Modifying method for activated carbon

An activated carbon and modification technology, applied in the field of activated carbon modification, can solve problems such as application limitation and limited number of active groups, and achieve the effects of simple operation, simple raw materials, and improved dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

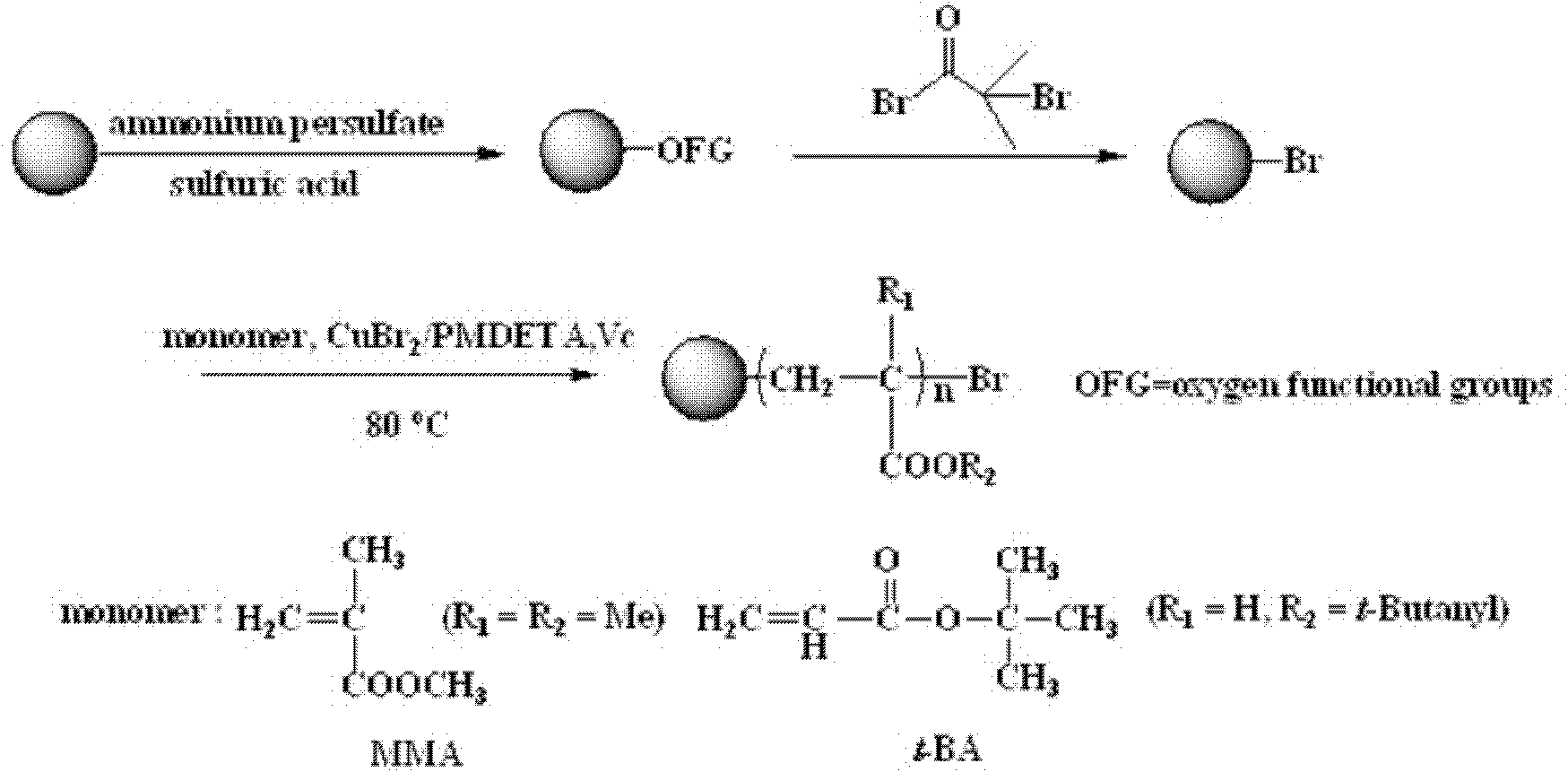

[0045] A modification method of activated carbon, comprising the steps of:

[0046] (1) Mix the commercial activated carbon sample (5g) with 100mL ammonium persulfate 1M sulfuric acid solution with a concentration of 2 mol / L, stir at 60°C for 3 hours, separate by suction filtration, and fully wash with deionized water until neutral. ℃ in a vacuum drying oven overnight to obtain activated carbon (ACOFG) with oxygen-containing functional groups on the surface;

[0047] (2) The above activated carbon (2.46 g) with oxygen-containing functional groups on the surface was mixed with THF (50 mL), 4-dimethylaminopyridine (DMAP) (0.1467 g, 0.0012 mol) and triethylamine (TEA) (2.8 mL, 0.02 mol) into a 100mL round-bottomed flask, ultrasonicated for 30 minutes, transferred to an ice-water bath (-5~0 ℃), stirred under the protection of argon, and then dibromoisobutyryl bromide (BiBB) (2 g) tetrahydrofuran solution (13 mL) was added dropwise to the system, and the system was stirred in an ice...

Embodiment 2

[0058] A modification method of activated carbon, comprising 4 steps, wherein steps 1 to 2 are identical to those in Example 1, and the follow-up steps are as follows:

[0059] (3) AGET ATRP polymerization on the surface of activated carbon with tert-butyl acrylate (t-BA) as monomer: according to the ratio [t-BA] 0 / [CuBr 2 ] 0 / [PMDETA] 0 / [VC] 0 =689 / 2.3 / 2.3 / 0.1, add CuBr in turn 2 (0.0156 g, 0.069mmol), PMDETA (14.6 uL, 0.069mmol), t-BA (3 mL, 20.7mmol), AC-macroinitator (0.1 g), VC (0.0053 g, 0.03mmol), and anisole ( 1 mL). Put it into a 5 mL ampoule bottle, use the bubbling method to catch oxygen for ten minutes, and then seal the tube;

[0060] Place the sealed ampoule in an oil bath at a constant temperature (70°C) for a predetermined time to react for 2-10 h;

[0061] After the reaction, take out the sealed tube, immediately cool it with cold water, open the sealed tube, dilute with an appropriate amount of tetrahydrofuran, pour it into methanol for precipitation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com