Isotatic polypropylene extrusion foaming device and process

An isotactic polypropylene, extrusion foaming technology, applied in the field of serial screw extrusion foaming devices, can solve the problems of easy collapse, low melt strength, and fast dissipation of foaming agent, and improve extrusion efficiency. , The effect of reducing production cost and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

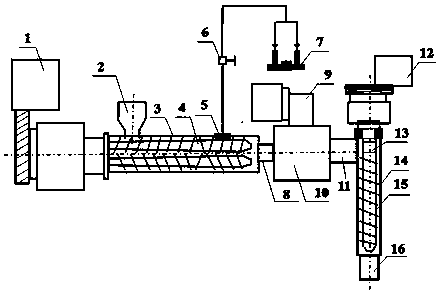

[0033] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes a twin-screw extruder 3, a twin-cylinder air pump 7, a melt pump 10, and a single-screw extruder 14 arranged in sequence.

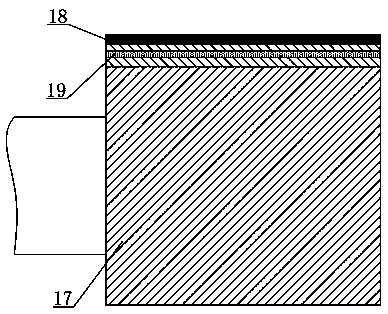

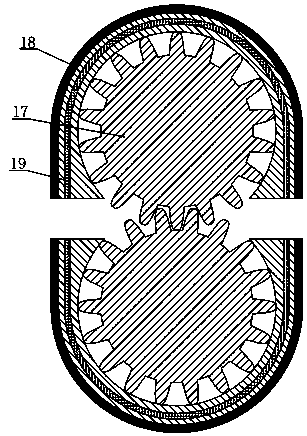

[0034] The melt pump 10 includes: a melt pump transmission system 9 , a melt pump rotor 17 , a melt pump heating system 18 , and a melt pump cooling system 19 . The melt pump cooling system 19 is provided with a cooling pipeline (not shown in the figure).

[0035] The melt pump cooling system 19 is provided in the melt pump housing. The melt pump rotor 17 is a gear structure. The gear structure is a straight tooth type.

[0036] The single-screw extruder 14 adopts a single-screw 15 with a diameter of ф45mm, and the power of the transmission motor of the transmission system 12 of the single-screw extruder is 30KW, and a thrust bearing is used. The motor power of the melt pump transmission system 9 is 10KW.

[0037] The twin-screw extruder 3 is provided wi...

Embodiment 2

[0047] Embodiment 2 has the same functions as those in Embodiment 1, and will not be repeated for the sake of brevity.

Embodiment 2

[0048] Example 2 is different from Example 1 in that its formulation and process are different: when working, mix 99.0% isotactic polypropylene and nucleating agent DMDBS1.0% with a high-speed mixer for 5 minutes, and open the double-cylinder air pump 7 And valve 6, put the raw material into the hopper 2, after passing through the twin-screw extruder 3, connecting body I8, melt pump 10, connecting body II11, single-screw extruder 14, and extruding through the single-screw extruder head 16 out.

[0049] The process temperature of the twin-screw extruder 3: 160°C in the first zone, 175°C in the second zone, 180°C in the third zone, 190°C in the fourth zone, 190°C in the fifth zone, 185°C in the sixth zone, and 180°C in the seventh zone. The process temperature of the linker I8: 165°C. Process temperature of the melt pump 10: 155°C. The process temperature of the linker II11: 145°C. The process temperature of the single-screw extruder 14 is: 135°C in the first zone, 145°C in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com