ABS composition suitable for being laser-welded and preparation method thereof

A technology of laser welding and composition, applied in the field of polymer material processing, can solve the problems of high melting temperature, unfavorable welding promotion and use, etc., and achieve the effects of low melting temperature, good appearance and wide processing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

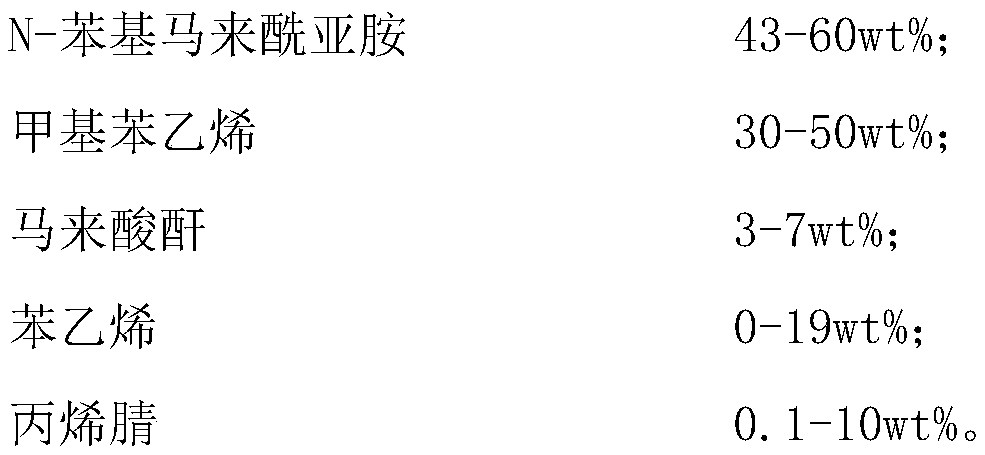

Method used

Image

Examples

preparation example Construction

[0040] The present embodiment also provides a preparation method suitable for laser welding ABS resin composition, comprising the following steps:

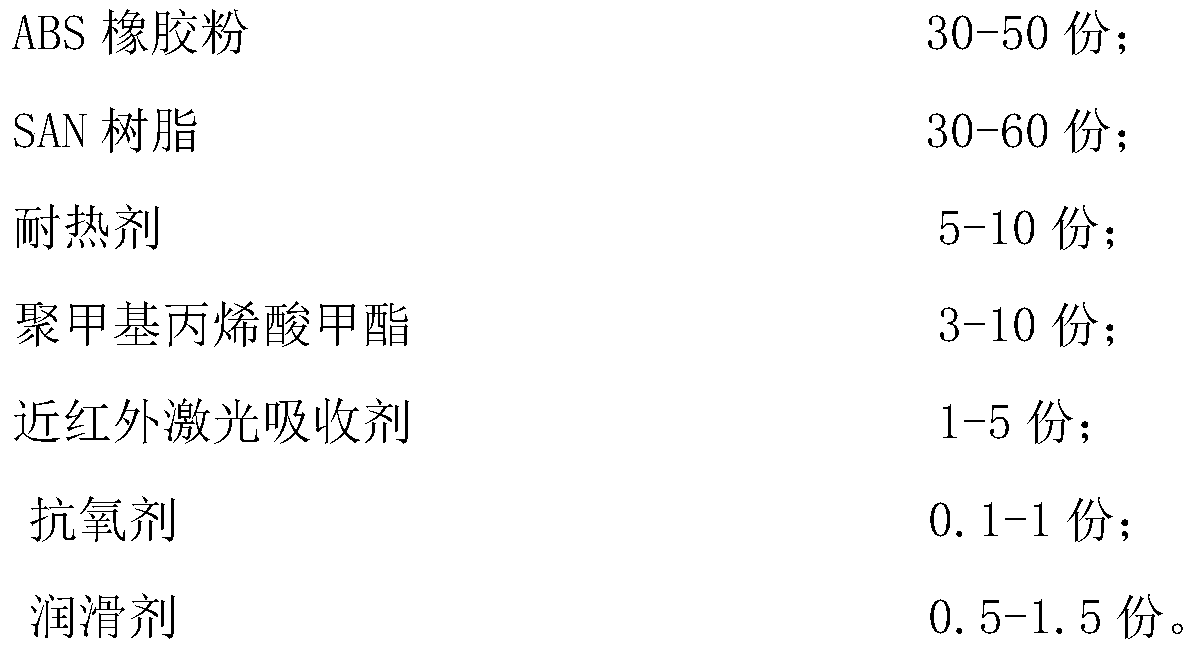

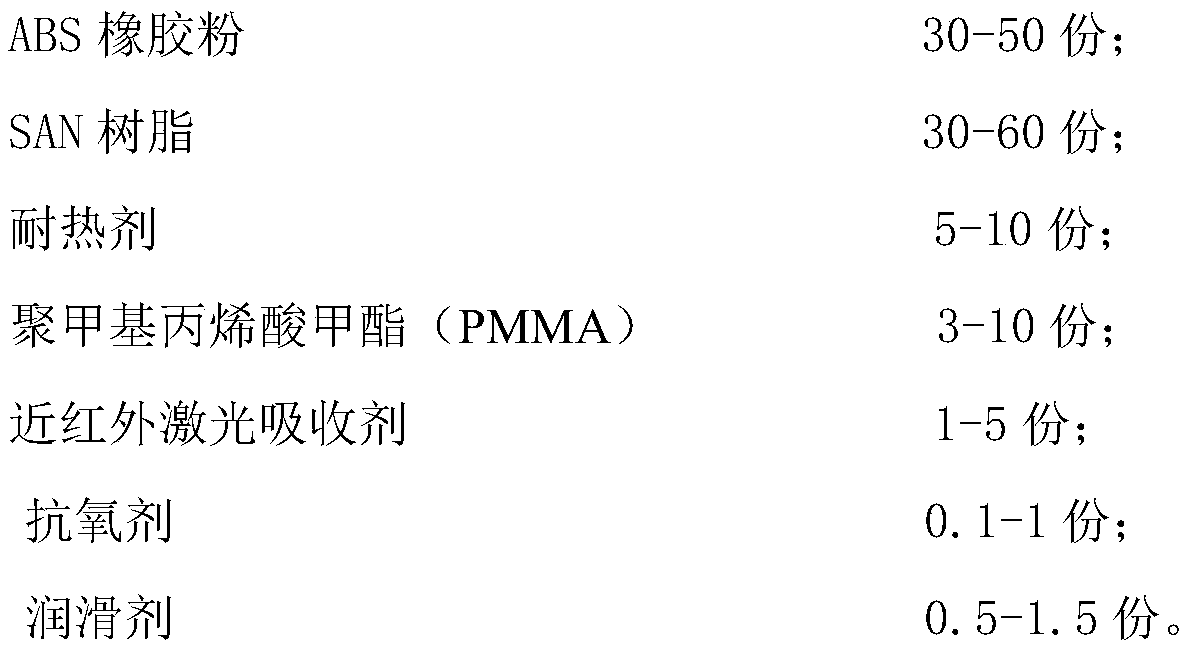

[0041] S1. 30-50 parts of ABS rubber powder, 30-60 parts of SAN resin, 5-10 parts of heat-resistant agent, 3-10 parts of PMMA, 1-5 parts of near-infrared laser absorber, 0.1-1 part of antioxidant, 0.5-1.5 parts of lubricant are pre-mixed in high-speed mixing equipment;

[0042] S2. Pass the premixed material obtained in step S1 through a twin-screw extruder, melt and extrude it at an extrusion temperature of 180-250°C and a screw speed of 200-500 rpm, and cool and granulate to obtain the Suitable for laser welding ABS resin composition.

Embodiment 1-5

[0053] Embodiments 1-5 respectively provide a kind of ABS composition suitable for laser welding, and the specific components are as shown in Table 1:

[0054] The preparation method that is suitable for laser welding ABS composition comprises the following steps:

[0055] (1) Prepare materials by the components and content of ABS rubber powder, SAN resin, heat-resistant agent, PMMA, near-infrared laser absorber, antioxidant, lubricant in Table 1;

[0056] (2) Premix the materials prepared in the step (1) in a high-speed mixer;

[0057] (3) Pass the premixed material obtained in step (2) through a twin-screw extruder, melt and extrude it at an extrusion temperature of 180-250° C. and a screw speed of 200-500 rpm, and cool and granulate. An ABS resin composition suitable for laser welding is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com