Poly(L-lactic acid) foaming material with rapid crystallization capacity and preparation method of poly(L-lactic acid) foaming material

A polylactic acid foaming and lactic acid technology, which is applied in the field of poly-L-lactic acid foaming materials and its preparation, can solve the problems of insufficient strength and density of foaming materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] The present invention completes and refines the overall technical scheme, better ensures the structure and parameters of the poly-L-lactic acid resin, improves the heat-resistant temperature and cell density of the polylactic acid foaming material, and enhances the foaming stability of the polylactic acid foaming material , the preparation method of the poly-L-lactic acid resin preferably comprises the following steps:

[0097] Under the action of an initiator and a catalyst, the L-lactide is polymerized, and then a capping agent is added to carry out a capping reaction to obtain a poly L-lactic acid resin.

[0098] more specific:

[0099] In the late stage of lactide polymerization under the action of initiator and catalyst, add an appropriate amount of end-capping agent, stir at 130-200°C for 5-30 minutes, and discharge to obtain poly-L-lactic acid resin with rapid crystallization characteristics.

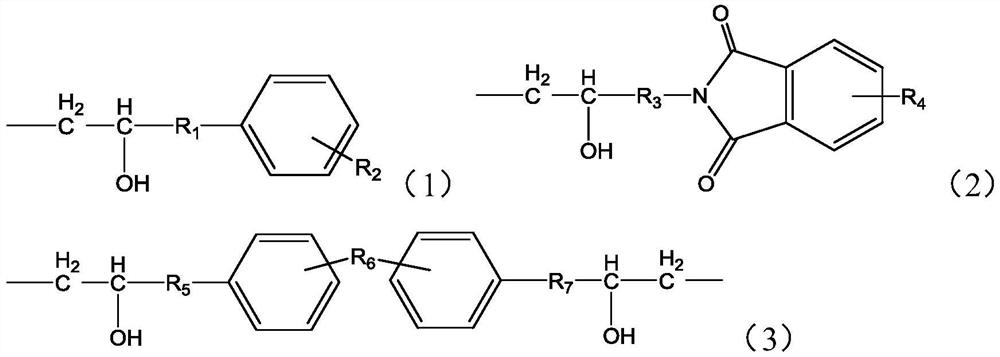

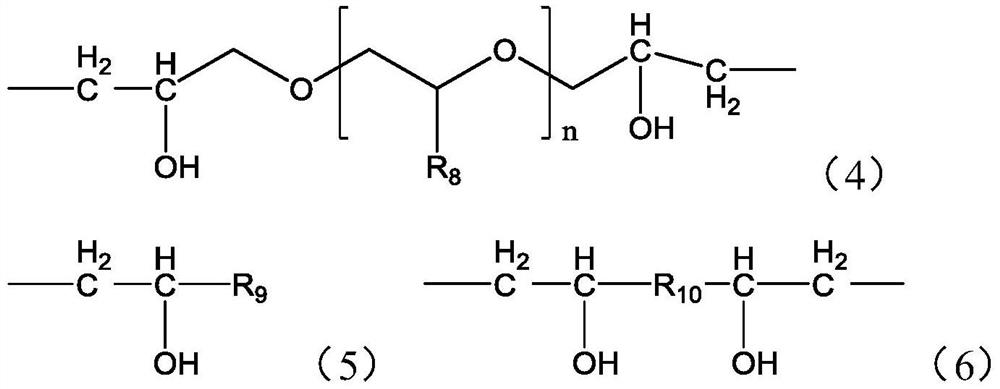

[0100] In the invention, the L-lactide is polymerized under the action...

preparation example 1

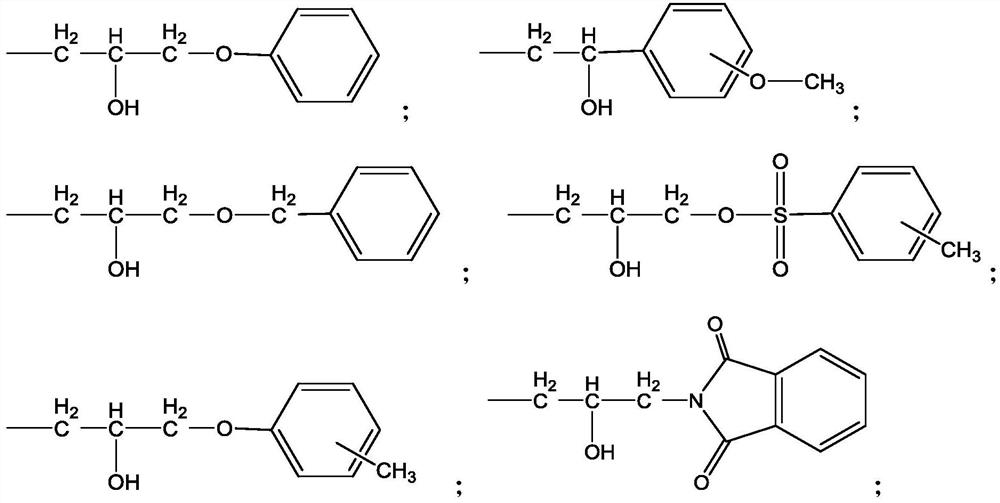

[0135] In the L-lactide monomer, add corresponding initiators, catalysts, etc., react at 150°C for 2 hours, and then add end-capping agents, phenoxymethyloxirane, 1,2-epoxytetradecane, Among them, the molar ratio of the monomer raw material L-lactide monomer, phenoxymethyl oxirane, and 1,2-epoxytetradecane is 1:1:2, and the reaction is continued for 30 minutes, and the material is discharged , to obtain rapid crystallization type poly L-lactic acid resin A1, which was detected by GPC and had a number-average molecular weight of 170,000. It was detected by DSC that the semi-crystallization time of the resin was 1.8 minutes under isothermal conditions of 120°C.

preparation example 2

[0137] In the L-lactide monomer, add corresponding initiators, catalysts, etc., react at 150°C for 2 hours, and then add end-capping agents, glycidyl p-toluenesulfonate, 1,7-octadiene diepoxy Compound, wherein the molar ratio of L-lactide monomer, glycidyl p-toluenesulfonate, and 1,7-octadiene diepoxy compound is 1:2:2, continue to react for 30 minutes, and discharge , to obtain fast crystallization type poly L-lactic acid resin A2, the number average molecular weight of the resin is 220,000 as detected by GPC, and the semi-crystallization time of the resin is 1.6 minutes under the isothermal condition of 120° C. as detected by DSC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com