PP/PA6 porous composite material and preparation method thereof

A technology of porous composite materials and polymers, applied in the field of foamed plastics, can solve the problems of poor cell nucleation effect and poor performance of foamed materials, and achieves improved interface bonding, high surface energy, and improved interface compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

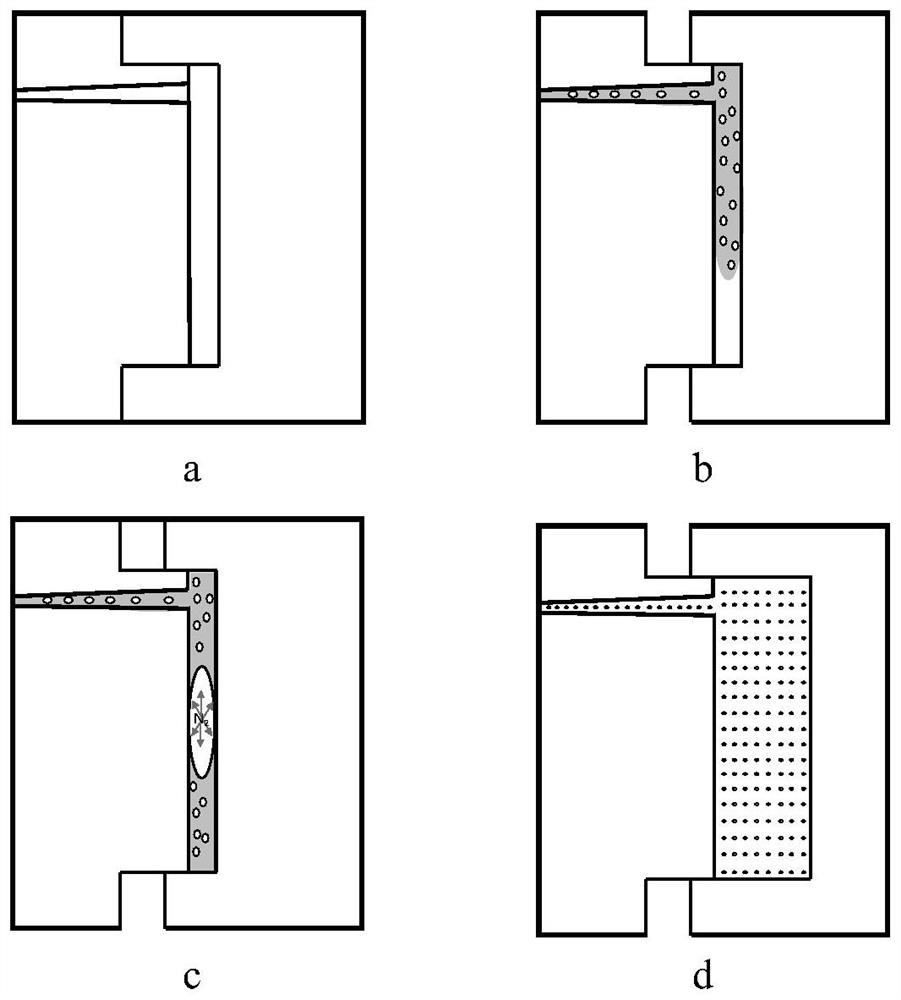

preparation example Construction

[0044] A preparation method of PP / PA6 porous composite material, comprising the following steps:

[0045] Step 1, first dry PP, PA6 and nano-nucleating agent, and stand-by, the nano-nucleating agent is nano-silica or nano-calcium carbonate;

[0046] Step 2, then modify the AF fiber:

[0047] Degreasing operation: Soak the AF fibers in the sodium dodecylbenzenesulfonate aqueous solution and sonicate for 0.5-1 hour, and filter the obtained mixture through a nanofiltration membrane, wash it with water for 3-5 times, and dry it for use;

[0048] The Friedel-Crafts reaction operation is: soak the degreased AF fiber in epichlorohydrin, vacuumize, fill with nitrogen, repeat several times, keep an inert atmosphere, and keep the reaction system at 110-130°C for 0.5-1h to condense and reflux. Add AlCl to the system several times 3 , and reacted for 8-10 hours to obtain the modified AF crude product;

[0049] Purification operation: Then the modified AF crude product is washed with et...

Embodiment 1

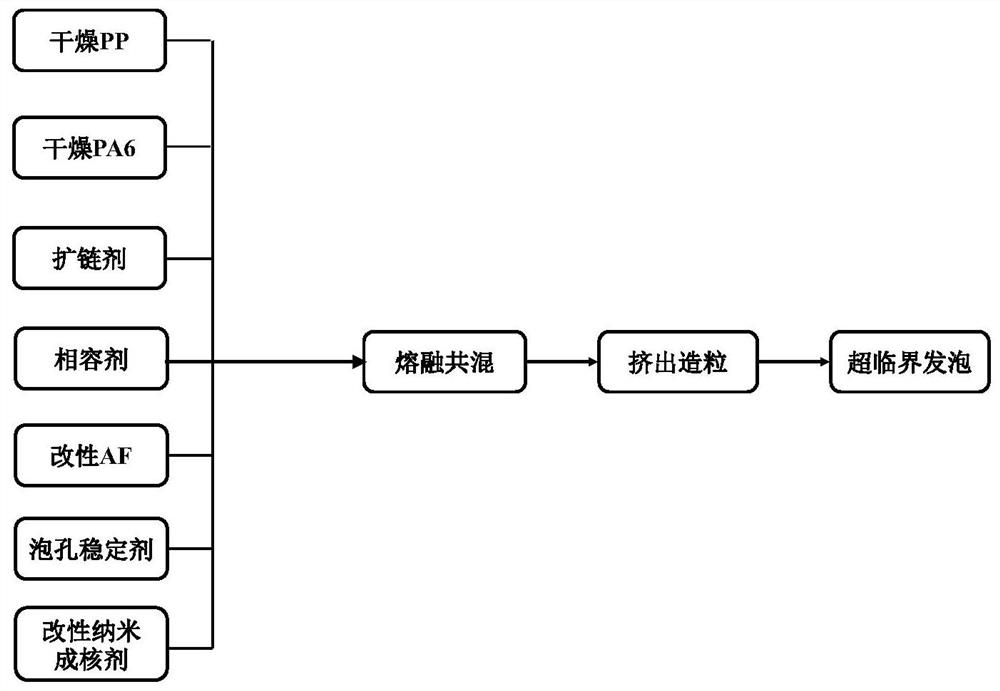

[0081] A kind of preparation method of PP / PA6 porous composite material, such as figure 2 shown, including the following steps:

[0082] Step 1. First vacuum-dry nano-silica and PP at 80°C for 4 hours, and vacuum-dry PA6 at 100°C for 4 hours;

[0083] Step 2, then modify the AF fiber:

[0084] The degreasing operation is as follows: immerse 25g of AF fibers in 150mL of sodium dodecylbenzenesulfonate aqueous solution with a mass concentration of 1% and sonicate for 0.5h at an ultrasonic frequency of 80MHz. After the obtained mixture is filtered through a nanofiltration membrane, Wash 5 times with water, dry at 80°C for 2 hours, and set aside;

[0085] The Friedel-Crafts reaction operation is as follows: soak the degreased AF fiber in 50mL of epichlorohydrin, vacuumize, fill with nitrogen, repeat three times, keep an inert atmosphere, keep the reaction system at 120°C for 0.5h, and pour into the system Add AlCl five times 3 , reacted for 8h, obtained modified AF crude produ...

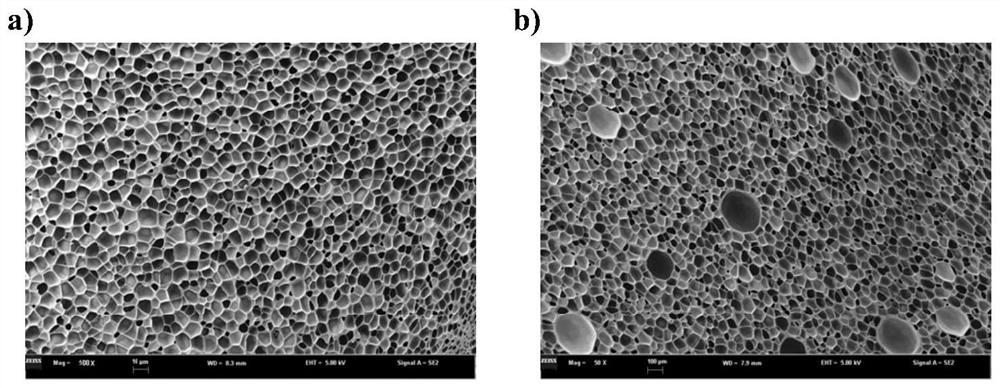

Embodiment 2

[0094] The difference from Example 1 is that in this example:

[0095] Step 4. According to the formula ratio, 70g PP, 40g PA6, 6g ADR-4368, 3g PP-g-MAH, 20g modified AF fiber, 0.4g polyisobutyl methacrylate and 8g modified nano silicon dioxide were mixed in Stir under the rotating speed of 250r / min into powder, obtain premixed resin;

[0096] Refer to the preparation method of Example 1 for other steps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com