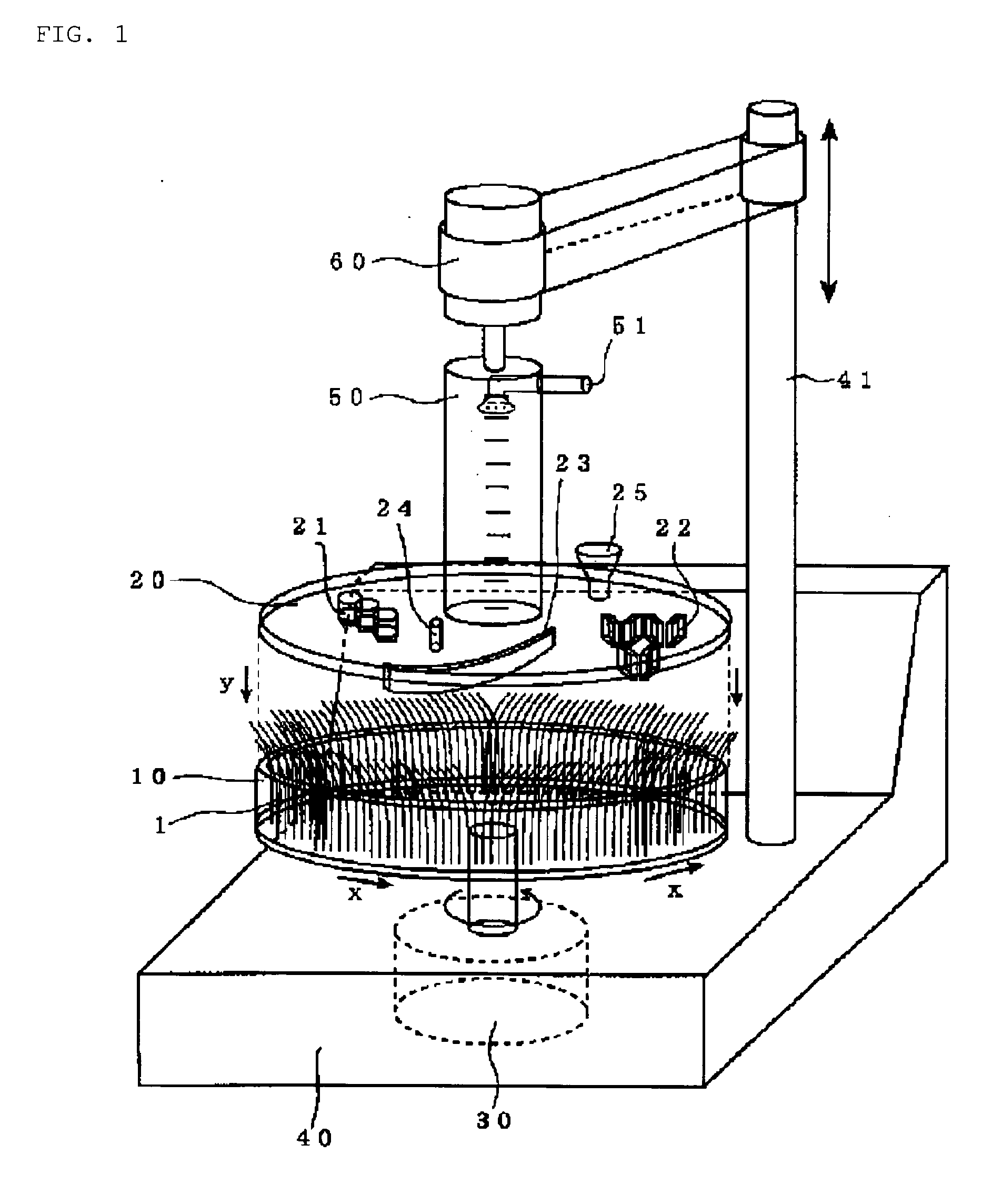

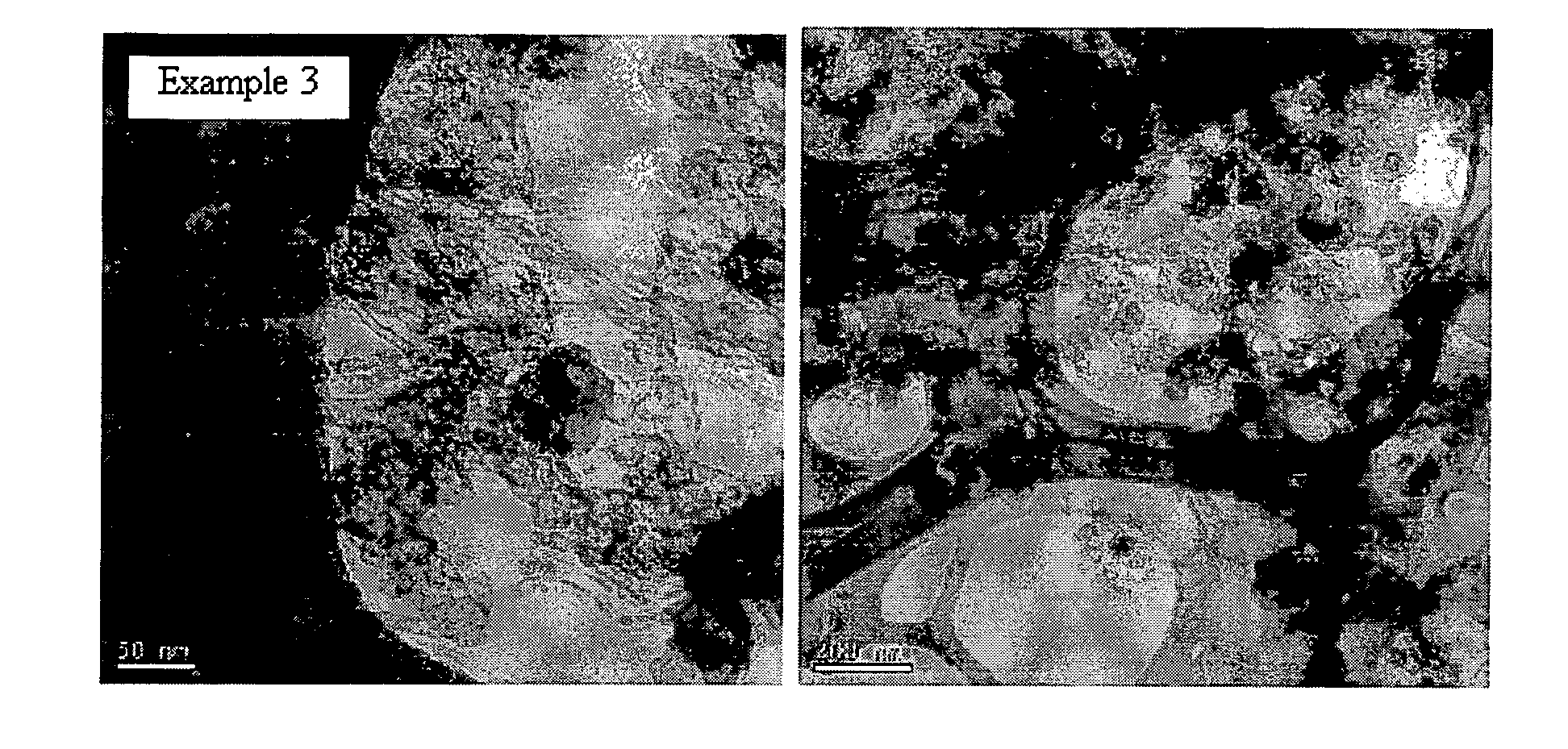

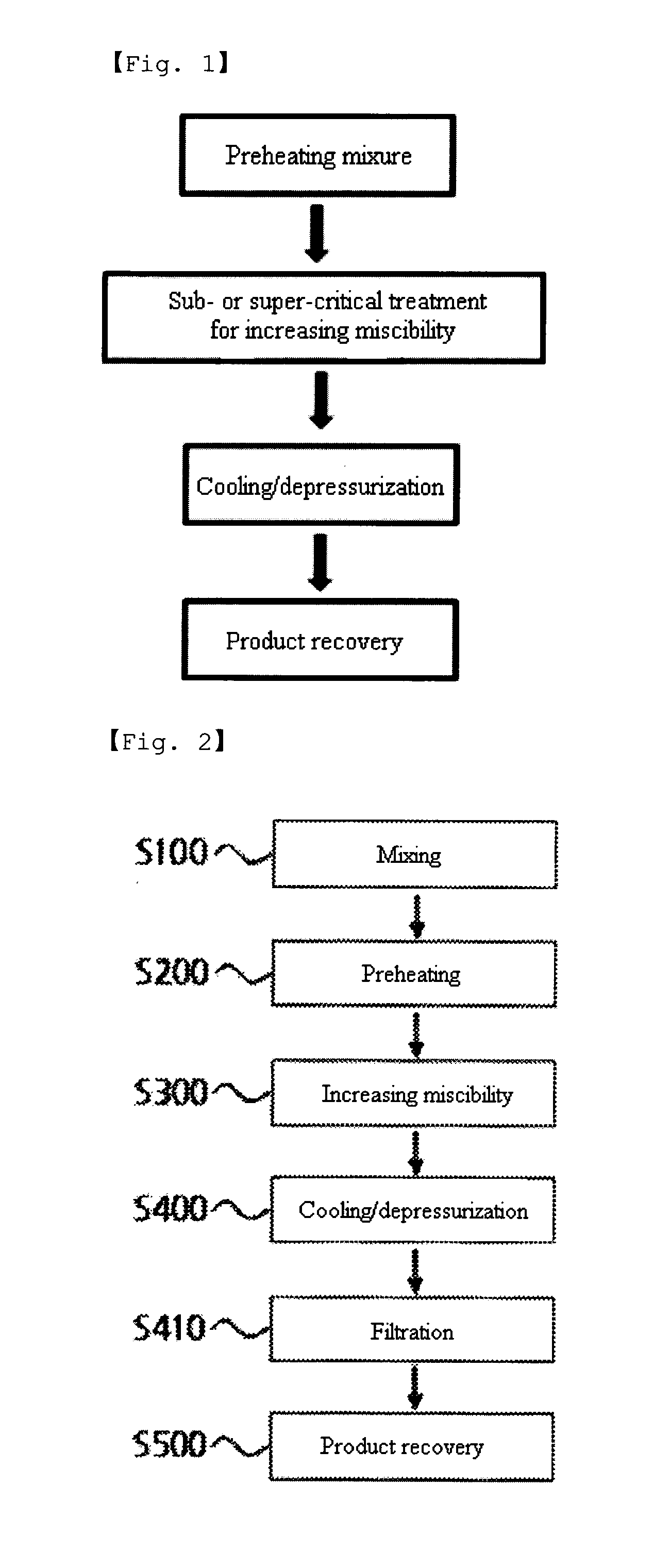

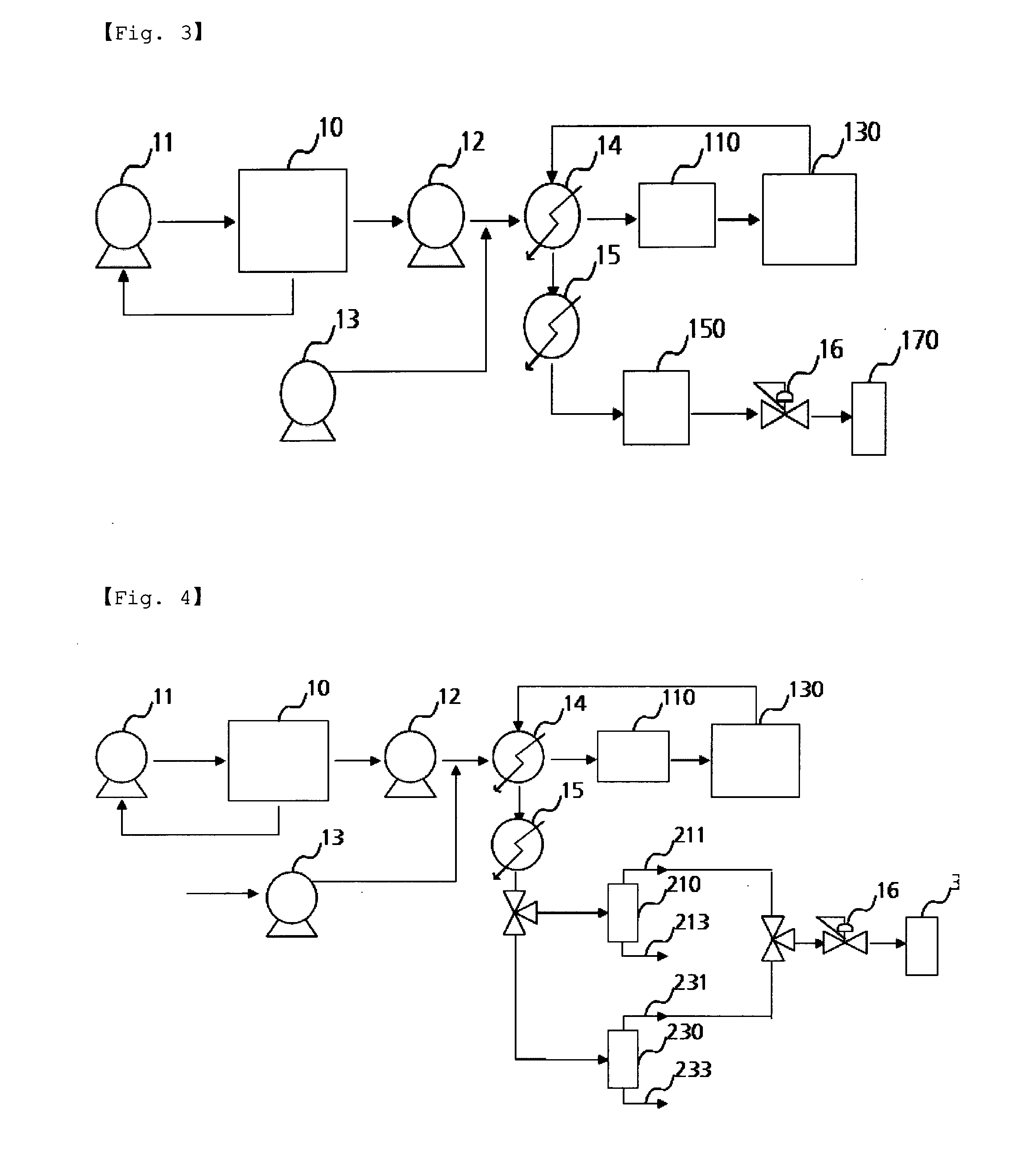

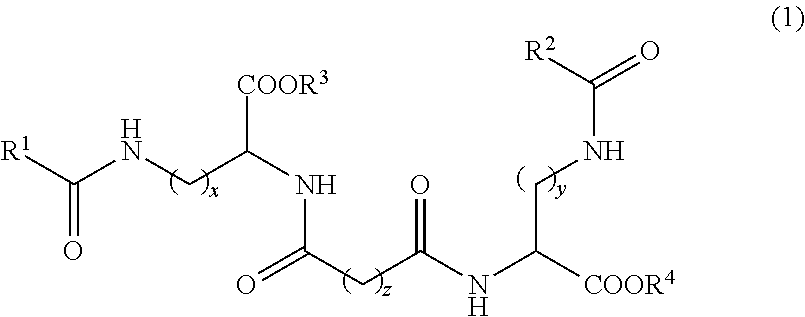

Provided area carbon nanotube composite material obtained by treating a mixture including carbon nanotubes, at least one carbon compound other than carbon nanotubes and a dispersion medium under a sub-critical or super-critical condition of 50-400 atm, and a method for producing the same. More particularly, the method for producing a carbon nanotube composite material, includes: introducing a mixture including carbon nanotubes, at least one carbon compound other than carbon nanotubes and a dispersion medium into a preheating unit under a pressure of 1-400 atm to preheat the mixture; treating the preheated mixture under a sub-critical or super-critical condition of 50-400 atm; cooling and depressurizing the resultant product to 0-1000 C and 1-10 atm; and recovering the cooled and depressurized product. Provided also is an apparatus for producing a carbon nanotube composite material in a continuous manner.

Owner:HANWHA CHEMICAL CORPORATION

Polyurethane base paint for coiled material

InactiveCN1702133AFast curingStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsFoaming agentPhosphate

A coiled material using polyurethane priming paint is prepared by homogeneously mixing polyester resin 1, polyester resin 2, cross linker, colourant, epoxy phosphate compound, solidification catalyst with solvent. The priming paint has a high solidification speed, resistance to solvent (MEK) can amount to 20 times, and has excellent adhesive force to metallic backing. The lacquer film has perfect toughness, and T curving can obtain 0-2T, applying to the field T curving highly required, such as construction and household electrical appliance, and so on. And it has fine foamobility, the blowing agent cohering on the lacquer film amounting to above 90% after foaming.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Fluorosurfactant-free foam fire-extinguisher

The present invention provides a foam fire-extinguishing agent devoid of environmentally harmful fluorochemical surfactant. The foam fire-extinguishing agent comprises a foamable synthetic surfactant consisting of (a) polyoxyethylene alkyl sulfate ester salt, and (b) at least either one of lauric acid amide propyldimethyl amino betaine acetate and lauric acid amide propylhydroxy sulfobetaine. This foam fire-extinguishing agent may further include at least either one of (c) polyoxyalkylenediamine having both terminal ends substituted with amino alkyl, and derivatives thereof, (d) polyoxyethylene coconut fatty acid monoethanol amide phosphate ester and (e) dodecyl alcohol. The foam fire-extinguishing agent is usable as both high- and low-expansion foam fire-extinguishing agents and in both seawater-diluted and freshwater-diluted forms while maintaining excellent performances such as water-retentivity within foams, durability to heat, liquid resistance allowing foams to stay on a burning liquid surface over an extended time-period, and flowability capable of covering over the burning liquid surface in a short time-period.

Owner:TERAYAMA RIYAKO +2

Preparation method of foamed polypropylene beads

The invention discloses a preparation method of foamed polypropylene beads. The method comprises the following steps that 1, polypropylene resin, an active filler and auxiliaries are added into a high-speed mixing machine and mixed to be uniform at the temperature of 10-20 DEG C, and a polypropylene foaming material is obtained; 2, the polypropylene foaming material is added into a triple-screw extruder, plastification and mixing are conducted, a supercritical fluid is injected, the mouth mold pressure is controlled to be 5-25 MPa, the mouth mold temperature is 110-160 DEG C, instant pressure release is conducted through a mouth mold, foaming is conducted, and super-fine hole foamed polypropylene is obtained; 3, super-fine hole foamed polypropylene is subjected to mold surface water-ring hot-cutting granulation, drying and sieving, and the foamed polypropylene beads are obtained. The method is low in production cost, high in capacity, safe and environmentally friendly, no foaming agent decomposed residue exists in the prepared foamed polypropylene beads, secondary foaming can be conducted, the foaming ratio can be adjusted, the rebound resilience of a finished product is high, decomposing and recycling are easy, and the foamed polypropylene beads can be widely used in the fields of plastic packaging, transportation industry, military aerospace, office supplies and the like.

Owner:湖北聚石新材料科技有限公司

Foaming propylene copolymer, and foamed particles and foams thereof

PCT No. PCT / JP98 / 02926 Sec. 371 Date Feb. 26, 1999 Sec. 102(e) Date Feb. 26, 1999 PCT Filed Jun. 30, 1998 PCT Pub. No. WO99 / 01486 PCT Pub. Date Jan. 14, 1999Provided are a foaming propylene-ethylene random copolymer which is characterized in that (1) its ethylene unit content [x (wt. %)] falls between 0.2 and 10% by weight, (2) its MI falls between 1 and 16 g / 10 min, (3) its boiling diethyl ether extraction [E (wt. %)] and x satisfy the relation of a formula (I): E< / =0.25x+1.1(I), (4) its melting point [Tm ( DEG C.)] and x satisfy the relation of a formula (II): Tm< / =165-5x(II), (5) its isotactic triad fraction in the PPP chain moiety as measured through 13C< / =NMR is not smaller than 98 mol %, and preferably, (6) the relation between the time of relaxation tau (sec) of the copolymer and MI of the copolymer satisfies a formula (III): tau < / =0.80-0.42xlog MI(III), and also its foaming beads and cellular articles. The copolymer and its foaming beads have improved primary and secondary foamability, and the cellular articles of the copolymer have excellent mechanical properties including rigidity.

Owner:PRIME POLYMER CO LTD

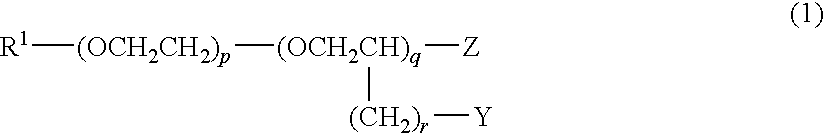

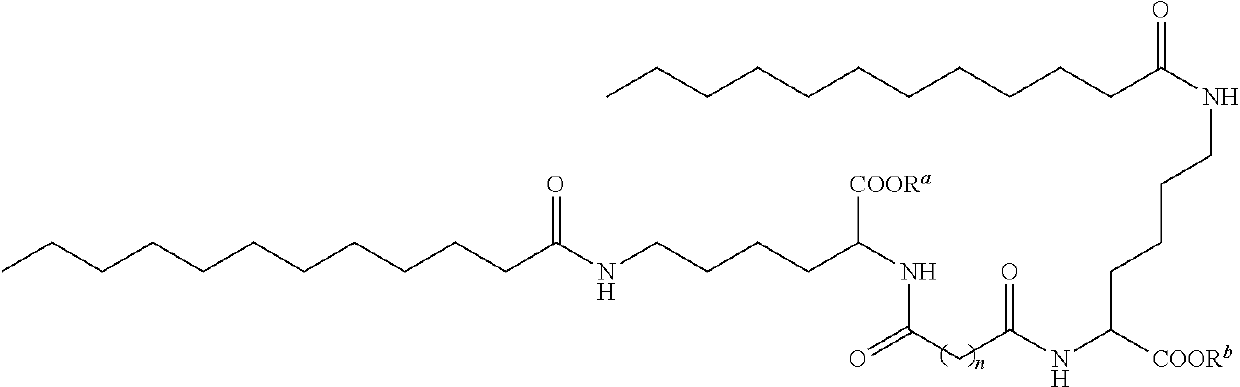

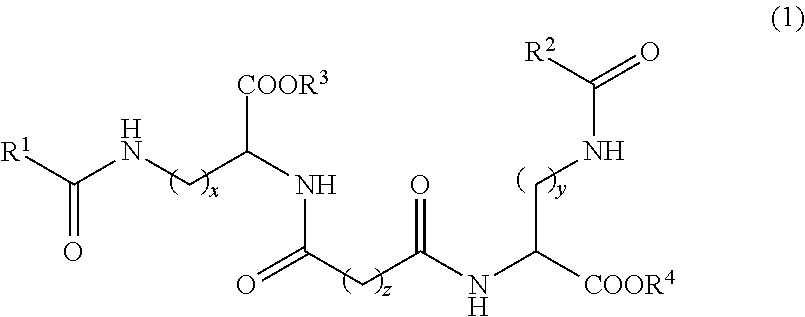

Cleaning agent composition containing acyl basic amino acid derivative

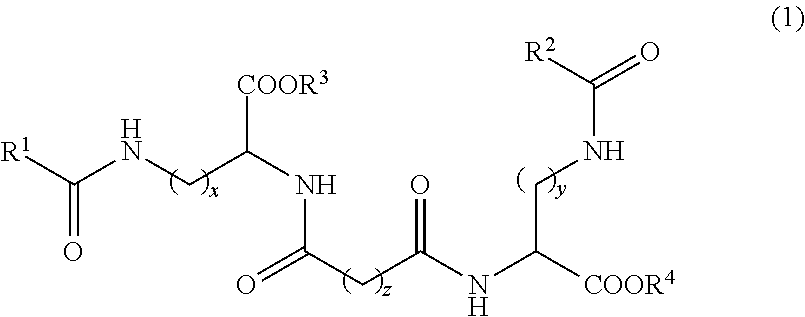

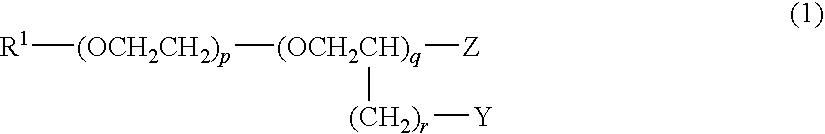

ActiveUS20170281497A1Feel smoothRinsing performance smoothCosmetic preparationsHair cosmeticsActive agentAcyl group

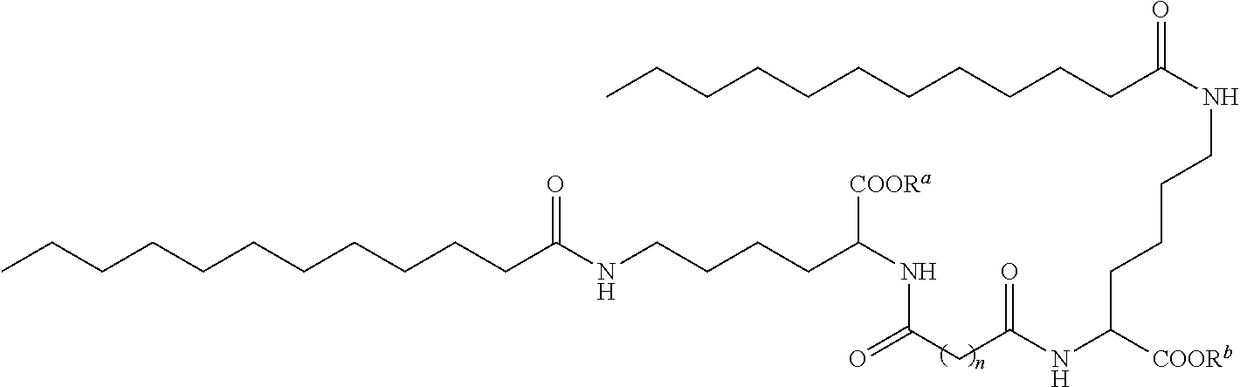

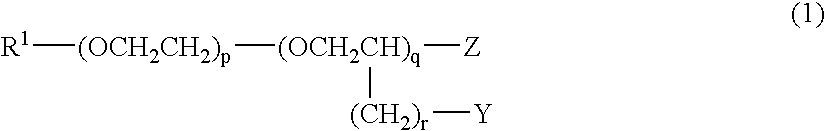

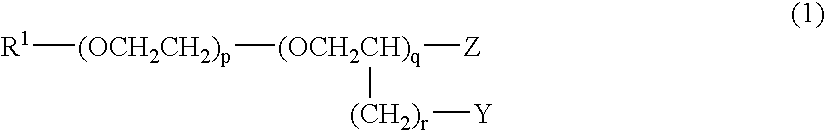

The present invention provides a composition containing component (A): a compound represented by the formula (1)wherein each symbol is as described in the DESCRIPTION, or a salt thereof, and component (B): at least one kind of surfactant selected from the group consisting of an anionic surfactant having a carboxyl group, an amphoteric surfactant and a nonionic surfactant, which is superior in foamability and foam volume and affording improved rinsing performance and smooth feeling after drying.

Owner:AJINOMOTO CO INC

Oral care compositions

InactiveUS20130084254A1Improve foamabilityGood storage stabilityCosmetic preparationsPeptide/protein ingredientsCleansing AgentsDentistry

The invention provides a non-aerated, foamable oral care composition comprising less than 1.5% anionic surfactant (by total weight anionic surfactant based on the total weight of the composition), abrasive cleaning agent and hydrophobin. The composition is mild to oral mucosa yet exhibits excellent foamability, texture and storage stability.

Owner:CONOPCO INC D B A UNILEVER

High-toughness flame-retardant amorphous copolyester foam and preparation method thereof

The invention relates to high-toughness flame-retardant amorphous copolyester foam and a preparation method thereof. The amorphous copolyester foam is obtained by blending, foaming and molding amorphous copolyester and a multifunctional master batch, wherein the multifunctional master batch is prepared from 25-50 parts by weight of a toughening and compatibilizing low-melting-point carrier resin,40-60 parts by weight of a halogen-free flame retardant, 5-10 parts by weight of a tackifier and 2-5 parts by weight of an antioxidant by adopting internal mixer-single screw combination equipment. The obtained amorphous copolyester foam material has the excellent characteristics of high toughness, excellent elongation, oxygen index (LOI) being greater than or equal to 27%, combustion grade of B2or above, high compression strength, high shear strength and the like, and can be applied to the high-end fields of aerospace, wind power, rail transit and the like.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

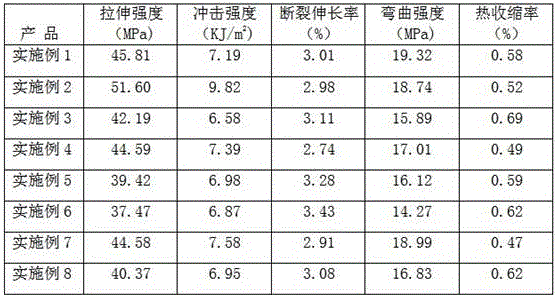

PVC (Polyvinyl Chloride) wood plastic foaming material and preparation method thereof

The invention discloses a PVC (Polyvinyl Chloride) wood plastic foaming material. The PVC wood plastic foaming material is prepared from the following raw materials in parts by weight: 20 to 70 parts of SG5 type PVC resin, 30 to 80 parts of SG7 type PVC resin, 10 to 60 parts of natural plant fiber, 30 to 80 parts of nano calcium carbonate, 5 to 30 parts of activated heavy calcium carbonate, 8 to 40 parts of modifier, 0.3 to 3 parts of polyethylene glycol, 0.5 to 3 parts of G60 type lubricant, 0.3 to 2 parts of maleic acid grafted PE (Poly Ethylene) wax compatibilizer, 2 to 6 parts of organic tin stabilizer, 5 to 10 parts of foam regulator, 1 to 8 parts of processing agent and 1 to 3 parts of composite foaming agent. All components in a formula of the PVC wood plastic foaming material provided by the invention are good in compatibility and have excellent dispersity and fluidity, so that the PVC wood plastic foaming material has good processing performance; meanwhile, the PVC wood plastic foaming material also is excellent in impact resistance, tensile strength, crack resistance, heat resistance and toughness, and has a wide market prospect.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

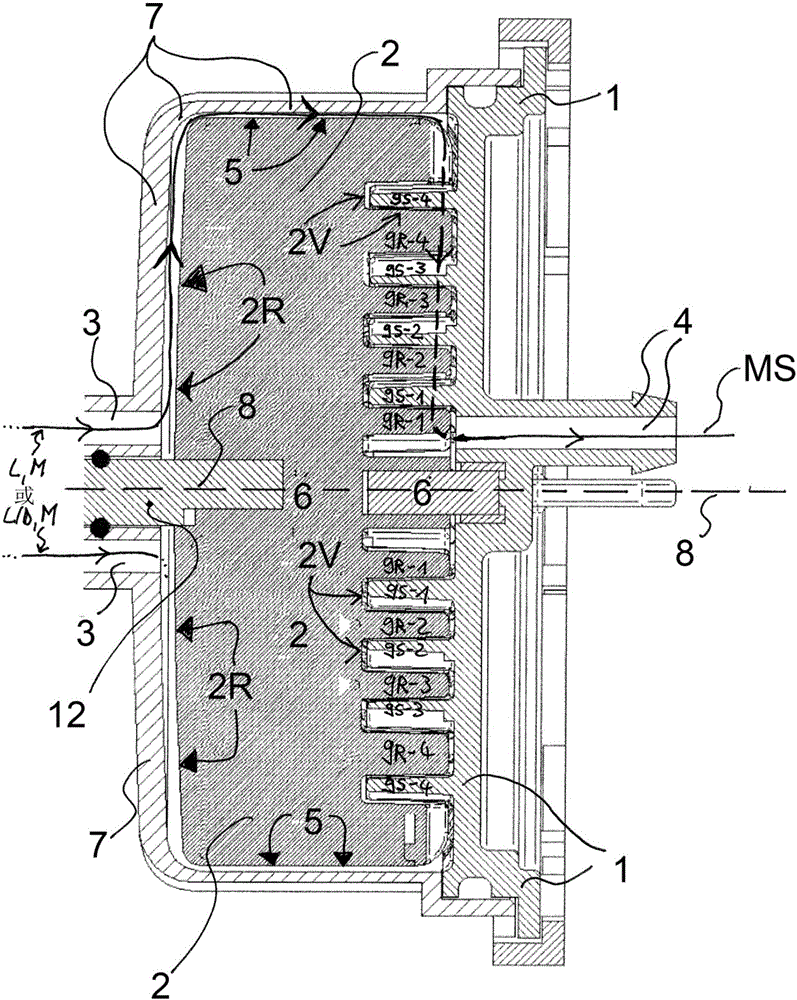

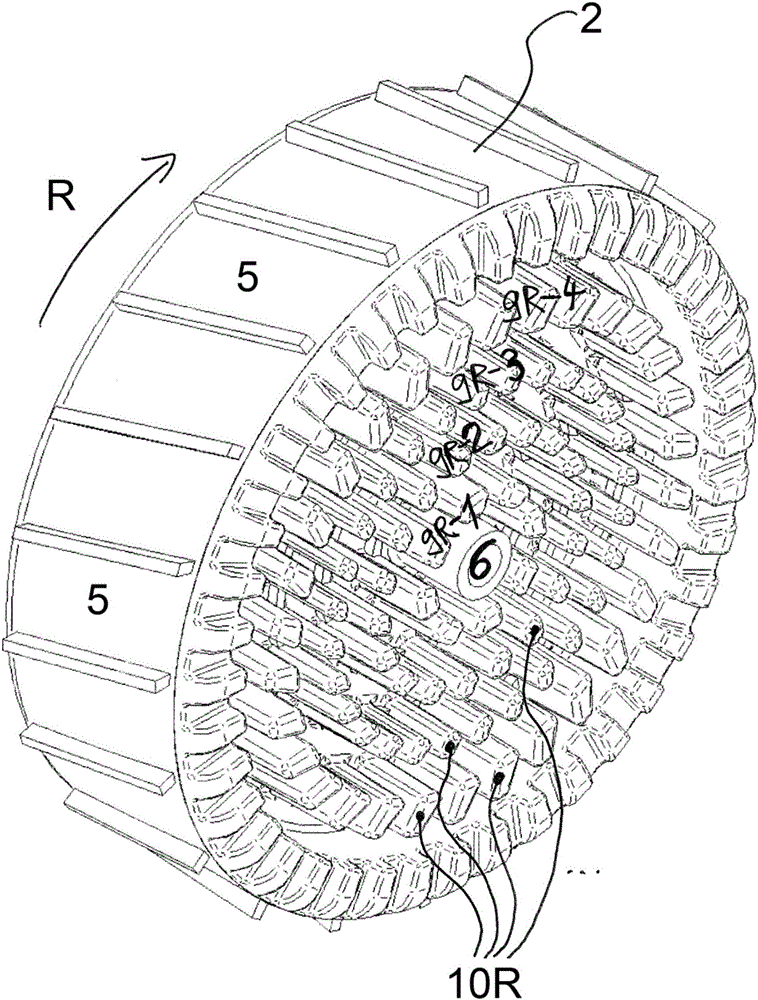

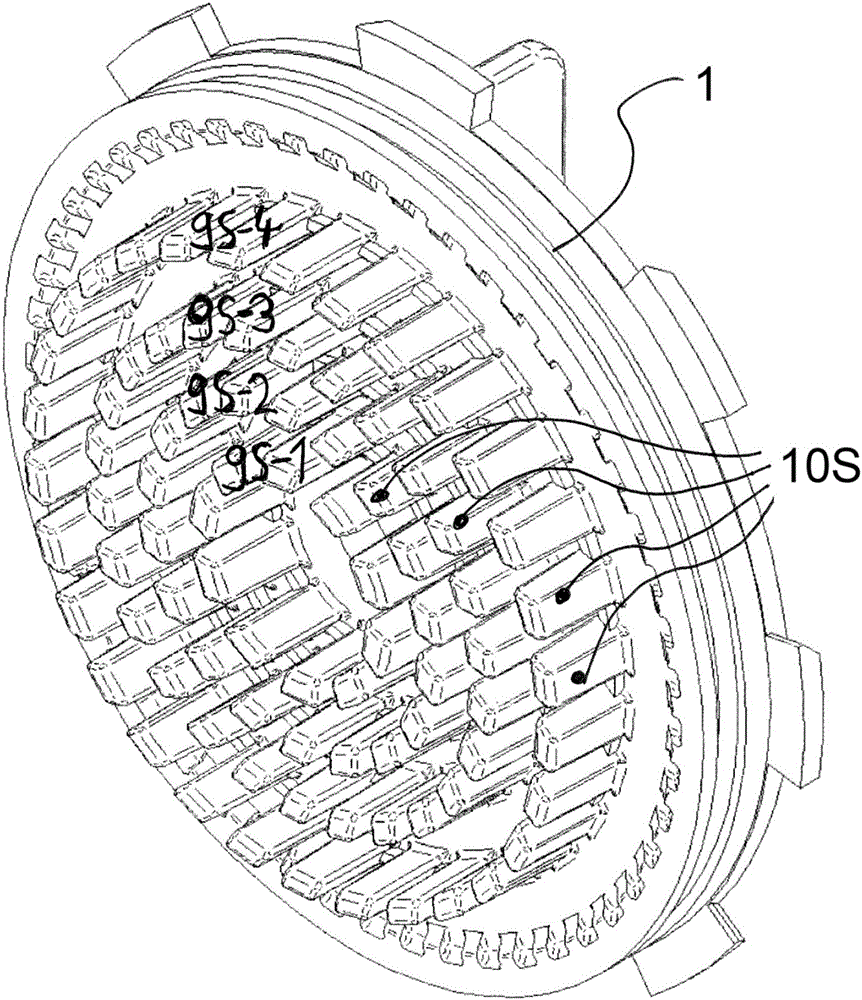

Milk-frothing device with dynamic mixing unit, and beverage maker containing the same

ActiveCN105960186AImprove foamabilityAchieve heatingTransportation and packagingMixer accessoriesEngineeringMechanical engineering

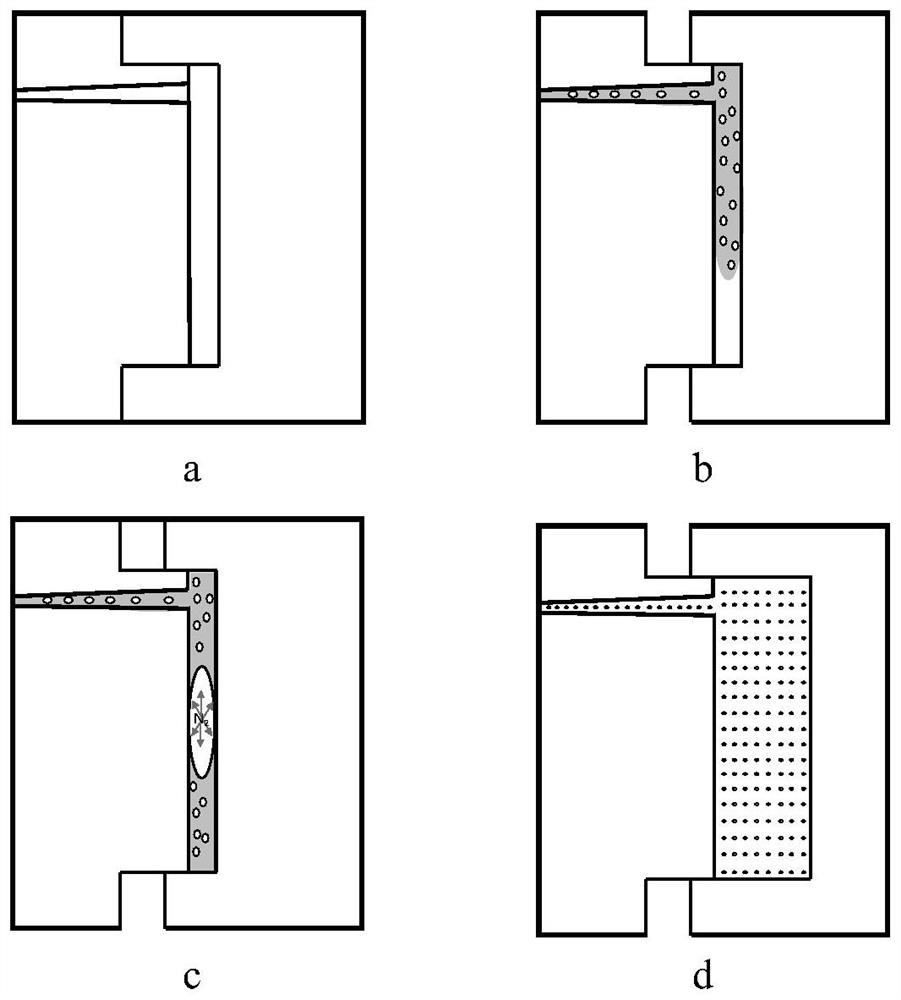

The invention relates to a milk-frothing device with a dynamic mixing unit, having a stator (1) and a rotor (2), which can be made to rotate (R) relative to the stator (1), wherein the rotor (2) and stator (1) are designed such that milk (M) and air (L, L / D) first of all can be directed to (3) the dynamic mixing unit, then can be subjected a number of times to a shearing action for frothing purposes in the dynamic mixing unit, by rotation (R) of the rotor (2) relative to the stator (1), and finally can be directed out (4) of the dynamic mixing unit.

Owner:WMF GRP

Blending improvement carbon-composite having carbon-nanotube and its continuous manufacturing method and apparatus

ActiveUS9567222B2Good dispersionImprove conductivityMaterial nanotechnologyNon-metal conductorsCarbon compositesCritical condition

Owner:HANWHA CHEMICAL CORPORATION

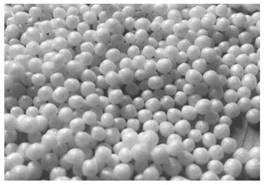

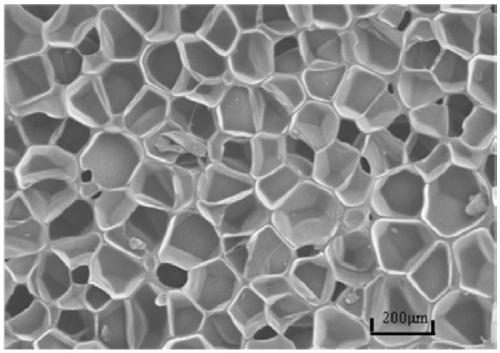

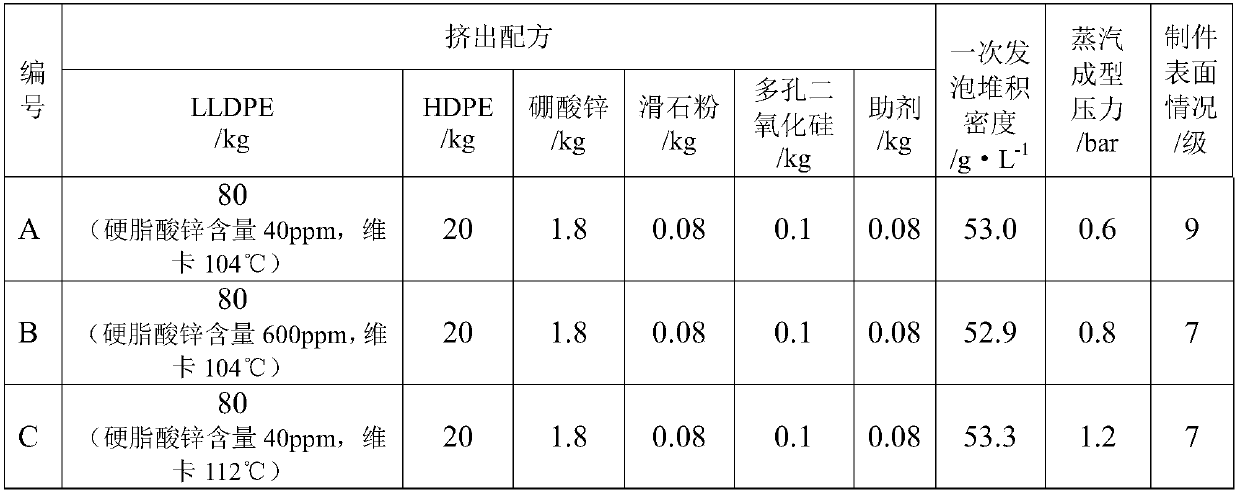

Easily melted foamed polyethylene bead with strong temperature tolerance and preparation method thereof

ActiveCN109651695AIncrease elasticityImprove temperature resistanceLow-density polyethyleneThermal insulation

The invention discloses an easily melted foamed polyethylene bead with strong temperature tolerance and a preparation method thereof. Low density polyethylene with a Vicat softening point of 90 to 105DEG C and high density polyethylene are compounded, at the same time, an inorganic compounding foaming aid is adopted, and through the synergistic effect generated by three components, goals of easily melting and high temperature tolerance are realized. Through the cooperation of formula and technology, the size of inner pores of primarily foamed EPE beads is controlled in a range of 200 to 230 [mu]m, after foaming, no thermal insulation device is needed, and a step of introducing steam with a certain air pressure into a pipe for delivering polypropylene resin particles is not needed either.The moulding steam pressure is obviously reduced, the melting stability between particles is excellent, and the curing degree is 95% or more. Because the inner pores in the beads are increased, and the pore uniformity is increased, the polyethylene bead can tolerate a certain moulding temperature, the stiffness of pores in the surface of a moulded product is improved, and the beauty of the surfaceof a EPE bead moulded product is obviously improved.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

A kind of preparation method of expanded polypropylene beads

The invention discloses a preparation method of foamed polypropylene beads. The method comprises the following steps that 1, polypropylene resin, an active filler and auxiliaries are added into a high-speed mixing machine and mixed to be uniform at the temperature of 10-20 DEG C, and a polypropylene foaming material is obtained; 2, the polypropylene foaming material is added into a triple-screw extruder, plastification and mixing are conducted, a supercritical fluid is injected, the mouth mold pressure is controlled to be 5-25 MPa, the mouth mold temperature is 110-160 DEG C, instant pressure release is conducted through a mouth mold, foaming is conducted, and super-fine hole foamed polypropylene is obtained; 3, super-fine hole foamed polypropylene is subjected to mold surface water-ring hot-cutting granulation, drying and sieving, and the foamed polypropylene beads are obtained. The method is low in production cost, high in capacity, safe and environmentally friendly, no foaming agent decomposed residue exists in the prepared foamed polypropylene beads, secondary foaming can be conducted, the foaming ratio can be adjusted, the rebound resilience of a finished product is high, decomposing and recycling are easy, and the foamed polypropylene beads can be widely used in the fields of plastic packaging, transportation industry, military aerospace, office supplies and the like.

Owner:湖北聚石新材料科技有限公司

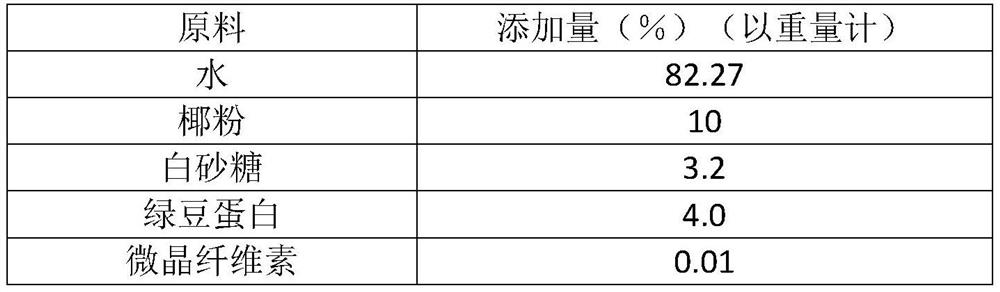

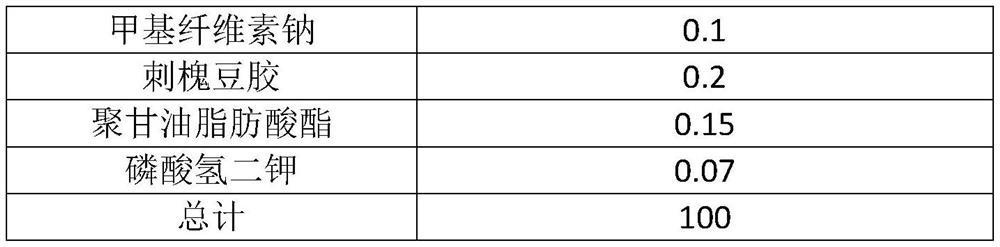

Coconut milk beverage and preparation method thereof

ActiveCN112042760AStable stateGood foaming effectRoasted coffee treatmentCoffee extractionAnimal scienceBiotechnology

The invention discloses a coconut milk beverage. The coconut milk beverages comprises the following raw materials in percentage by mass of 5%-15% of a coconut syrup raw material, 2.5%-4.0% of vegetable protein, 0.12%-0.6% of a thickening agent, 0.1%-0.5% of an emulsifying agent, 0.05%-0.2% of buffer salt and the balance water, wherein the total percentage by mass of the raw materials is 100%. Thepreparation method of the coconut milk beverage comprises the following steps: (1) adding the coconut syrup raw material into the water for hydration to obtain a mixed solution A; (2) uniformly mixinga stabilizer with protein to obtain a mixture, and adding the mixture into the mixed solution A obtained in the step (1) to obtain a mixed solution B; (3) performing pre-homogenization on the mixed solution B obtained in the step (2), and then performing ultra-high temperature sterilization to obtain a mixed solution C; and (4) homogenizing the mixed solution C in the step (3) under a sterile condition, and performing cooling to obtain the coconut milk beverage. The coconut milk beverage disclosed by the invention has good frothing and foam holding properties, fine and smooth milk foams, goodstability and stable shelf life, and can be stored at normal temperature for 6 months.

Owner:BRIGHT DAIRY & FOOD

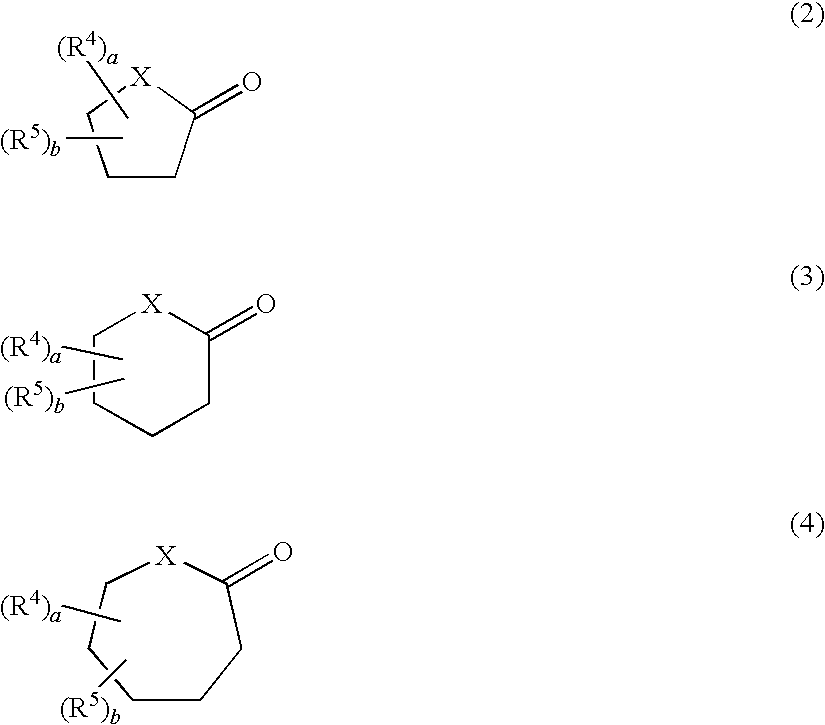

Thermoplastic elastomer composition for foaming, molded foam thereof, composite molded product using the molded foam, and instrument panel for automobile

ActiveUS20110117358A1Increase flexibilityImprove foamabilitySynthetic resin layered productsLaminationElastomerPolymer science

[Problem] To provide a thermoplastic elastomer composition for foaming, which has sufficient foamability and provides a molded article having good appearance.[Solution to Problem] A thermoplastic elastomer composition for foaming, which comprises 10 to 40% by weight of a partially or completely crosslinked ethylene / α-olefin / non-conjugated polyene copolymer rubber (A) comprising ethylene, an α-olefin of 3 to 20 carbon atoms and a non-conjugated polyene, 3 to 33% by weight of an ethylene / α-olefin copolymer (B) comprising ethylene and an α-olefin of 3 to 20 carbon atoms, 10 to 40% by weight of polypropylene (C) having a melting point, as determined by differential scanning calorimetry (DSC), of 40 to 170° C., 10 to 45% by weight of a softener (D) for rubbers, and at least one substance selected from an isotactic propylene-based polymer (E-a) in an amount of 1 to 30% by weight and a syndiotactic α-olefin-based copolymer (E-b) in an amount of 1 to 20% by weight, with the proviso that the total amount of the components (A), (B), (C), (D), (E-a) and (E-b) is 100% by weight.

Owner:MITSUI CHEM INC

Hair cleansing compositions

InactiveUS20090075854A1Improve stabilityEffectively impart luster and softness and manageabilityCosmetic preparationsHair cosmeticsHydroxydicarboxylic acidOrganic solvent

A hair cleansing composition comprises the following ingredients (A) to (C):(A) a dicarboxylic acid or hydroxydicarboxylic acid, or a salt thereof,(B) an organic solvent, and(C) an anionic surfactant having a sulfate group; and has a pH of from 1 to 4 when diluted 20-fold by weight with water and a buffer capacity not lower than 0.005 gram equivalent / L but lower than 0.2 gram equivalent / L.The hair cleansing composition has good foamability and high-lubricity foam quality upon washing, and are excellent in the luster, softness and manageability of hair after drying and also superb in stability.

Owner:KAO CORP

Thermoplastic elastomer composition for foaming, molded foam thereof, composition molded product using the molded foam, and instrument panel for automobile

ActiveUS8329821B2Increase flexibilityImprove foamabilitySynthetic resin layered productsSpecial tyresPolymer scienceShell molding

[Problem] To provide a thermoplastic elastomer composition for foaming, which has sufficient foamability and provides a molded article having good appearance. [Solution to Problem] A thermoplastic elastomer composition for foaming, which comprises 10 to 40% by weight of a partially or completely crosslinked ethylene / α-olefin / non-conjugated polyene copolymer rubber (A) comprising ethylene, an α-olefin of 3 to 20 carbon atoms and a non-conjugated polyene, 3 to 33% by weight of an ethylene / α-olefin copolymer (B) comprising ethylene and an α-olefin of 3 to 20 carbon atoms, 10 to 40% by weight of polypropylene (C) having a melting point, as determined by differential scanning calorimetry (DSC), of 40 to 170° C., 10 to 45% by weight of a softener (D) for rubbers, and at least one substance selected from an isotactic propylene-based polymer (E-a) in an amount of 1 to 30% by weight and a syndiotactic α-olefin-based copolymer (E-b) in an amount of 1 to 20% by weight, with the proviso that the total amount of the components (A), (B), (C), (D), (E-a) and (E-b) is 100% by weight.

Owner:MITSUI CHEM INC

Hair cleansing compositions

InactiveUS20070086970A1Improve stabilityEffectively impart lusterCosmetic preparationsHair cosmeticsHydroxydicarboxylic acidOrganic solvent

A hair cleansing composition comprises the following ingredients (A) to (C): (A) a dicarboxylic acid or hydroxydicarboxylic acid, or a salt thereof, (B) an organic solvent, and (C) an anionic surfactant having a sulfate group; and has a pH of from 1 to 4 when diluted 20-fold by weight with water and a buffer capacity not lower than 0.005 gram equivalent / L but lower than 0.2 gram equivalent / L. The hair cleansing composition has good foamability and high-lubricity foam quality upon washing, and are excellent in the luster, softness and manageability of hair after drying and also superb in stability.

Owner:KAO CORP

Preparation method with high yield, low cost and environmental protection for polypropylene beads

The invention provided a preparation method with high yield, low cost and environmental protection for polypropylene beads. The preparation method is characterized by comprising the following steps: adding polypropylene resin, an active filling material, caprolactam and an auxiliary agent into a high-speed mixer, and carrying out uniform mixing at 10 to 20 DEG C so as to obtain a polypropylene foamed material.

Owner:绵阳旺通科技有限公司

Acrylic copolymer composition, method for preparing acrylic copolymer, and vinyl chloride resin composition containing the acrylic copolymer

Provided are an acrylic copolymer composition, a method for preparing an acrylic copolymer, and a vinyl chloride resin composition including the acrylic copolymer. The acrylic copolymer composition includes 5-15 wt % of a crosslinking agent and an alkyl acrylate monomer constituting an alkyl acrylate crosslinked polymer and 85-95 wt % of methyl methacrylate and at least one monomer selected from the group consisting of alkyl acrylate and alkyl methacrylate. Addition of the acrylic copolymer to the vinyl chloride resin composition enhances the foaming property of the vinyl chloride resin. Combination of the acrylic copolymer with an impact modifier further enhances the impact strength of the vinyl chloride resin.

Owner:LG CHEM LTD

Hair cleansing compositions

ActiveUS7754195B2Improve foamabilityQuality improvementCosmetic preparationsHair removalPolymer chemistryLubricity

To provide a hair cleansing composition having good foamability and high-lubricity foam quality upon washing and smooth touch upon rinsing, and providing excellent feeling in use.

Owner:KAO CORP

Thermally expanding microcapsules

ActiveUS9493625B2Sufficient shape retention propertySuppress of aggregationMicroballoon preparationMicrocapsule preparationMonomer compositionThermal dilatation

The present invention provides a thermally expandable microcapsule that has a high expansion ratio and durability at high temperatures, and is not likely to cause discoloration and odor when used for foam molding. The thermally expandable microcapsule of the present invention includes: a shell formed from a polymer; and a volatile expansion agent as a core agent encapsulated by the shell, the shell obtained by polymerizing a monomer composition that contains a nitrile monomer and a compound having a glycidyl group in a molecule, the shell exhibiting a value y of 50% or higher and a ratio y / x of 1.1 or higher, in which x represents a gel fraction at ordinary temperature, and y represents a gel fraction upon heating at 180° C. for 30 minutes.

Owner:SEKISUI CHEM CO LTD +1

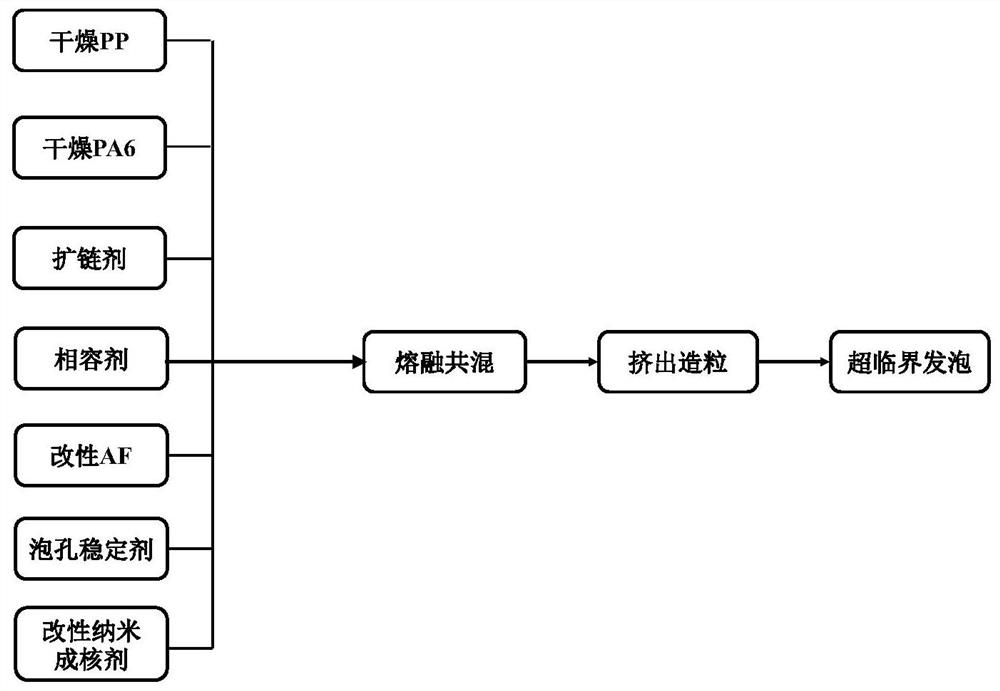

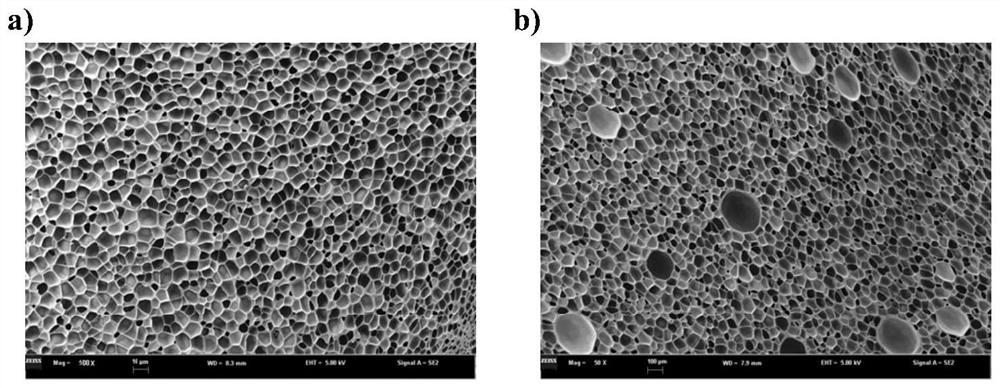

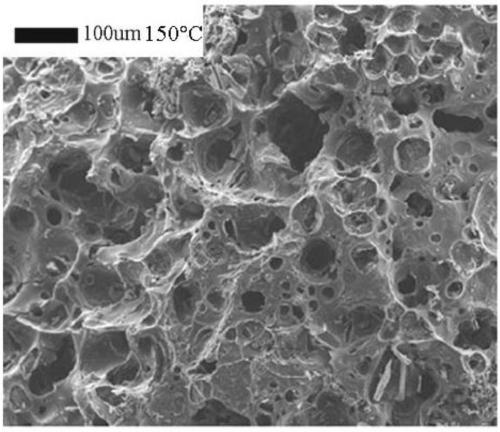

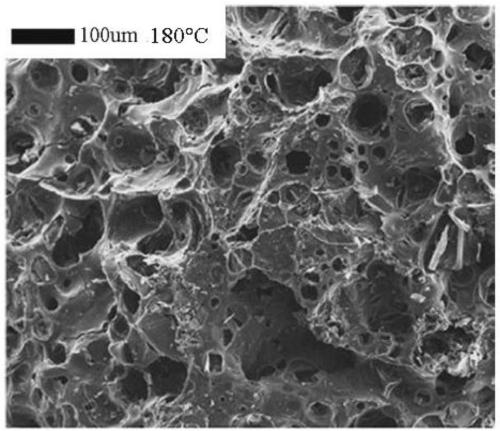

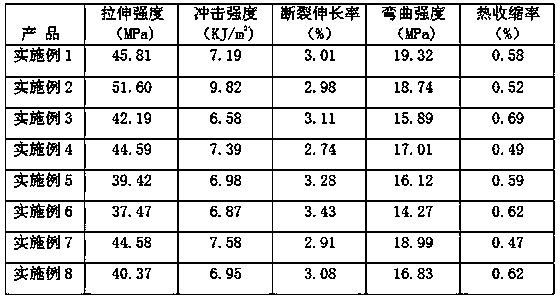

PP/PA6 porous composite material and preparation method thereof

The invention discloses a PP / PA6 porous composite material, which is prepared from the following raw materials in parts by weight: 50 to 70 parts of PP, 30 to 50 parts of PA6 resin, 5 to 8 parts of epoxy chain extender, 3 to 7 parts of compatilizer, 20 to 35 parts of modified AF fiber, 0.4 to 0.6 part of foam stabilizer and 3 to 15 parts of modified nano nucleating agent. The invention also discloses a preparation method of the PP / PA6 porous composite material, the PP / PA6 composite material is sequentially subjected to melting, extrusion granulation and gas-assisted mold opening and closing microcellular foaming injection molding processes to obtain the composite material, and the prepared PP / PA6 porous composite material has the advantages of good melting formability, high foaming ratio, high percentage of close area and uniform and moderate size; the tensile strength is high, and the comprehensive mechanical property is good; the density is small, the characteristic of light weight is realized, and the use performance is good.

Owner:LIMING VOCATIONAL UNIV

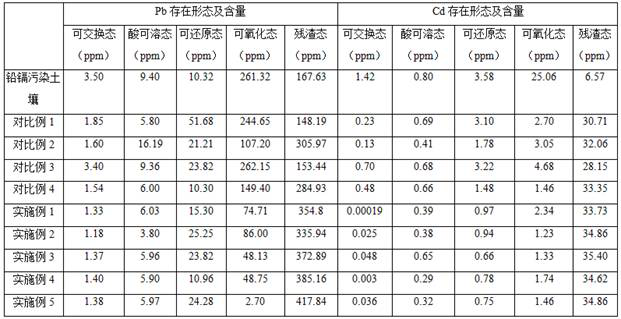

A kind of foam carbon immobilization passivator and its preparation method and application

ActiveCN112111281BLow viscosityViscosity can be adjustedContaminated soil reclamationCarbon preparation/purificationActivated carbonFoaming agent

The invention discloses a foam carbon holding passivator, which is prepared from the following raw materials in parts by weight: 100 parts of resin, 1-10 parts of curing agent, 1-10 parts of foaming agent, 1-10 parts of surfactant, 1-15 parts of salt modifier; the above raw materials are prepared, mixed, autoclaved and foamed, and carbonized to finally obtain a foam carbon holding passivator; the specific surface area of the obtained foam carbon holding passivator is 300~500m 2 / g, the micropore diameter is 1.9~2.5nm, and the cell diameter is 200~500μm; the preparation process of this material is simple, the cost is low, and the performance is stable; through comparison with wood activated carbon, coal activated carbon, walnut shell biochar and ordinary foam carbon It can be found that the foam carbon immobilization passivator of the present invention can convert lead and cadmium in the soil into a residue state and effectively reduce the precipitation of lead and cadmium.

Owner:SOUTHWEST FORESTRY UNIVERSITY

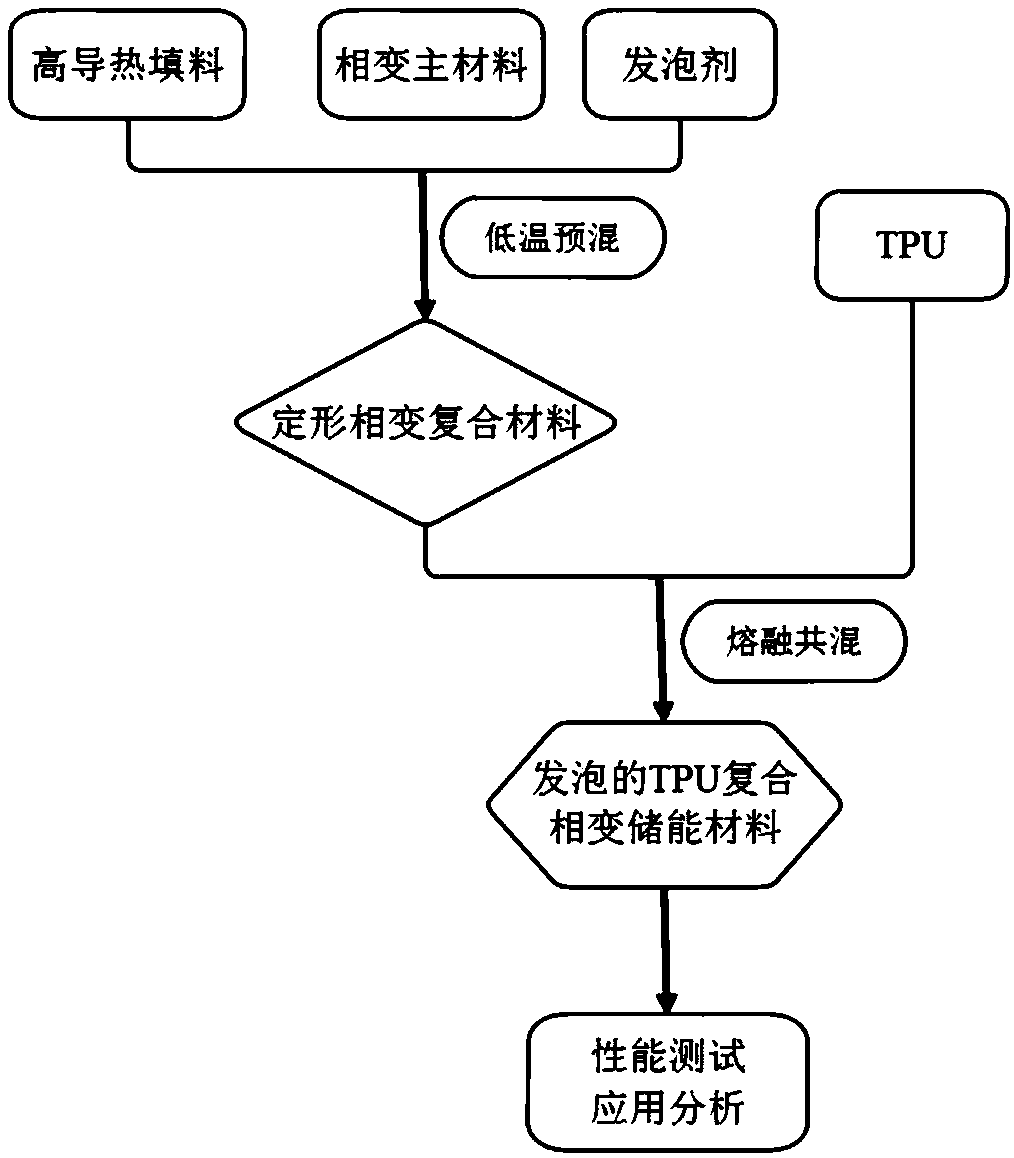

A kind of foamed TPU composite phase change energy storage material and preparation method thereof

Owner:SHAANXI SCI TECH UNIV +1

A kind of pvc wood-plastic foam material and preparation method thereof

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Cleaning agent composition containing acyl basic amino acid derivative

ActiveUS10441520B2Improve foamabilityOptimize volumeCosmetic preparationsNon-ionic surface-active compoundsChemical compoundCleansing Agents

The present invention provides a composition containing component (A): a compound represented by the formula (1)wherein each symbol is as described in the DESCRIPTION, or a salt thereof, and component (B): at least one kind of surfactant selected from the group consisting of an anionic surfactant having a carboxyl group, an amphoteric surfactant and a nonionic surfactant, which is superior in foamability and foam volume and affording improved rinsing performance and smooth feeling after drying.

Owner:AJINOMOTO CO INC

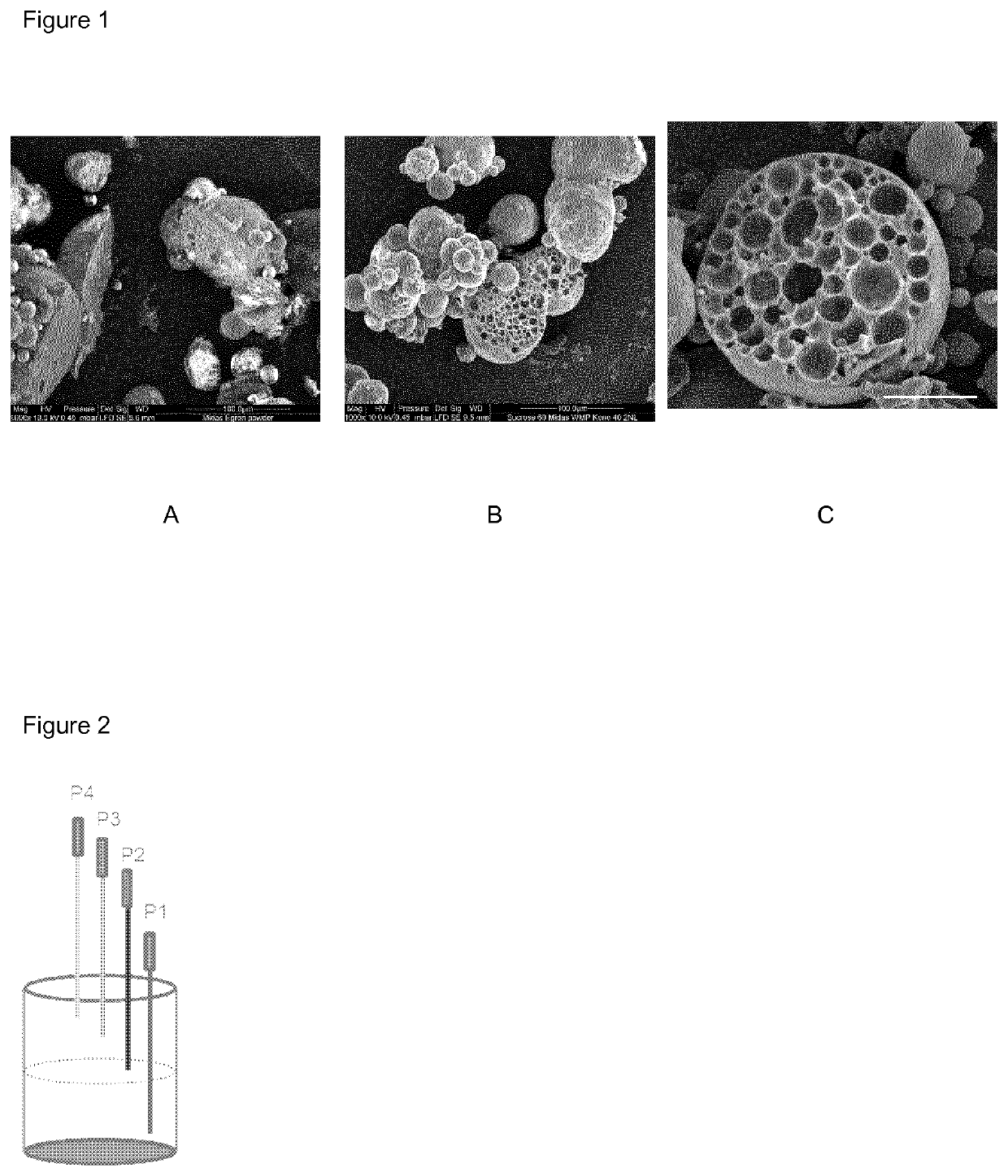

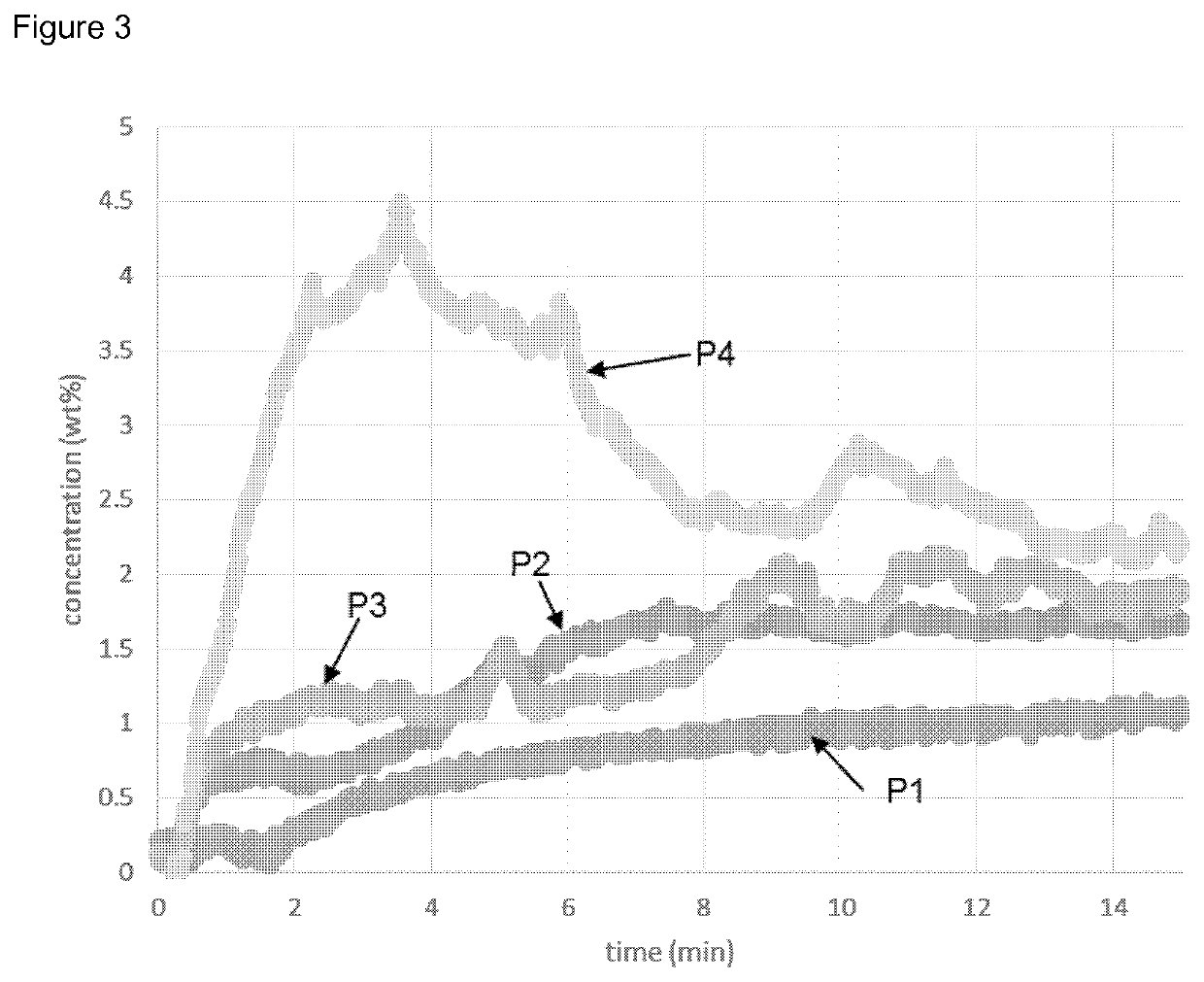

Beverage powder comprising porous particles and partially aggregated protein

PendingUS20210186061A1Increase viscosityIncrease porosityMilk preparationFood preservationProtein proteinActive agent

The present invention relates to a beverage powder comprising porous particles and partially aggregated proteins, the porous particles having an amorphous continuous phase comprising a sweetener, a soluble filler and a optionally a surfactant, wherein the porous particles have a closed porosity of between 10 and 80%. A further aspect of the invention is a process for manufacturing a beverage powder.

Owner:SOC DES PROD NESTLE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com