Polypropylene with low gel content and high melt strength, preparation method and application thereof

A technology of high melt strength and polypropylene, applied in the field of polymer materials, can solve the problems of uneven concentration distribution, easy gelation, and affecting the performance of polypropylene, so as to improve quality stability, strong selectivity, and avoid partial The effect of the gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

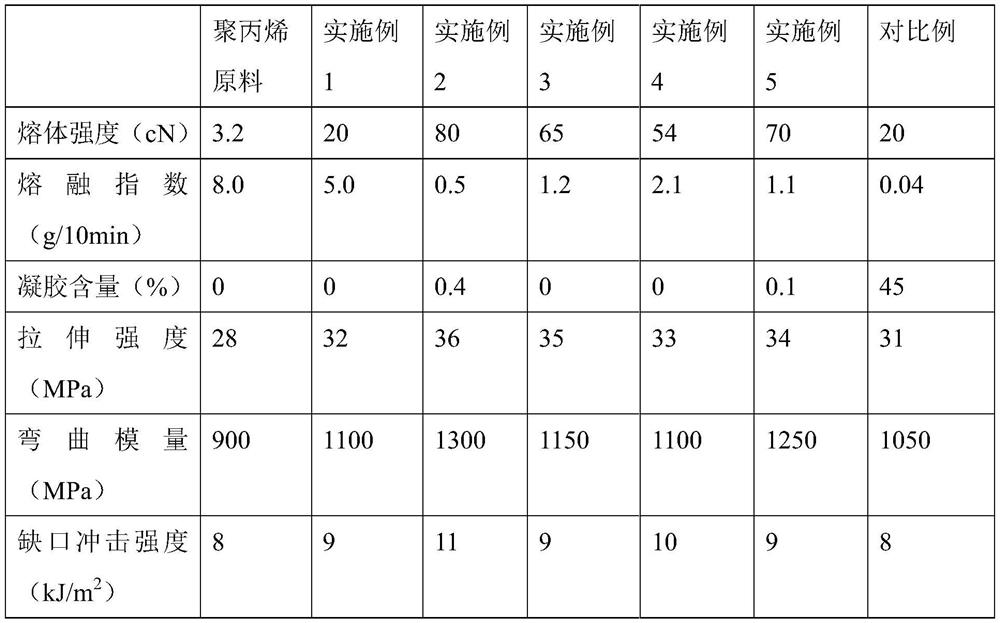

Examples

Embodiment 1

[0035] Example 1 Crosslinked polypropylene was prepared by the following method.

[0036] In parts by weight, 100 parts of polypropylene raw material, 0.5 part of benzoyl peroxide, 0.1 part of allyl alcohol and 0.5 part of antioxidant (antioxidant 1010 and 168 are mixed in a mass ratio of 2:1), set The extrusion temperature of the fixed screw is 180° C., the rotational speed of the screw is 300 rpm, and the grafted polypropylene is formed through twin-screw melt extrusion reaction.

[0037]In parts by weight, mix 100 parts of grafted polypropylene, 0.1 part of ethylene glycol diglycidyl ether and 0.1 part of antioxidant (mixture of antioxidant 1010 and 168 in a mass ratio of 2:1), set the screw extrusion The outlet temperature is 200° C., the screw speed is 500 rpm, and the cross-linked polypropylene is formed through twin-screw melt extrusion reaction.

Embodiment 2

[0039] Example 2 Crosslinked polypropylene was prepared by the following method.

[0040] In parts by weight, mix 100 parts of polypropylene raw material, 0.01 part of lauroyl peroxide, 0.5 part of allyl alcohol and 0.1 part of antioxidant (mixture of antioxidant 1010 and 168 in a mass ratio of 2:1), set The screw extrusion temperature is 180° C., the screw speed is 300 rpm, and the grafted polypropylene is formed through twin-screw melt extrusion reaction.

[0041] In parts by weight, mix 100 parts of grafted polypropylene, 2 parts of polybutylene oxide and 0.5 parts of antioxidant (mixture of antioxidants 1010 and 168 in a mass ratio of 2:1), set the screw to extrude The temperature is 200° C., the screw speed is 500 rpm, and the cross-linked polypropylene is formed through twin-screw melt extrusion reaction.

Embodiment 3

[0043] Example 3 Crosslinked polypropylene was prepared by the following method.

[0044] In parts by weight, 100 parts of polypropylene raw materials, 0.2 parts of tert-butyl peroxide 2-ethylhexanoate, 2 parts of 2-hexen-1-ol and 0.35 parts of antioxidant (antioxidants 1010 and 168 or more 2:1 mass ratio mixture) mixed, set the screw extrusion temperature at 180°C, and the screw speed at 300rpm, and reacted through twin-screw melt extrusion to form grafted polypropylene.

[0045] In parts by weight, 100 parts of grafted polypropylene, 1 part of 1,4 butanediol diglycidyl ether and 0.3 parts of antioxidant (mixture of antioxidants 1010 and 168 in a mass ratio of 2:1) were mixed to set The extrusion temperature of the fixed screw is 200° C., the rotational speed of the screw is 500 rpm, and the cross-linked polypropylene is formed through twin-screw melt extrusion reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com