A polymer blend film that inhibits protein adsorption and its preparation method and application

A polymer and protein technology, applied in the field of polymers, can solve the problems of unstable dewetting and easy adsorption of protein molecules, and achieve the effect of inhibiting protein adsorption performance, strong protein adsorption performance, and excellent stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

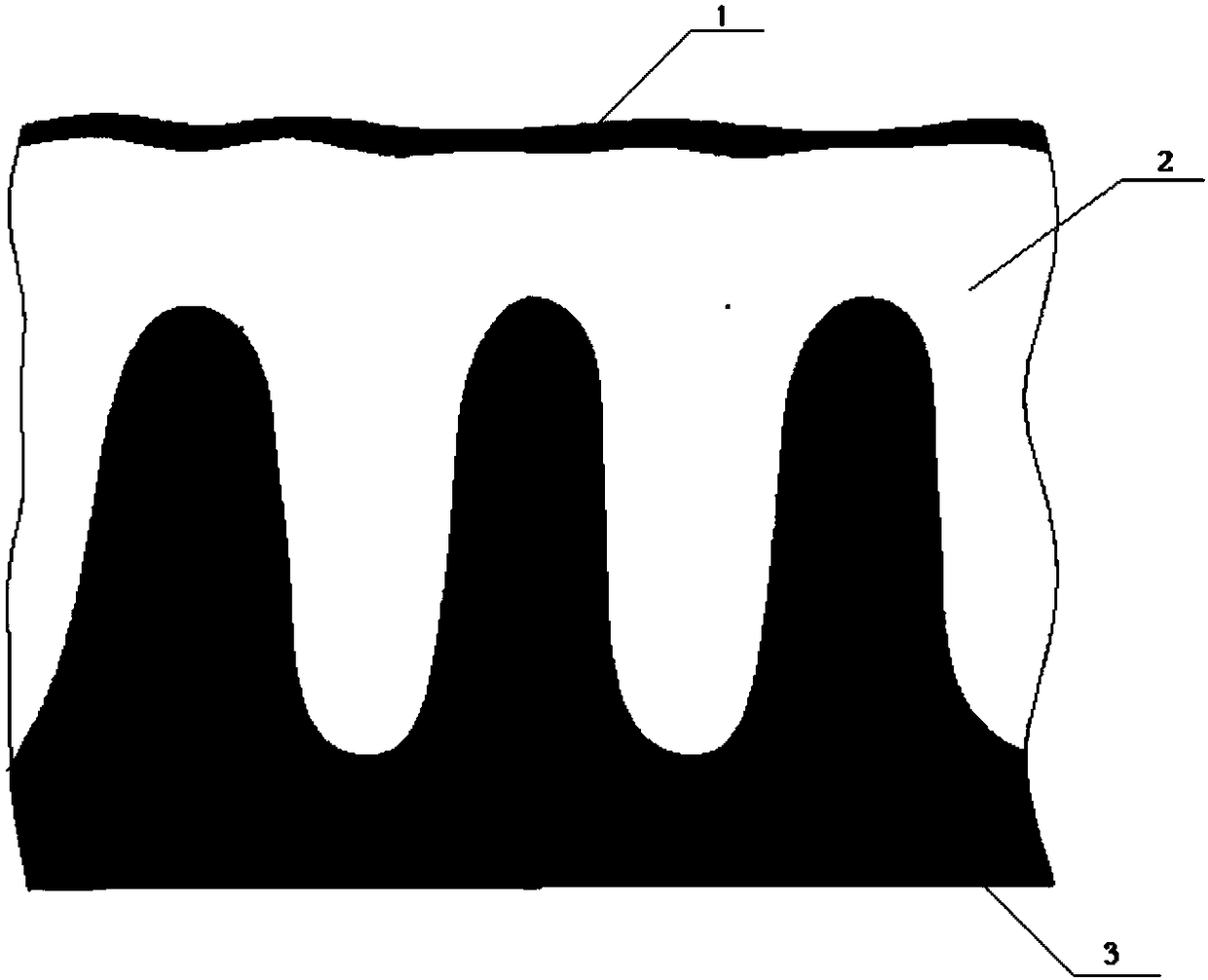

[0025] A polymer blend film that inhibits protein adsorption, prepared by the following method:

[0026] (1) Preparation of solution: weigh polystyrene (PS) 5.4mg, poly-n-butyl methacrylate (PBMA) 3.6mg,

[0027] Add 1000ul toluene and mix thoroughly to obtain a clear solution, the relative molecular weight of the polystyrene is 300000, and the relative molecular weight of the poly-n-butyl methacrylate is 337000;

[0028] (2) Preparation of film: set the rotating speed of the spin coater to 3000r / s, and the spin coating time is 40s; adopt the method of dynamic spin coating, drop an appropriate amount of solution in the spinning spin coater, and make a polymer after 40 blend films.

[0029] The PS / PBMA mass ratio of polymer blend film described in this embodiment is 6:4, and the thickness of polymer blend film is 52nm, take PBMA film as comparative example, the polymer blend film obtained in this embodiment The protein adsorption test was carried out together with the PBMA fi...

Embodiment 2

[0031] A polymer blend film that inhibits protein adsorption, prepared by the following method:

[0032] (1) Preparation of solution: Weigh polystyrene (PS) 5.6mg, poly-n-butyl methacrylate (PBMA) 2.4mg, add 600ul toluene and fully mix to obtain clear solution, the relative molecular weight of described polystyrene is 300000 , the relative molecular weight of the poly-n-butyl methacrylate is 337000;

[0033] (2) Preparation of film: set the rotating speed of the spin coater to 3000r / s, and the spin coating time is 40s; adopt the method of dynamic spin coating, drop an appropriate amount of solution in the spinning spin coater, and make a polymer after 40 polymer blend film, the thickness of the polymer blend film is 48nm.

[0034] The PS / PBMA mass ratio of the film in this example is 7:3, and the obtained polymer blend film is tested for protein adsorption. The results measured by the atomic force microscope show that the surface of the polymer blend film is consistent before...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com