Honeycomb plate for kitchen marble and preparation method thereof

A marble and honeycomb panel technology, applied in chemical instruments and methods, polyurea/polyurethane adhesives, epoxy resin adhesives, etc., can solve problems such as water resistance cannot be known, edge warping, etc., and achieve a low probability of warping. , The effect of improving water resistance and low water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

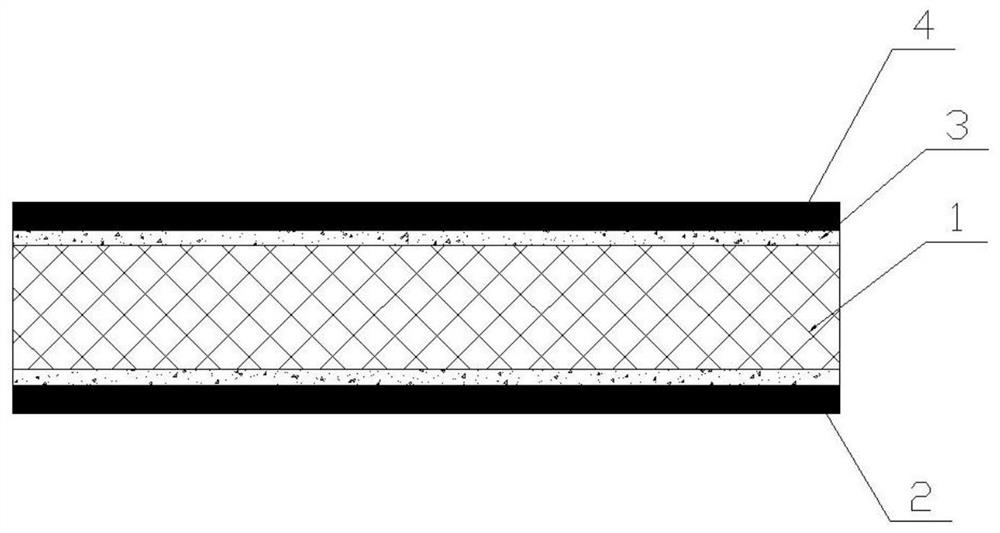

[0033] Embodiment 1, a kind of honeycomb panel for kitchen marble

[0034] It includes an upper panel 4, an adhesive film 3, a plastic base plate 1 and a lower panel 2, the lower panel 2 is connected to one side of the plastic base plate 1 through the adhesive film 3, and the other side of the plastic base plate 1 is connected to the upper The panels 4 are connected through the adhesive film 3, and the plastic base plate 1 is a honeycomb structure.

[0035] The preparation method of the honeycomb panel for kitchen marble comprises the following steps:

[0036] S1) preparing an upper panel and a lower panel;

[0037] Step A, soaking the aluminum alloy in an aqueous solution containing 50 g / L trisodium phosphate at a temperature of 40° C. for 3 minutes, washing with water 3 times, and obtaining the pretreated aluminum alloy;

[0038] Step B, place the aluminum alloy pretreated in step A in an aqueous solution containing 30g / L sodium phosphate, 0.5g / L allyl alcohol polyoxyeth...

Embodiment 2

[0050] Embodiment 2, a kind of honeycomb panel for kitchen marble

[0051] It includes an upper panel 4, an adhesive film 3, a plastic base plate 1 and a lower panel 2, the lower panel 2 is connected to one side of the plastic base plate 1 through the adhesive film 3, and the other side of the plastic base plate 1 is connected to the upper The panels 4 are connected by the adhesive film 3, and the plastic base plate 1 is a honeycomb structure.

[0052] The preparation method of the honeycomb panel for kitchen marble comprises the following steps:

[0053] S1) preparing an upper panel and a lower panel;

[0054] Step A, soaking the aluminum alloy in an aqueous solution containing 50 g / L trisodium phosphate at a temperature of 50° C. for 3 minutes, washing with water 4 times, and obtaining the pretreated aluminum alloy;

[0055] Step B, place the aluminum alloy pretreated in step A in an aqueous solution containing 30g / L sodium phosphate, 0.5g / L allyl alcohol polyoxyethylene...

Embodiment 3

[0067] Embodiment 3, a kind of honeycomb panel for kitchen marble

[0068] It includes an upper panel 4, an adhesive film 3, a plastic base plate 1 and a lower panel 2, the lower panel 2 is connected to one side of the plastic base plate 1 through the adhesive film 3, and the other side of the plastic base plate 1 is connected to the upper The panels 4 are connected by the adhesive film 3, and the plastic base plate 1 is a honeycomb structure.

[0069] The preparation method of the honeycomb panel for kitchen marble comprises the following steps:

[0070] S1) preparing an upper panel and a lower panel;

[0071] Step A, soaking the aluminum alloy in an aqueous solution containing 60 g / L trisodium phosphate at a temperature of 50° C. for 3 minutes, washing with water 5 times, and obtaining the pretreated aluminum alloy;

[0072] Step B, place the aluminum alloy pretreated in step A in an aqueous solution containing 30g / L sodium phosphate, 0.5g / L allyl alcohol polyoxyethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com