A kind of preparation method of polyethylene glycol graft polybutylmethacrylate amphiphilic graft copolymer

A technology of polybutylmethacrylate and polyethylene glycol grafting, which is applied in the field of chemical materials, can solve the problems of less research on amphiphilic graft polymers, and achieve controllable side chain molecular weight and adjustable graft density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

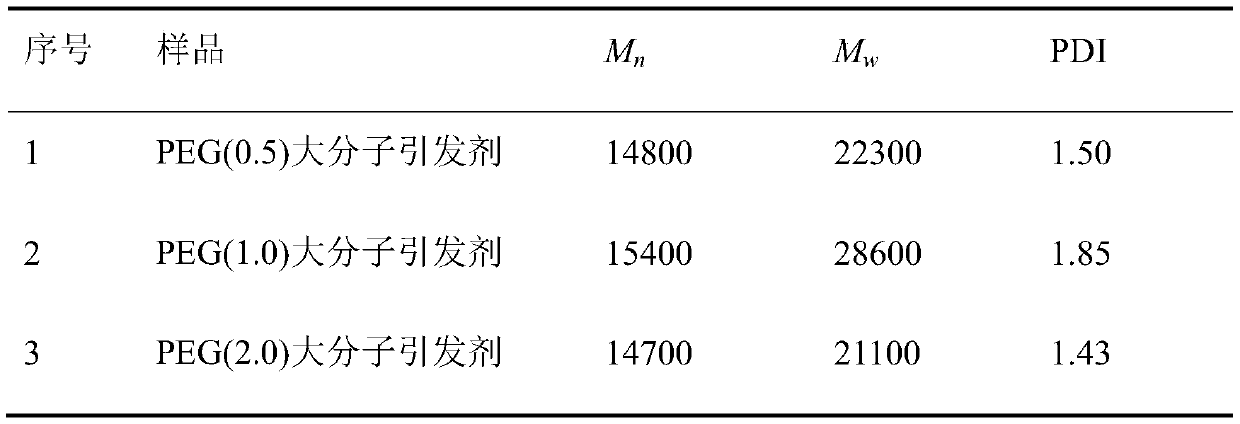

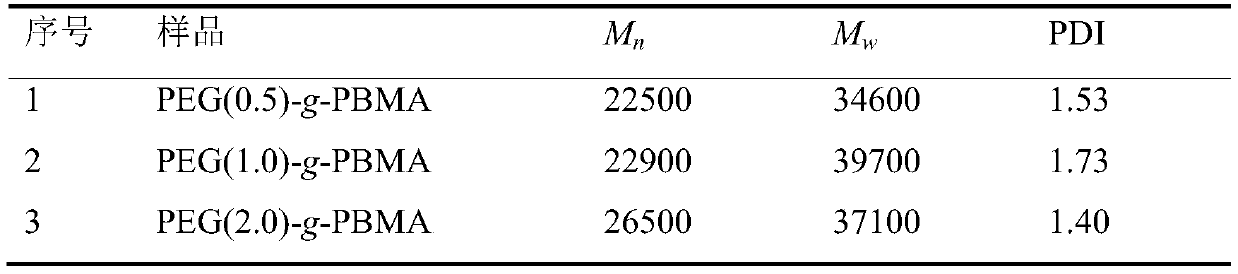

Embodiment 1

[0027] (1) Preparation of small molecule dihydroxy initiator

[0028] Into a four-neck flask equipped with a thermometer and a stirring paddle, add 800 mL of solvent tetrahydrofuran, 74.6 g (0.50 mol) of triethanolamine, and 5.06 g (0.05 mol) of acid binding agent triethylamine, place it in an ice water bath, and stir it mechanically. The internal temperature dropped below 3°C, 11.50g (0.05mol) of α-bromoisobutyryl bromide was added as slowly as possible with a constant pressure dropping funnel, the ice water bath was removed after the addition, and the reaction was carried out at room temperature overnight. After the reaction, filter paper to remove the salt generated, the filtrate was rotated under reduced pressure to remove the solvent tetrahydrofuran, the concentrated solution was dissolved in ethyl acetate, passed over a basic alumina column, collected and rotated to obtain the product. After drying in a vacuum oven and weighing, the product was about 8.3 g, and the yield wa...

Embodiment 2

[0035] (1) Preparation of small molecule initiator

[0036] Into a four-neck flask equipped with a thermometer and a stirring paddle, add 800 mL of solvent tetrahydrofuran, 74.6 g (0.50 mol) of triethanolamine, and 5.06 g (0.05 mol) of acid binding agent triethylamine, place it in an ice water bath, and stir it mechanically. The internal temperature dropped below 3°C, and 10.79g (0.05mol) of α-bromopropionyl bromide was added as slowly as possible with a constant pressure dropping funnel. After the addition was completed, the ice-water bath was removed, and the reaction was carried out at room temperature overnight. After the reaction, filter paper to remove the salt generated, the filtrate was rotated under reduced pressure to remove the solvent tetrahydrofuran, the concentrated solution was dissolved in ethyl acetate, passed over a basic alumina column, collected and rotated to obtain the product. After drying in a vacuum oven and weighing, the product was about 8.3 g, and the ...

Embodiment 3

[0043] (1) Preparation of small molecule initiator

[0044] Add solvent tetrahydrofuran 800mL, trimethylolpropane 67.09g (0.50mol), acid binding agent triethylamine 5.06g (0.05mol) into a four-necked flask equipped with a thermometer and a stirring paddle, and place it in an ice water bath with mechanical stirring When the internal temperature of the system drops below 3°C, 11.50 g (0.05 mol) of α-bromoisobutyryl bromide is added as slowly as possible with a constant pressure dropping funnel. After the addition is completed, the ice-water bath is removed, and the reaction is carried out at room temperature overnight. After the reaction, filter paper to remove the salt generated, the filtrate was rotated under reduced pressure to remove the solvent tetrahydrofuran, the concentrated solution was dissolved in ethyl acetate, passed over a basic alumina column, collected and rotated to obtain the product. After drying in a vacuum oven and weighing, the product was about 8.3 g, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com