Modified polycarbonate composition, electronic equipment shell and preparation method of electronic equipment shell

A technology of polycarbonate and composition, applied in the field of plastics, to achieve the effects of improving scratch resistance, facilitating dispersion, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

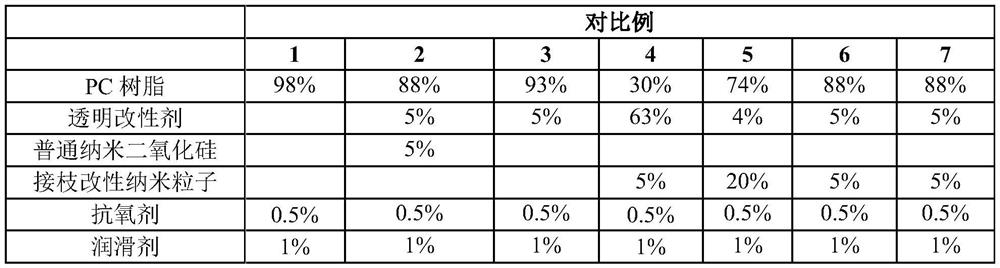

Examples

Embodiment approach

[0047] According to a preferred embodiment of the present invention, a method for preparing an electronic device casing provided by the present invention may include the following steps:

[0048] (1) Weigh each component according to the above parts by weight, and add the above components into a high-speed mixer, mix at 200 rpm for 1-2 min, and at 400 rpm for 1 min to obtain a mixture.

[0049] (2) Add the mixture in step 1 to the main feed of the twin-screw extruder, extrude and granulate to obtain pellets. The extrusion temperature is set to 100-120°C for zone 1, 180-200°C for zone 2, 200-220°C for zone 3, 230-250°C for zone 4, 230-250°C for zone 5, 230-250°C for zone 6, and 230°C for zone 7. -250°C, eighth zone 230-250°C, nine zone 230-250°C, machine head 230-250°C.

[0050] (3) Dry the pellets, and put them into an injection molding machine, and inject them to obtain a product. The injection molding temperature is set at 230-240°C for the first zone, 240-250°C for the se...

preparation example 1

[0058] This preparation example is to illustrate the modified nanoparticles prepared by the present invention.

[0059] Inorganic nanoparticle SiO with hydroxyl groups on the surface 2, a monomer phenyl methacrylate grafted after being modified by the silane coupling agent KH-570;

[0060] As a result, the prepared modified nanoparticles have a core-shell structure, and the core-shell structure includes core materials, silane coupling agents and shell materials that are coated sequentially from the core to the shell, wherein the core material is an inorganic nanoparticle containing a hydroxyl group, and the shell The material is a polymer layer after monomer polymerization, the core material and the shell material are connected by a silane coupling agent; the thickness of the shell material is 40nm, and the solubility parameter is 19.04; and the average particle size of the modified nanoparticles is 90nm, and the refractive index is 1.54.

preparation example 2

[0062] This preparation example is to illustrate the modified nanoparticles prepared by the present invention.

[0063] Using SiO with hydroxyl groups on the surface 2 / TiO 2 Composite particles, grafted monomer benzyl methacrylate after modified by silane coupling agent KH-570;

[0064] Results The prepared modified nanoparticles have a core-shell structure, and the core-shell structure includes core materials, silane coupling agents and shell materials coated in sequence from the core to the shell. The core material is an inorganic nanoparticle containing a hydroxyl group, and the shell material is The polymer layer after monomer polymerization, the core material and the shell material are connected by a silane coupling agent; the shell material has a thickness of 20nm, a solubility parameter of 18.99; and the average particle diameter of the modified nanoparticles is 60nm , the refractive index is 1.51.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com