PVC (Polyvinyl Chloride) wood plastic foaming material and preparation method thereof

A wood-plastic foaming and PVC resin technology, applied in the field of wood-plastic composite materials, can solve the problems of increasing the foaming difficulty of PVC plant fiber composite materials, the viscosity of resin melt, the increase of product rigidity, and the limitation of PVC development, etc., to solve the problem of interface Poor compatibility, improved toughness and processing fluidity, excellent dispersibility and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

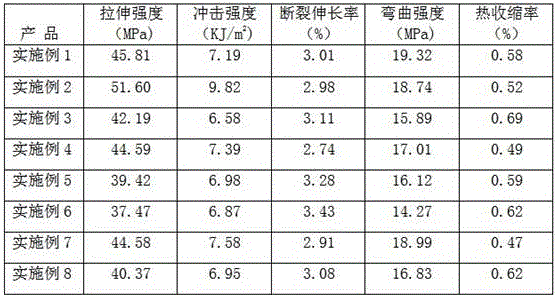

Examples

Embodiment 1

[0032] A PVC wood-plastic foaming material, comprising the following raw materials in parts by weight: 30 parts of SG5 type PVC resin, 70 parts of SG7 type PVC resin, 40 parts of wood powder, 30 parts of nano calcium carbonate, 20 parts of active ground calcium carbonate, 8 parts of EVA resin, 10 parts of ACM resin, 1.5 parts of polyethylene glycol, 0.5 parts of G60 lubricant, 1 part of maleic acid grafted PE wax compatibilizer, 4 parts of organotin stabilizer, LS-530 foam regulator 8 parts of agent, 6 parts of methyl methacrylate / acrylate copolymer processing aid, 1 part of AC foaming agent and 1 part of sodium bicarbonate.

Embodiment 2

[0034] A PVC wood-plastic foaming material, made of the following raw materials in parts by weight: 50 parts of SG5 type PVC resin, 50 parts of SG7 type PVC resin, 50 parts of bamboo powder, 40 parts of nano calcium carbonate, 15 parts of active ground calcium carbonate, 10 parts of EVA resin, 15 parts of ACM resin, 2 parts of polyethylene glycol, 1.5 parts of G60 lubricant, 1.5 parts of maleic acid grafted PE wax compatibilizer, 3 parts of organotin stabilizer, LS-530 foam regulator 5 parts of agent, 4 parts of methyl methacrylate / acrylate copolymer processing aid, 0.5 part of AC foaming agent and 1 part of sodium bicarbonate.

Embodiment 3

[0036] A PVC wood-plastic foaming material, comprising the following raw materials in parts by weight: 60 parts of SG5 type PVC resin, 40 parts of SG7 type PVC resin, 30 parts of rice bran, 50 parts of nano calcium carbonate, 10 parts of active ground calcium carbonate, EVA 5 parts of resin, 20 parts of ACM resin, 1 part of polyethylene glycol, 2 parts of G60 lubricant, 0.5 parts of maleic acid grafted PE wax compatibilizer, 5 parts of organic tin stabilizer, LS-530 foam regulator 6 parts, 2 parts of methyl methacrylate / acrylate copolymer processing aid, 1.5 parts of AC blowing agent and 1 part of sodium bicarbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com