Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148results about How to "High print density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous ink, ink-jet recording method, ink cartridge, recording unit, ink-jet recording apparatus and image forming method

ActiveUS7276112B2Increase the areaHigh print densityDuplicating/marking methodsInksOrganic solventAtomic group

Disclosed is an aqueous ink comprising at least water, a plurality of water-soluble organic solvents and a coloring material. The coloring material is a pigment, and, it contains a pigment particle having at least one ionic group bonded to a surface of the pigment particle directly or via another atomic group. The plurality of water-soluble organic solvents have a good medium or good mediums for the pigment and a poor medium or poor mediums for the pigment. The poor medium does not solvate perfectly or substantially the pigment. The ionic group undergoes perfectly or substantially no ionic dissociation in the poor medium. Also, among the respective Ka values of the plurality of water-soluble organic solvents as determined by the Bristow method, the Ka value of the poor medium is maximum.

Owner:CANON KK

Process for the preparation of pigment dispersion, pigment dispersion obtained by the same, ink jet recording ink comprising the same, and recording method and recorded material using the same

InactiveUS6916862B2Good printabilityGood storage stabilityPigmenting treatmentMeasurement apparatus componentsAqueous mediumPigment

Provided is a process for the preparation of a pigment dispersion which comprises a pigment surface treatment step of introducing at least one hydrophilic dispersibility-providing group onto the surface of a pigment directly and / or with the interposition of a polyvalent group, and a dispersion step of dispersing a surface-treated pigment obtained at the surface treatment step in an aqueous medium, characterized in that the dispersion step involves the dispersion of the surface-treated pigment in admixture with a wetting agent and water and a resin for providing dispersibility and / or fixability is added during and / or after the dispersion step.

Owner:SEIKO EPSON CORP

Photopolymerizable polymer micelle, method of producing the same, and ink composition containing photopolymerizable polymer micelle

A photopolymerizable polymer micelle includes a spherical micelle that encapsulates a hydrophobic photopolymerization initiator, the spherical micelle being formed by a block copolymer having a hydrophilic block segment and a hydrophobic block segment, the block copolymer having a number average molecular weight exceeding 10000, and the hydrophobic block segment at least partially having a radically polymerizable group.

Owner:SEIKO EPSON CORP

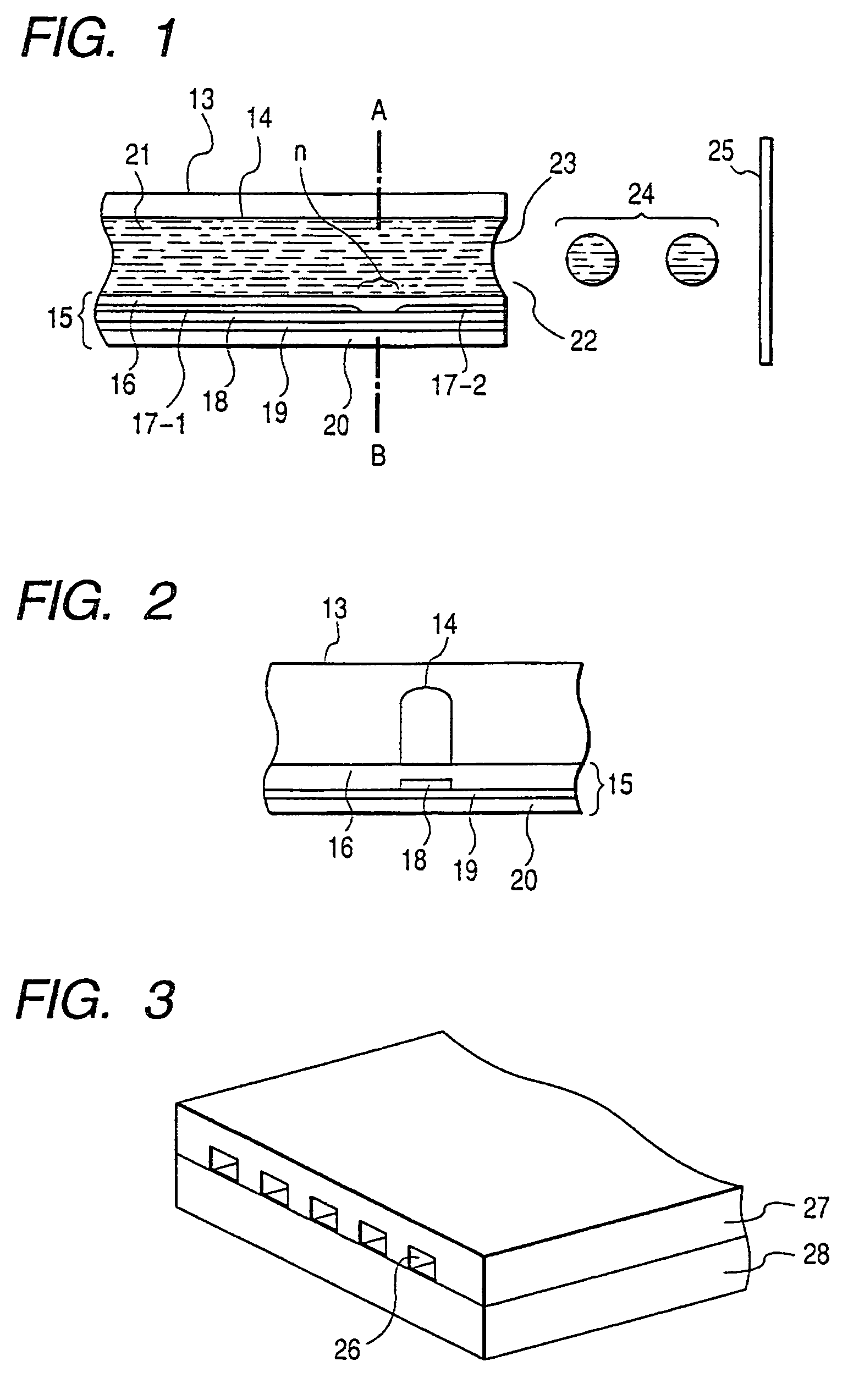

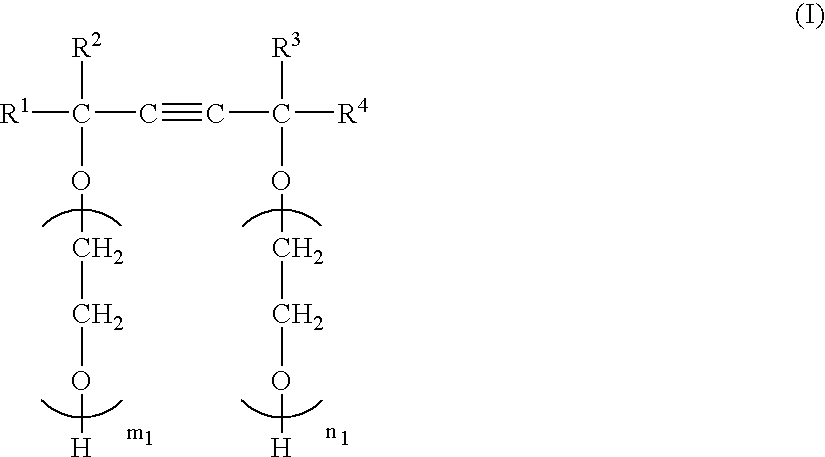

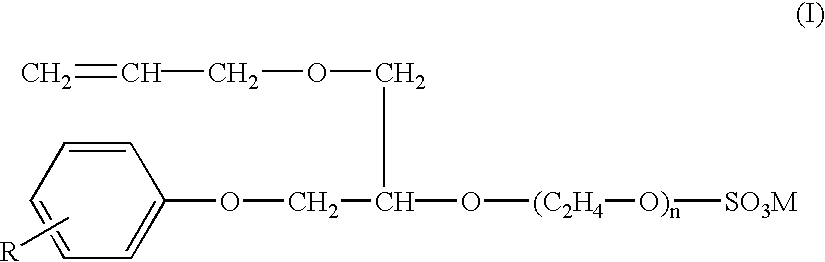

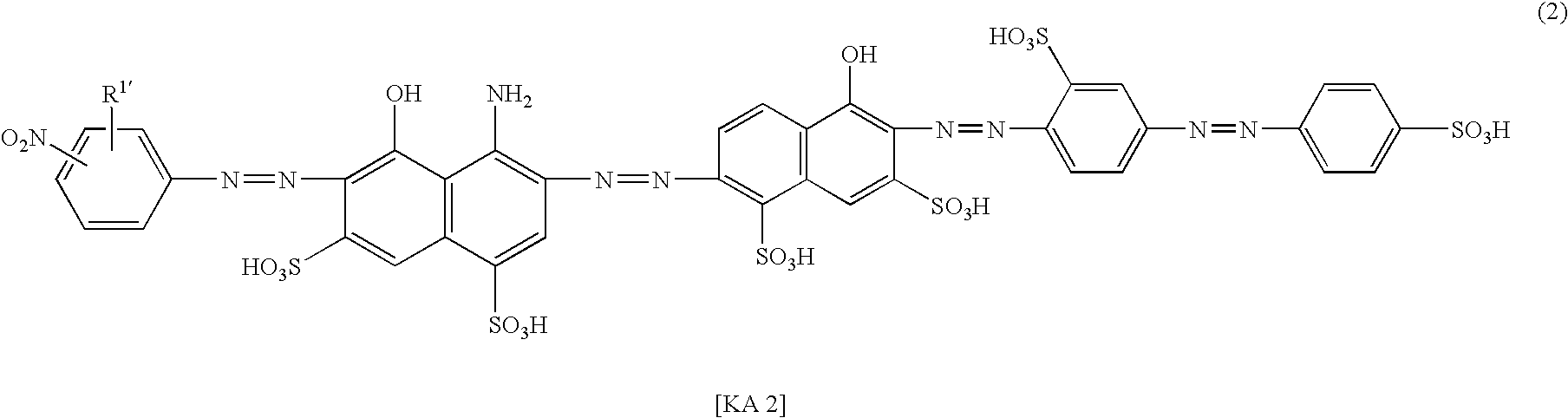

Ink jet black ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

ActiveUS7144452B2Sufficient image fastnessIncreased durabilityMeasurement apparatus componentsDuplicating/marking methodsPolymer scienceOrganic solvent

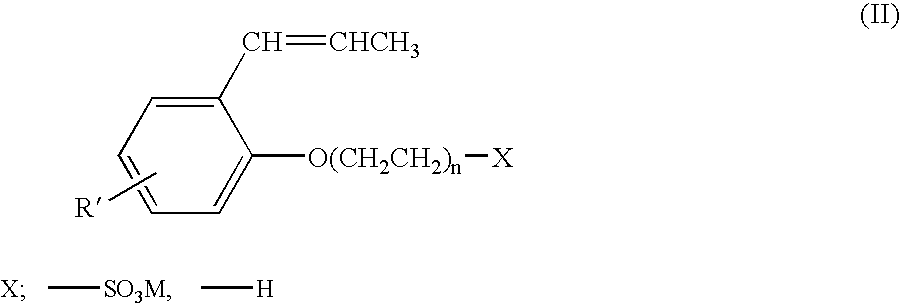

The present invention aims to provide an ink jet black ink which can improve weatherability, optical density and sticking recovery property of nozzles of a recording head. According to the present invention, an ink jet black ink is provided which comprises at least a coloring-material and a water-soluble organic solvent, wherein the coloring material is a compound represented by the following general formula (I) or a salt thereof, and the water-soluble organic solvent is a water-soluble organic solvent having a relative permittivity of from 30.0 or more to less than 70.0 at 20° C. and capable of dissolving the compound represented by the following general formula (I) or a salt thereof, by 1.0 mass % or more at 25° C., and is in a content of 50.0 mass % or more with respect to the total content of all water-soluble organic solvents contained in the ink jet black ink

Owner:CANON KK

Ink jet recording element

InactiveUS6110601AIncrease volumeResistance to image bleedingLayered productsDuplicating/marking methodsPolyvinyl alcoholPolyethylene glycol

An ink jet recording element comprising a water-impervious support having thereon the following layers: a) a water-absorbing layer; and b) an image-recording layer comprising a colloidal oxide and a pigment dispersed in a binder, the binder comprising a mixture of poly(ethylene glycol) having a molecular weight of from about 1400 to about 35,000 and poly(vinyl alcohol), the ratio of the poly(ethylene glycol) to the poly(vinyl alcohol) being from about 1:0.8 to about 1:1.5.

Owner:EASTMAN KODAK CO

Ink-jet recording ink, ink-jet recording ink set, recording method, print, and ink-jet recording apparatus

InactiveUS7307109B2Excellent long-term storage stabilityHigh print densityInksPrintingAlcoholGlycol ethers

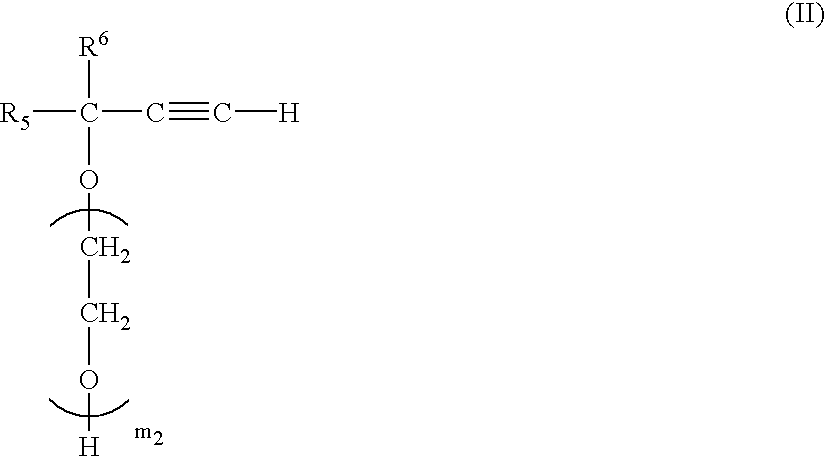

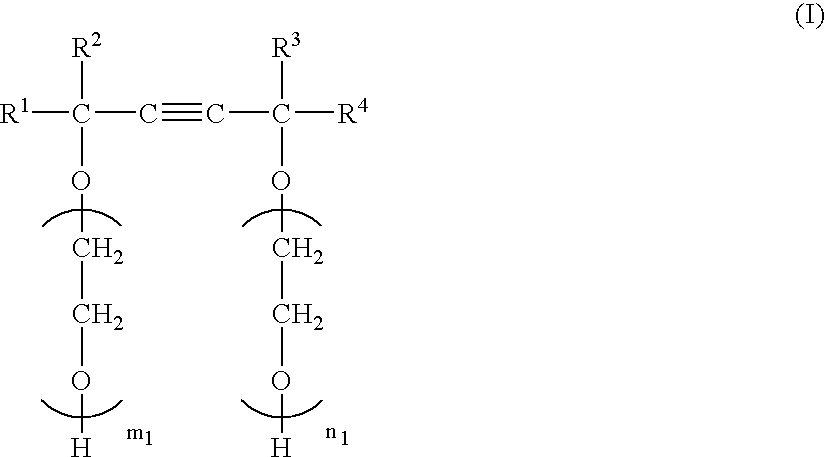

An ink jet recording ink (IJ ink) containing a colorant of a pigment and / or dye enveloped in a polymer, and water, and containing at least one compound from the group of acetylene glycol surfactants and acetylene alcohol surfactants, and another compound from the group of glycol ethers and 1,2-alkylene glycols; an IJ ink set including a plurality of the inks; a recording method of using the ink and / or the ink set; recorded matter printed according to the recording method; and an ink jet recording apparatus having an electrostrictive unit mounted thereon and designed so as to be capable of ejecting the ink.

Owner:SEIKO EPSON CORP

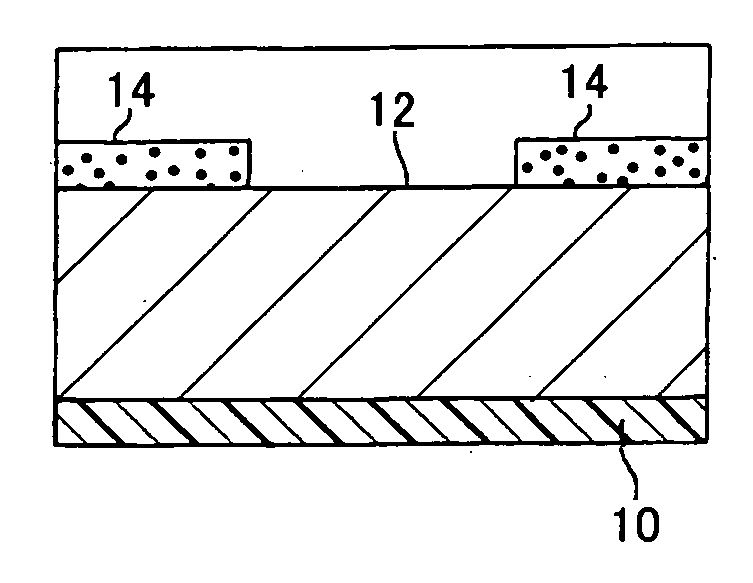

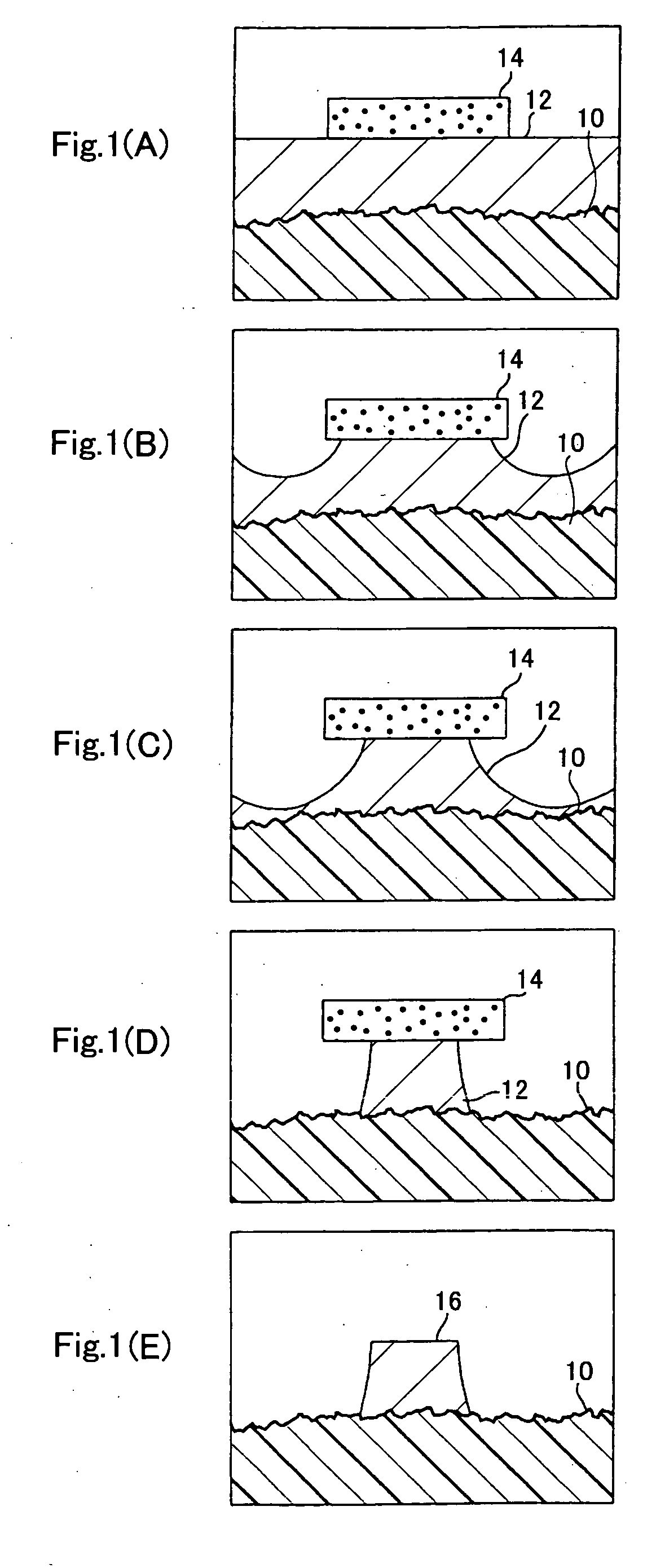

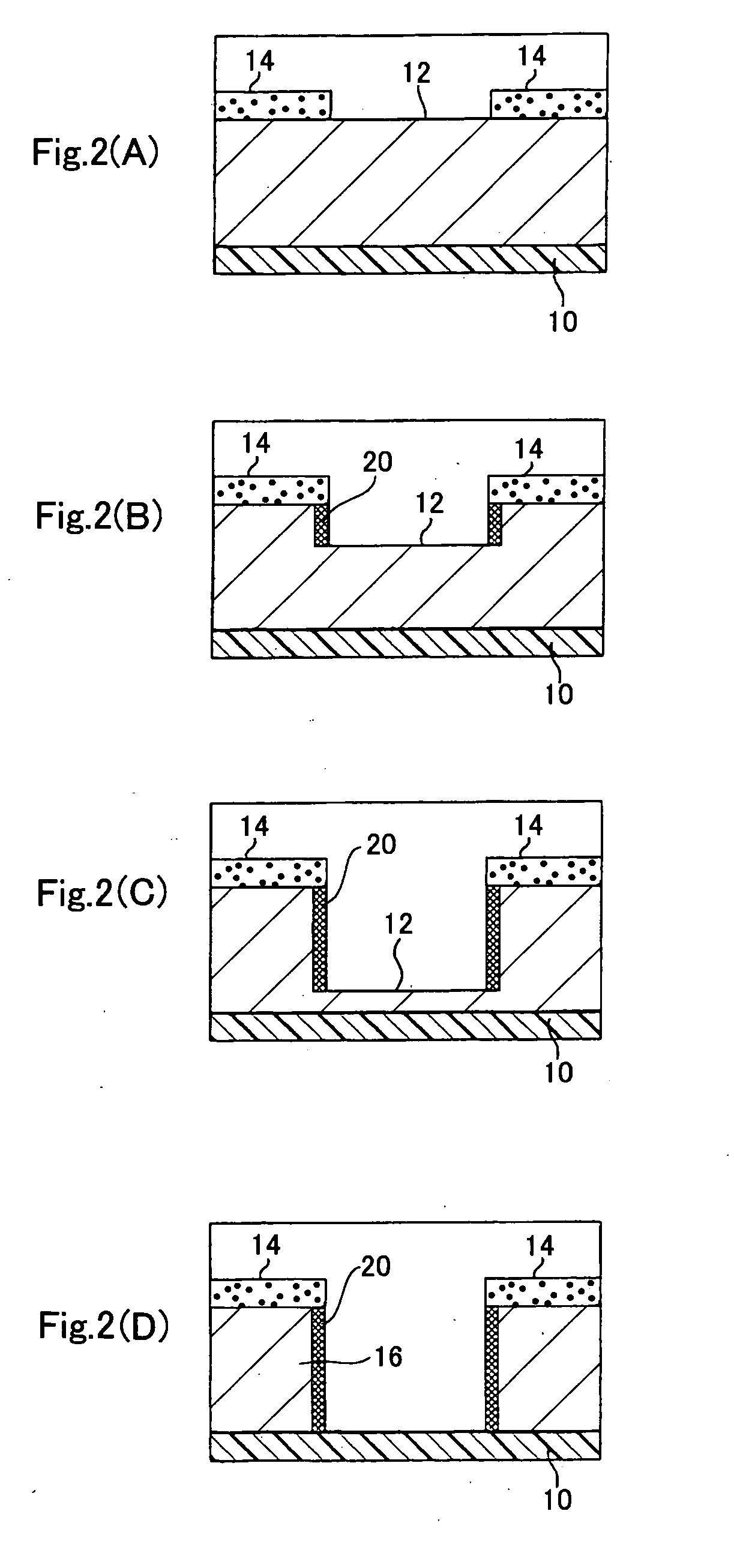

Etching solution, method of etching and printed wiring board

ActiveUS20060199394A1Efficient processEfficient coatingInsulating substrate metal adhesion improvementDecorative surface effectsTriazole antifungalsHigh concentration

There is provided an etching solution comprised of a cupric chloride solution and a high-concentration triazole type compound added to the cupric chloride solution and capable of forming an etching-inhibiting coating. In a process of forming a circuit pattern by etching with the etching solution, an etching-inhibiting coating is selected formed on parts of a copper foil laid under the edge of an etching resist to effectively inhibit horizontal side-etching of the copper foil from the edge of the etching resist. Also, nonuniform irregularities formed on the side wall of the circuit pattern by the etching improves the adhesion between the circuit pattern and an insulating resin layer covering the circuit pattern.

Owner:IBIDEN CO LTD

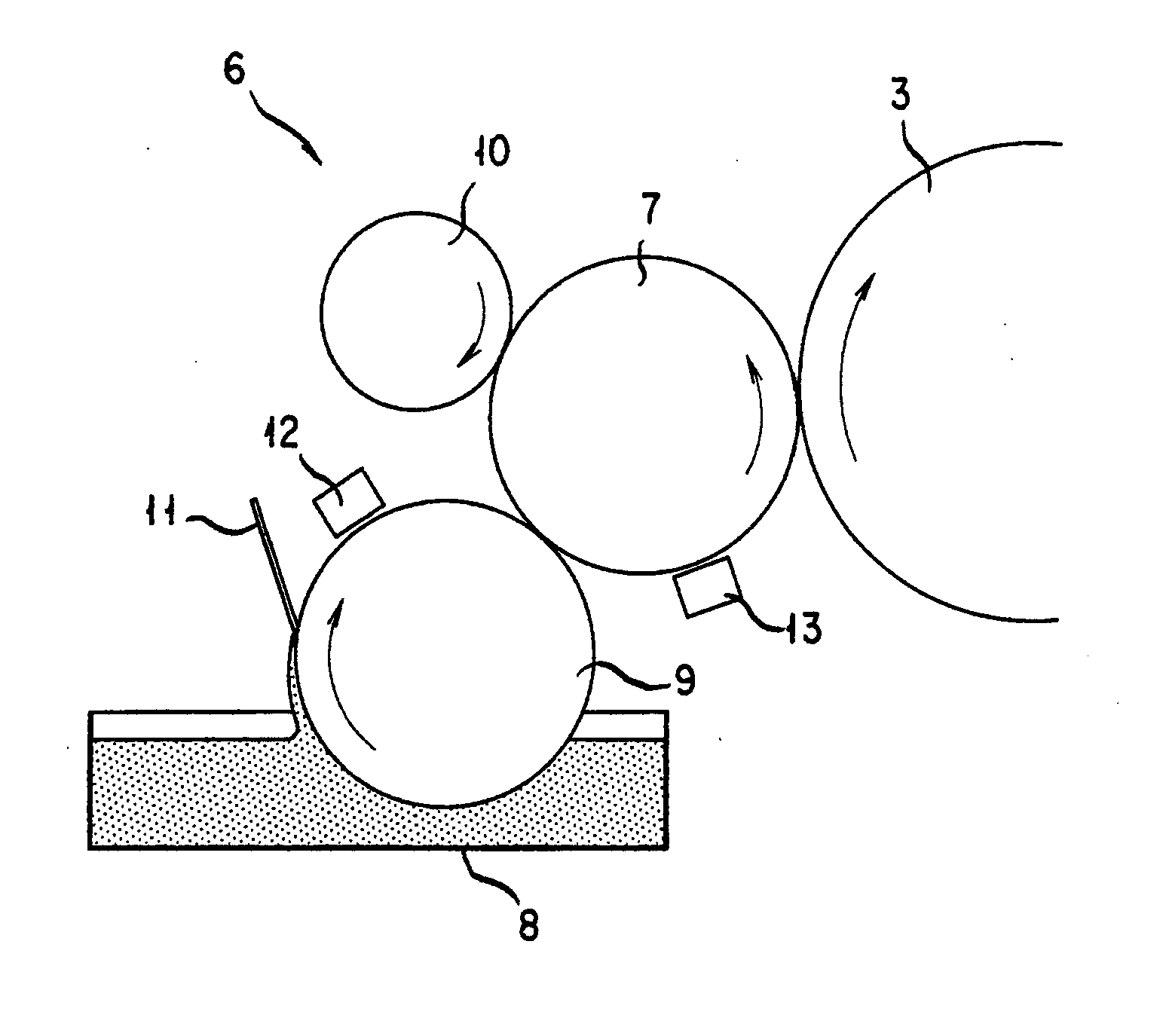

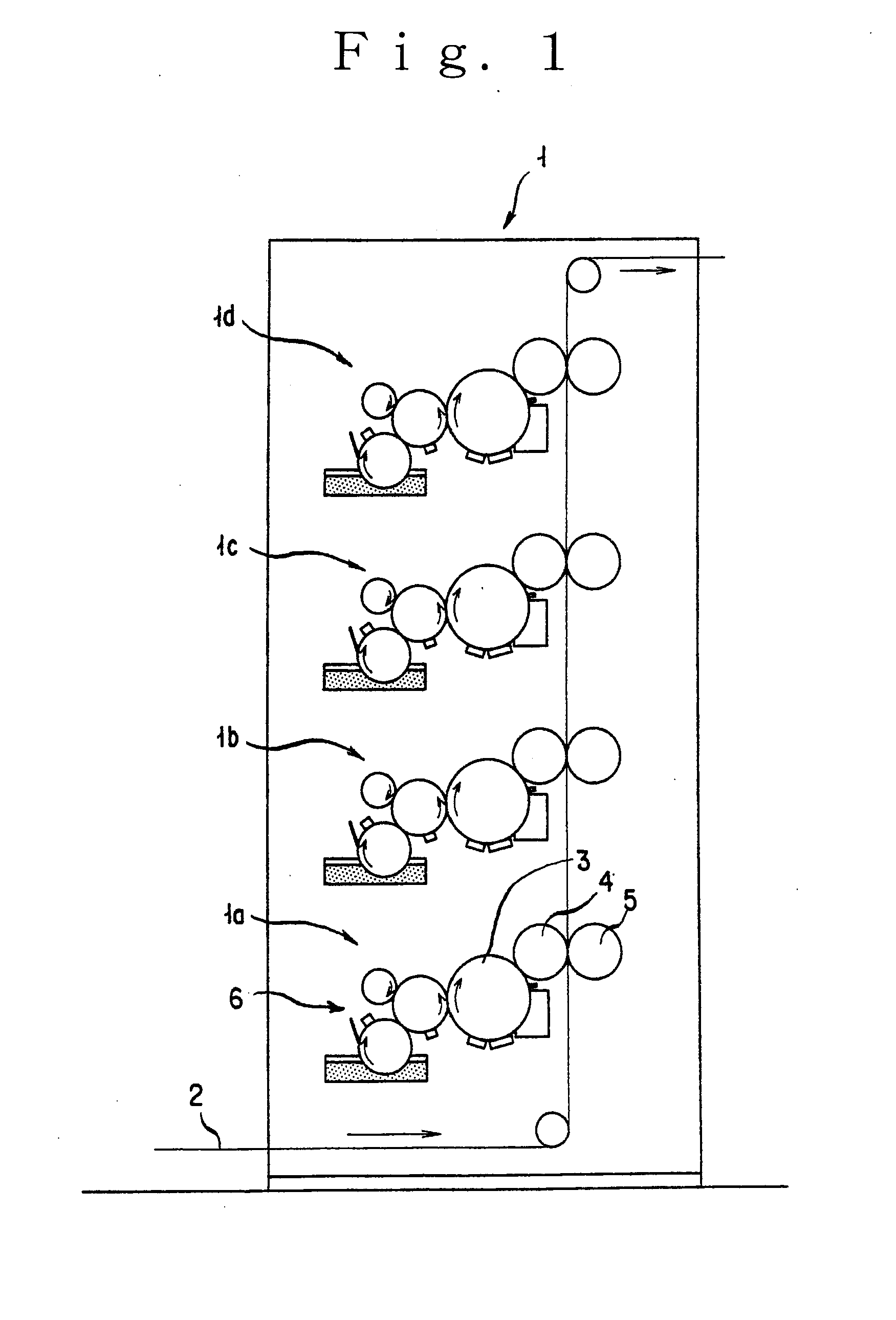

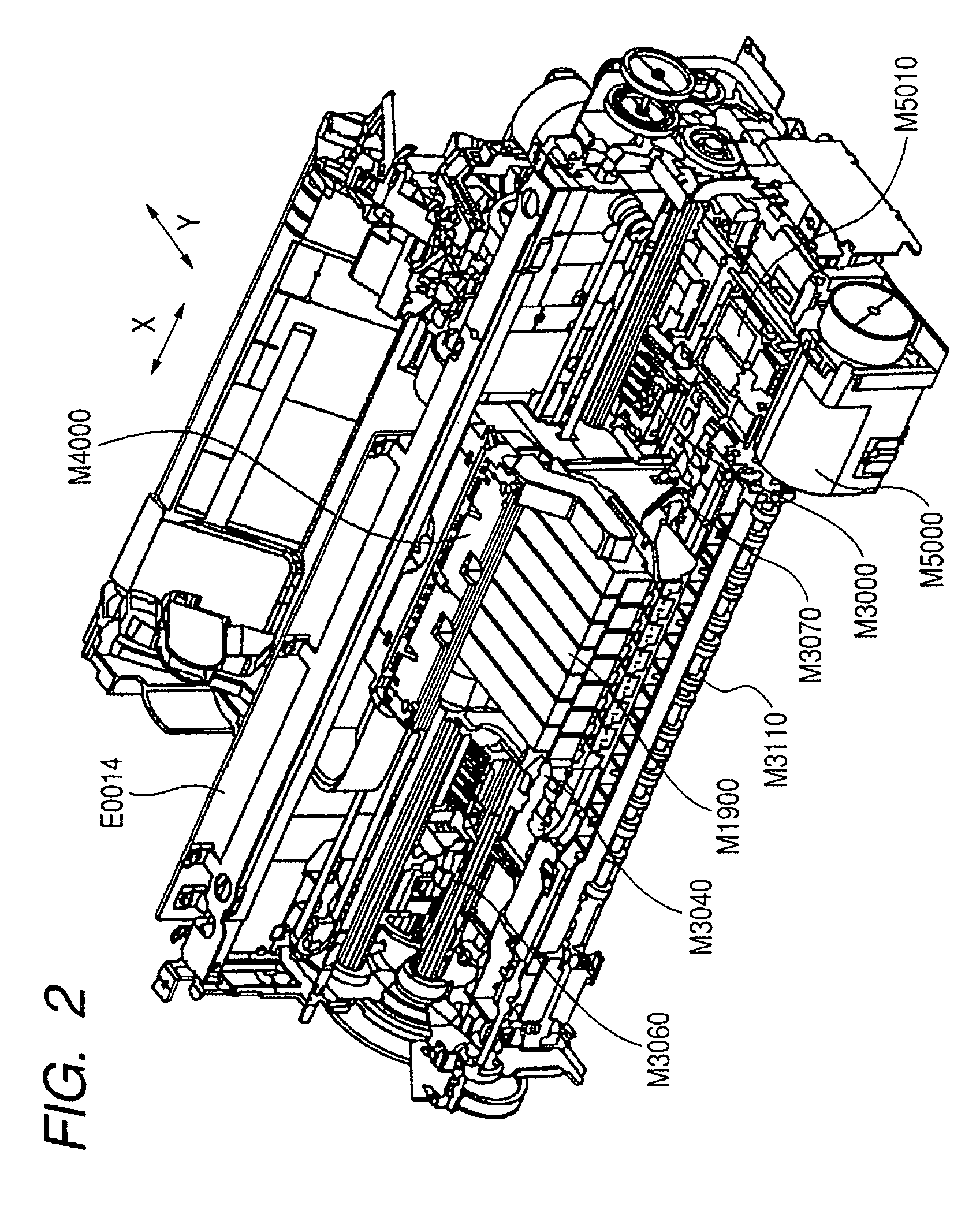

Wet type developing apparatus and wet type developing method

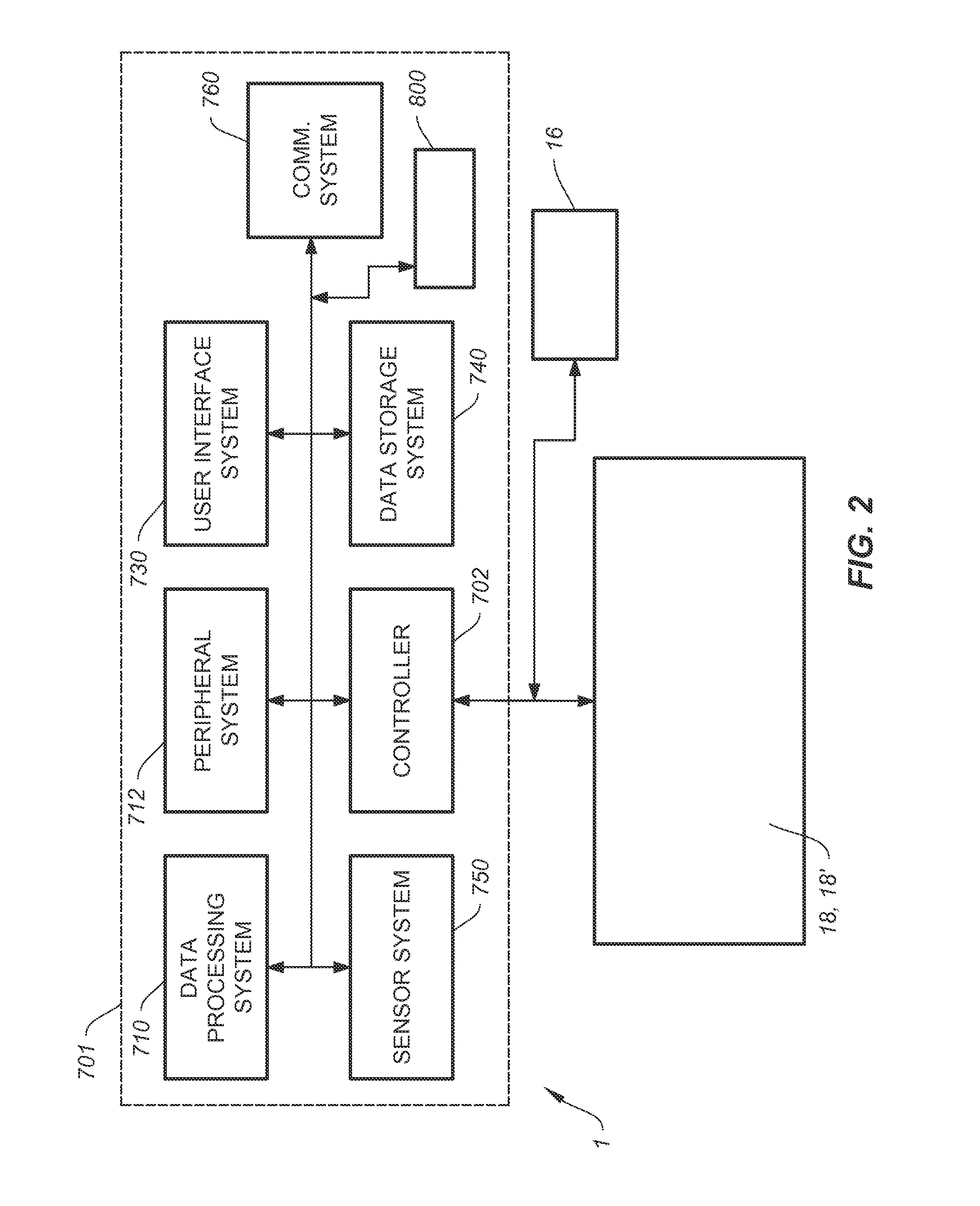

ActiveUS20110249990A1Improve maintainabilityImprove accuracyElectrographic process apparatusEngineeringMechanical engineering

A wet type developing apparatus is provided which allows printing in a quality that is stable at an increased printing speed and also with changes in physical property of a liquid developer. The wet type developing apparatus to this end includes a liquid developer feed pathway which comprises a developing roller 7 for feeding the liquid developer onto a photoconductor drum 3; an anilox roller 9 immersed in part in the liquid developer and driven to rotate in rotational contact with the developing roller; and a doctor blade 11 disposed in contact with a surface of the anilox roller for controlling the rate of drawing up of the liquid developer. The developing and anilox rollers have their peripheral surfaces moving in an identical direction and at an identical rate of movement in an area of their rotational contact. A toner charger 12 is disposed opposite to a surface of the anilox roller downstream of an area of contact of the doctor blade with the anilox roller and upstream of an area of rotational contact of the anilox roller with the developing roller in a rotation direction of the anilox roller.

Owner:MIYAKOSHI PRINTING MACHINERY

Increased inkjet printed density

InactiveUS20090051749A1High print densityDuplicating/marking methodsTypewritersEngineeringVolumetric Mass Density

A method of improving the density of an inkjet image comprising the step of printing the image on an inkjet receiver having a layer of Al2O3 less than 100 nm thick deposited on the surface thereof.

Owner:EASTMAN KODAK CO

Aqueous inkjet ink composition

InactiveUS20080206465A1High print densityImprove text qualitySpecial tyresInksWater solubleVolumetric Mass Density

An inkjet ink comprising water, a self-dispersing carbon black pigment, and a water soluble polymer containing acid groups neutralized by an inorganic base, wherein said carbon black pigment comprises greater than 11 weight % volatile surface functional groups. The inks of the present invention have improved print density on plain paper, good text quality, improved print durability such as waterfastness and excellent jetting performance over an extended printing period. They further provide good print uniformity over a wide variety of inkjet receivers.

Owner:EASTMAN KODAK CO

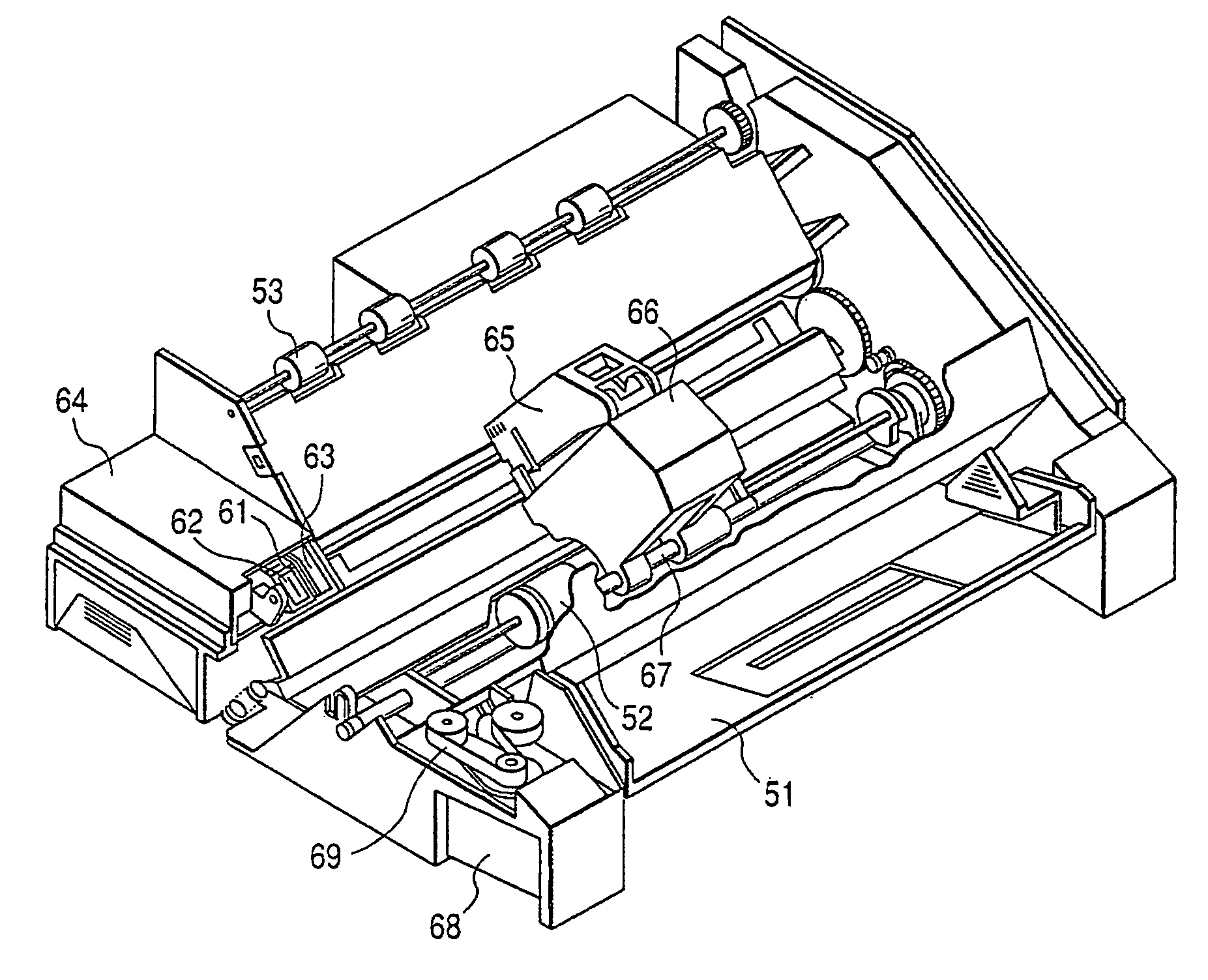

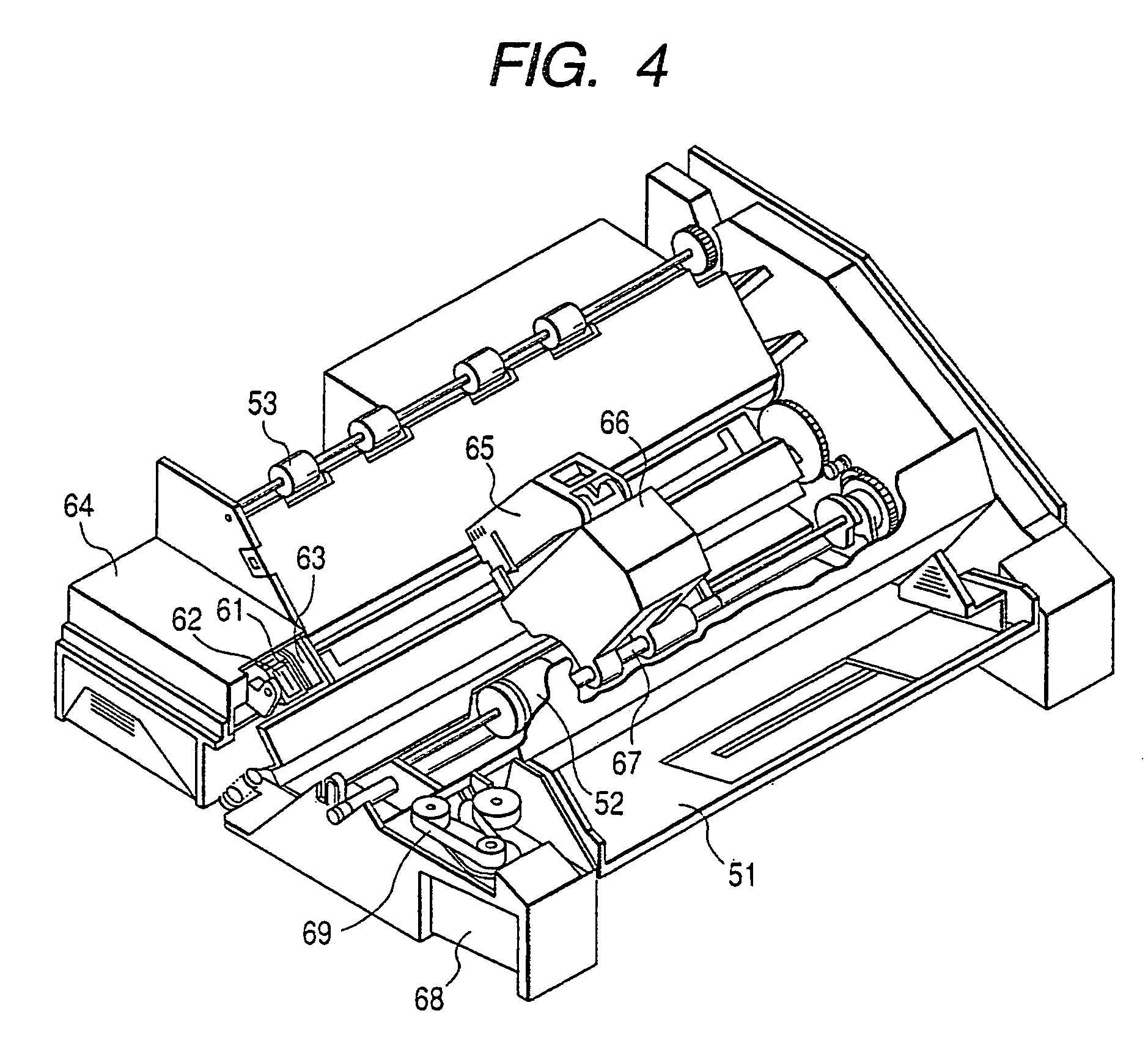

Ink jet recorded matter and production process therefor, and thermal transfer sheet, ink jet recording apparatus, thermal transfer apparatus, and ink jet recording medium

InactiveUS6857736B2Good light fastnessExcellent in resistance to scratch and gas and heatInking apparatusTypewritersInorganic particleEngineering

On ink jet recorded matter comprising an ink jet recording medium having a substrate and an ink receiving layer formed thereon containing porous inorganic particles and an image formed with a pigment ink on the ink receiving layer, a protective layer covering the image is formed by thermally transferring a transfer layer from a heat-resistant carrier onto the image. The ink jet recording medium comprises a substrate and an ink receiving layer formed on one side of the substrate, wherein an ink jet recorded image and a protective layer covering the image are to be formed on the surface of the ink receiving layer, said side of the substrate, before the formation of the ink receiving layer, having a Bekk's surface smoothness of 200 seconds or higher and the surface of the ink receiving layer having a Bekk's surface smoothness of 60 seconds or higher. Also disclosed is an ink jet recording medium having no ink receiving layer, which comprises a substrate treated with a solution of a metal salt and in which the front and back sides of the substrate each have a Bekk's surface smoothness of 200 seconds or higher.

Owner:SEIKO EPSON CORP

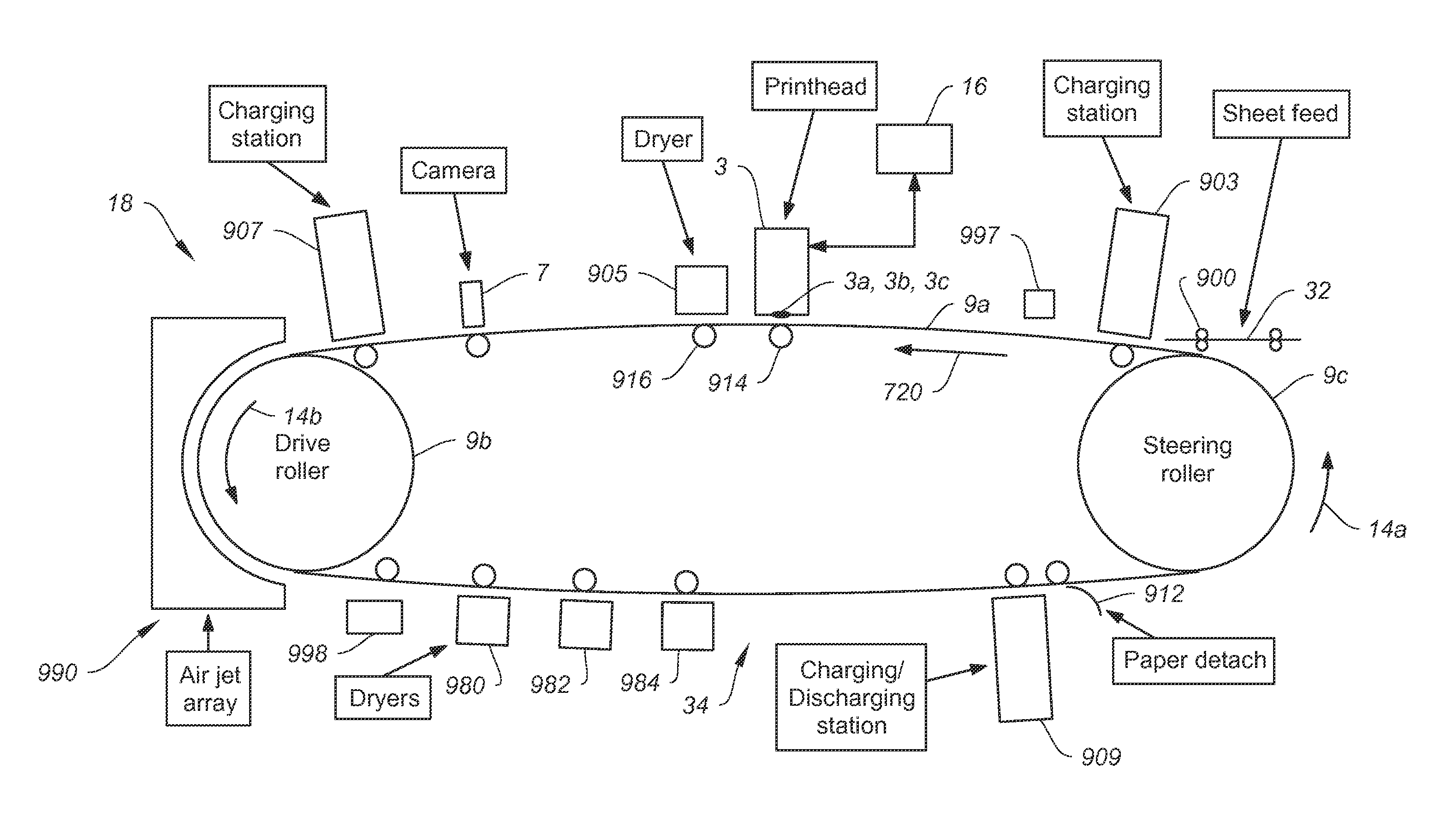

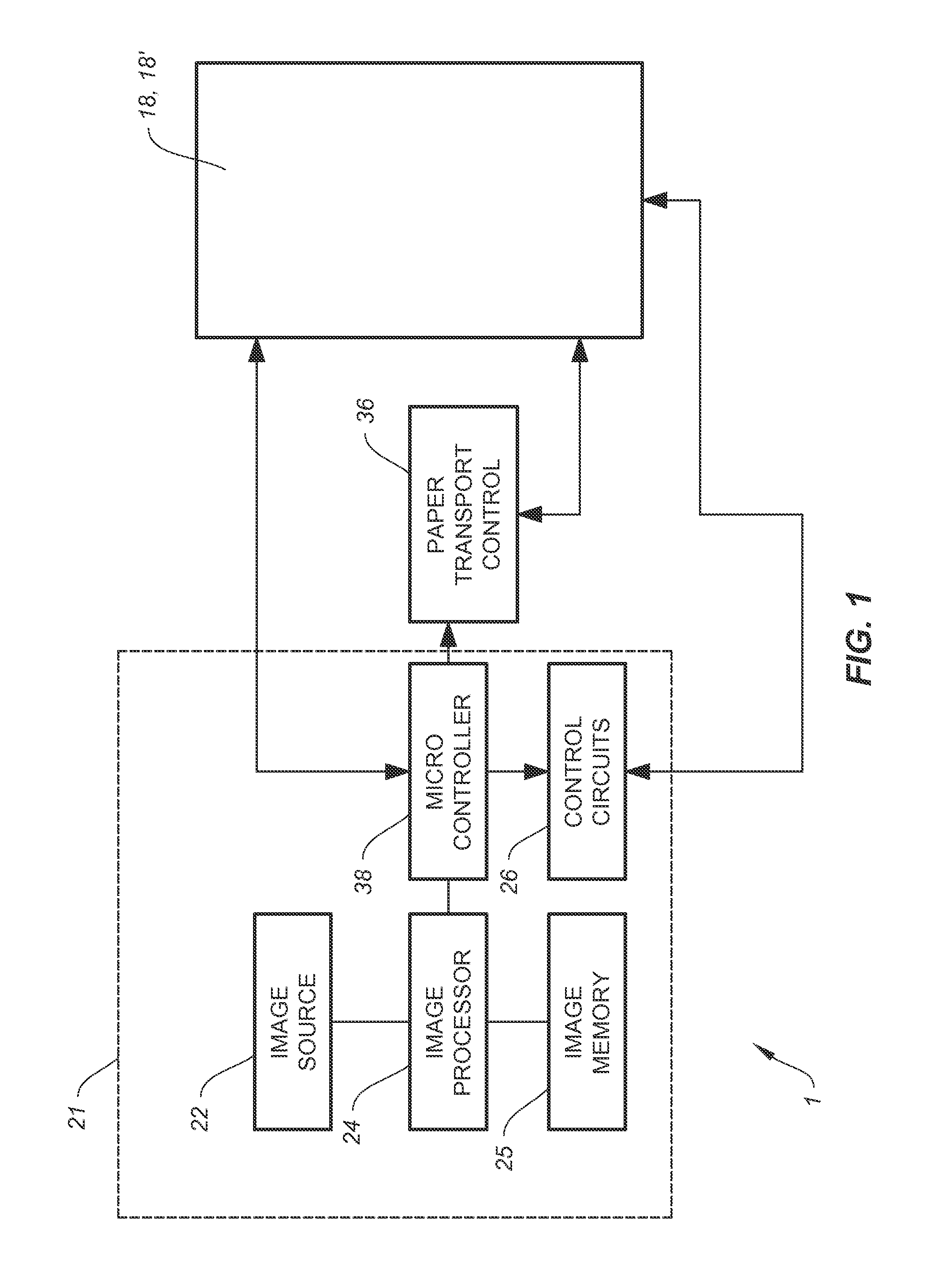

High optical density inkjet printing method

InactiveUS20150138288A1Reduce riskHigh print densityPower drive mechanismsOther printing apparatusEngineeringOptical density

An inkjet printing method and system includes an arrangement that is adapted to repair a printed image using a combination of in-line imaging and feedback control of an inkjet printhead or printing with a redundant inkjet printhead. The inkjet printing method and system is further adapted to print at higher optical density than is normally possible by use of multi-pass capabilities.

Owner:EASTMAN KODAK CO

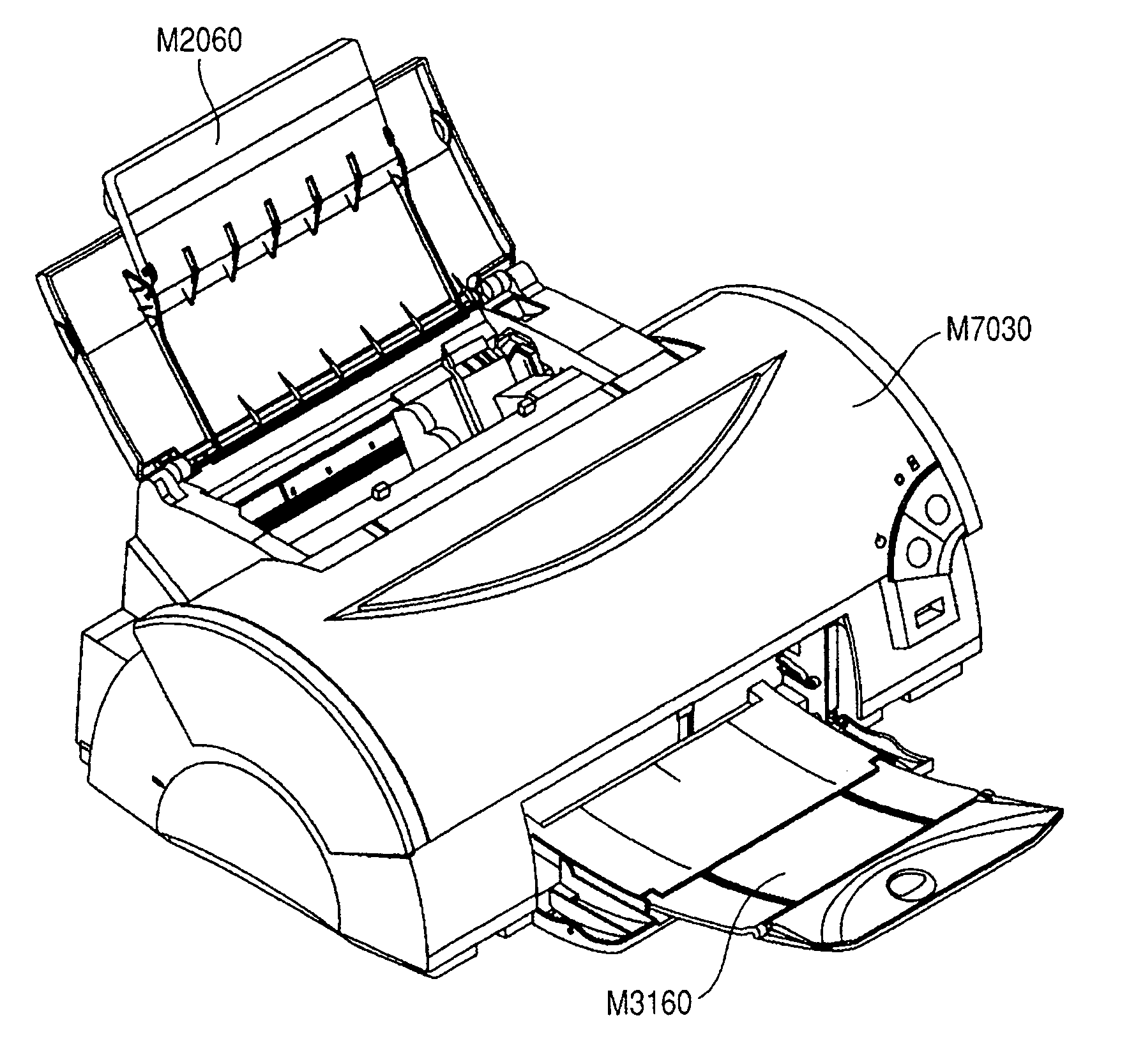

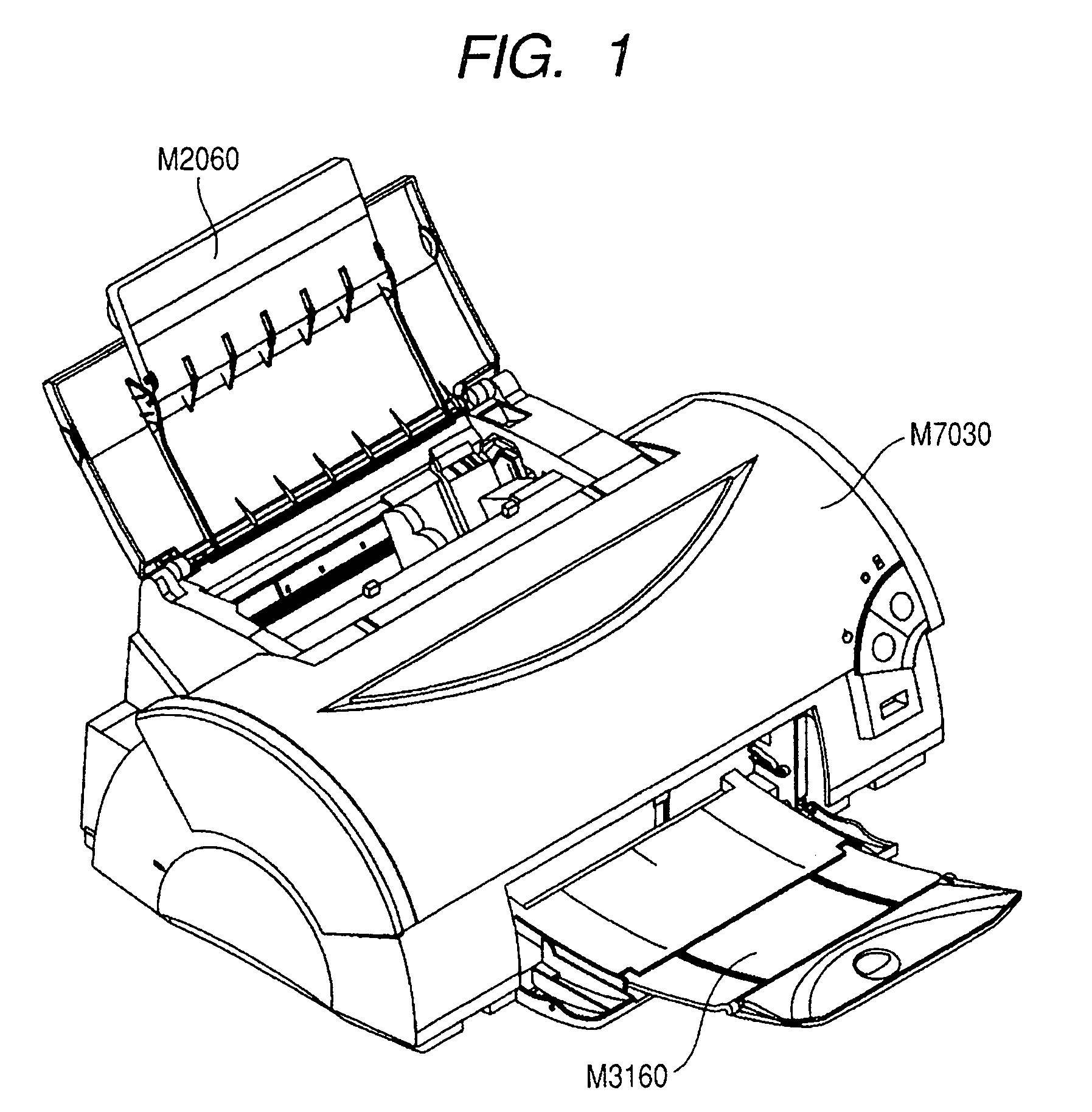

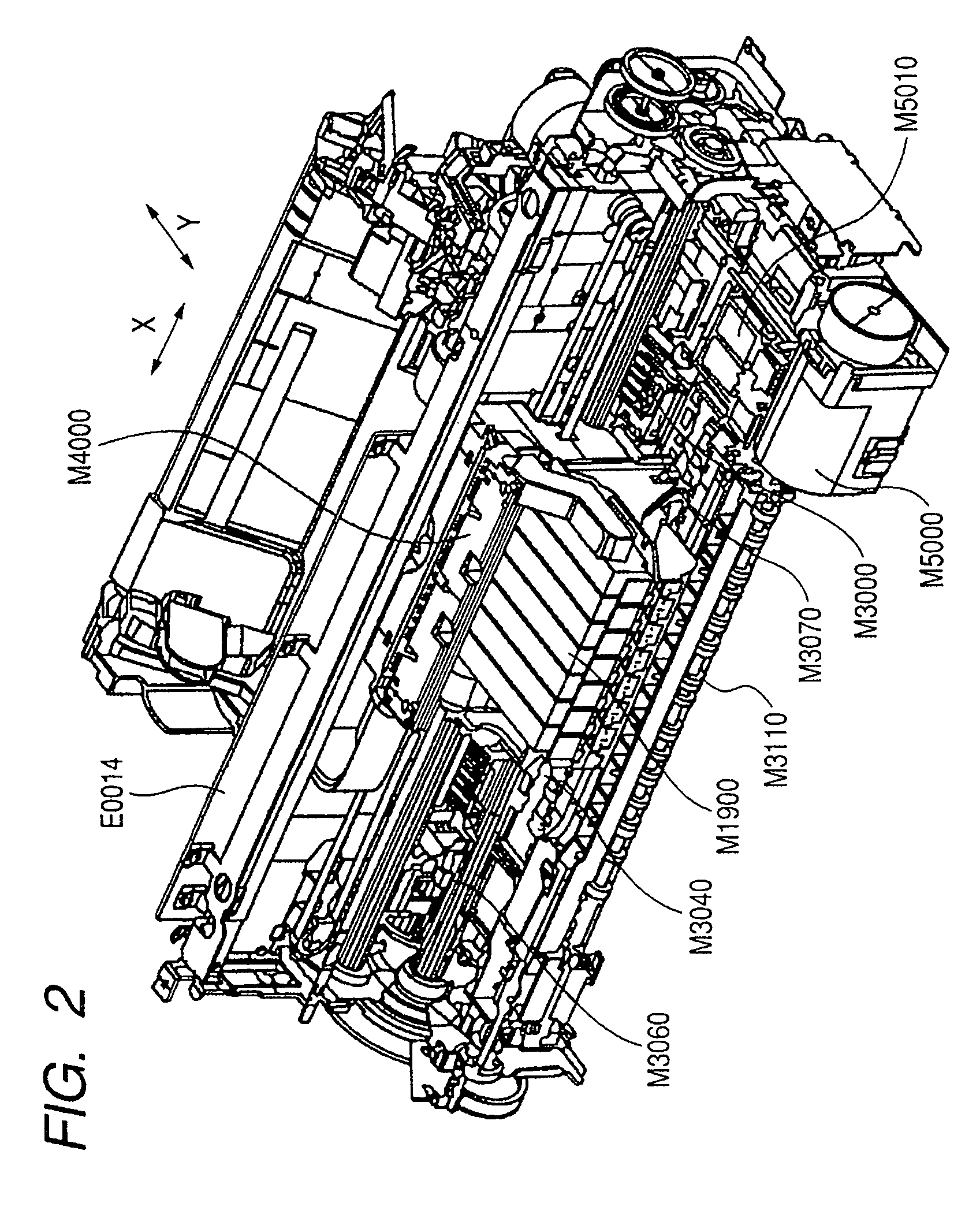

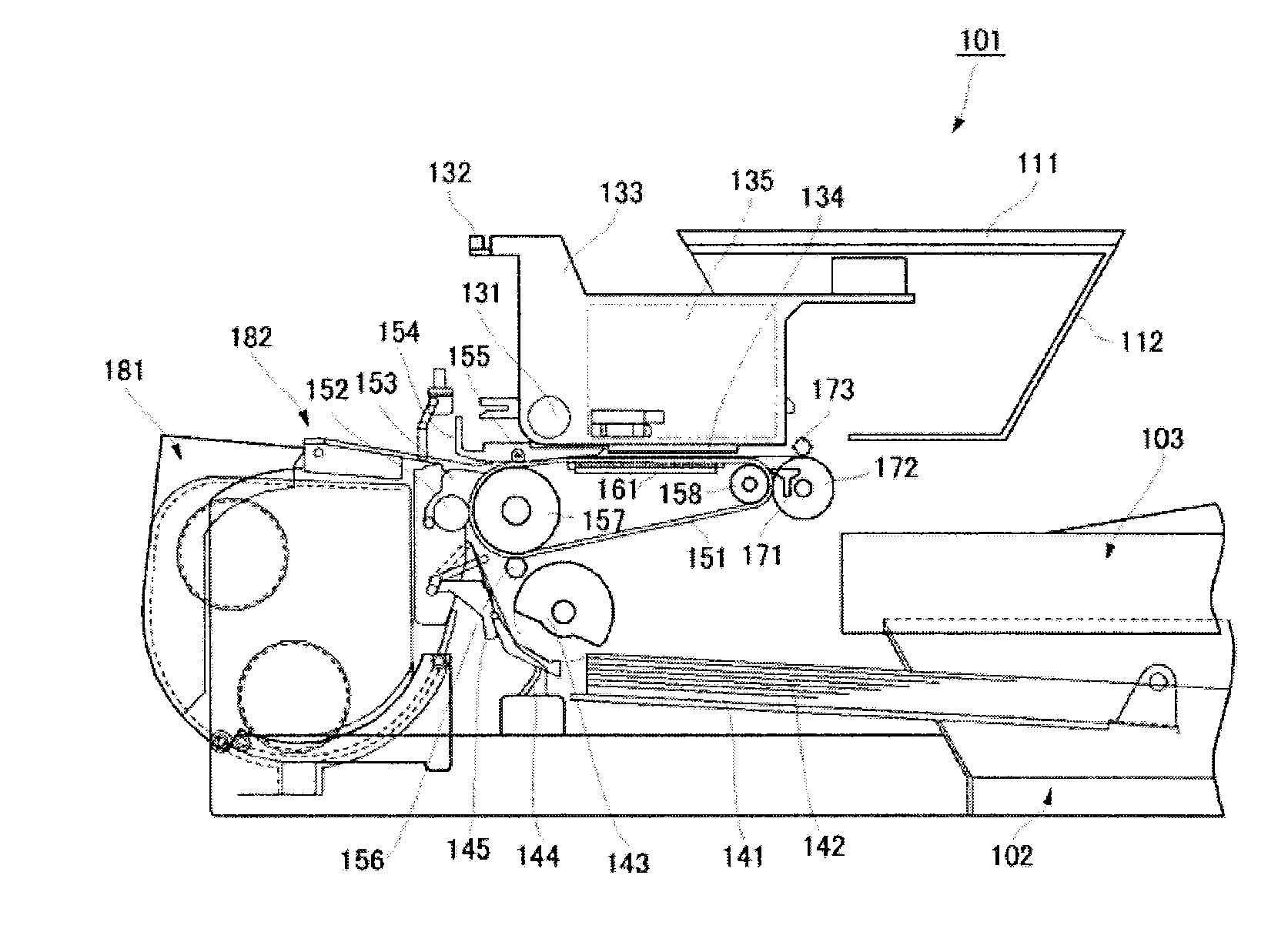

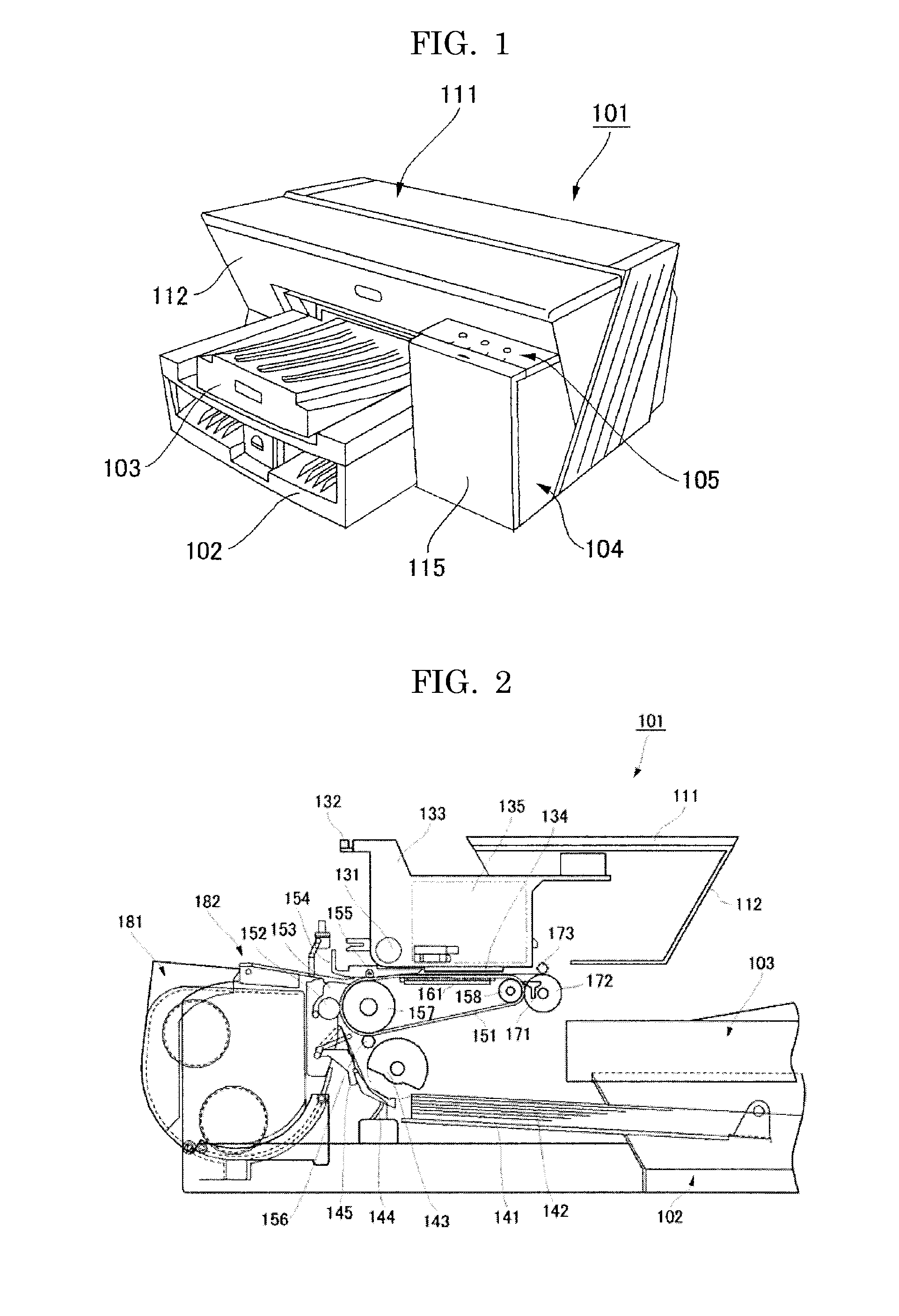

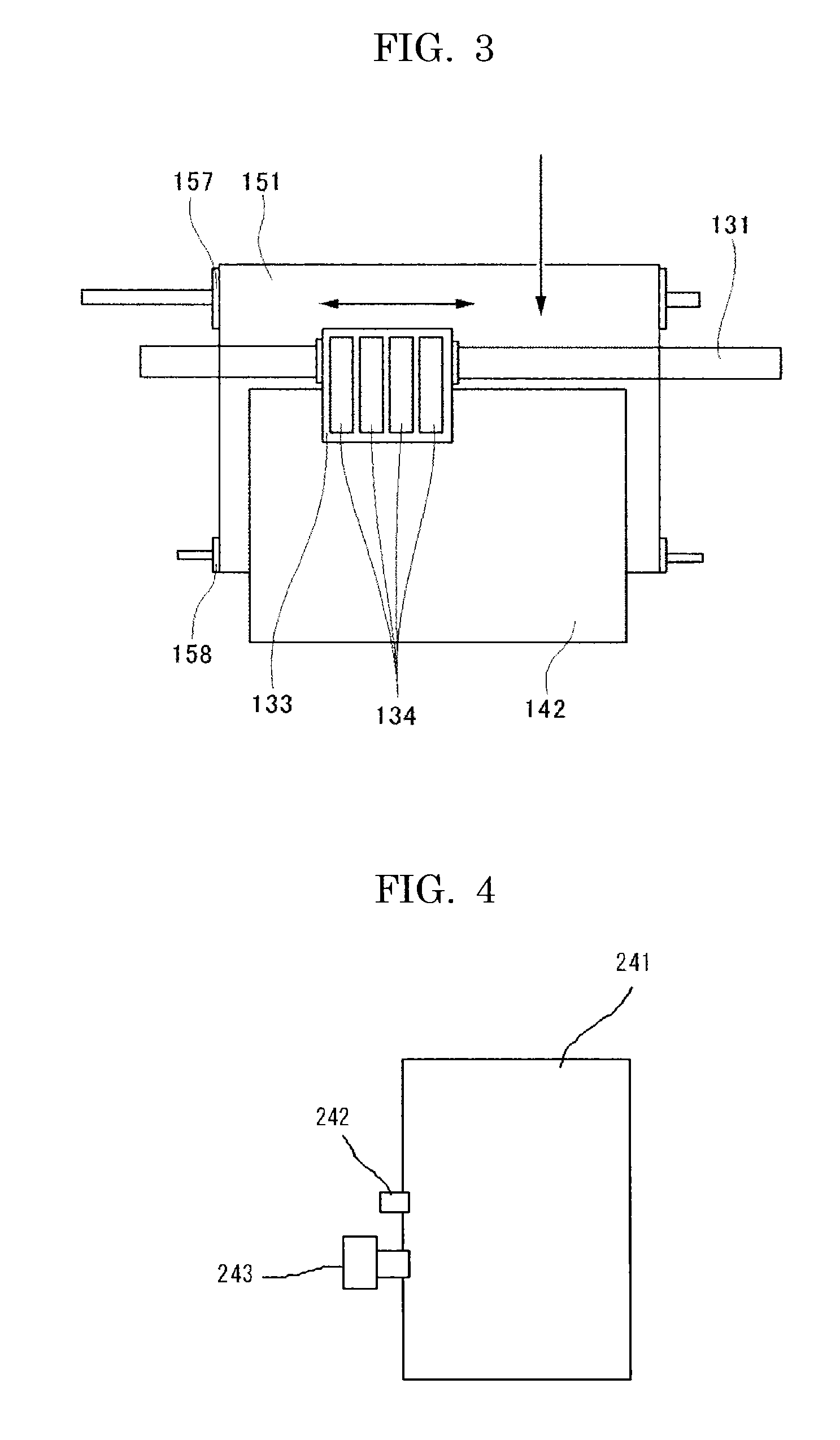

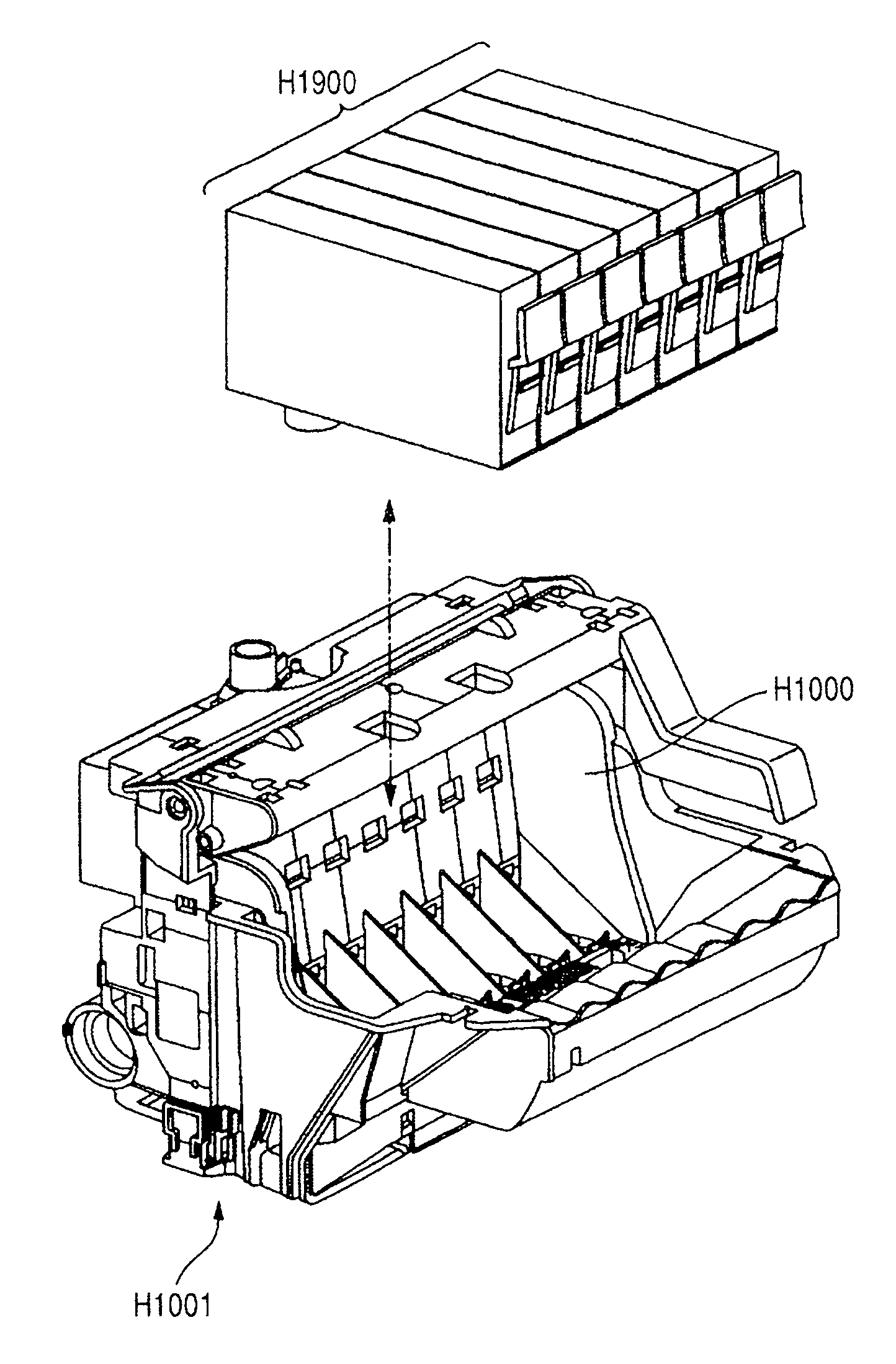

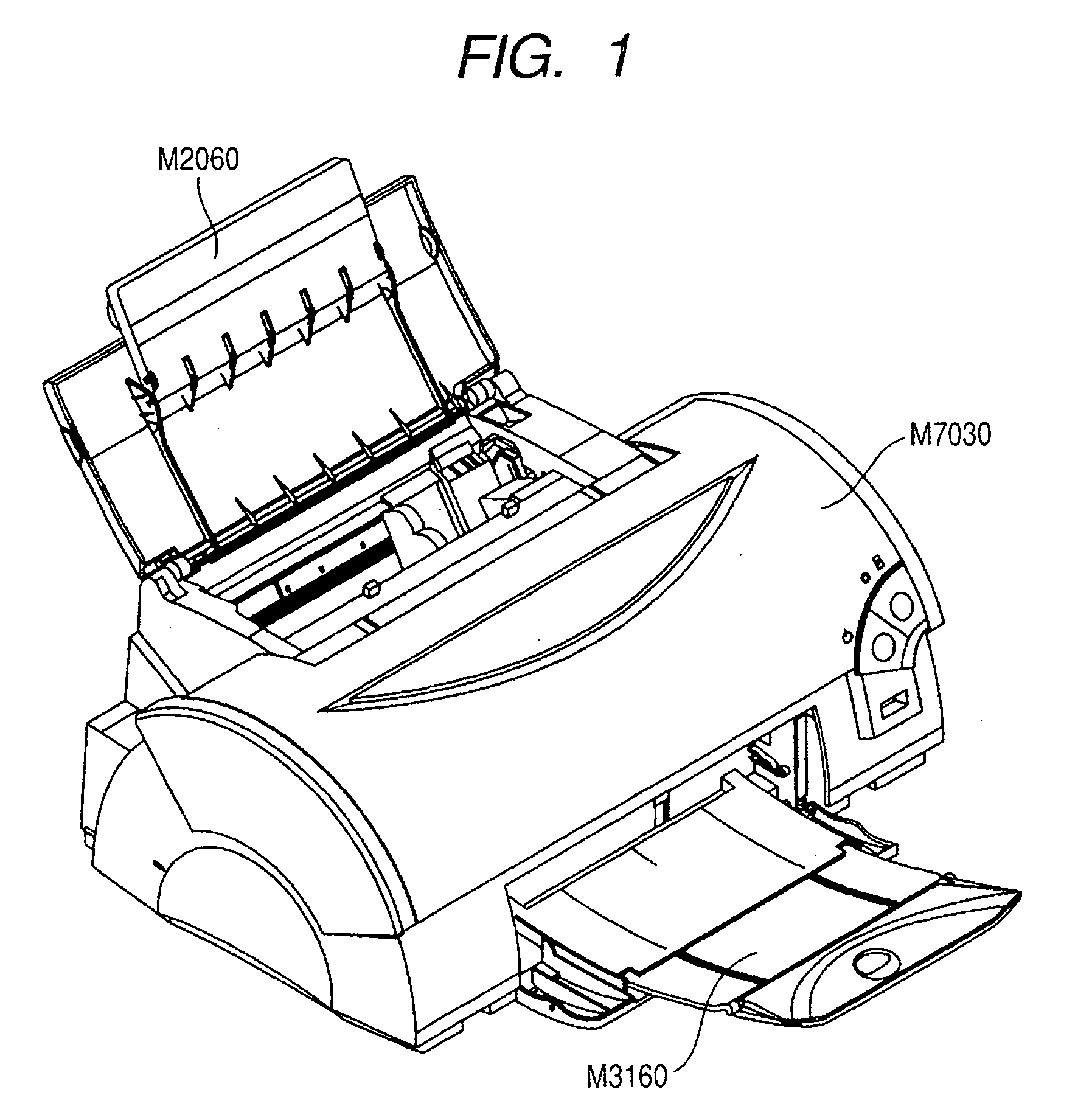

Inkjet printing apparatus and inkjet printing method

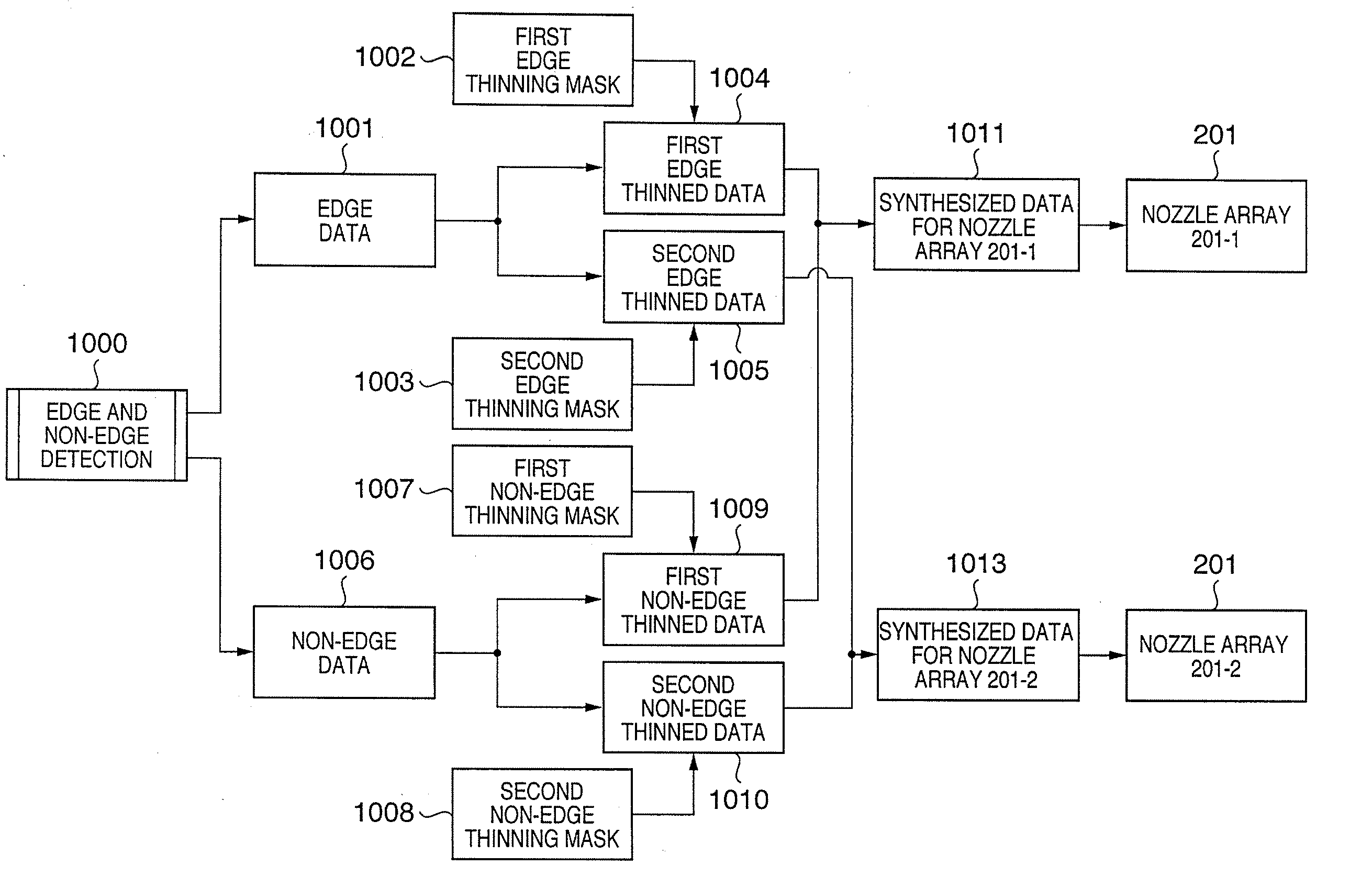

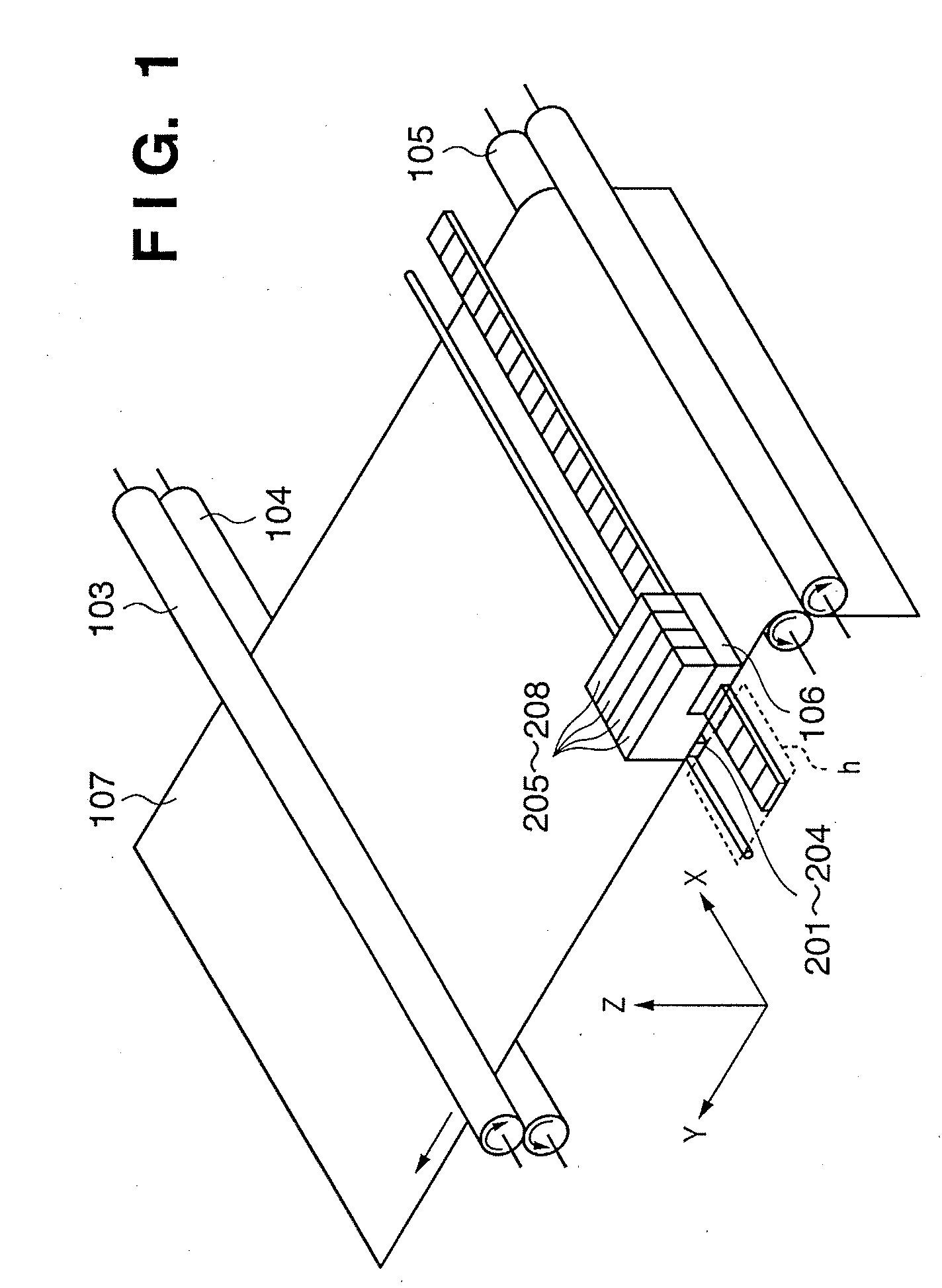

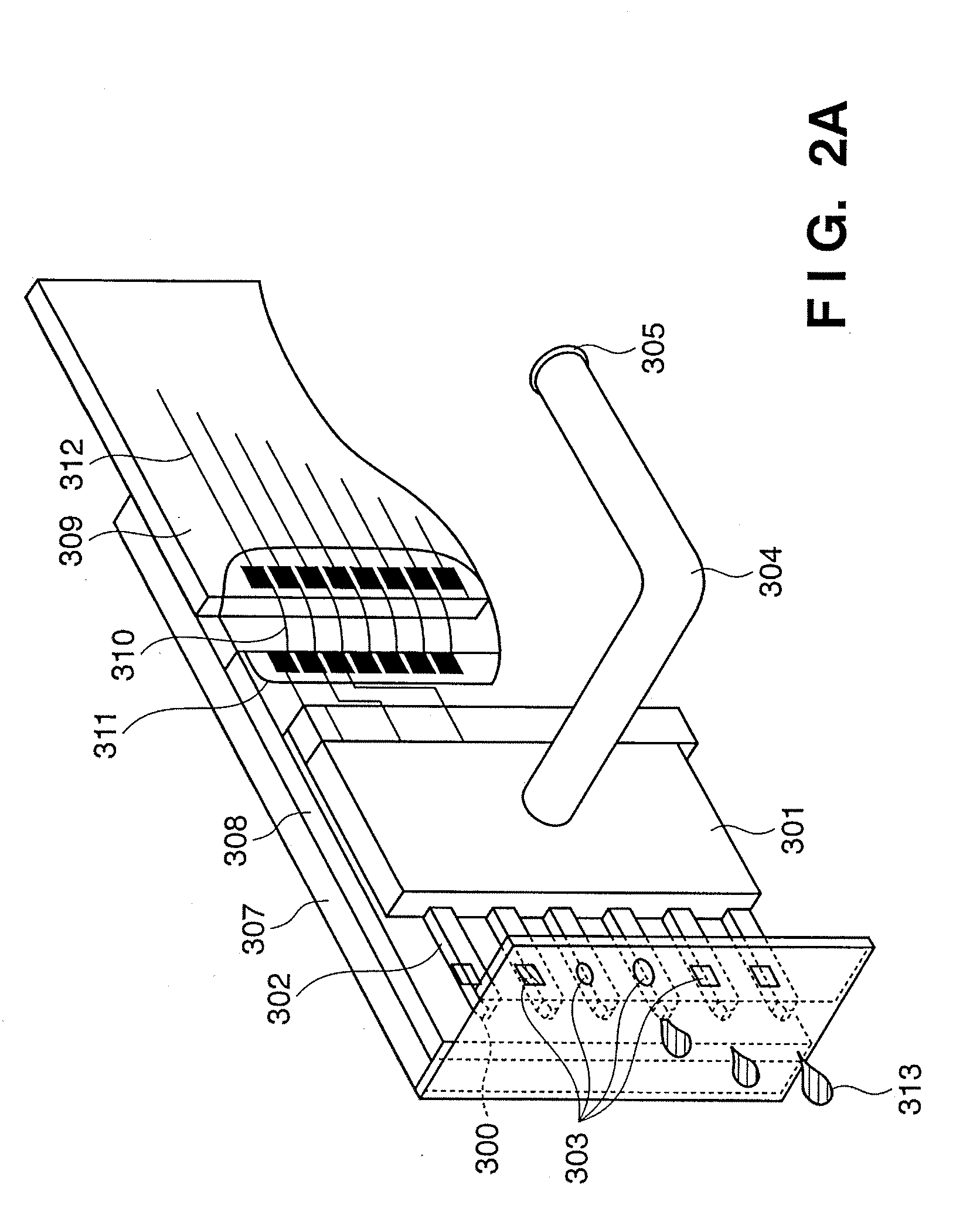

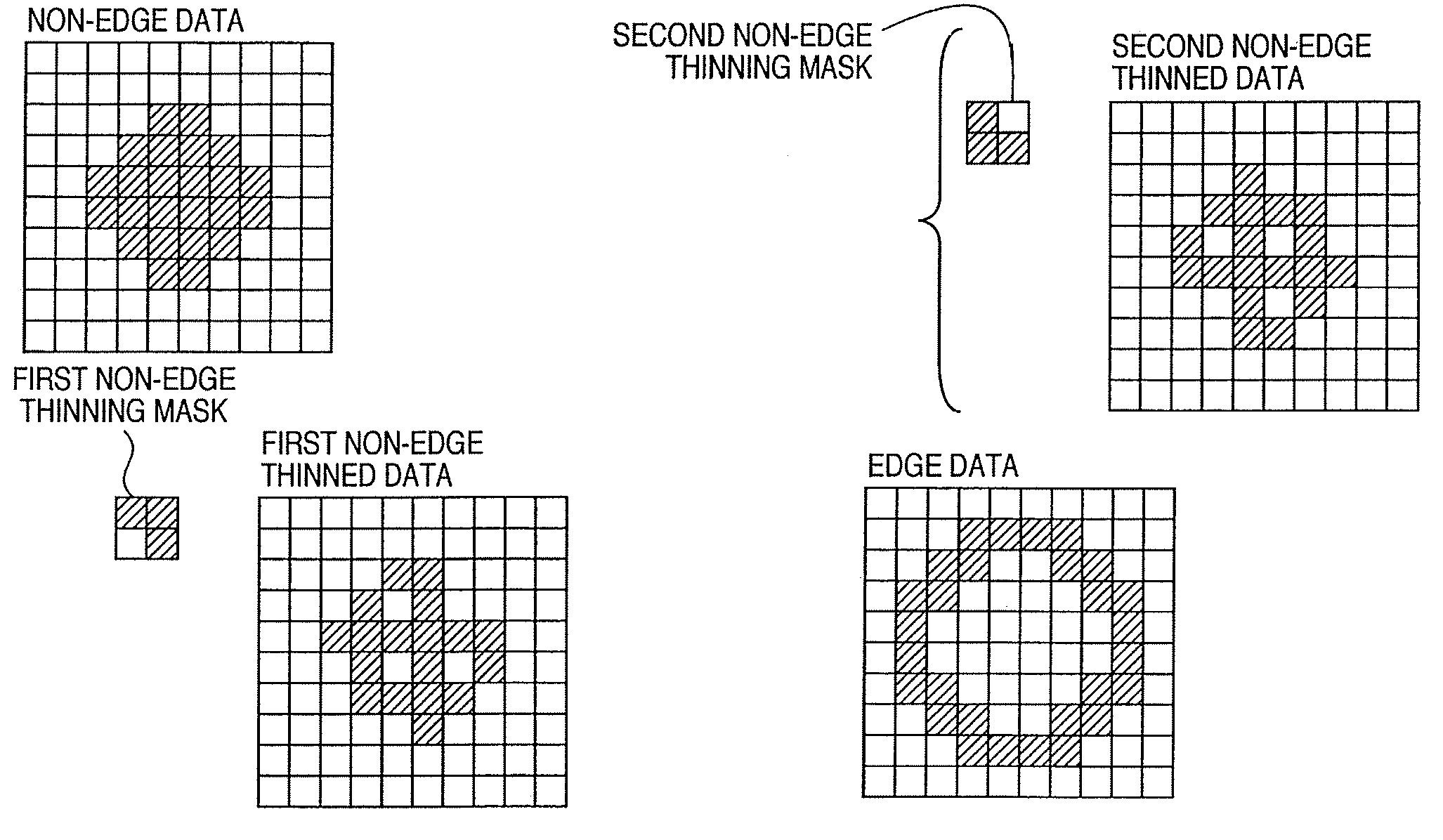

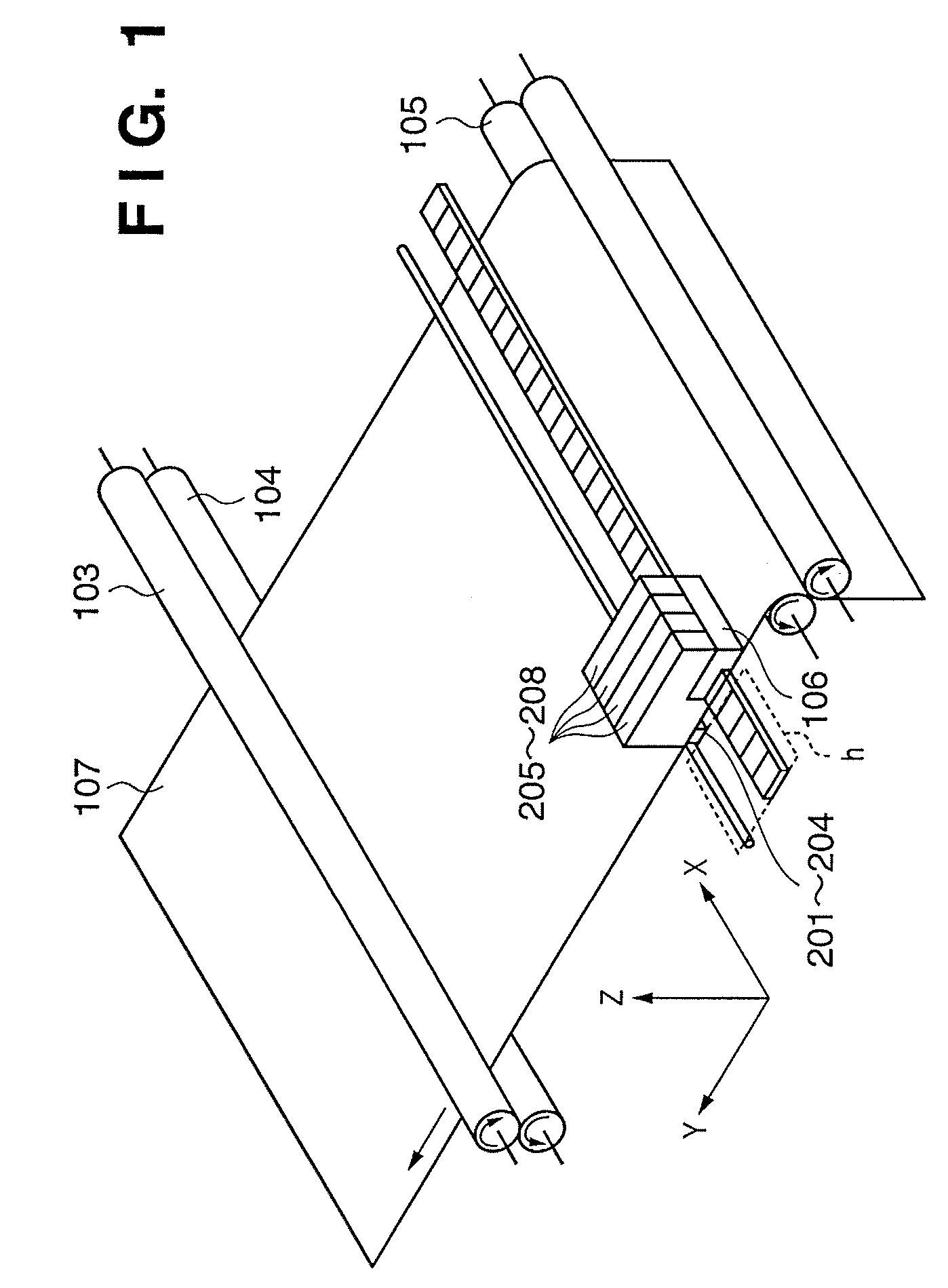

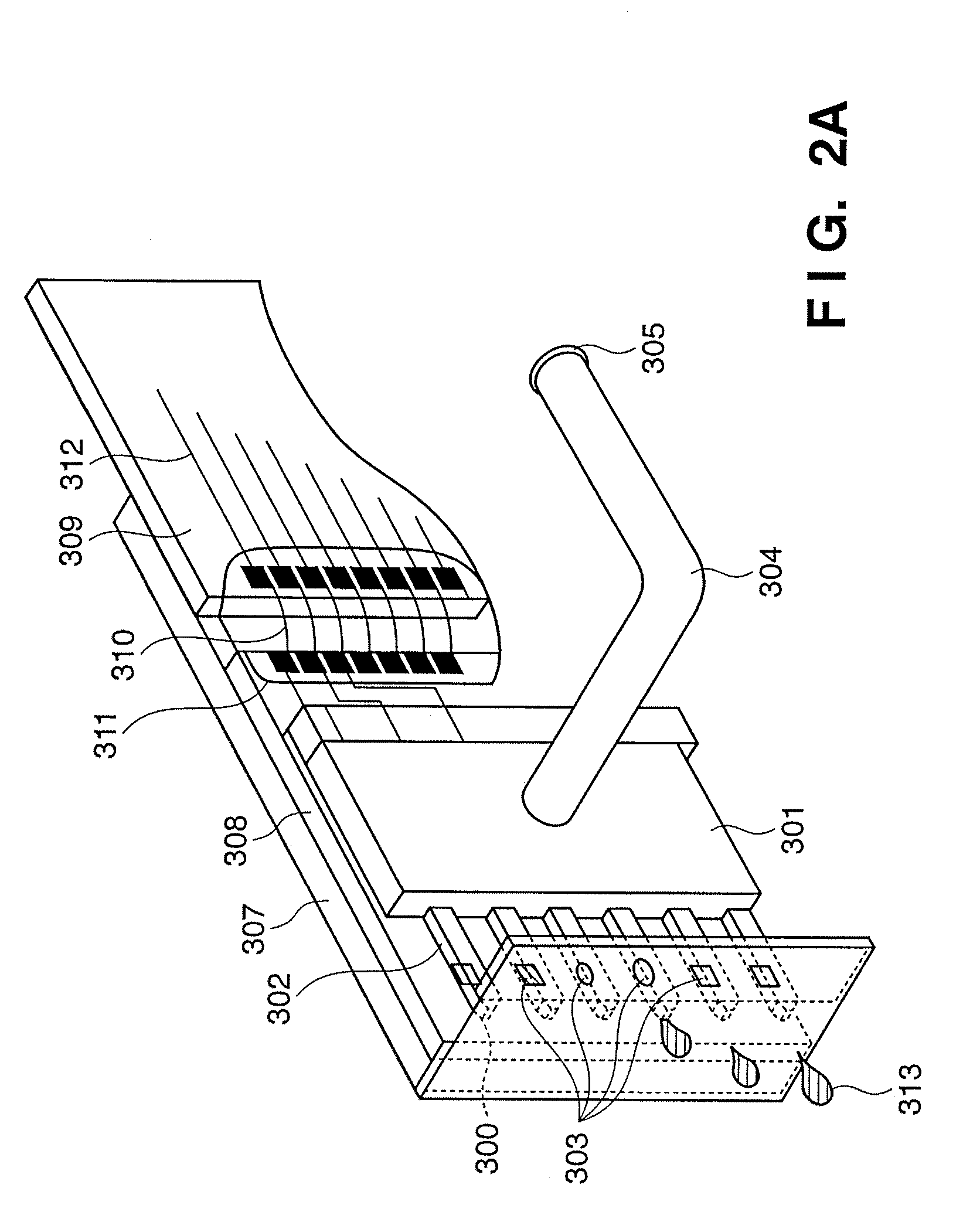

ActiveUS20070153046A1High print densityReduces ink bleedDigitally marking record carriersDigital computer detailsComputer graphics (images)Imaging data

An inkjet printing apparatus includes an edge detecting unit adapted to detect an edge portion or a non-edge portion in the image data a memory adapted to store a plurality of edge reducing masks used to reduce image data in the edge portion and a plurality of non-edge reducing masks used to reduce image data in the non-edge portion; a reduced data generating unit adapted to generate multiple sets of edge reduced data from image data in the edge portion using the plurality of edge reducing masks and to generate multiple sets of non-edge reduced data from image data in the non-edge portion using the plurality of non-edge reducing masks; and a printing data generating unit adapted to generate multiple sets of printing data by combining the multiple sets of edge reduced data and the multiple sets of non-edge reduced data.

Owner:CANON KK

Inkjet printing apparatus and inkjet printing method

ActiveUS7396098B2High print densityReduces ink bleedDigitally marking record carriersDigital computer detailsComputer graphics (images)Imaging data

An inkjet printing apparatus includes an edge detecting unit adapted to detect an edge portion and a non-edge portion in the image data; a memory adapted to store a plurality of edge reducing masks used to reduce image data in the edge portion and a plurality of non-edge reducing masks used to reduce image data in the non-edge portion; a reduced data generating unit adapted to generate multiple sets of edge reduced data from image data in the edge portion using the plurality of edge reducing masks and to generate multiple sets of non-edge reduced data from image data in the non-edge portion using the plurality of non-edge reducing masks; and a printing data generating unit adapted to generate multiple sets of printing data by combining the multiple sets of edge reduced data and the multiple sets of non-edge reduced data.

Owner:CANON KK

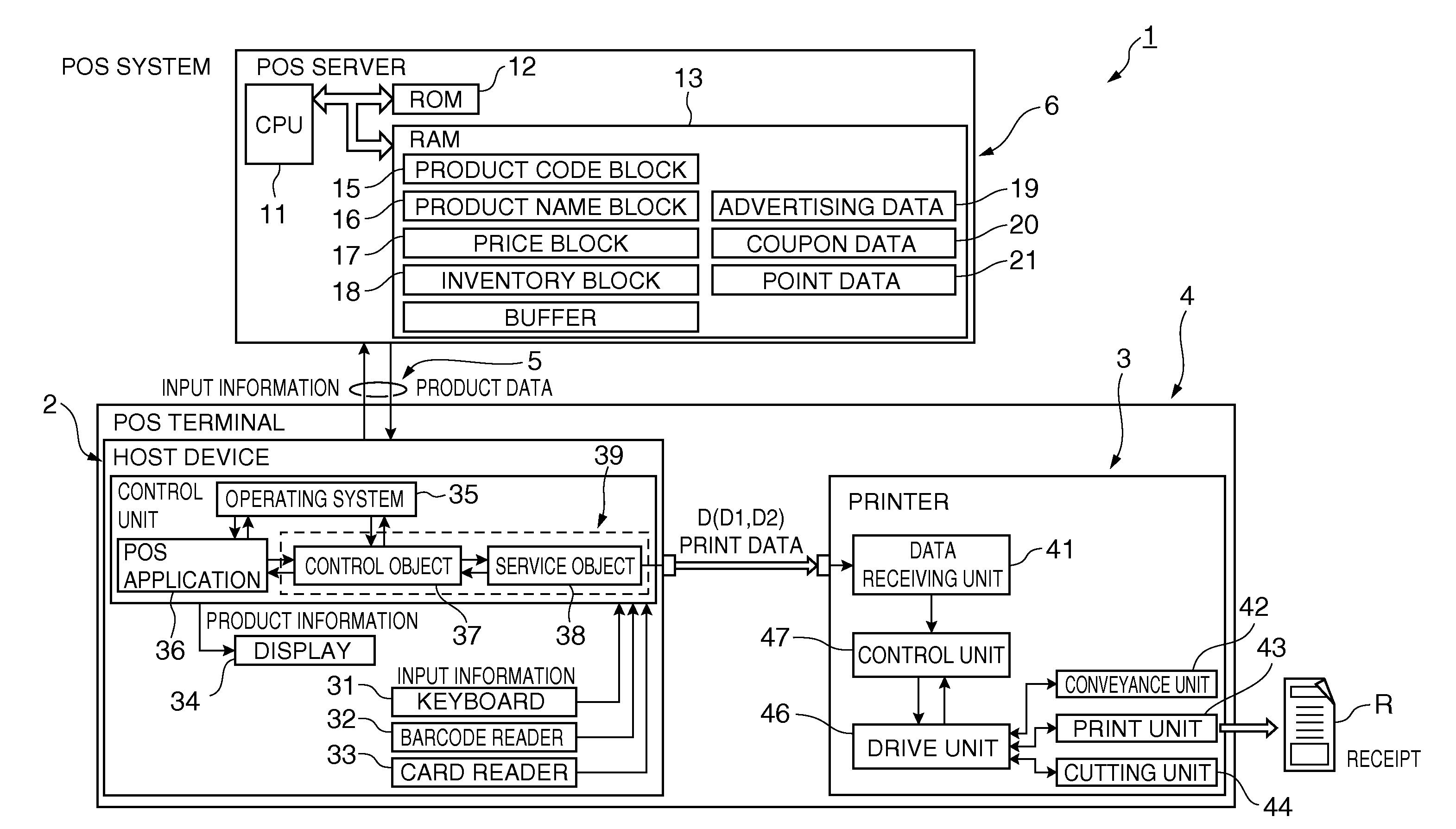

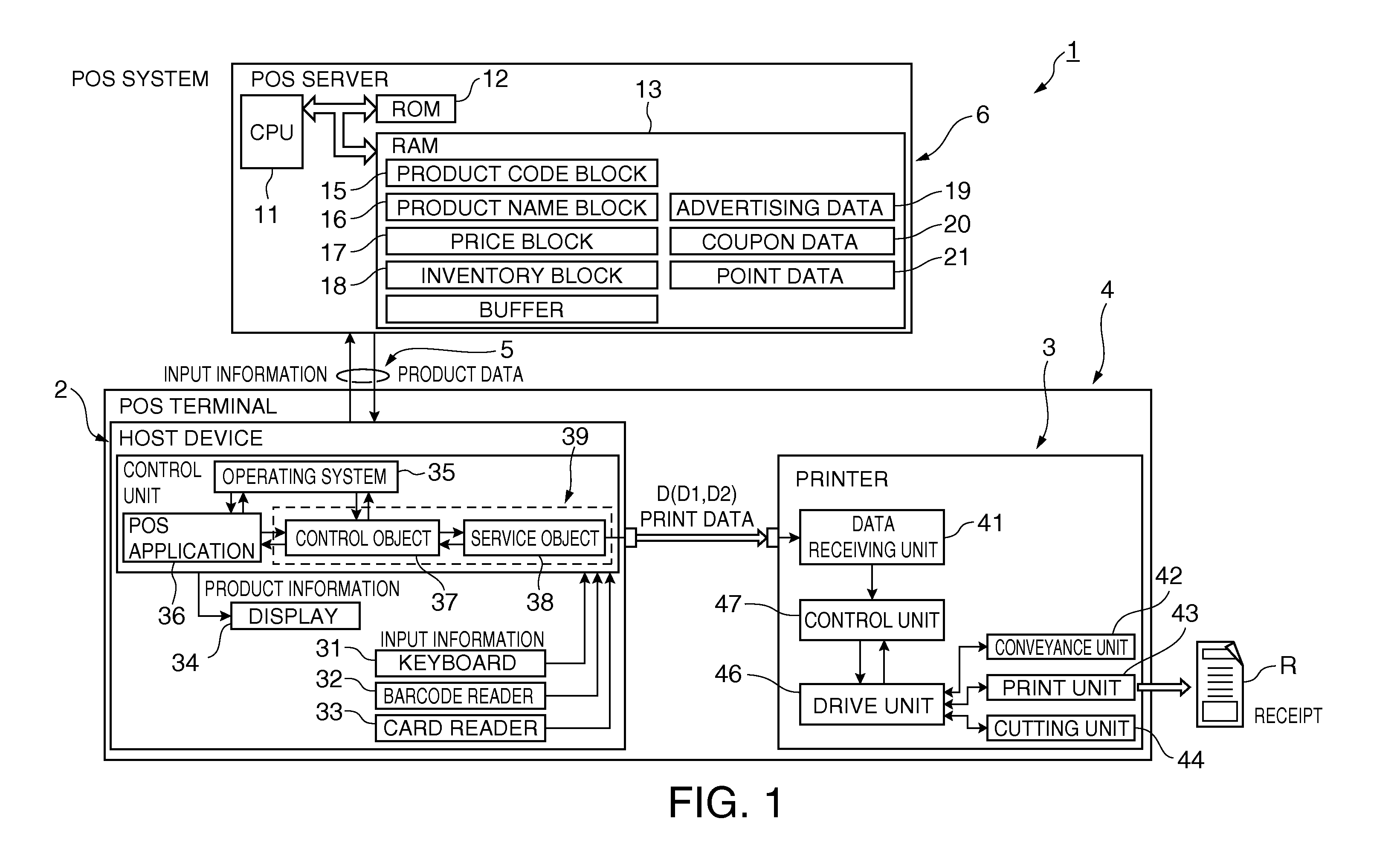

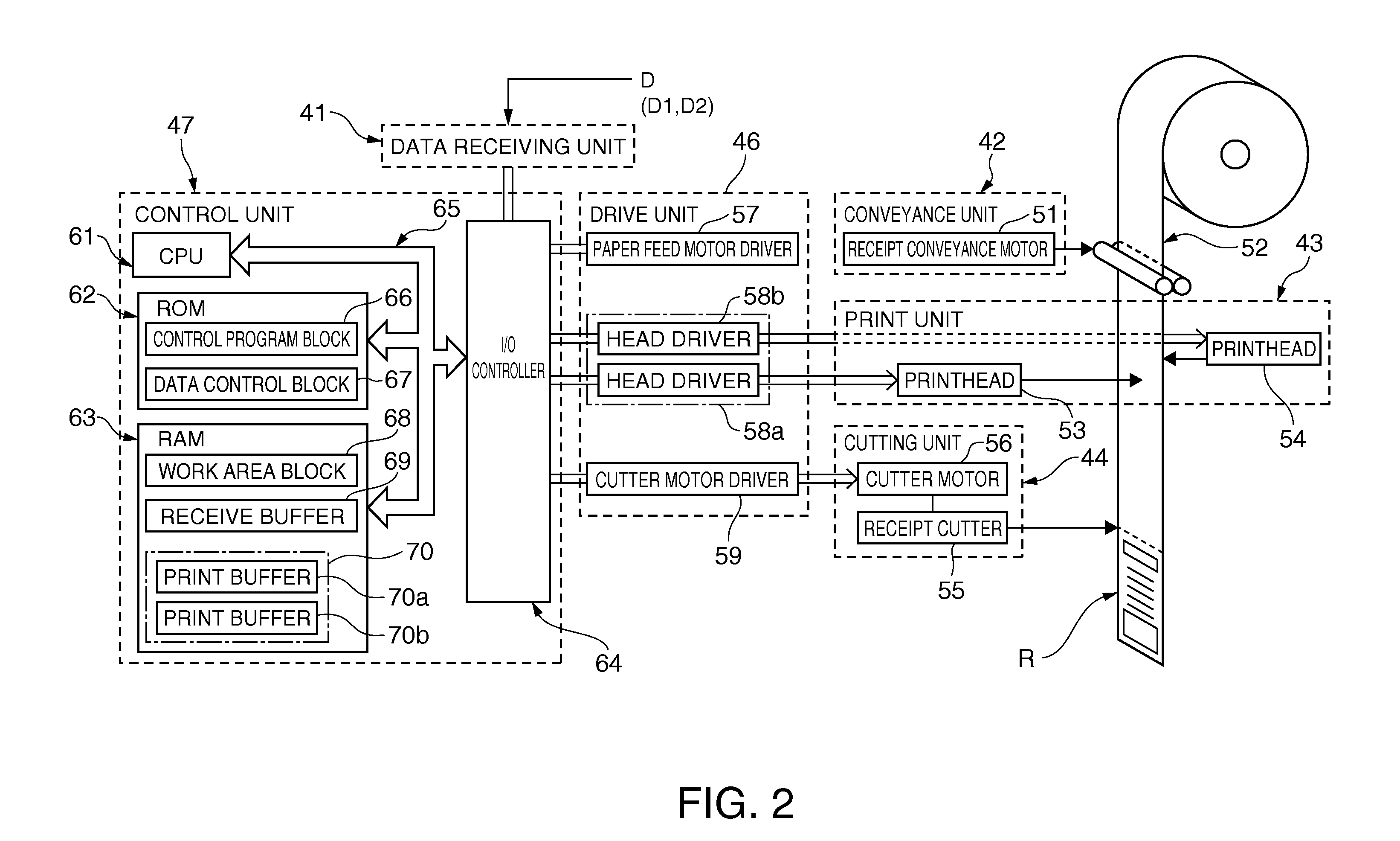

Print Data Processing Method, Print Data Processing Device, And Print Data Processing System

ActiveUS20120127501A1High print densityReliably prevented from causing a drop in the readabilityVisual presentation using printersReceipt giving machinesGraphicsData processing system

A print data processing method can generate print data for duplex printing so that the scanning accuracy of a barcode printed on one side of a receipt is not reduced by a logo or other graphic that is printed on the other side of the receipt. Whether or not a linear barcode or other code data B is contained in the front print data D1 that is printed on the front of the receipt is determined, and whether graphic data G is contained in the back print data D2 that is printed on the other side of the receipt is determined. If graphic data G is contained, the back print data D2 is adjusted so that the graphic data G is not printed to a position overlapping the code data B on the opposite side of the receipt.

Owner:SEIKO EPSON CORP

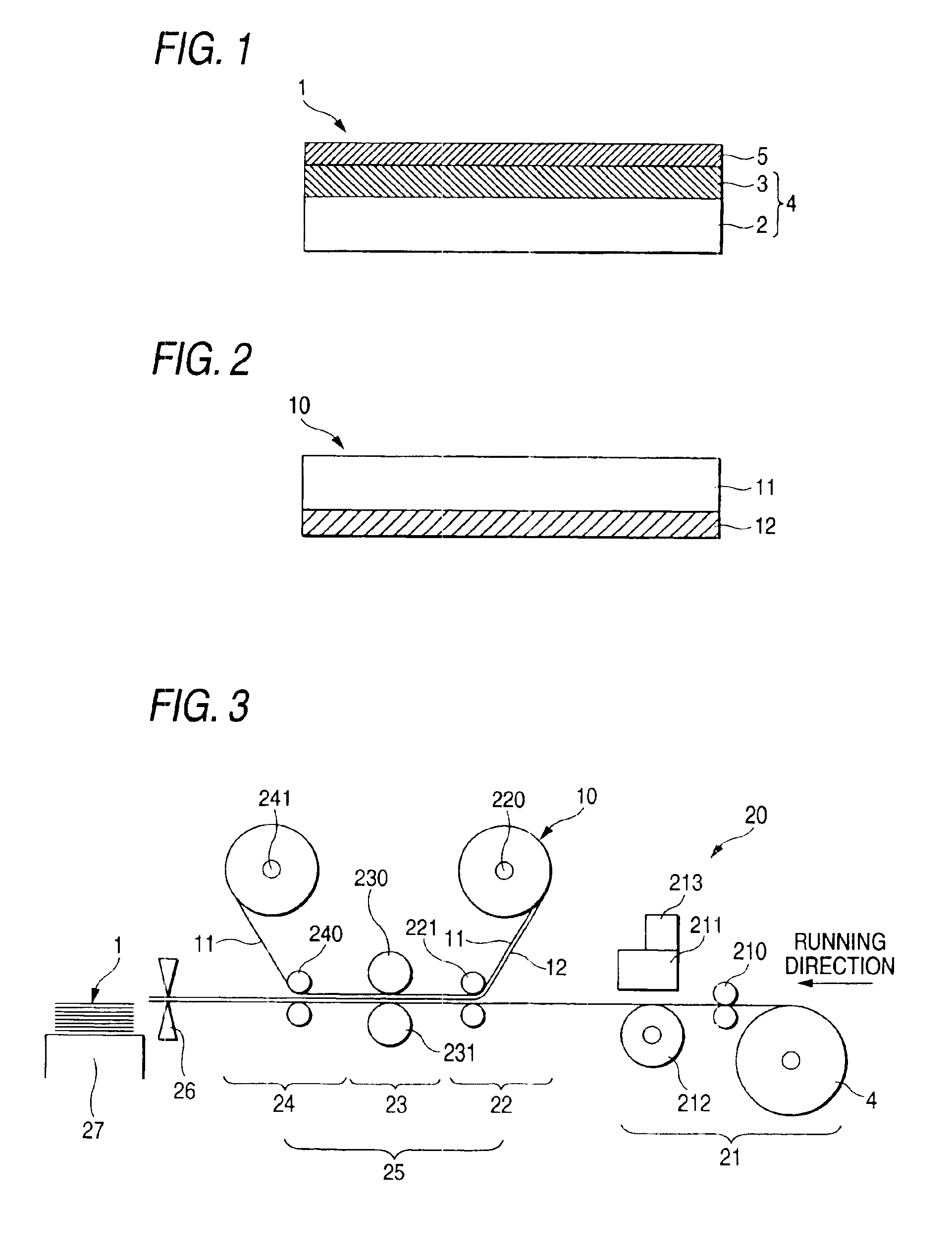

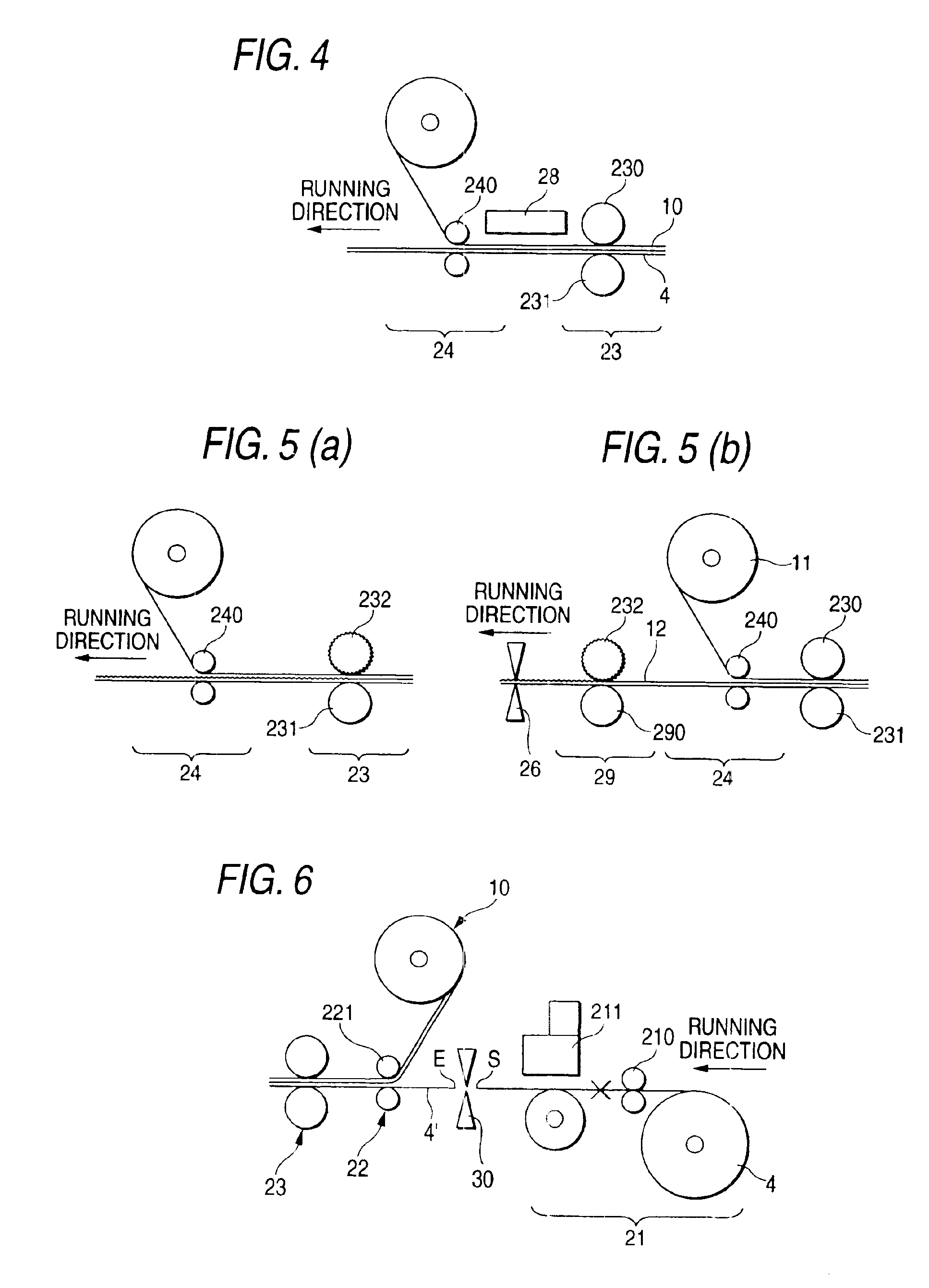

Process For Producing Coated Sheet

InactiveUS20070202263A1High glossPromote absorptionDuplicating/marking methodsSpecial surfacesImaging qualityEngineering

A process for producing a coated sheet, in which there can be formed a coating layer simultaneously attaining an ink absorption rate and coating film cracking control suitable for use as an inkjet recording layer, in particular, there can be realized high gloss, high ink absorption, high printing density and high image quality required for use as a glossy inkjet recording sheet. There is provided a process for producing a coated sheet, comprising coating a support, or undercoat layer superimposed on the support, with a coating liquid containing a thermosensitive polymeric compound reversibly exhibiting hydrophilicity and hydrophobicity depending on temperature change, characterized in that the coating liquid containing a thermosensitive polymeric compound is applied concurrently with application of a treatment liquid whose temperature is in the range in which the thermosensitive polymeric compound exhibits hydrophilicity, or after the application of the treatment liquid without drying after the application.

Owner:OJI PAPER CO LTD

Inkjet recording medium and method of manufacturing the same

InactiveUS20090109270A1Fine surfaceHigh transparencyDuplicating/marking methodsTypewritersSILICONE DIOXIDEChemistry

An inkjet recording medium including at least a first ink-receiving layer and a second ink-receiving layer on a support, the first ink-receiving layer being positioned farthest from the support and containing pseudo-boehmite alumina, and the second ink-receiving layer being positioned between the first ink receiving layer and the support and containing a water-soluble polyvalent metal salt and fumed silica that is dispersed using the water-soluble polyvalent metal salt.

Owner:FUJIFILM CORP

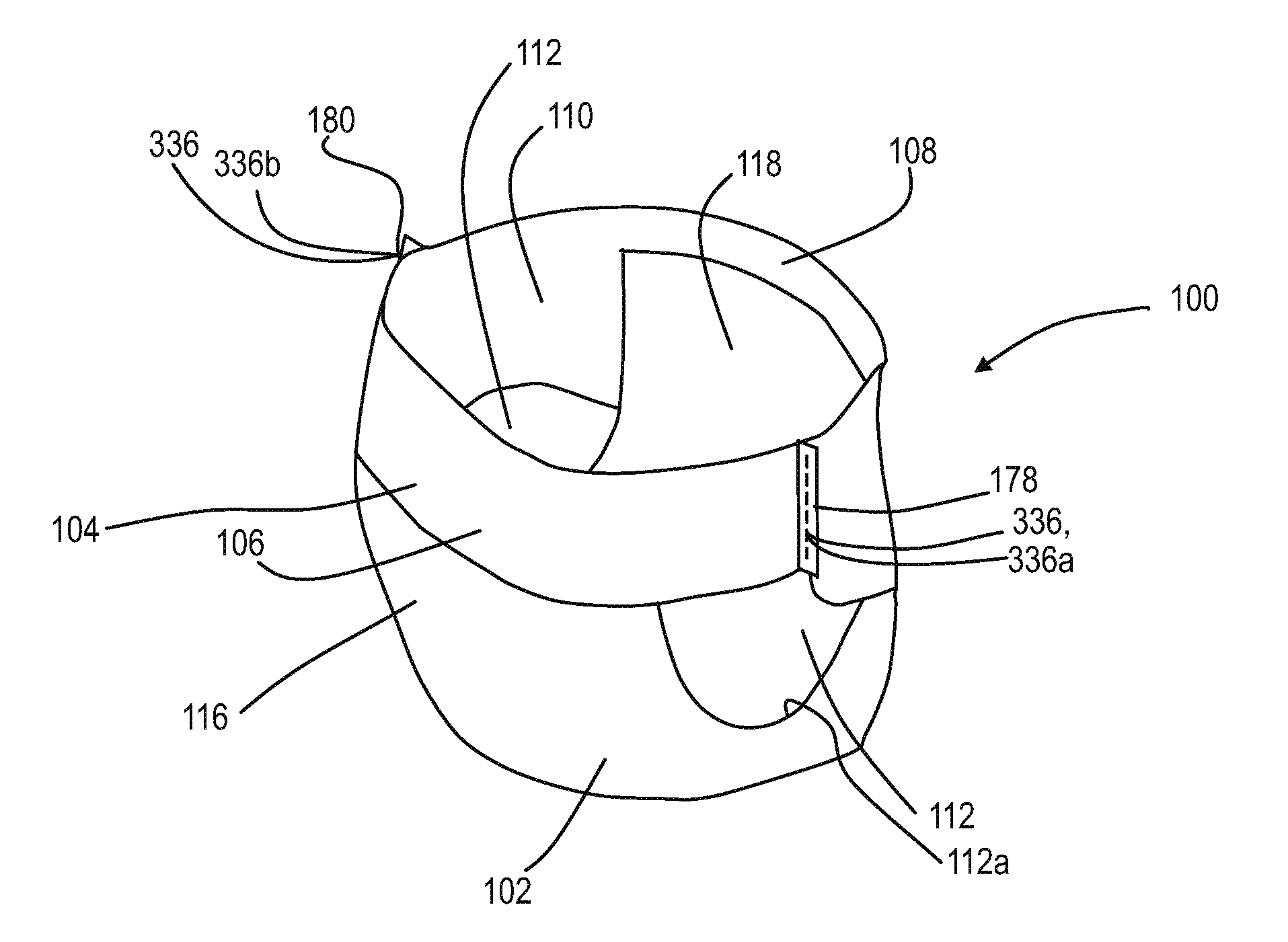

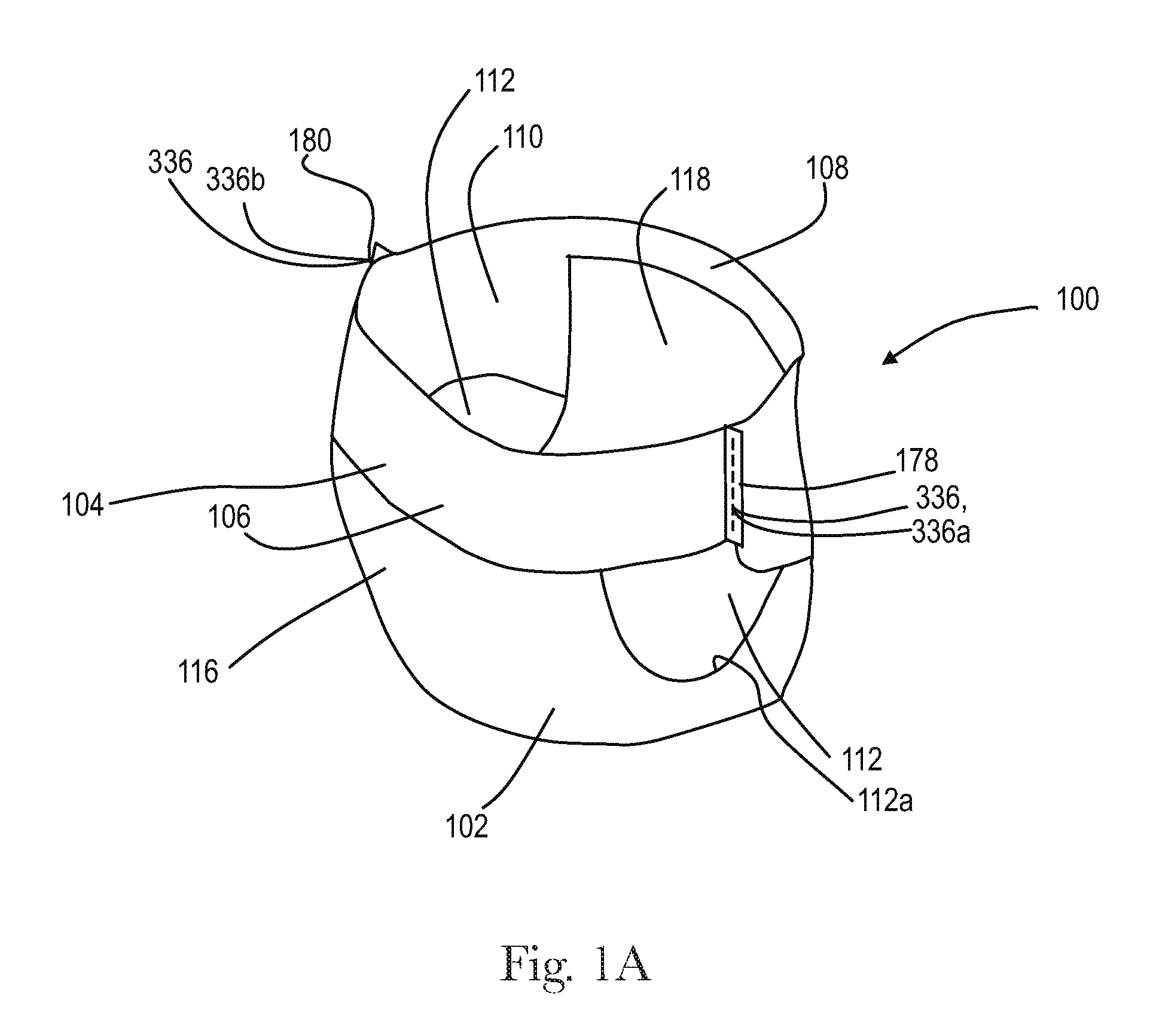

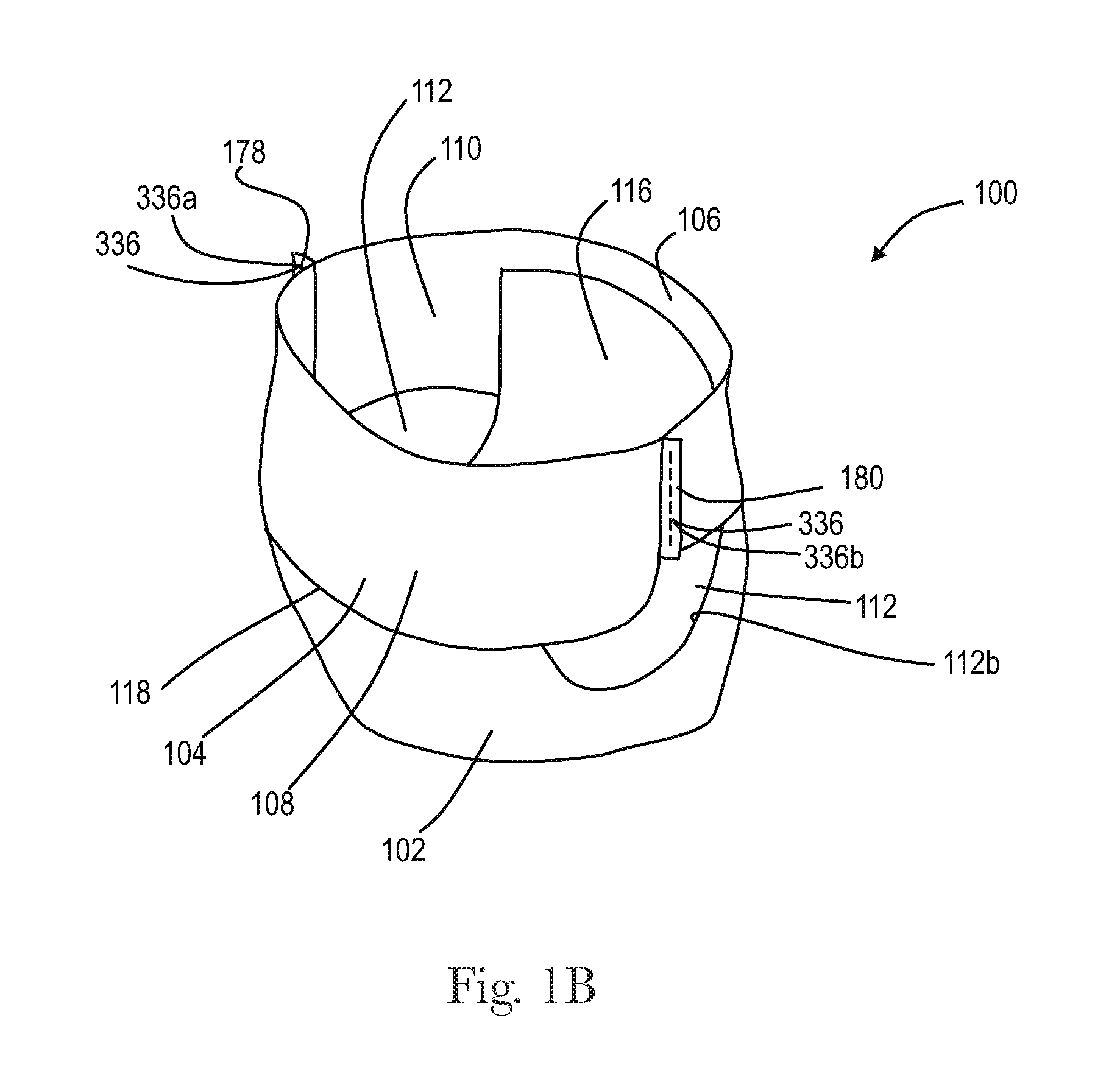

Assembled Absorbent Article Components with Graphics Having Aligned Low Intensity Zones

InactiveUS20160175168A1Reduce noticeable visible resultHigh print densityBaby linensTamponsGraphicsVolumetric Mass Density

The present disclosure relates to absorbent articles with components having graphics including zones of relatively high print densities and zones of relatively low print densities. In particular, substrates and / or components to be incorporated into manufactured absorbent articles include graphics that may be positioned and / or printed in such a manner so as to functionally reduce noticeable visible results of imprecise and / or inconsistent assembly operations performed in areas where the graphics are located.

Owner:THE PROCTER & GAMBLE COMPANY

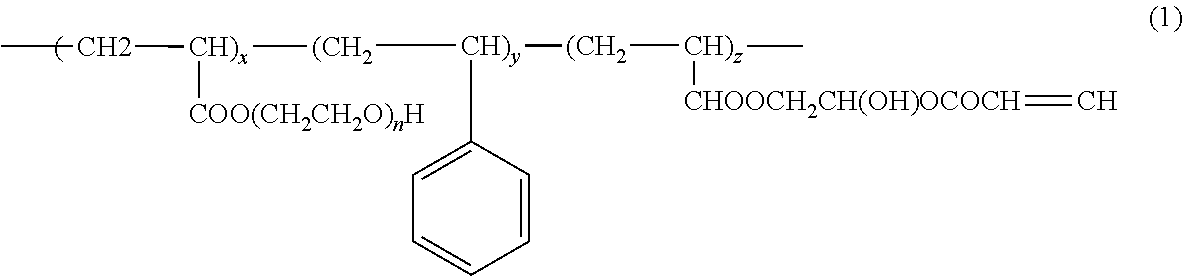

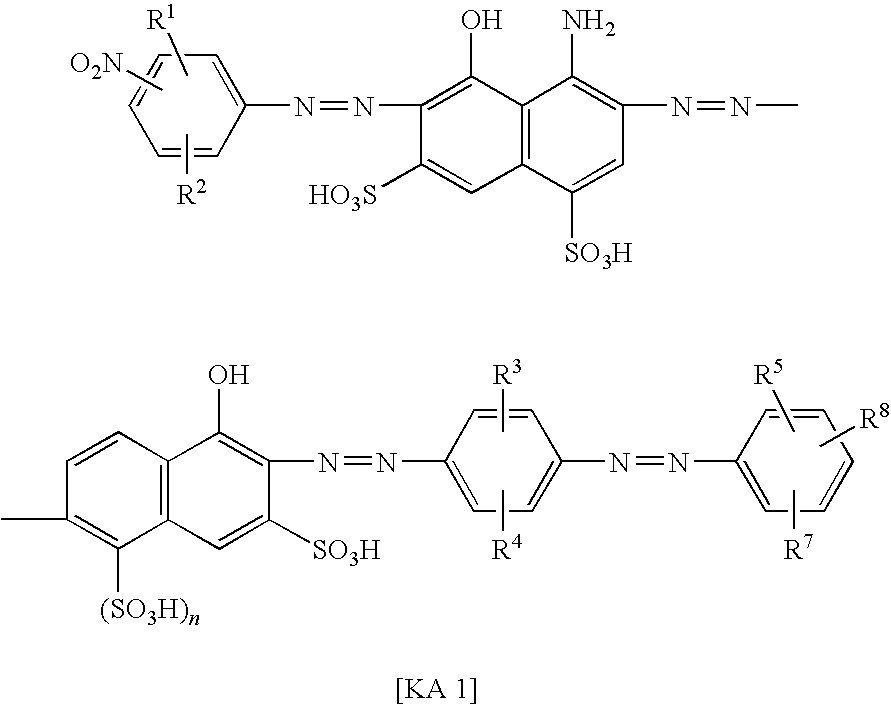

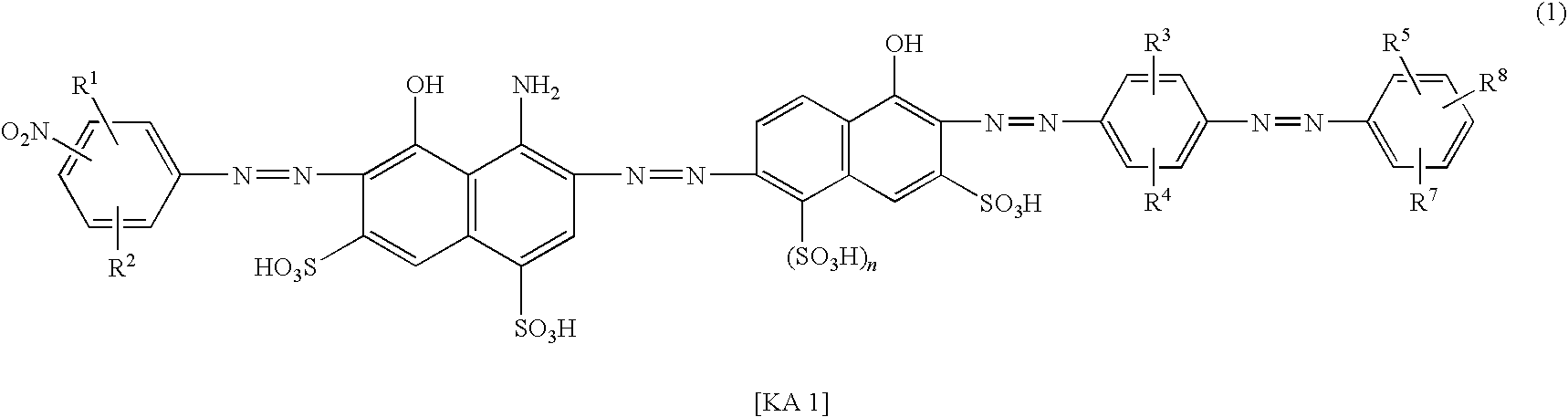

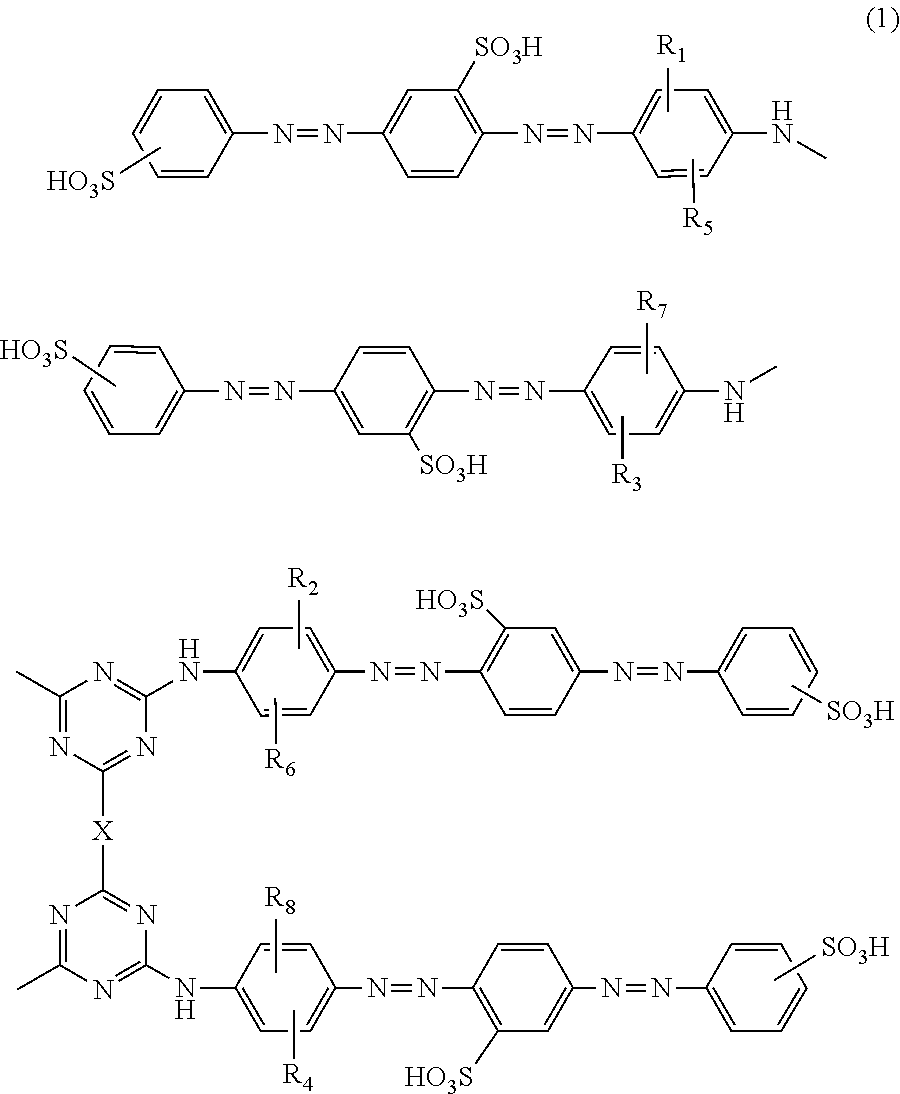

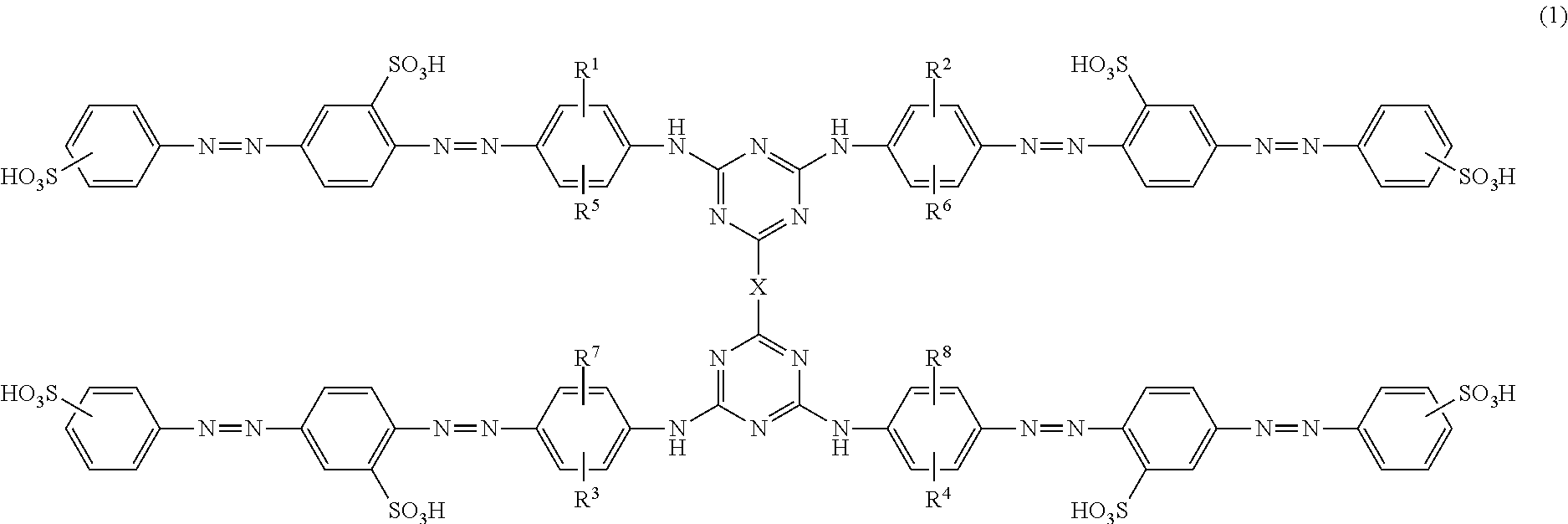

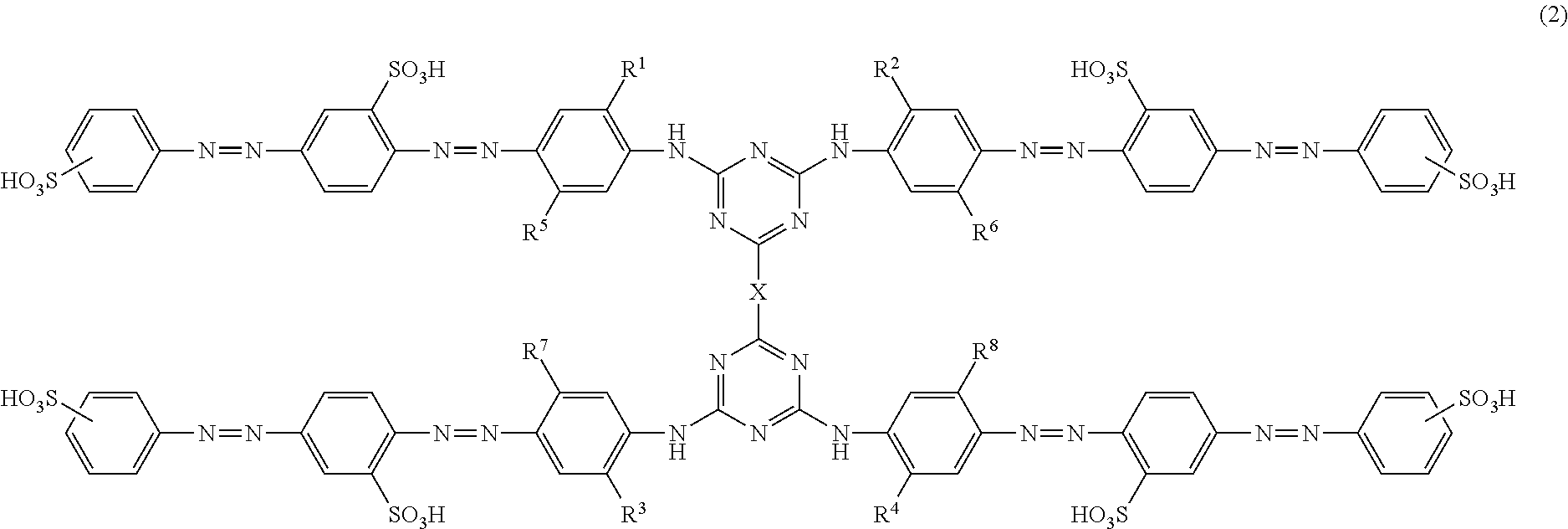

Azo compound, ink composition and colored article

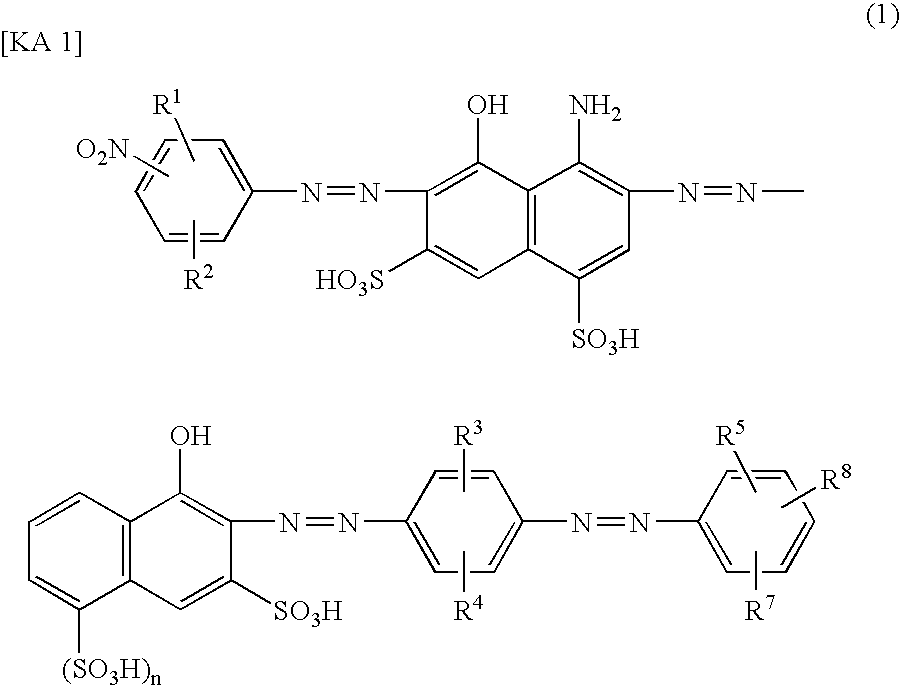

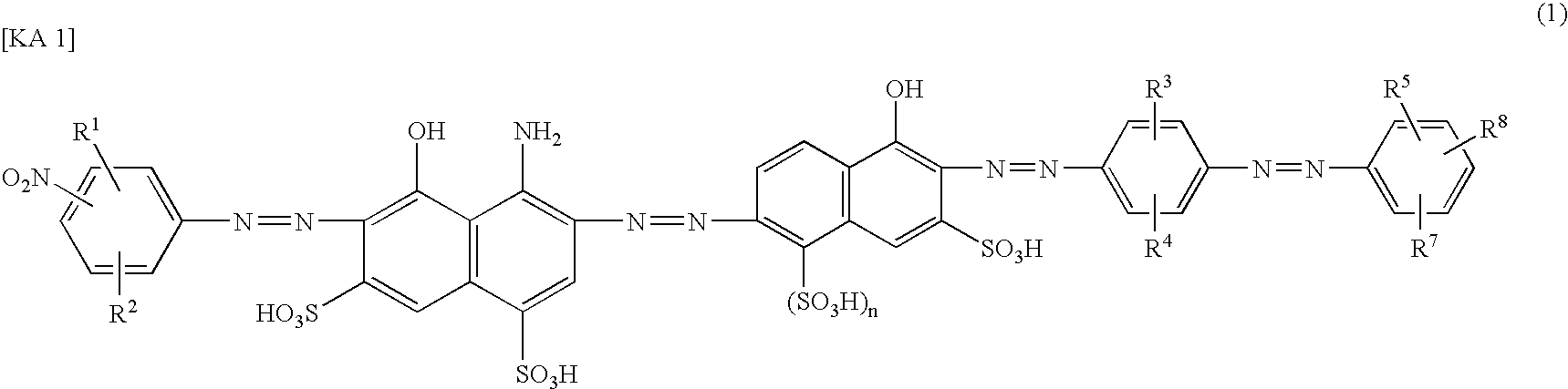

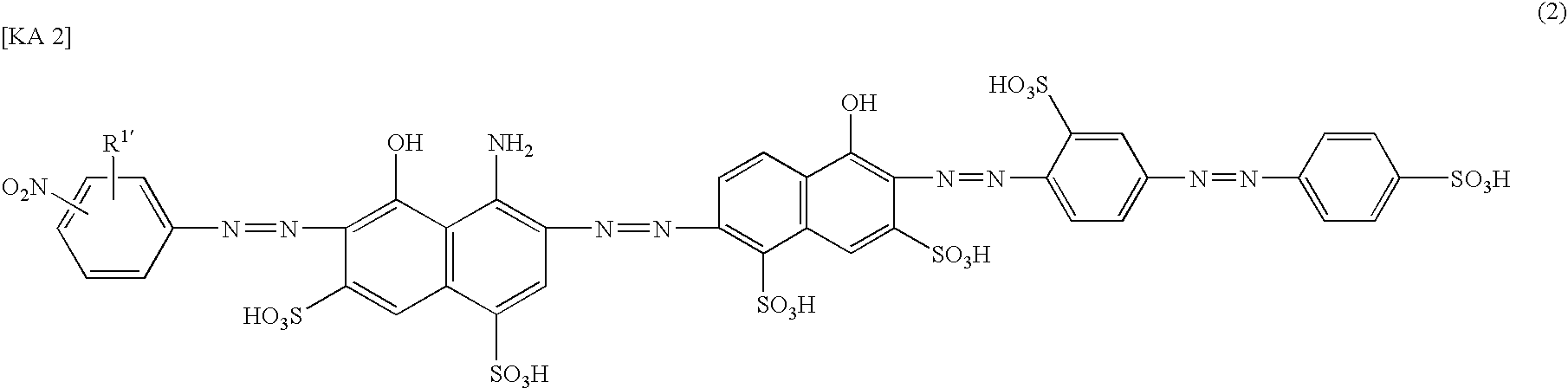

ActiveUS7503967B2Good water solubilityHigh print densityMonoazo dyesOrganic chemistryHydrogen atomAlkoxy group

An azo compound represented by the following Formula (1) or a salt thereof, and an ink composition comprising the same(wherein, each of R1, R2, R5, R6 and R7 independently represents a hydrogen atom, a carboxyl group, a sulfo group and the like, each of R3 and R4 independently represents a hydrogen atom, a sulfo group, a nitro group, a (C1 to C4) alkyl group (which may be substituted by a hydroxyl group or a (C1 to C4) alkoxy group), a (C1 to C4) alkoxy group (which may be substituted by a hydroxyl group, a (C1 to C4) alkoxy group, a sulfo group or a carboxyl group) and the like, and n represents 0 or 1, respectively).

Owner:NIPPON KAYAKU CO LTD

Inkjet recording apparatus, method for inkjet recording, and ink

ActiveUS20130063524A1Prevent decreased water-repellencyImprove discharge stabilityDuplicating/marking methodsSpecial tyresPolymer scienceOrganic solvent

An inkjet recording apparatus including an ink; and an ink discharging head configured to discharge the ink, wherein the ink discharging head is provided with a nozzle having a silicone-containing water-repellent film on a surface thereof on which the ink contacts, wherein the ink contains a colorant; water; and a water soluble organic solvent, wherein the colorant contains a carbon black partially coated with a resin, and wherein the ink meets the following expressions (1) and (2):1.0×104<N×R / 100<1.0×106 (1)20.0<R≦100.0 (2)where R (% by mass) denotes a rate of the mass of the carbon black partially coated with a resin relative to the mass of the colorant, and N denotes the number of coarse particles having a particle diameter of 0.5 μm or more per 5 μL of the ink where the number thereof is determined with a number counting method.

Owner:RICOH KK

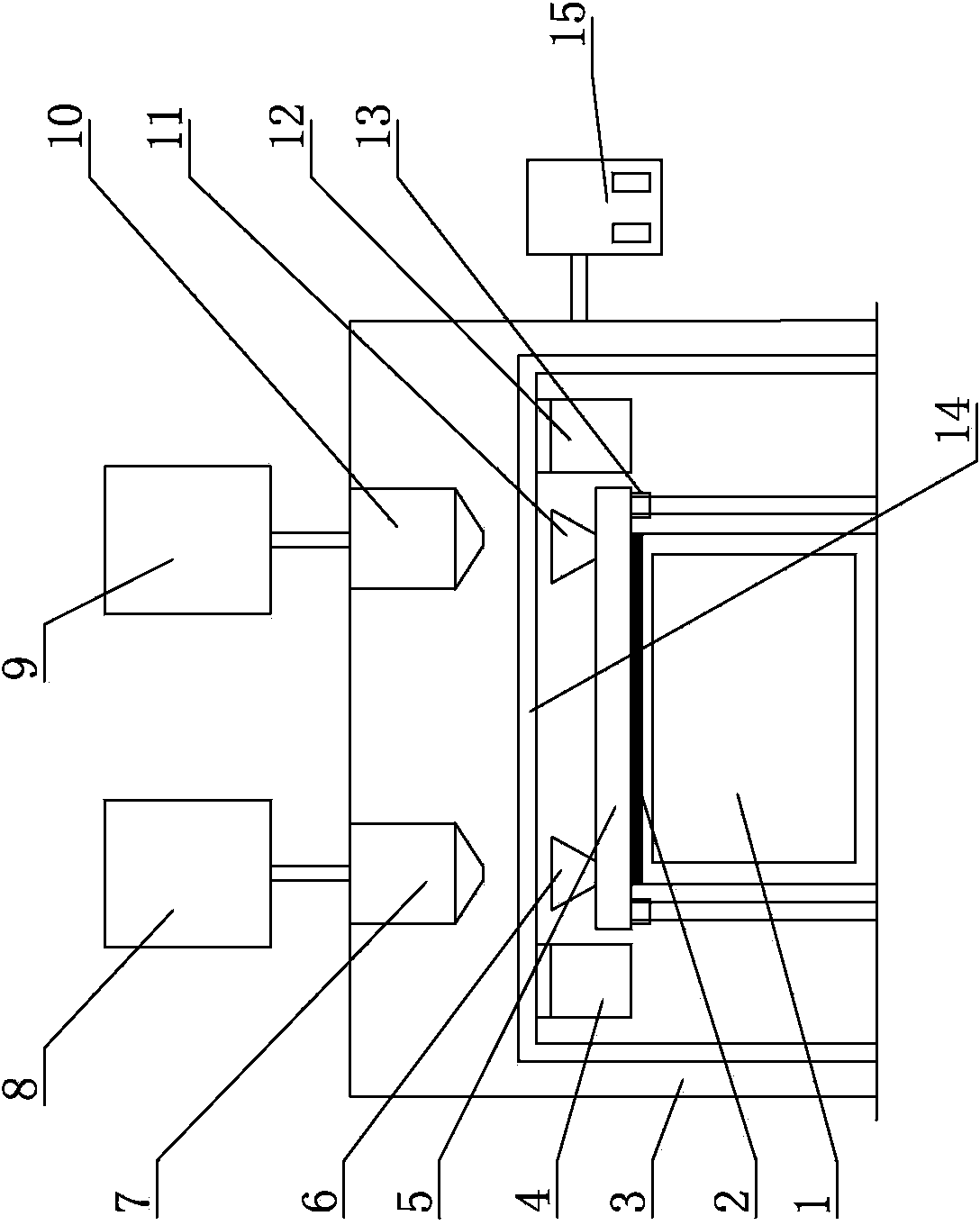

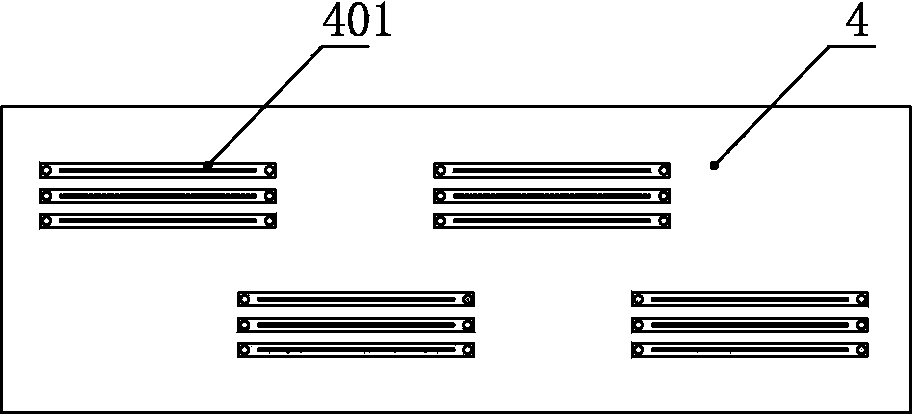

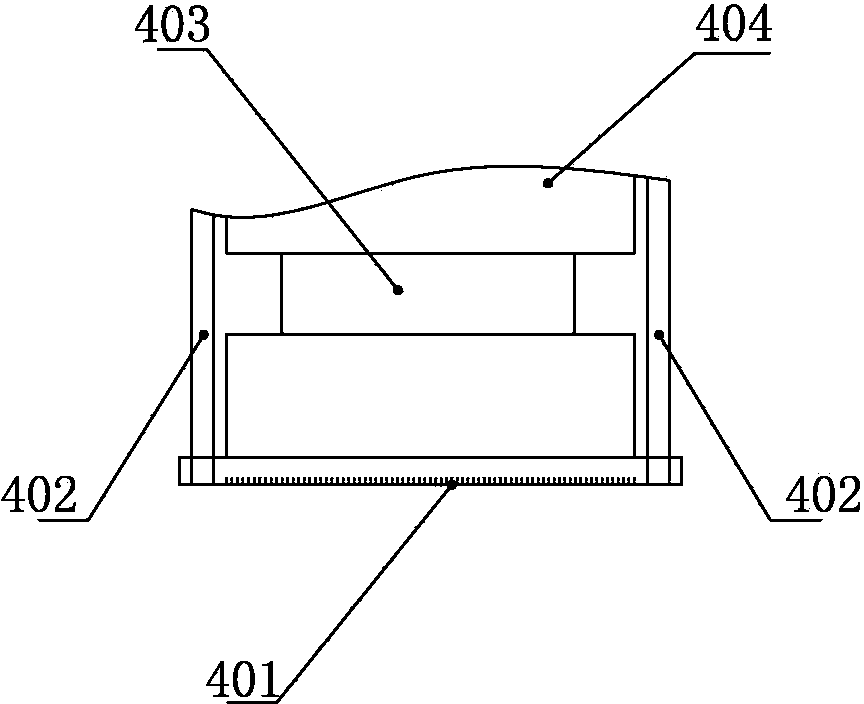

Multifunctional double-printing-head 3D printing equipment based on 3DP technology

ActiveCN104028713AHigh print densitySimple structureMoulding toolsFoundry mouldsPrinting inkEngineering

The invention discloses multifunctional double-printing-head 3D printing equipment based on the 3DP technology in the field of 3D printing equipment. The equipment comprises a first feeding hopper and a second feeding hopper, the first feeding hopper and the second feeding hopper are arranged on a rack, a first mixing bowl is arranged below the first feeding hopper, a second mixing bowl is arranged below the second feeding hopper, a powder spreading device is arranged below the first mixing bowl and the second mixing bowl, a working box is arranged below the powder spreading device, and a lifting platform is arranged in the working box. A first feeding opening and a second feeding opening are formed in the two ends of the powder spreading device respectively, the first feeding opening corresponds to the first mixing bowl, and the second feeding opening corresponds to the second mixing bowl. The powder spreading device is arranged on a powder spreading device guide rail, a printing head guide rail is arranged above the powder spreading device, a first printing head and a second printing head are arranged on the two sides of the printing head guide rail, and the orthographic projection trajectory of the powder spreading device, the first printing head and the second printing head covers the whole lifting platform in the moving process. In the working process, the first printing head or the second printing head can be selected for working, a sand mould can be printed out, a mould also can be printed out, the equipment can achieve two purposes, and the equipment cost is reduced.

Owner:NINGXIA KOCEL MOLD

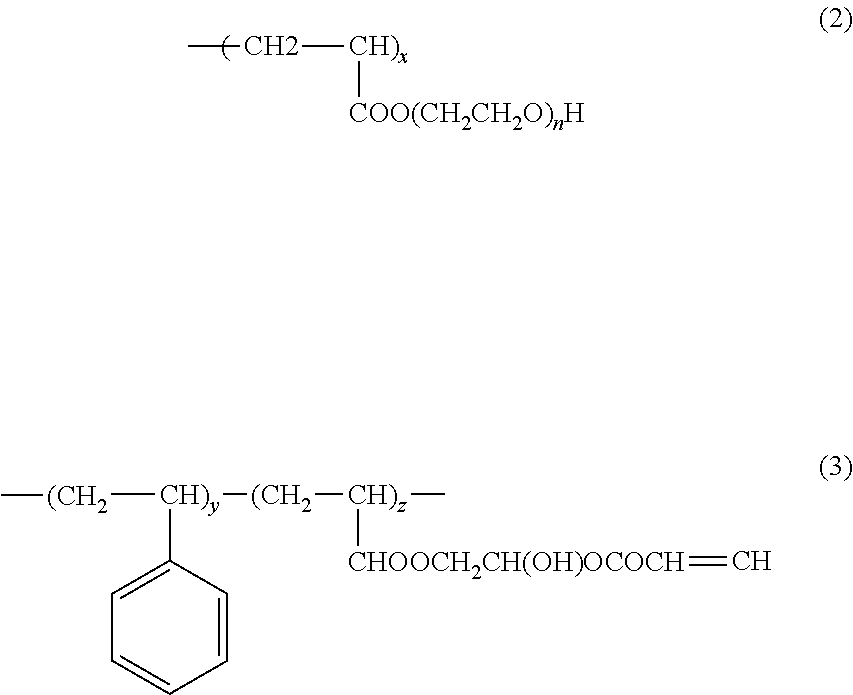

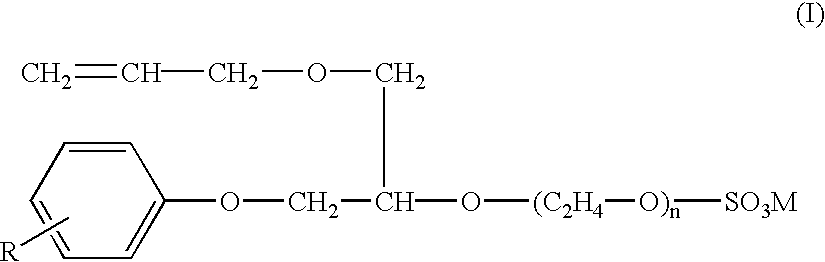

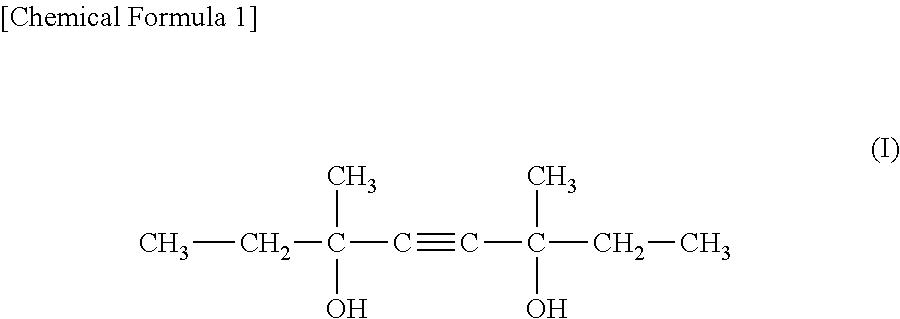

Ink for inkjet textile printing and dyeing method

ActiveUS20150116419A1Improve recording performanceHigh print densityInksDyeing processDisperse dyeTextile printer

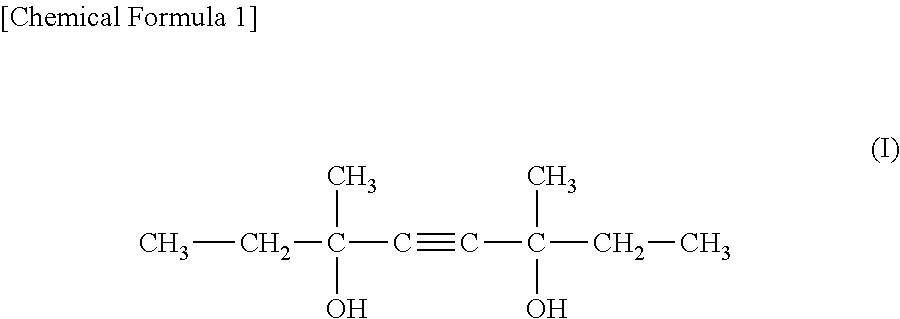

Ink for inkjet textile printing of the present invention contains water, a disperse dye, a water-soluble organic solvent and an anionic high-molecular dispersant. The water-soluble organic solvent is a polyhydric alcohol such as glycerin. The water-soluble organic solvent is contained in an amount of 25 to 50 mass % with respect to the total mass of the ink. The anionic high-molecular dispersant is a styrene-(meth)acrylic acid-based copolymer having an acid value of 160 to 250 mg KOH / g and a weight-average molecular weight of 8,000 to 20,000. The ink for inkjet textile printing further contains an acetylene glycol-based compound expressed by the following Chemical Formula (I) as a penetrant. With this ink for inkjet textile printing, provided is disperse dye-containing ink for inkjet textile printing that has a high-quality and stable recording performance and achieves a high print density on the surface of a fabric while maintaining an ink storage stability, and an inkjet textile printing method using the ink for inkjet textile printing.

Owner:KIWA CHEM IND CO LTD

Azo Compound, Ink Composition and Colored Article

ActiveUS20080193660A1Good water solubilityHigh print densityMonoazo dyesOrganic chemistrySolubilityHydrogen atom

[Problems] A compound of a black ink which has such excellent fastnesses of a recorded article as light fastness, ozone gas fastness and moisture fastness, excellent solubility, and storage stability as a recording liquid, when used for inkjet recording and writing tools, and an ink composition comprising the same are provided.[Method for solving the problems] An azo compound represented by the following Formula (1) or a salt thereof, and an ink composition comprising the same(wherein, each of R1, R2, R5, R6 and R7 independently represents a hydrogen atom, a carboxyl group, a sulfo group and the like, each of R3 and R4 independently represents a hydrogen atom, a sulfo group, a nitro group, a (C1 to C4) alkyl group (which may be substituted by a hydroxyl group or a (C1 to C4) alkoxy group), a (C1 to C4) alkoxy group (which may be substituted by a hydroxyl group, a (C1 to C4) alkoxy group, a sulfo group or a carboxyl group) and the like, and n represents 0 or 1, respectively).

Owner:NIPPON KAYAKU CO LTD

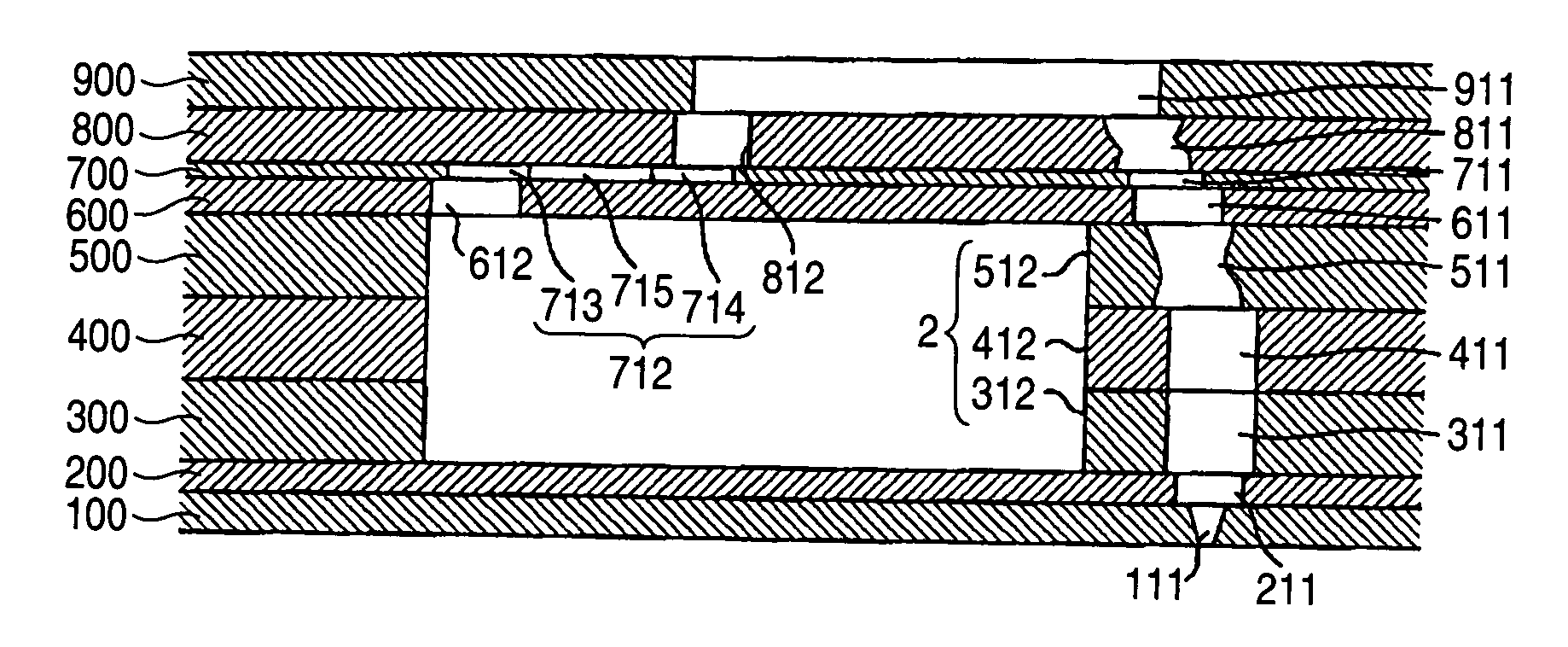

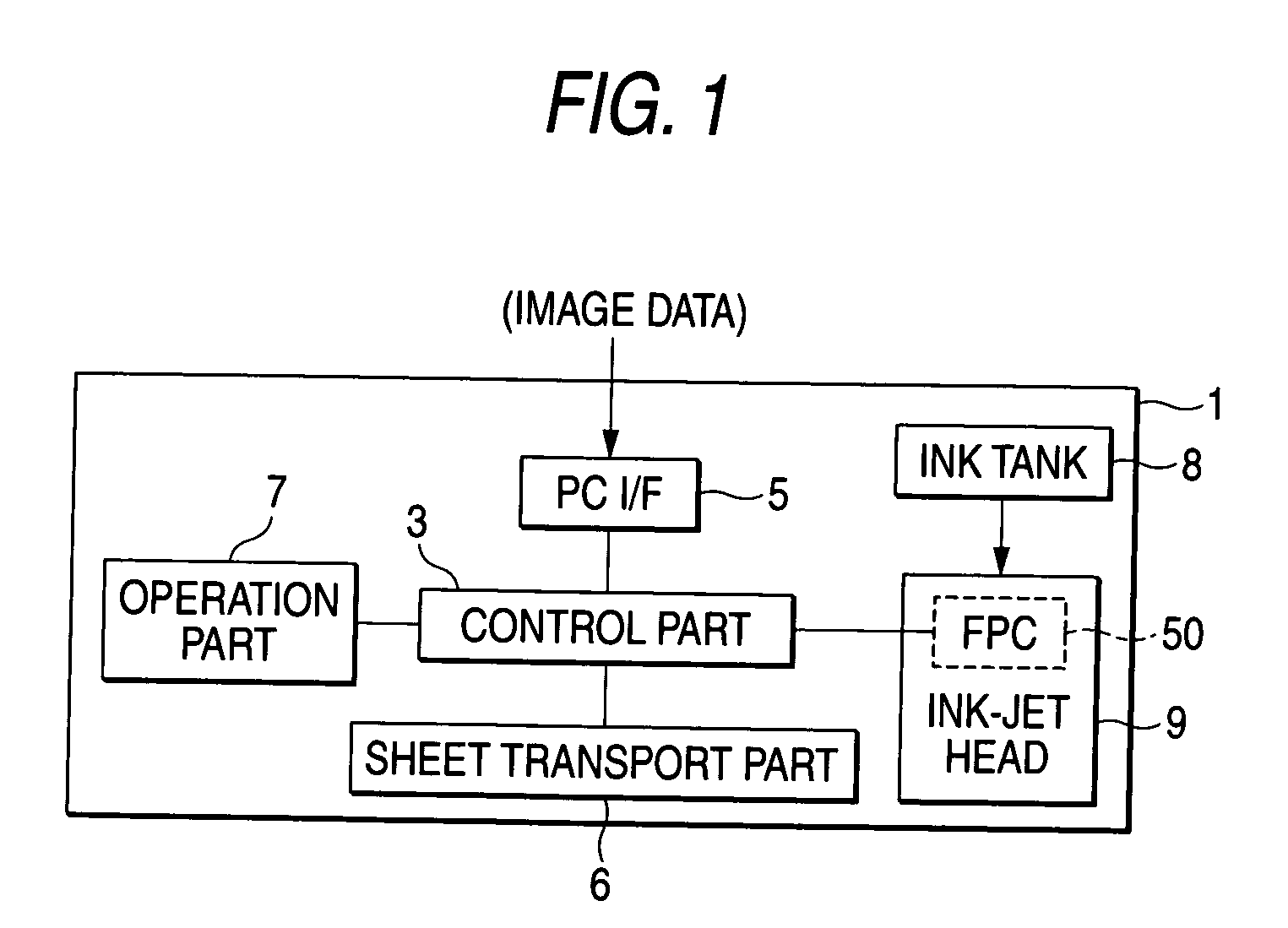

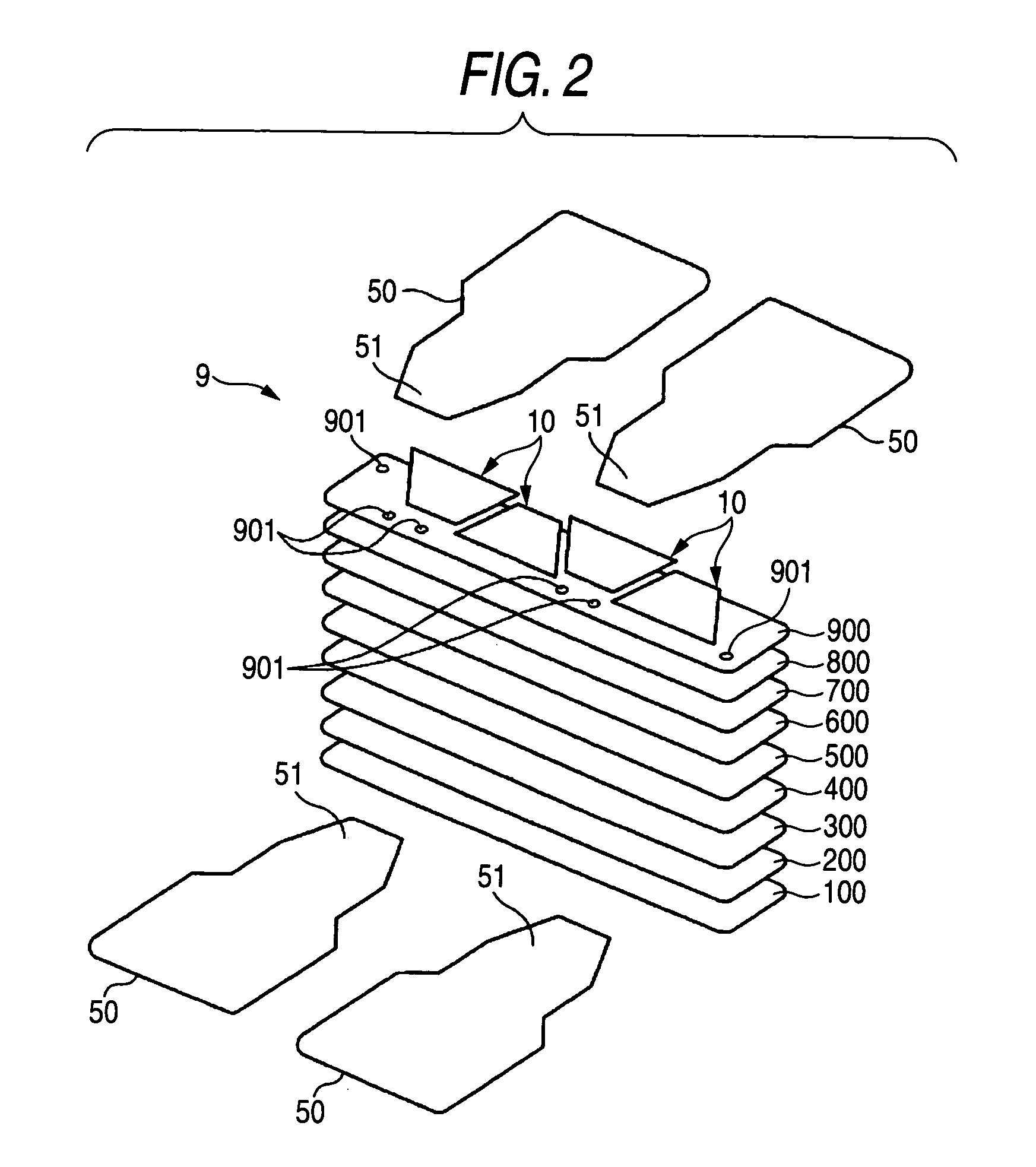

Ink-jet printer, ink-jet head and method of manufacturing the ink-jet head

ActiveUS20050041074A1Improve reliability and durabilityHigh print densityInking apparatusPrinted circuit detailsEngineeringVoltage

A piezoelectric sheet of an ink-jet head includes dummy individual electrodes in addition to individual electrodes which corresponds to respective nozzles. The dummy individual electrodes are in an outer periphery of the individual electrodes. FPC board applies drive voltage to the individual electrodes in a drive area, and deforms the area in the piezoelectric sheet in the direction of an ink pressure chamber, while the drive voltage is not applied to the individual electrodes of the non-drive area. When the dummy individual electrodes are formed in the non-drive area, a boundary area of the drive area and the non-drive area is uniformly fired when the piezoelectric sheet is manufactured. In the drive area, since surrounding structures of the respective individual electrodes become equal to one another, ink discharge characteristic is substantially uniform in the boundary area of the drive area and the non-drive area.

Owner:BROTHER KOGYO KK

Azo compounds, ink compositions, and colored bodies

ActiveUS8512462B2Good water solubilitySatisfactory filterabilityMeasurement apparatus componentsDecorative surface effectsHydrogen atomWater soluble

Azo compounds represented by general formula (1) or salts thereof are provided as highly water-soluble colorants which have hues of yellow, orange, brown or red, and excellent color development properties and which, when used in various recording processes, particularly in an inkjet recording process, ensure various excellent fastnesses such as light fastness, ozone fastness, and fading balance. Ink compositions containing the colorants are also provided. In general formula (1), R1 to R8 are each independently a hydrogen atom, C1-4 alkyl, C1-4 alkoxy, or the like; and X is C1-8 alkylenediamino, xylylenediamino, or the like.

Owner:NIPPON KAYAKU CO LTD

Method for manufacturing an inkjet recording medium

InactiveUS20090087568A1High print densitySuppressing coating defectDuplicating/marking methodsPretreated surfacesPseudoboehmiteAlumina hydrate

The present invention provides a method for manufacturing an inkjet recording medium having at least applying, on a support, a coating liquid A, a coating liquid B and a coating liquid C in this order from the support to form an ink receiving layer. The coating liquid A contains at least a crosslinking agent. The coating liquid B contains at least a vapor-phase-process silica and a water-soluble binder, in which the content of a pseudo boehmite alumina hydrate with respect to the content of the vapor-phase-process silica in the coating liquid B is less than 3% by mass, and the content of a crosslinking agent with respect to the content of the vapor-phase-process silica in the coating liquid B is less than 3% by mass. The coating liquid C contains at least a pseudo boehmite alumina hydrate and a water-soluble binder.

Owner:FUJIFILM CORP

Plasma treatment of porous inkjet receivers

InactiveUS20050123696A1Small spreadReduce optical densityCoatingsThermographyRecord elementMaterials science

An inkjet recording element comprising a porous ink-receiving layer having interconnecting voids is disclosed in which an upper surface of the ink-receiving layer has been subjected to plasma treatment, and wherein the upper surface of the ink-receiving layer, prior to the plasma treatment, has a measured carbon elemental content of at least 40 percent. The invention can provide increased dot spread.

Owner:EASTMAN KODAK CO

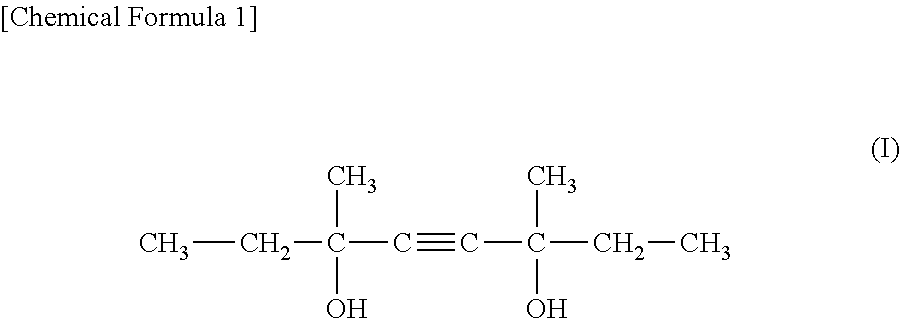

Ink jet black ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

ActiveUS20060156952A1Sufficient weatherabilityHigh optical densityMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater soluble

The present invention aims to provide an ink jet black ink which can improve weatherability, optical density and sticking recovery property of nozzles of a recording head. According to the present invention, an ink jet black ink is provided which comprises at least a coloring-material and a water-soluble organic solvent, wherein the coloring material is a compound represented by the following general formula (I) or a salt thereof, and the water-soluble organic solvent is a water-soluble organic solvent having a relative permittivity of from 30.0 or more to less than 70.0 at 20° C. and capable of dissolving the compound represented by the following general formula (I) or a salt thereof, by 1.0 mass % or more at 25° C., and is in a content of 50.0 mass % or more with respect to the total content of all water-soluble organic solvents contained in the ink jet black ink.

Owner:CANON KK

Ink jet recording sheet

InactiveUS20050179759A1High transparencyHigh print densityDuplicating/marking methodsCoatingsPolyvinyl alcoholRecording layer

This invention is an inkjet recording sheet having a high gloss cast coating recording layer containing a pigment and a binder comprising mainly polyvinyl alcohol on a support having air permeability, wherein the pigment is a mixture comprising alumina (A) and silica (B) having an average particle diameter of 100˜500 nm, blended in the proportion of A:B=95:5˜50:50 in terms of weight ratio. The silica (B) is preferably a silica to which cationic properties have been imparted, and the alumina (A) is preferably γ-alumina. Due to this, the gloss of a silver halide photograph together with excellent ink absorption properties and print density can be obtained.

Owner:NIPPON PAPER IND CO LTD

Method for producing polymerized toner

ActiveUS20040110081A1High print densityGuaranteed uptimeDistillation separationDevelopersDefoamerPolymer particle

Methods for producing a polymerized toners are provided, where, a dispersion including colored polymer particles obtained by polymerizing a polymerizable composition is treated stably in the process of reducing the remaining monomer, the resultant polymerized toners include a sufficiently low content of remaining monomer, and the resultant polymerized toners have excellent properties and are useful as developers for printing and copying. In the process of reducing the remaining monomer, the dispersion of the colored polymer particles is treated by stripping in the presence of a specific antifoaming agent.

Owner:ZEON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com